Rubber Testing Equipment

Standards

Description

The Salt Spray Tester - GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample. Read more about corrosion testing and our Salt Spray Tester in our newest mega blog!

Salt Spray Tester - GenSalt Unique Features

- Robust impact resistant 5mm PVC plate capable of withstanding up to 85°C

- The inner and outer edges are 15mm thick reinforced PVC material to prevent deformation resulting from long-term high temperature exposure

- Saturated air tank adopts SUS#304 stainless steel high pressure for optimal insulation

- The sample placing anvil is made of 8mm temperature-resistant ABS plate developed for high weight support.

- The spray nozzle is made of special glass nozzle, which can adjust the amount of spray and the angle of spray

- The spray amount is adjustable from 1 to 2 ml/h (ml/80 cm2/h where the standard requires 16 hours on average).

- Using the Bernotte principle to absorb the brine and then atomize it, the atomization degree is uniform and has no obstruction resulting from crystallization, which ensures the standard of continuous testing.

- The section is roughly adjusted to 2Kg/cm2, and the inlet air filter is provided with a drainage function.

- The second section is a precision adjustment 1Kg/cm2, 1/4 pressure gauge, showing precise and accurate results.

- Fast heating rate for maximum efficiency.Pure titanium heating tube, resistant to acid and alkali corrosion with long service life

- The test chamber heating tank adopts liquid expansion safety temperature controller 0-120°C (1 EGO of Italy)

- LCD digital display time controller, power failure memory function 0.1S - 999hr (Japan OMRON 1)

- Accumulator 0-99999hr (1 VEMER, Italy)

- Relay (Japan OMRON 1 group)

- Rocker with light switch, can work 25,000 times continuously

Safety Protection Device

- When the water level is low, the power is automatically turned off and the safety warning light device lights up.

- When the temperature is over the limit, the heater power is automatically turned off, and the safety warning light device lights up.

- When the water level of the reagent (salt) is low, the safety warning light device lights up and alarms.

- Leakage protection function to prevent personal injury and instrument failure caused by line leakage or short circuit

- Water adding system - Automatic and manual two watering systems are used to automatically or manually replenish the pressure tank and the test room water level to prevent water shortage and ultra-high temperature damage instruments.

- Defogging system - During the test process and shutdown, the salt spray in the test chamber is removed to prevent the corrosion gas from flowing out of the damage chamber and other precision instruments.

Specifications

| GenSalt-60 | GenSalt-90 | GenSalt-120 | |

| Laboratory Temperature |

35°C±1°C (RT - 60°c)

|

||

| Temperature of Saturated Air Cylinder | 47°C±1°C (RT - 60°c) | ||

| Interior Dimensions |

23.6x17.7x15.7-in

60x45x40 cm

|

35.4x23.6x19.7-in

90x60x50 cm

|

42.25x39.4x19.7-in

120x100x50 cm

|

| Exterior Dimensions |

42.1x23.6x46.5-in

107x60x118 cm

|

5.5x3.5x5.1-in 140x90x130 cm |

7.5x4.3x5.5-in 190x110x140 cm |

| Weight |

150 lbs / 68 kg

|

183 lbs / 82 kg

|

214 lbs / 97 kg

|

| Power | 110V/60Hz or 220V/50Hz |

220V/50Hz 1ph

|

|

Sample Examples:

FAQs

Yes, the Salt Spray Tester complies with ISO 9227. This standard specifies the requirements for conducting corrosion tests in artificial atmospheres using neutral salt spray (NSS), acetic acid salt spray (AASS), and copper-accelerated acetic acid salt spray (CASS) methods. Compliance with ISO 9227 makes sure that the Salt Spray Tester can effectively simulate corrosive environments to evaluate the corrosion resistance of metallic materials and their coatings.

Using this standard, the Salt Spray Tester provides valuable data that helps manufacturers and researchers understand how materials will perform under harsh environmental conditions, which is particularly important in industries where materials are often exposed to corrosive elements. The ability to perform tests in accordance with ISO 9227 confirms the tester's suitability for global use and assures users of its capability to deliver reliable and consistent results in corrosion resistance testing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Salt Spray Tester is designed to conform to ASTM B117, which is the standard practice for operating salt spray (fog) equipment used to evaluate metallic coatings and materials' corrosion resistance. This standard provides guidelines on the setup, conditions, and duration of salt spray tests, which are necessary for simulating accelerated corrosive atmospheres. Compliance with ASTM B117 assures that the Salt Spray Tester can accurately assess the durability and longevity of coatings by exposing them to concentrated salt spray environments, replicating the effects of saline exposure over extended periods.

ASTM B117 standard is required for industries where materials are exposed to corrosive environments, such as the marine, automotive, and construction sectors. By meeting these specifications, the Salt Spray Tester provides manufacturers and researchers with reliable data on how materials will withstand corrosion, aiding in the development of more durable and corrosion-resistant products. This standardization also makes sure that testing processes are repeatable and consistent, providing a solid foundation for comparative analysis and quality assurance evaluations.

Click here to learn more about the product or here to receive a personalized quote.

GenSalt is used to assess the corrosion resistance of different materials. This testing is crucial for determining how different surfaces - such as metals, coatings, and paints - endure when exposed to corrosive environments that mimic salt spray conditions. Such testing is necessary in sectors where materials must withstand harsh environments to maintain durability and safety.

