Plastic Testing Equipment

Standards

Certified

Description

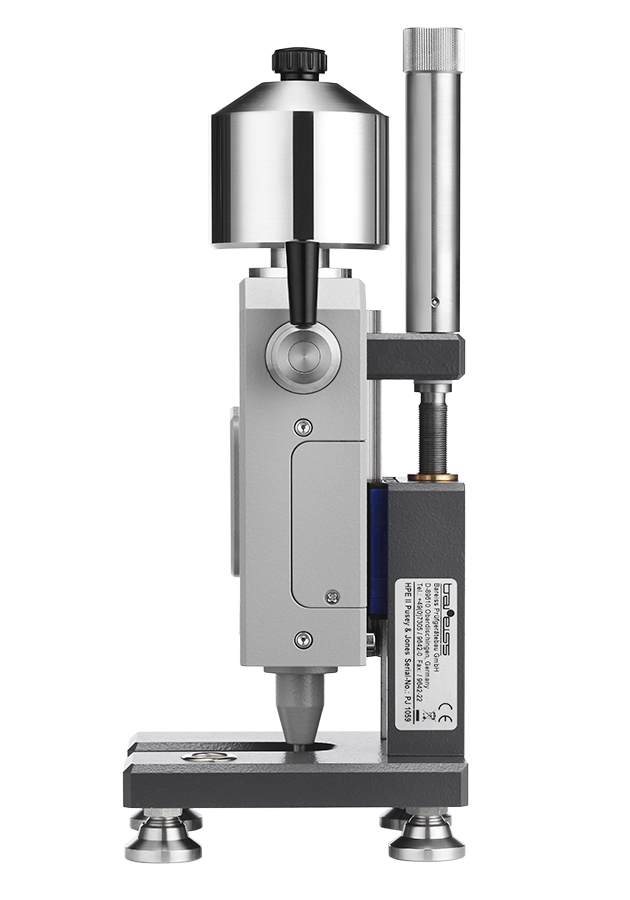

Pusey & Jones is a rubber and rubber like material testing plastometer system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm. This portable solution can be upgraded to the automatic test stand which allows for the ultimate accuracy and repeatability results regardless and elimination of operator error.

The system is equipment with an intuitive electronic dial gauge which indicates the penetration depth directly in 0.00 mm units and comes equipped with a zero-setting option. The primary benefit is that the dial gauge display can be set for zero by pressing a single button, as soon as the indenter with measuring rod is raised approximately for about 3 mm after lowering the body of the hardness tester. The integration of a vertical spindle found at the back of the testing system allows for accurate lowering or the lifting movements.

A specific test load of 9.8 N is applied by lowering the lateral load lever. The measurement results can be read after a 60 second testing time. This results can be displayed directly on the user-friendly digital interface of the Pusey & Jones system or on a PC should you choose to upgrade to the HardTest software. The latter feature allows to generate reports in Excel and PDF format for your optimal accuracy and ease of data management.

Features

- Built-In Timer for Precise and Repeatable Measurement

- 1kg load weight

- RS232 Output for Connection to Optional HardTest Software

Ranges of Application

Pusey & Kones this hardness method is for the hardness measuring on rubber or rubber-like materials and rubber rollers in the paper industry.

Accessories

- DAKKS/DKD-calibration certificate for the instrument

- Test stand for HPEII Barcol

- Software for Data Transfer and Analysis

- Standard test block with DAKKS/DKD-calibration certificate

System Dimensions

FAQs

NextGen's Pusey & Jones portable hardness tester is primarily designed for testing rubber and rubber-like materials and rubber rollers in the paper industry. Rubber materials have a wide range of hardness levels. The system applies a specific test load of 9.8 N, which is suitable for measuring the hardness of various rubber materials.

You can also test similar properties using NextGen's Pusey & Jones system. However, it is important to remember that the system's accuracy and reliability may vary depending on the material being tested. Moreover, the specimen being tested should not exceed 13 mm, as this is the maximum thickness the NextGen's Pusey & Jones system can handle.

