In our everyday lives, fabric is an integral component of clothing, upholstery, and a number of industrial applications. Recent studies show that the global textile market is expected to experience significant growth, reaching over $1 trillion by 2027. As the manufacturing of clothes and other fabric-based products continues to expand, there is a growing need for accurate and reliable fabric testing methods.

Fabric testing requires several types of tools, including the Martindale abrasion tester. A Martindale abrasion tester measures fabric pilling and abrasion resistance of textiles. Fabrics with higher abrasion resistance are able to withstand friction better than those with lower abrasion resistance.

As one of the latest and most advanced products on the market for fabric testing, we are pleased to present our GenDale – 9-Station Martindale Abrasion Tester. The aim of this article is to provide you with an overview of the features of our product, to outline the technical specifications of this product, and to discuss who benefits from its use.

Understanding the Martindale Abrasion Test

In order to better grasp the capabilities of our GenDale – 9-Station Martindale Abrasion Tester, it is important to have a basic understanding of Martindale abrasion testing and Pilling Testing.

The Martindale abrasion test is a commonly used method for determining textile abrasion resistance. This test measures how well a fabric can withstand wear and tear caused by friction. Material durability and longevity can be determined by this test. Here is a detailed explanation of how the Martindale abrasion test works:

Test Procedure

In the Martindale abrasion test, a fabric sample is placed against an abrasive surface, typically sandpaper, worsted wool, or a wire mesh. A figure-eight (Lissajous) pattern is then applied to the fabric using a multi-directional rubbing motion. During regular use, this motion simulates the natural wear and tear that occurs. The test continues until visible wear is observed on the fabric, such as yarn breaks, pilling, or holes.

Evaluation Methods

There are 3 primary methods for evaluating the Martindale abrasion test results:

-

Specimen Breakage Method: The most common method, where the number of cycles (or rubs) is counted until the fabric breaks or shows significant wear. By using this method, abrasion resistance can be measured clearly and intuitively.

-

Mass Loss Method: This method measures the fabric sample’s mass loss after a set number of cycles. It is useful when determining the durability of a material based on its weight loss.

-

Appearance Change Method: This method determines whether a fabric has pilled or fuzzed after a specific number of cycles.

Significance of Martindale Scores

Fabric’s Martindale score is one of the most important indicators of how durable it will be. The Martindale score represents the number of rubs a fabric can withstand before showing signs of wear, providing a standardized measure of its durability. Here are the different Martindale score ranges:

-

Less than 10,000 rubs: Suitable for decorative items like throw pillows and cushions, where minimal wear is expected.

-

10,000 to 15,000 rubs: Ideal for light domestic use, such as curtains and occasional-use furniture.

-

15,000 to 25,000 rubs: Appropriate for general domestic use, including everyday furniture like sofas and chairs.

-

25,000 to 30,000 rubs: Suitable for heavy-duty domestic use and commercial environments, such as office furniture.

-

More than 30,000 rubs: These fabrics are highly durable and suitable for high-traffic commercial settings, such as hotels and restaurants.

Benefits of the Martindale Test

The Martindale abrasion test offers several benefits:

-

Quality Control: Before fabrics are used in production, they are checked to verify that they meet the required durability standards.

-

Consumer Confidence: Helps consumers and designers select fabrics based on wear resistance.

-

Consistency: Provides a standardized method for comparing fabric durability between different fabric manufacturers.

The Basics of the Pilling Test

Besides Martindale abrasion testing, our GenDale – 9-Station Martindale Abrasion Tester is also capable of handling a pilling test, and to fully grasp the capabilities of our product, it is necessary that we understand the basics of the Pilling Test.

The Pilling Test is used to determine fabrics’ resistance to pill formation, which are small balls of entangled fibers on the fabric surface. These tests are required for assessing textile durability and aesthetic performance.

Test Procedure

The Pilling Test, commonly conducted using the Martindale machine, involves several key steps. Fabric samples are rubbed against another piece of the same fabric under controlled conditions. The samples are mounted and subjected to a specific number of rubbing cycles in a figure-eight motion. This motion simulates frictional forces encountered during use. The degree of pilling is then assessed by comparing the tested samples to standard visual scales.

-

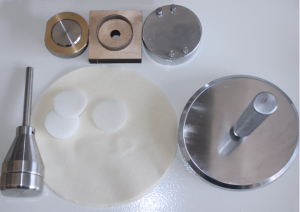

Sample Preparation: Circular specimens are cut from the fabric and mounted on the Martindale tester.

-

Testing Motion: The samples are subjected to a multi-directional rubbing motion, typically following a Lissajous pattern.

-

Evaluation: After the test, the fabric samples are compared against a standardized rating scale, ranging from 1 to 5. A rating of 5 indicates no pilling, while a rating of 1 signifies severe pilling.

Importance of Pilling Resistance

Pilling resistance is an attribute in upholstery, apparel, and other high-use applications. Fabrics with poor pilling resistance can quickly become unsightly and less functional, reducing their lifespan and customer satisfaction.