GenSalt enables a systematic evaluation of how materials react to prolonged exposure to salt-laden atmospheres, which is vital for predicting the longevity and structural integrity of products used in corrosive conditions. By simulating these conditions, the Salt Spray Tester helps develop materials that are more resistant to corrosion, thereby enhancing product reliability and performance in real-world applications. This capability is indispensable in industries where corrosion prevention is critical to maintaining product safety and effectiveness.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is primarily used to assess the corrosion resistance of coated metallic materials within a controlled corrosive environment. This unit is especially useful in industries where metal components are prone to corrosion due to environmental exposure. By simulating salt spray conditions, the tester provides valuable insights into the durability of protective coatings such as paints, varnishes, and electroplating on metal substrates.

These tests are essential for verifying that coatings on metals can withstand degradation from exposure to saline or corrosive atmospheres, commonly encountered in marine, automotive, and industrial settings. The ability to test these materials under controlled conditions allows manufacturers to optimize their products for longevity and reliability, making sure that they meet the high standards required for performance in corrosive environments. This testing capability is indispensable for developing materials that require high resistance to corrosion, thus aiding in quality control and product development processes.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is specifically designed for evaluating the effectiveness of different types of protective coatings applied to metallic surfaces. These include rust-proof paints, anodizing treatments, electroplating, and grease-based rust preventatives. By simulating corrosive environments, the tester can precisely assess how well these treatments protect against rust and degradation over time.

This capability is important for industries that rely on metal components where long-term exposure to harsh environmental conditions is common. The tester's ability to evaluate different protective barriers allows manufacturers and researchers to optimize coatings for maximum corrosion resistance. Understanding how these treatments perform under simulated conditions helps improve product reliability and durability, assuring that they meet safety and quality standards before being brought to market. This detailed testing is integral to advancing materials science and enhancing the performance of coated products exposed to corrosive environments.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt imitates the accelerated corrosion process through salt spray application directly onto test samples. This method is designed to rapidly evaluate the resistance of various materials and coatings to oxidation and corrosion. By creating a controlled corrosive environment, the machine sprays a saline solution onto the samples, which mimics saltwater exposure - a common cause of corrosion in natural settings.

This testing process is necessary for determining the longevity and effectiveness of protective coatings and materials used in environments prone to salt-induced corrosion, such as maritime and coastal applications, the automotive industries, and any outdoor infrastructure. The ability to replicate these harsh conditions in a controlled setting allows researchers and manufacturers to predict how well a product will withstand real-world corrosive forces over time, thereby aiding in the development of more durable and resilient materials and coatings.

Click here to learn more about the product or here to receive a personalized quote.

Test results from the Salt Spray Tester - GenSalt are principally determined based on the duration a material can withstand visible corrosion when exposed to a simulated corrosive environment. The test assesses the longevity of the material's resistance to corrosion by noting the time it takes for signs of rust or other forms of oxidation to appear on the sample surface. This metric is important for evaluating the effectiveness of corrosion-resistant treatments and coatings applied to different materials.

By measuring how long a sample can resist visible corrosion, the Salt Spray Tester provides valuable data that helps manufacturers and researchers understand the durability and protective qualities of materials under harsh conditions. This information is essential for developing products intended for use in environments where corrosion is a significant concern. The test results assist in refining product designs and selecting suitable materials and coatings that meet specific durability standards.

Click here to learn more about the product or here to receive a personalized quote.

The PVC plate incorporated in the Salt Spray Tester - GenSalt is engineered for high durability and impact resistance, qualities essential for withstanding salt spray testing environments. This plate, with its robust construction, is 5mm thick, increasing its ability to endure physical impacts and maintain structural integrity throughout testing processes.

Furthermore, the PVC plate can withhold temperatures up to 85°C, making it highly suitable for fluctuating thermal conditions typically experienced during salt spray tests. This temperature resilience is crucial as it ensures that the plate does not deform or degrade under heat stress generated in accelerated corrosion testing scenarios.

These characteristics are vital for preserving the test chamber's operational accuracy and reliability. The use of such a durable and heat-resistant PVC plate supports the Salt Spray Tester - GenSalt in providing precise and reliable assessments of material corrosion resistance, making it an indispensable tool in industries where understanding material durability in corrosive environments is vital.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt features inner and outer edges constructed from 15mm thick reinforced PVC material. This design choice is critical for preventing deformation due to long-term exposure to high temperatures during testing processes. The reinforced PVC provides superior structural integrity and stability, meaning that the tester retains its shape and functionality even under continuous use under harsh conditions.

Additionally, the thickness and reinforcement of the PVC material act as an effective barrier against thermal stress and corrosive conditions typical of salt spray testing. This durability is important not just for maintaining test precision but also for extending the tester's lifespan. By integrating such robust materials, the Salt Spray Tester - GenSalt offers reliable performance and resilience, making it a valuable tool for industries requiring rigorous corrosion resistance testing. This guarantees that materials and coatings tested meet the stringent quality standards necessary for applications exposed to corrosive environments.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is equipped with a saturated air tank made from SUS#304 stainless steel, a material known for its durability and corrosion resistance. This high-grade stainless steel is necessary for maintaining optimal insulation within the tank, guaranteeing that the air remains at a consistent temperature and pressure during testing. Such stability is necessary for the accurate simulation of corrosive environments in salt spray tests.

The use of SUS#304 stainless steel not only improves the structural integrity of the tank but also minimizes the risk of contamination by rust or other impurities, which could otherwise affect test results. This high-pressure tank design is key to delivering the reliable and uniform conditions necessary for assessing materials and coatings' corrosion resistance. By maintaining a controlled environment, the Salt Spray Tester - GenSalt can provide precise and consistent outcomes, making it a valuable tool in industries that require durability and longevity from their materials.