To sum up, Pusey & Jones portable hardness tester from NextGen Material Testing is a reliable and accurate tool for measuring the hardness of rubber and rubber-like materials and is particularly well-suited for testing rubber rollers in the paper industry.

Click here to request a personalized quote from our team!

ASTM D531 is a standard test method for measuring the dynamic mechanical properties of plastic materials using a torsional pendulum. This test method is designed to measure the loss factor and modulus of rigidity of plastic materials, which are important mechanical properties that can affect the performance of plastic products in a variety of applications.

The test involves subjecting a sample of the plastic material to a small, sinusoidal twist at a known frequency and measuring the resulting torque and phase angle of the twist. From these measurements, the loss factor and modulus of rigidity can be calculated, which provides information about the material's ability to dissipate energy and resist deformation under dynamic loading.

ASTM D531 is widely used in the plastics industry for quality control and material specification. It is also used in research and development to study the effects of various factors on the dynamic mechanical properties of plastic materials, such as temperature, frequency, and composition.

NextGen's Pusey & Jones Portable Hardness Tester complies with ASTM D531 standard.

Click here to request a personalized quote from our team!

ISO 7267-3 is a standard that specifies a method for measuring the dynamic mechanical properties of rubber and rubber-like materials using a torsional oscillation method. This standard is part of a series of ISO standards related to the measurement of dynamic mechanical properties of rubber materials, which are important mechanical properties that can affect the performance of rubber products in a variety of applications.

The test method specified in ISO 7267-3 involves subjecting a sample of the rubber material to a small, sinusoidal twist at a known frequency and measuring the resulting torque and phase angle of the twist. From these measurements, the loss factor and modulus of rigidity can be calculated, which provide information about the material's ability to dissipate energy and resist deformation under dynamic loading.

ISO 7267-3 is widely used in the rubber industry for quality control and material specification purposes. It is also used in research and development to study the effects of various factors on the dynamic mechanical properties of rubber materials, such as temperature, frequency, and composition.

NextGen's Pusey & Jones Portable Hardness Tester complies with ISO 7267-3 standard.

Click here to request a personalized quote from our team!

NextGen's Pusey & Jones Portable Hardness Tester is designed to test rubber rollers and rubber-like materials with flat surfaces and a thickness of up to 13 mm. This means that specimens with a thickness greater than 13 mm cannot be tested with this system.

Keep in mind that specimen's thickness can affect the test results accuracy. Thicker specimens may not deform as easily under the applied load, which can lead to inaccurate measurements of the material's hardness.

If you need to test specimens thicker than 13 mm, you may need to consider other testing methods or equipment designed for thicker materials. Additionally, it is recommended to consult with the manufacturer or an experienced testing professional from NextGen Material Testing to ensure that you are using the appropriate testing method and equipment for your specific application.

Click here to request a personalized quote from our team!

Yes, the Pusey & Jones Portable Hardness Tester offered by NextGen Material Testing can be upgraded to an automatic test stand for even greater accuracy and repeatability. The automatic test stand eliminates operator error and ensures consistent testing conditions, leading to more reliable results.

The automatic test stand upgrade is designed to integrate seamlessly with NextGen's Pusey & Jones Portable Hardness Tester and can be easily installed by NextGen's technical support team. Once the upgrade is complete, the user can perform automatic tests with greater precision and efficiency.

The automatic test stand upgrade is an optional feature and comes at an additional cost. If you are interested in upgrading your Pusey & Jones Portable Hardness Tester to an automatic test stand or looking to obtain a quote, please get in touch with our team today.

Upgrading NextGen's Pusey & Jones Portable Hardness Tester to an automatic test stand offers several benefits over using the manual testing method. Firstly, the automatic test stand eliminates the risk of operator error, which can affect the accuracy and repeatability of the test results. The automatic test stand ensures consistent testing conditions, leading to more reliable results.

Secondly, the automatic test stand offers greater precision and efficiency in testing. The automatic test stand is designed to maintain a constant rate of loading, ensuring that the applied load is consistent across all tests. Thus, leading to more precise measurements and reduces the need for repeated testing.