-

Aesthetic Quality: Pilling makes a fabric appear worn out and prematurely aged, reducing its visual appeal.

-

Durability: High pilling resistance indicates that the fabric can withstand everyday wear and maintain its integrity and appearance over time.

The GenDale – 9-Station Martindale Abrasion Tester

The GenDale – 9-Station Martindale Abrasion Tester is designed for testing the abrasion resistance and pilling of different textiles, with a focus on shoe fabrics and linings. Our advanced tester can handle up to 9 specimens at once, greatly increasing productivity.

Abrasion testing involves subjecting fabric specimens to a multi-directional, back-and-forth rubbing motion. This replicates real-life wear conditions to provide an accurate measure of fabric durability. The accuracy of the abrasion strength is determined by counting the number of cycles until a hole appears in the test area of the fabric specimen.

For technical specifications, the GenDale tester features a maximum stroke of movement of 60.5 ± 0.5 mm during the abrasion test. The holder and spindle used in this test weigh 200 ± 1 g, providing the required pressure to simulate real-world abrasion conditions accurately.

For pilling tests, the GenDale tester operates with a maximum movement stroke of 24 ± 0.5 mm. This precise motion helps in evaluating the fabric’s tendency to form small balls or pills on its surface under friction. The holder and spindle for the pilling test weigh 155 ± 1 g, applying the appropriate force to test the fabric’s pilling resistance properly.

GenDale – 9-Station Martindale Abrasion Tester Features

The GenDale – 9-Station Martindale Abrasion Tester comes equipped with a number of advanced features. Central to its operation is the PLC programmable control system, which includes a large touch-screen interface. This intuitive interface allows precise adjustments and easy monitoring of the testing process.

Another feature of the GenDale tester is its adjustable test speed, which can be adjusted to meet different testing requirements. This allows the tester to be customized to fit the specific needs of different fabrics and materials.

Another feature of the GenDale tester is its adjustable test speed, which can be adjusted to meet different testing requirements. This allows the tester to be customized to fit the specific needs of different fabrics and materials.

As we already mentioned, the unit is designed with 9 testing stations, enabling parallel testing of multiple specimens. Additionally, the standard configuration includes sample holders and weights of 9 and 12 kPa, making the equipment ready for immediate use.

To support operators in maximizing the tester’s capabilities, the GenDale – 9-Station Martindale Abrasion Tester comes with a comprehensive manual and a certificate of quality.

Technical Specifications of the Martindale Abrasion Tester

Our tester offers an extensive list of specifications in order that it can be assured that it is accurate and reliable. Here, we highlight the main specifications that make the 9-Station GenDale an ideal tool for testing:

Speed:

-

Range: 50-2 revolutions per minute (r/min)

Dimensions:

-

Size: 34.85 x 23.6 x 16 inches

-

Metric Size: 88.5 x 60 x 41 cm

Power Supply:

-

Options: 110V / 220V, single-phase (1ph)

Abrasion Test Specifications:

-

Max Stroke of Movement: 60.5 ± 0.5 mm

-

Weight of Holder and Spindle: 200 ± 1 g

Pilling Test Specifications:

-

Max Stroke of Movement: 24 ± 0.5 mm

-

Weight of Holder and Spindle: 155 ± 1 g

Annual Calibration Services from NextGen

At NextGen Material Testing, we know how important it is to maintain the Martindale Abrasion Testing system’s accuracy and reliability. Because of this, we offer comprehensive annu al calibration services, relying on our extensive global network of agencies to guarantee you have a hassle-free experience.

al calibration services, relying on our extensive global network of agencies to guarantee you have a hassle-free experience.

One of the key benefits of our calibration services is precision assurance. Accurate calibration is critical for reliable test results, and our services ensure that your equipment meets the highest industry standards. This precision not only increases the quality of your testing processes but also helps maintain compliance with various regulatory requirements.

Additionally, our services are designed to be convenient and efficient. By simply requesting a quotation and providing your model number and address, our process will be made easier for you. We manage the entire calibration procedure, minimizing equipment downtime and allowing you to focus on your core operations without interruption.

Moreover, partnering with NextGen for your calibration needs means you have access to our experienced and knowledgeable team. Our experts are dedicated to ensuring that your equipment performs optimally, providing you with peace of mind and confidence in your testing results.

Compliance with Industry Standards

Our GenDale – 9-Station Martindale Abrasion Tester complies with many stringent industry standards. For a better understanding of the capabilities of our product, we will take a closer look at some of the most popular standards on that list:

ISO 12945-2

ISO 12945-2 specifies a method for determining textile fabrics’ resistance to surface pilling, fuzzing, and matting. This standard uses a modified Martindale method to simulate fabric wear and tear in real-life conditions. The method provides a reliable assessment of how well a fabric will maintain its appearance over the long run, based on its appearance.