Click here to learn more about the product or here to receive a personalized quote.

Salt Spray Tester - GenSalt uses an anvil made of a temperature-resistant ABS plate, which is specifically designed to support high weights and can be placed as a sample in the test vessel. Due to its precise thickness of 8 mm, the plate is very robust and resists deformation even under extreme testing conditions. This feature is necessary for maintaining structural integrity and stability when exposed to high temperatures during salt spray tests.

The use of ABS material is significant as it provides durability and heat resistance for such testing environments. Its ability to withstand heavy loads without warping ensures that the samples are uniformly exposed to corrosive conditions, contributing to the accuracy and reliability of the corrosion testing process. Additionally, the anvil's high-performance design enhances the tester's longevity, reducing frequent maintenance and ensuring consistent test results over time.

Click here to learn more about the product or here to receive a personalized quote.

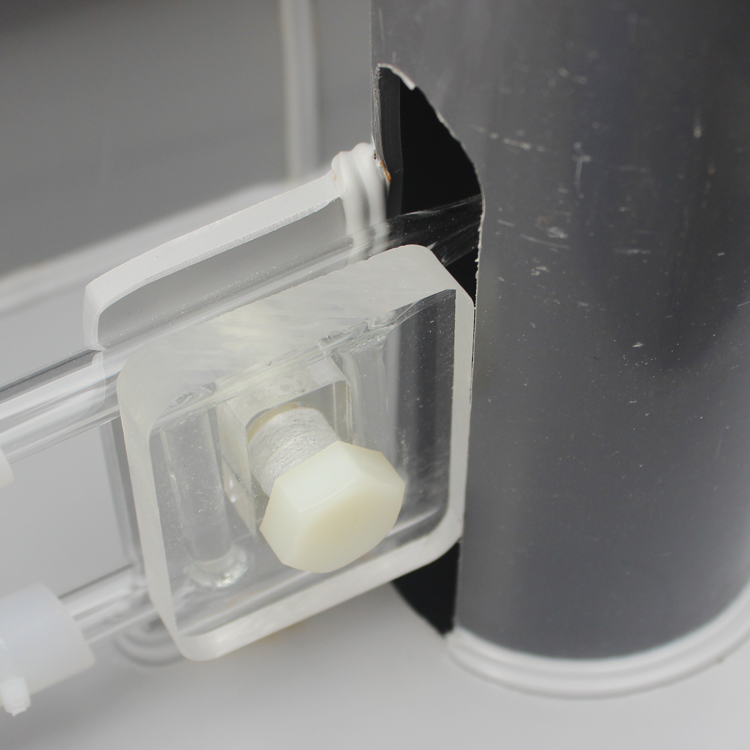

The spray nozzle in the Salt Spray Tester - GenSalt is crafted from a special glass material, enhancing its durability and resistance to corrosion in the saline testing environment. This nozzle is intricately designed to offer adjustability in both the amount and angle of the spray, key features that allow uniform distribution of salt spray throughout test samples.

The ability to adjust the spray volume and angle allows users to fine-tune the testing conditions to meet specific test requirements, which is crucial for accurate and consistent corrosion testing results. The use of special glass for the nozzle provides chemical resistance but also maintains spray precision over prolonged use. This design consideration is vital for replicating real-world corrosive environments in a controlled setting, thereby aiding in the comprehensive evaluation of material durability against salt-induced corrosion. The nozzle customization features contribute significantly to the tester's flexibility and reliability in assessing corrosion resistance in different industrial applications.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt features an adjustable spray system capable of finely controlling the spray amount to meet precise testing standards. Specifically, the spray output can be adjusted from 1 to 2 ml/h per 80 cm² of surface area. This range allows for compliance with standard requirements that often necessitate 16 hours of continuous testing.

The ability to adjust the spray amount is essential for making sure that each test can be adapted to replicate different types of corrosive environments accurately. This customization aids in evaluating materials' corrosion resistance under different conditions, providing reliable data for industrial applications. Spray adjustment provides consistency and control results, which are necessary to achieve reproducible and accurate test results. This feature underscores the flexibility and effectiveness of the Salt Spray Tester - GenSalt in meeting the stringent testing protocols required in corrosion resistance testing.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt uses the Bernotte principle, a method that effectively absorbs brine and atomizes it into a fine mist. This technique ensures uniform atomization, crucial for saline spray application across test samples. The advantage of using the Bernotte principle lies in its ability to prevent the nozzle from clogging due to salt crystallization, a common issue in salt spray testing that can interrupt the uniformity and continuity of the test conditions.

By preventing blockages, the system maintains a steady flow of atomized salt solution, essential for meeting continuous testing standards required in corrosion resistance assessments. This feature is particularly useful in long-duration tests where consistent exposure to corrosive environments is necessary to accurately evaluate coatings and materials' protective qualities against corrosion. The Bernotte principle enhances the reliability and effectiveness of the Salt Spray Tester - GenSalt, assuring that it delivers precise and reproducible results in a range of industrial applications where corrosion resistance is critical.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt features a sophisticated air supply system initially adjusted to roughly 2 kg/cm² to provide optimal operation. This pressure setting is necessary for maintaining the correct force needed to atomize the saline solution effectively during the corrosion testing process. Additionally, the system is equipped with an inlet air filter with drainage.