Finally, the automatic test stand offers increased ease of use and convenience. The operator simply needs to load the specimen and initiate the test. The automatic test stand will take care of the rest. This saves time and effort and allows the operator to focus on other tasks.

Click here to request a personalized quote from our team!

NextGen's Pusey & Jones Portable Hardness Tester System uses a specific test load of 9.8 N to measure the hardness of materials. This load is applied by lowering the lateral load lever on the instrument, and the measurement results can be read after a 60-second testing time.

The test load of 9.8 N is suitable for testing rubber or rubber-like materials and rubber rollers in the paper industry. Different materials may require different test loads to achieve accurate and reliable hardness measurements.

In addition to the test load, NextGen's Pusey & Jones Portable Hardness Tester System also features an electronic dial gauge that indicates the penetration depth directly in 0.00 mm units. Integrating a vertical spindle at the back of the testing system allows for more accurate lowering or lifting movements, ensuring precise and reliable measurements.

Click here to request a personalized quote from our team!

The measurement results with NextGen's Pusey & Jones Portable Hardness Tester system can be obtained after a testing time of 60 seconds. This testing time complies with the ASTM D531 standard, which is the primary standard used for testing the hardness of rubber and rubber-like materials.

During the 60-second testing time, the specific test load of 9.8 N is applied to the specimen, and the electronic dial gauge on the instrument indicates the penetration depth directly in 0.00 mm units. Moreover, once the testing time is complete, the measurement results can be read directly on the user-friendly digital interface of the Pusey & Jones system.

The measurement results can also be displayed on a PC if the operator upgrades to the HardTest software. This software allows operators to generate reports in Excel and PDF format for optimal accuracy and ease of data management.

Click here to request a personalized quote from our team!

NextGen's Pusey & Jones Portable Hardness Tester system is designed for measuring the hardness of rubber or rubber-like materials and rubber rollers in the paper industry. The instrument can test specimens with flat surfaces and a thickness of up to 13 mm, making it suitable for various materials commonly used in industrial applications.

The range of application for the Pusey & Jones Portable Hardness Tester system is defined by the ASTM D531standard, which specifies the test method for measuring the indentation hardness of rubber and rubber-like materials. The instrument is suitable for use in the automotive, construction, and manufacturing industries, where rubber and rubber-like materials are widely used.

In addition to the standard test method, you can upgrade the NextGen’s Pusey & Jones Portable Hardness Tester system with the HardTest software, allowing operators to generate reports in Excel and PDF format for optimal accuracy and ease of data management. Summarizing, the Pusey & Jones Portable Hardness Tester system from NextGen Material Testing is a versatile and reliable solution for measuring the hardness of rubber and rubber-like materials.

Click here to request a personalized quote from our team!

To answer your question - Yes. NextGen's Pusey & Jones Portable Hardness Tester comes equipped with a built-in timer for precise and repeatable measurement. The timer is an essential component of the instrument, allowing for accurate measurement and reliable results. The built-in timer ensures that the load weight is applied for the correct amount of time, complying with the ASTM D531 standard. This test method is intended to determine the loss factor and modulus of rigidity of plastic materials, both of which are key mechanical parameters that can influence the performance of plastic products in a range of applications.

The built-in timer also ensures that the results are repeatable, meaning that the same measurement can be obtained each time the test is performed. This feature is especially important in manufacturing or quality control settings, where consistency and accuracy are critical. Overall, the built-in timer is an important feature of the Pusey & Jones system, providing users with reliable and consistent measurement results.

Click here to request a personalized quote from our team!

Yes, NextGen's Pusey & Jones Portable Hardness Tester system features an RS232 output that allows for connection to optional HardTest software. This software allows for data transfer and analysis, providing operators with additional tools to manage and analyze their data. With the software, you can generate reports in Excel and PDF format for optimal accuracy and ease of data management. The HardTest software also allows for remote control of the tester, providing additional convenience and flexibility in the testing process. System operators can improve their testing process and data management efficiency and accuracy by upgrading.