ASTM D4966

ASTM D4966 outlines the test method for measuring textile fabrics’ abrasion resistance using the Martindale abrasion tester. This standard is critical for evaluating the durability of fabrics used in different applications, including apparel and upholstery. It replicates fabrics’ frictional forces during use.

ISO 20344

ISO 20344 specifies footwear general requirements and test methods. It includes methods for testing abrasion resistance, ensuring that shoe materials meet high durability and safety standards.

JIS L1096

JIS L1096 is a Japanese industrial standard that specifies testing methods for woven and knitted fabrics. It covers various aspects, including tensile strength, tear resistance, air permeability, and dimensional change after washing. This standard guarantees that fabrics meet stringent quality criteria, vital for textile manufacturers.

Alternative for GenDale – Martindale Abrasion Tester (4 Specimens)

Our GenDale tester is also available in another version. With this model, you can test up to 4 specimens at once, instead of 9, making it a more compact and efficient solution for moderate testing requirements.

The primary difference between this 4-station model and our 9-station Martindale abrasion tester is the number of specimens it can test at the same time.

Designed to test shoe fabric, shoe lining, and a multitude of other shoe-related materials, the 4-station GenDale measures fabric abrasion by applying a complex back-and-forth rubbing motion to the specimen. The accuracy of the abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen. This model produces accurate, repeatable, and user-friendly testing results every time.

The 4-station GenDale tester operates in a speed range of 50-2 revolutions per minute, adjustable to meet different testing requirements. It features a PLC programmable control system with a large touch-screen interface, allowing for easy operation and precise control of the testing process. For the abrasion test, the maximum stroke of movement is 60.5 ± 0.5 mm, with the holder and spindle weighing 200 ± 1 g. For the pilling test, the maximum stroke of movement is 24 ± 0.5 mm, and the holder and spindle weigh 155 ± 1 g.

Measuring 34.85″ x 23.6″ x 16.15″ (88.5 x 60 x 41 cm), the GenDale tester is compact enough to fit in most laboratory environments while still providing robust testing capabilities. It operates on an AC220V single-phase power supply, making it compatible with standard electrical systems.

Versatile Applications of the GenDale – Martindale Abrasion Tester

GenDale – 9-Station Martindale Abrasion Tester offers comprehensive functionality to meet the demanding requirements of a broad range of industries. Its ability to test up to 9 specimens at once provides efficiency and precision, which makes it a very useful tool for many types of applications. Below are some key industries that benefit from advanced testing equipment.

Footwear Manufacturers

For footwear manufacturers, the GenDale tester is an essential tool for testing the durability of fabrics, linings, and other materials. The tester simulates real-life wear conditions by applying a complex, multi-directional rubbing motion to fabric specimens. This process accurately measures abrasion resistance and makes sure that the materials can withstand everyday wear and tear. For example, a manufacturer can use the tester to verify that a new shoe lining material will maintain its integrity and comfort after extensive use. This will reduce product returns and increase customer satisfaction.

Textile Industry

In the textile industry, the GenDale tester allows precise and simultaneous testing of up to 9 specimens, significantly improving material assessment efficiency. This capability is particularly valuable for evaluating the durability of fabrics used in clothing, upholstery, and industrial applications. For instance, textile producers can use the tester to compare the abrasion resistance of different fabric blends. The goal is to be sure that the most durable options are selected for high-stress applications such as workwear or automotive interiors. This not only improves the quality of the final products but also boosts the manufacturer’s reputation for reliability and durability.

Quality Assurance Departments

Its programmable control and touchscreen interface make the GenDale tester very useful for quality assurance departments in various industries. With these features, abrasion strength can be measured accurately, allowing rigorous quality control protocols to be implemented. As an example, a furniture manufacturer can use the tester to ensure that the upholstery fabrics used in their products are durable. Companies can minimize defects, ensure customer satisfaction, and adhere to industry standards by rigorously testing materials before they go into production.

Final Thoughts on the GenDale – 9 Station Martindale Abrasion Testers

The GenDale – 9-Station Martindale Abrasion Tester represents the next step in fabric testing technology. Its ability to test up to 9 specimens at the same time increases efficiency and guarantees precise and reliable results. Our advanced tester is a must for many industries, including footwear manufacturing, textile manufacturing, and quality assurance departments. Its comprehensive testing capabilities help manufacturers maintain high standards of durability and quality, ultimately leading to high customer satisfaction and reduced product returns.

For those with limited time and space in their laboratories, we also offer the 4-station GenDale – Martindale Abrasion Tester. This more compact version provides the same reliable and accurate testing in a smaller footprint, making it an ideal solution for smaller labs or those with moderate testing requirements. It provides high-quality testing results without extensive space.

At NextGen Material Testing Inc., we are committed to supporting your material testing needs. We offer a wide selection of equipment for numerous types of testing and a range of services designed to help you achieve the highest quality results. If you need an online quote or direct assistance, our team is here to help you every step of the way. Get in touch with us to learn more about how we can assist you with your testing requirements.