This drainage function is particularly important as it helps to remove any accumulated moisture or debris from the air supply, making sure that the air entering the testing chamber is clean and dry. Clean air is essential for preventing unintended variables that could affect corrosion tests' consistency and accuracy. By maintaining a precise pressure setting and guaranteeing the purity of the air supply, the Salt Spray Tester - GenSalt enhances corrosion resistance testing reliability and effectiveness, providing accurate conditions that meet rigorous industrial standards.

Click here to learn more about the product or here to receive a personalized quote.

How does the precision adjustment feature benefit the Salt Spray Tester - GenSalt air supply system?

The Salt Spray Tester - GenSalt includes a precision adjustment feature in its air supply system, set to 1Kg/cm², which plays a crucial role in ensuring the accuracy and consistency of the test environment. This precision adjustment is complemented by a 1/4 pressure gauge that displays the pressure settings accurately, allowing for meticulous control over the air pressure used during salt spray tests.

This level of control is essential for the proper atomization of the saline solution so that the salt mist is distributed uniformly over the samples being tested. The precise pressure adjustment helps maintain the integrity of the test conditions, providing a stable and controlled environment which is essential to reliable corrosion testing. The accurate readings from the pressure gauge allow technicians to make fine adjustments as needed, making sure that the system operates within the optimal range for accurate corrosion resistance testing. This precision ultimately contributes to the effectiveness of the Salt Spray Tester - GenSalt in assessing materials' durability against corrosive environments, making it an invaluable tool in quality control and product development processes.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt features a fast heating rate and a heating tube made from pure titanium, which is important for increasing the unit's efficiency and longevity. The fast heating rate provides assurance that the tester reaches the required temperature quickly, maximizing operational efficiency and reducing the time needed to start each test cycle. This is particularly beneficial in laboratory environments where time and accuracy are a priority.

Moreover, the use of pure titanium for the heating tube offers significant advantages due to its exceptional resistance to acid and alkali corrosion. Titanium is well-known for its durability and resistance to harsh chemicals, making it ideal for salt spray testing. Titanium's corrosion resistance extends the heating tube's service life, ensuring reliable performance over extended periods and reducing the need for frequent replacements.

These features combined - instant heating and robust tube material - significantly contribute to the overall efficiency, reliability, and cost-effectiveness of the Salt Spray Tester - GenSalt, making it a valuable tool for testing and verifying material durability in corrosive environments.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt incorporates a high-tech test chamber heating tank that incorporates a liquid expansion safety temperature controller, capable of regulating temperatures from 0 to 120°C. This controller, sourced from EGO of Italy, is a key component for providing precise temperature management within the testing environment. The use of a liquid expansion safety temperature controller is an essential component to maintaining consistent test conditions, crucial for corrosion resistance testing accuracy.

The ability to control the temperature accurately helps in preventing overheating, which not only protects the samples from damage but also contributes to the safety of the testing process. By maintaining a stable temperature within the specified range, the Salt Spray Tester can simulate different types of corrosive environments reliably, which is essential for testing materials' durability under different conditions. The inclusion of a high-quality temperature controller like the EGO increases the tester's overall reliability and efficiency, making it an indispensable tool in material testing labs focused on corrosion analysis.

Click here to learn more about the product or here to receive a personalized quote.

What features does the LCD digital display time controller offer in the Salt Spray Tester - GenSalt?

The Salt Spray Tester - GenSalt is equipped with an advanced LCD digital display time controller, featuring a power failure memory function that ranges from 0.1 seconds to 999 hours. This component, sourced from Japan's OMRON, is essential for optimizing the testing process's usability and reliability. The LCD digital display provides a clear and user-friendly interface for setting and monitoring test durations accurately, which is vital for conducting precise and controlled corrosion tests.

The power failure memory function is particularly valuable as it guarantees that in the event of an unexpected power interruption, the device will remember the last recorded settings and continue the test from where it stopped once power is restored. This functionality minimizes the risk of data loss and test disruption, thereby maintaining the integrity of test results even under less-than-optimal operating conditions. Such features make the Salt Spray Tester - GenSalt a robust tool for material testing, assuring that it can deliver reliable and consistent performance in demanding laboratory environments.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt includes an accumulator, sourced from VEMER in Italy, capable of tracking operational time up to 99999 hours. This extensive range allows for detailed and long-term monitoring of the tester’s usage, crucial for maintenance schedules and quality control over the equipment’s lifecycle. The accumulator's primary function is to log the total hours the tester has been operational, providing valuable data for verifying that the machine is performing within its expected parameters and identifying when it may require servicing or calibration.

Tracking such extensive usage helps laboratories manage their equipment more effectively, ensuring optimal performance and reliability. This feature is particularly helpful for maintaining corrosion test accuracy, as it helps make certain that the Salt Spray Tester remains in proper working condition, which is crucial for achieving consistent and reliable test results. This long-range accumulator is an invaluable tool for extending the tester's lifespan and maximizing its efficiency in rigorous testing environments.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is equipped with a high-quality relay from OMRON, a renowned manufacturer based in Japan. This choice of relay is critical for the tester, as OMRON is recognized for producing reliable and durable electronic components that excel in precision and longevity. The relay functions as an essential switch within the tester's electrical system, controlling the activation and deactivation of key components such as heating elements and spray mechanisms.