In addition, the HardTest software provides a simple and user-friendly interface for data analysis and management, enabling users to interpret their results and draw meaningful conclusions easily. Furthermore, the software is compatible with a wide range of operating systems, ensuring that it can be easily integrated into existing data management workflows. The software is an optional feature that can be purchased separately from the Pusey & Jones system, allowing users to customize their system to fit their specific needs.

Click here to request a personalized quote from our team!

Yes, the Pusey & Jones Portable Hardness Tester from NextGen comes with a DAKKS/DKD-calibration certificate for the instrument. This certificate ensures that the system has been calibrated to a recognized standard, providing users with confidence in the accuracy of their measurements. The DAKKS/DKD calibration certificate is a formal document that certifies that an instrument or testing system has been calibrated to a recognized standard. DAKKS stands for "Deutsche Akkreditierungsstelle GmbH," which is the German accreditation body responsible for the accreditation of testing and calibration laboratories. DKD stands for "Deutscher Kalibrierdienst," a calibration service in Germany responsible for calibrating and maintaining the accuracy of testing and measuring equipment.

The certificate is provided as a standard accessory with NextGen's Pusey & Jones system, ensuring users have everything they need to start their testing process. In addition to the DAKKS/DKD-calibration certificate, the Pusey & Jones Portable Hardness Tester system also comes with various other accessories, including a test stand for HPEII Barcol and software for data transfer and analysis. These accessories provide users with additional functionality and convenience in their testing process.

Click here to request a personalized quote from our team!

The zero-setting option on NextGen's Pusey & Jones Portable Hardness Tester system allows for quick and easy instrument calibration. By pressing a single button, the electronic dial gauge display can be set to zero. This is done by raising the indenter with a measuring rod approximately 3 mm after lowering the body of the hardness tester. This feature eliminates potential operator errors and ensures accurate and consistent measurements over time.

The zero-setting option also allows for a more efficient testing process as the operator can quickly calibrate the instrument between testing different specimens. This results in faster testing times and reduces the likelihood of errors caused by inaccurate measurements.

Overall, the zero-setting option on NextGen’s Pusey & Jones Portable Hardness Testing system provides a simple yet effective calibration solution and improves the testing results' accuracy and repeatability.

Click here to request a personalized quote from our team!

No, NextGen's Pusey & Jones Portable Hardness Tester system is designed to test specimens with flat surfaces only. The system applies a specific test load of 9.8 N by lowering the lateral load lever and measures the penetration depth directly in 0.01 mm units. Therefore, any specimen with an uneven or non-flat surface will not yield accurate results.

However, NextGen's Pusey & Jones Portable Hardness Tester system is specifically designed to test rubber or rubber-like materials and rubber rollers in the paper industry. These materials typically have flat surfaces, which can be easily tested with this system. If you need to test non-flat surfaces, there are other hardness testing methods and devices available on the market that may be more suitable for your needs. It is important to choose the right testing method and equipment for your specific application to ensure accurate and reliable results.

Click here to request a personalized quote from our team!

The accuracy of the measurement results with NextGen's Pusey & Jones Portable Hardness Tester system is highly dependent on the operator's skill and experience in using the instrument. However, the Pusey & Jones system is designed to be highly accurate and reliable, with a test load of 9.8 N and a built-in timer for a precise and repeatable measurement. Additionally, the system can be upgraded to an automatic test stand, eliminating operator error and providing ultimate accuracy and repeatability results.

The electronic dial gauge on NG Pusey & Jones Portable Hardness Tester indicates the penetration depth directly in 0.01 mm units. The measurement results can be displayed directly on the user-friendly digital interface of the system or a PC using the optional HardTest software. You can also generate reports in Excel and PDF format for optimal accuracy and ease of data management if you use HardTest software.

Overall, with proper use and calibration, NG Pusey & Jones Portable Hardness Tester system can provide highly accurate measurement results for testing rubber and rubber-like materials.

Click here to request a personalized quote from our team!