OMRON relays are specifically designed to handle the demanding operational requirements of laboratory equipment like the Salt Spray Tester. They guarantee that the device operates smoothly under various test conditions, providing consistent and reliable performance necessary for accurate corrosion testing. The use of such a reputable brand enhances the tester's ability to maintain precise control over its environmental conditions, which is vital for simulating corrosive atmospheres needed to assess materials and coatings' durability effectively.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is equipped with a durable rocker switch that includes a light indicator, enhancing the device's usability and functionality. This switch is designed to withstand significant pressure, capable of operating continuously up to 25,000 times. This level of durability makes sure that the switch can handle frequent on-off actions required in rigorous testing environments without failure.

The inclusion of a light indicator on the rocker switch provides visual feedback for operators, indicating whether the unit is active or in standby mode. This feature is particularly useful in environments where precision and safety are paramount, allowing for clear and immediate recognition of operational status. The switch's high durability and functional integration help maintain the efficiency and reliability of the Salt Spray Tester, assuring that it continues to perform optimally in demanding conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is designed with a built-in safety feature that automatically turns off the power when the water level becomes too low. This automatic shutdown helps prevent damage to the unit or safety hazards from operating without sufficient water. Concurrently, a safety warning light device activates, alerting the operator to the low water condition. This visual indication is extremely important for maintaining safe operating conditions, allowing personnel to promptly address the issue without risking damage to the equipment or compromising safety.

The integration of this automatic cutoff and warning system reflects the commitment to user safety and equipment reliability. It provides assurance that the tester can be operated with confidence, even in busy laboratory environments where constant monitoring might not be feasible. Such features are vital for maintaining the integrity of the testing process and ensuring that all operations are conducted within safe parameters.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt incorporates an advanced safety feature that automatically turns off the heater power when the temperature exceeds predefined limits. This preventative measure is necessary to avoid overheating, which could damage the unit or pose safety hazards. Meanwhile, a safety warning light activates to alert the operator to the high-temperature issue. This visual indicator is vital for verifying that any temperature anomaly is immediately recognized and addressed, maintaining safe and stable operating conditions.

This automatic shutdown mechanism coupled with the warning light enhances the reliability of the Salt Spray Tester by making sure that it operates within the safe temperature ranges essential for accurate and consistent corrosion testing. Such safety features protect both the equipment and the personnel operating it, allowing for peace of mind during extended testing procedures. This focus on safety is indicative of the tester's design, which prioritizes both performance and user safety.

Click here to learn more about the product or here to receive a personalized quote.

In the Salt Spray Tester - GenSalt, if the reagent (salt) level falls below the required minimum, the unit is equipped with a safety mechanism that activates a warning light and sounds an alarm. This feature is absolutely necessary for maintaining the integrity of the testing process, as the proper concentration of salt solution is required for accurate corrosion testing. The warning light alerts the operator that the salt level is insufficient, potentially compromising test results. Furthermore, the audible alarm ensures immediate attention to the issue, prompting the operator to refill the salt solution to the necessary level.

This safety feature not only helps prevent inaccurate test outcomes due to insufficient reagent levels but also makes sure that the equipment operates safely without risking damage that could occur if the machine continues to run without the required amount of salt solution. Such proactive measures are integral to maintaining the reliability and effectiveness of corrosion resistance testing, protecting both the quality of the results and the longevity of the tester itself.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt includes a valuable safety feature known as the leakage protection function. This function is designed to prevent personal injury and protect the instrument from damage due to electrical line leakage or short circuits. When a leakage or short circuit is detected, the leakage protection mechanism automatically shuts down the power supply to the tester. This immediate response is essential for mitigating any potential hazards, assuring that both the operator and the equipment are protected against electrical malfunctions.

The inclusion of this feature demonstrates the dedication to safety in the Salt Spray Tester - GenSalt design. It not only helps in preventing accidents that could result from electrical faults but also increases the reliability of the tester by protecting its internal components from electrical damage. Such proactive safety measures are integral to maintaining a safe working environment and prolonging the lifespan of the equipment, making it an ideal choice for conducting rigorous and extended corrosion tests.

Click here to learn more about the product or here to receive a personalized quote.

The Salt Spray Tester - GenSalt is equipped with both automatic and manual watering systems, increasing its functionality and safety during operation. These dual systems are designed to replenish water in both the pressure tank and the test chamber, making sure that the water levels are adequately maintained to prevent any issues related to water shortages or ultra-high temperatures, which could potentially damage the instruments.

The automatic watering system operates without manual intervention, providing convenience and consistency by maintaining optimal water levels at all times. This system is extremely important for long-duration tests where constant monitoring would be impractical. It is designed so that the tester can run uninterrupted while preventing the equipment from overheating due to low water levels.

On the other hand, the manual watering system allows for operator control, offering flexibility when adjustments are needed or when the automatic system needs to be supplemented or bypassed. This manual option provides assurance that the operator can directly manage water levels based on real-time observations and test requirements.

Click here to learn more about the product or here to receive a personalized quote.

The defogging system in the Salt Spray Tester - GenSalt assists in maintaining the integrity of both the test chamber and surrounding equipment. During the testing process and upon shutdown, this system actively removes salt spray from the test chamber. The main purpose of this defogging action is to prevent corrosive gases, inherent in salt spray environments, from escaping the chamber and causing potential damage to the tester itself and other sensitive precision instruments nearby.

By making certain that salt spray and corrosive gases are contained and then effectively removed, the defogging system helps to preserve the structural and functional integrity of the testing chamber. It also minimizes the risk of corrosion-related damage to other laboratory equipment, which could be severely affected by exposure to these harsh conditions. This feature not only increases the safety and cleanliness of the testing environment but also ensures that the Salt Spray Tester - GenSalt can operate continuously without compromising the accuracy of the corrosion tests or the longevity of the equipment involved.

Click here to learn more about the product or here to receive a personalized quote.

The GenSalt series, which includes the GenSalt-60, GenSalt-90, and GenSalt-120 models, specifies a laboratory temperature range of 35°C±1°C, with the capability to adjust from room temperature up to 60°C. This range of temperatures is required for maintaining a controlled environment suitable for accurate and consistent salt spray testing. The ability to keep the temperature within this narrow margin assures that the conditions under which corrosion tests are conducted remain constant, which is essential for reliable results.

The precision of temperature control allows these models to simulate different corrosive environments accurately, thereby aiding in assessing the corrosion resistance of materials and coatings effectively. This feature is highly valuable for industries that require rigorous quality control measures so that their products can withstand harsh conditions without degradation. The specified temperature ranges of GenSalt models highlight their versatility and adaptability to meet different testing standards and requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenSalt series, including the GenSalt-60, GenSalt-90, and GenSalt-120 models, maintains the saturated air cylinder temperature at 47°C±1°C. This temperature setting is key to maintaining the conditions within the air cylinder optimal for producing consistent and uniform salt spray during testing. The ability to control the temperature within such a narrow range, from room temperature up to 60°C, is essential for replicating different corrosive environments accurately.

This temperature control is a necessity for the reliability of salt spray tests conducted with these models. It helps to ensure that the saturated air, which aids in dispersing the salt solution within the chamber, has the right properties to maintain the test's integrity. By regulating the temperature of the saturated air cylinder so precisely, the GenSalt series improves corrosion resistance assessment accuracy, making these models suitable for rigorous industrial testing applications where consistent environmental conditions are necessary for valid results.

Click here to learn more about the product or here to receive a personalized quote.

The GenSalt series offers different interior dimensions to accommodate different testing needs, each customized to industry-specific size requirements. The GenSalt-60 features interior dimensions of 23.6 inches by 17.7 inches by 15.7 inches, or 60 cm by 45 cm by 40 cm, making it suitable for smaller sample sizes. The GenSalt-90 model provides a larger space with dimensions of 35.4 inches by 23.6 inches by 19.7 inches, or 90 cm by 60 cm by 50 cm, ideal for medium-sized samples. The largest, the GenSalt-120, offers even more extensive space at 42.25 inches by 39.4 inches by 19.7 inches, or 120 cm by 100 cm by 50 cm, designed for large samples or multiple small samples in a single test run.

With these dimensions, the GenSalt series can handle an array of testing protocols, allowing for precise control and accommodation of various test setups. The varied sizes ensure that regardless of the material or the scale of the test, there is a model that fits the requirements of nearly any salt spray test case, supporting accurate and reliable corrosion resistance testing.

Click here to learn more about the product or here to receive a personalized quote.

The GenSalt series, created to meet a range of testing requirements, offers different exterior dimensions for each of its models. The GenSalt-60 has dimensions of 42.1 inches by 23.6 inches by 46.5 inches or 107 cm by 60 cm by 118 cm. This size makes it compact enough for smaller lab spaces while still providing ample interior testing volume. Moving up in size, the GenSalt-90 measures 5.5 feet by 3.5 feet by 5.1 feet, or 140 cm by 90 cm by 130 cm, offering a larger footprint for medium to large-sized samples. The largest model, the GenSalt-120, stands at 7.5 feet by 4.3 feet by 5.5 feet, or 190 cm by 110 cm by 140 cm, accommodating larger samples or multiple test setups.

These dimensions allow that each model can be integrated into many laboratory settings, providing the necessary capacity for a range of salt spray testing scenarios. The size increments between models reflect their capability to handle progressively larger or more numerous samples, supporting comprehensive corrosion testing needs across industries.

Click here to learn more about the product or here to receive a personalized quote.

Different models in the GenSalt series are available in different weights, meeting different testing scales and laboratory requirements. The GenSalt-60 model weighs 150 pounds or approximately 68 kilograms, making it the lightest in the series and suitable for smaller or more confined laboratory spaces. The next model, the GenSalt-90, has a weight of 183 pounds or around 82 kilograms, offering a balance between size and maneuverability for medium-sized labs. The largest model, the GenSalt-120, weighs 214 pounds or about 97 kilograms, providing a sturdy and stable platform for extensive corrosion testing with large samples or multiple setups.

These weights reflect the robust construction of the GenSalt series, designed to provide stability and durability during extensive salt spray testing procedures. Each model's weight contributes to its overall performance and ease of installation in various testing environments, supporting its effectiveness in delivering reliable and consistent corrosion resistance assessments

Click here to learn more about the product or here to receive a personalized quote.

GenSalt series models are equipped with specific power requirements suited to their operational needs. The GenSalt-60 model offers flexibility with dual voltage options, supporting both 110V/60Hz and 220V/50Hz, making it adaptable for use in different regional power supply settings. This dual option increases the model’s ability to be used in different geographical locations. The GenSalt-90 and GenSalt-120 models operate on 220V/50Hz, 1 phase. This specification guarantees that they are compatible with the standard electrical systems commonly found in industrial environments, providing efficient power consumption while maintaining consistent performance during salt spray tests.

These power specifications make sure that each model can perform optimally within the electrical constraints of most laboratories and industrial settings, supporting their functionality in conducting reliable and effective corrosion tests. The choice of voltage and frequency is designed to match the testing environment's needs while ensuring safety and efficiency.

Click here to learn more about the product or here to receive a personalized quote.

Below are some example of specimens that our clients require testing with the Salt Spray System. They include zippers, clamps, tooling parts, belt buckles, and much more.

One of the unique values offer by our Salt Spray Chambers is that the the samples can be placed in a V-shaped groove as well as hung on a fiber bar to maximize exposure for the submerged specimen.

Absolutely. This is regular NaCl salt can be purchased virtually anywhere.

The unit comes standard with a 3 salt containers (NaCl). Each salt container will suffice to prepare 9500ml of water within the Salt Spray System.

The Salt Spray Chamber has a reservoir of nearly 10L.

The standard parts for the salt spray tester include the following:

| Thermostat | 2 |

| Pressure gauge | 1 |

| Indicator light | 5 |

| Timer | 1 |

| Control switch | 2 |

| SSR | 2 |

| Relay | 1 |

| Thermal line | 2 |

| Pressure regulating valve | 2 |

| Solenoid valve | 4 |

Request a quotation today to learn more.

Related Products

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

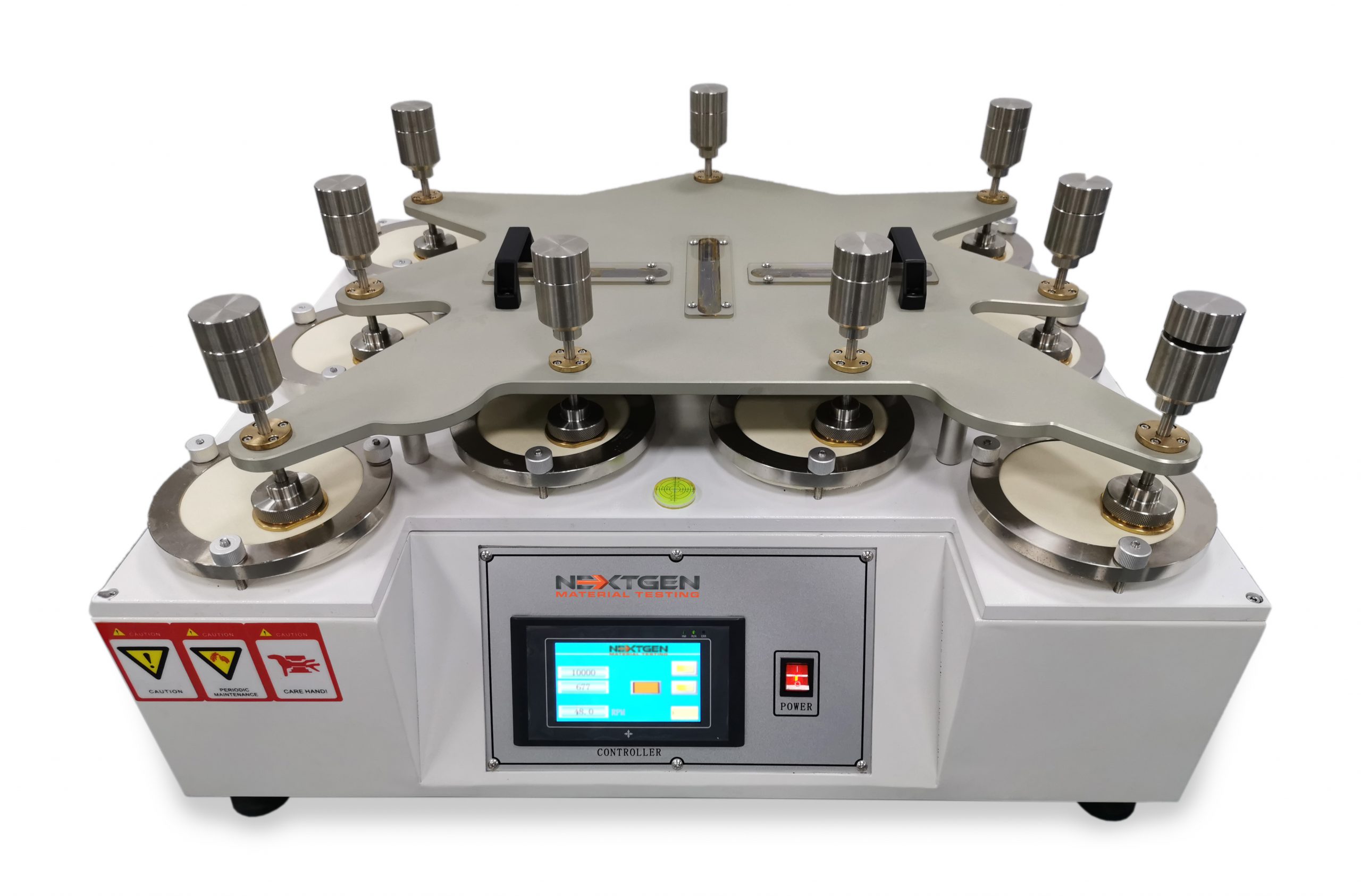

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

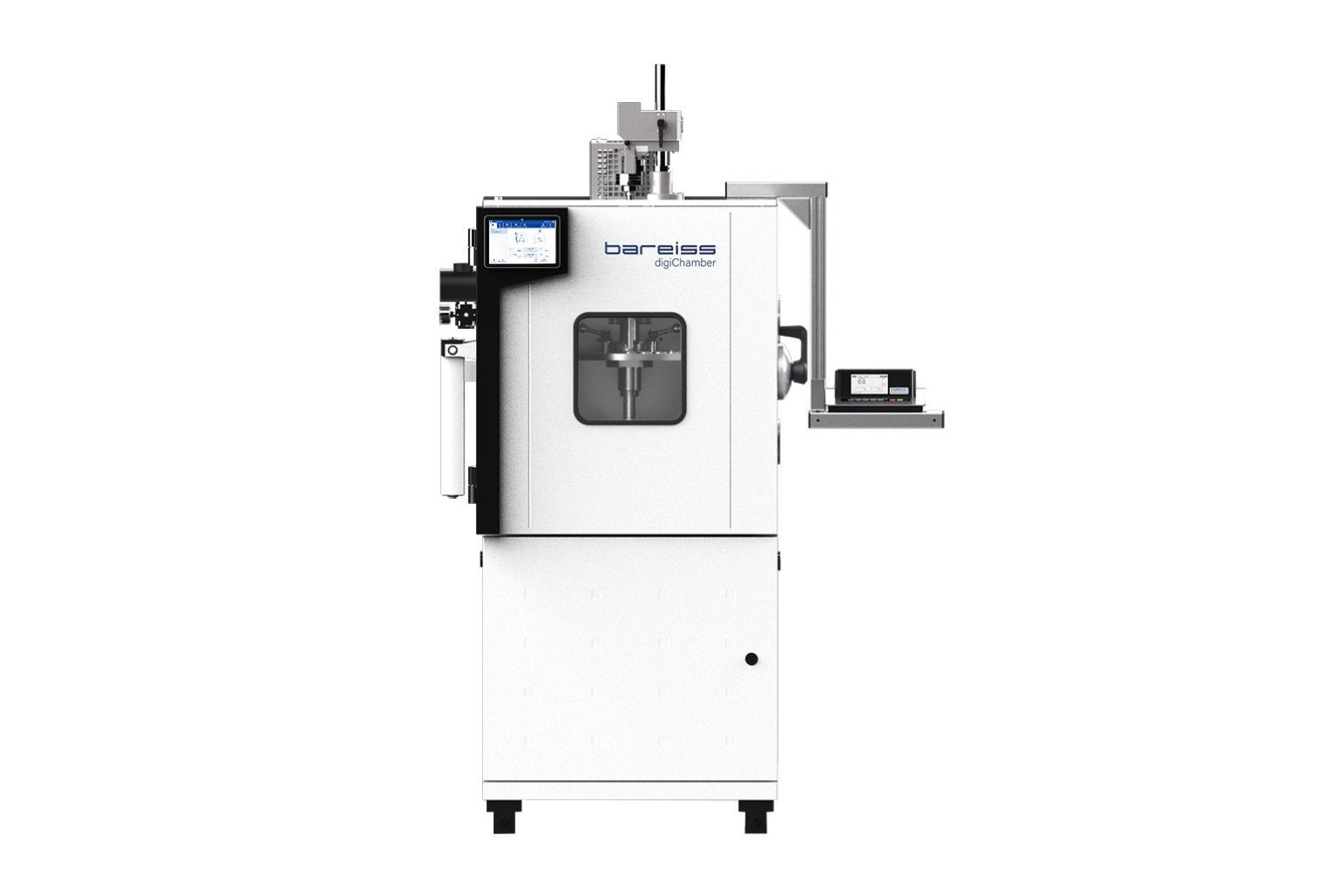

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is designed to test anti-rupture strength of variety of materials such as leather, paper and fabric. The unit tests the resistance of specimens to bursting using a hydraulic diaphragm bursting tester.

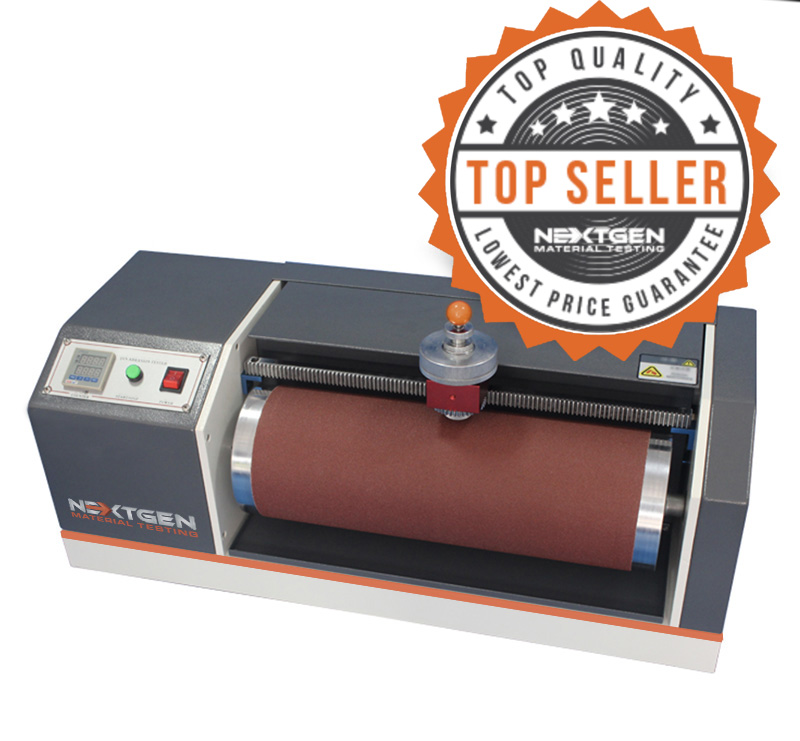

DIN Abrasion Tester

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.