NextGen's Pusey & Jones Portable Hardness Tester system comes with several accessories to enhance the machine operator's experience. These accessories include a DAKKS/DKD calibration certificate for the instrument, a test stand for HPEII Barcol, and software for data transfer and analysis. The DAKKS/DKD calibration certificate is a quality assurance measure that ensures the accuracy and precision of the instrument's measurements.

The test stand for HPEII Barcol allows for the testing of cylindrical specimens and is particularly useful for testing rubber rollers in the paper industry. The data transfer and analysis software enables the user to generate reports in Excel and PDF format, providing easy data management and analysis. A standard test block with DAKKS/DKD calibration certificate is also included, which can be used to calibrate and verify the instrument's performance. These accessories provide a comprehensive solution for accurate and reliable hardness testing of rubber and rubber-like materials.

Click here to request a personalized quote from our team!

Yes, the Pusey & Jones hardness testing system can be used to test materials in industries other than the paper industry. This machine can test the hardness of various materials, including metals, plastics, and composites. It can also be used for testing coatings, films, and other thin materials.

NextGen's Pusey & Jones Portable Hardness Tester system's versatility makes it an ideal tool for automotive, aerospace, construction, and manufacturing industries. All that is because hardness testing is a critical quality control process in those industries. The system's ability to test thin materials and coatings makes it particularly useful in industries such as electronics, where the thickness of thin films and coatings is crucial to the function of the final product.

Furthermore, the system's portable design allows it to be used in various locations, making it an excellent option for fieldwork or testing materials at remote sites. NG Pusey & Jones portable hardness testing system's versatility makes it an essential tool for many industries, including those beyond the paper industry.

Click here to request a personalized quote from our team!

The zero-setting option on NextGen's Pusey & Jones Portable Hardness Tester system offers several important benefits.

First, this function enables the machine operator to adjust the measuring probe of the system to a zero-point reference before testing. Thus, allowing to eliminate any potential measurement errors caused by variations in the probe's position or deviations in the sample's surface. The system can obtain more accurate and reliable hardness readings by zeroing the probe before testing.

The zero-setting option also provides the user with the ability to test multiple areas on a specimen and obtain more precise data on the specimen's hardness distribution. This is crucial when analyzing complex materials with varying hardness levels.

Moreover, the zero-setting option simplifies the testing process by making it easy to set the system to the same reference point for each measurement. This makes it easier to compare and analyze hardness data obtained from different specimens or samples.

Click here to request a personalized quote from our team!

The vertical spindle found at the back of the Pusey & Jones Portable Hardness Tester System is an integral component of the device. It is responsible for holding the indenting tool in place, allowing precise and accurate measurements. The spindle is adjustable to accommodate different specimen thicknesses, ensuring that the indenting tool is placed at the correct height for accurate testing.

In addition to holding the indenting tool in place, the vertical spindle also guides the movement of the indenting tool during the testing process. This helps to ensure that the tool moves smoothly and evenly across the surface of the specimen, which is crucial for accurate and consistent measurements.

The vertical spindle is an essential component of the NextGen's Pusey & Jones Portable Hardness Tester system because it helps to ensure that the device is able to provide precise and reliable hardness measurements.

Click here to request a personalized quote from our team!

The maximum load weight of NextGen's Pusey & Jones Portable Hardness Tester is 1kg. The instrument can apply a force of up to 1 kilogram to the specimen being tested. The load weight is an important factor in the testing process because it determines the depth of the indentation made on the surface of the specimen, which is then used to calculate the hardness value. The machine can apply this force precisely and can detect very small differences in indentation depths, making it a highly reliable and accurate instrument for measuring the hardness of various materials.

The 1kg load weight makes the Pusey & Jones system suitable for testing a wide range of materials, including metals, plastics, and ceramics. It is important to note that the load weight is not adjustable on the portable version of the Pusey & Jones tester. However, the automatic test stand version of the tester does offer the option to change the load weight, which can be useful for certain applications.

Click here to request a personalized quote from our team!

Related Products

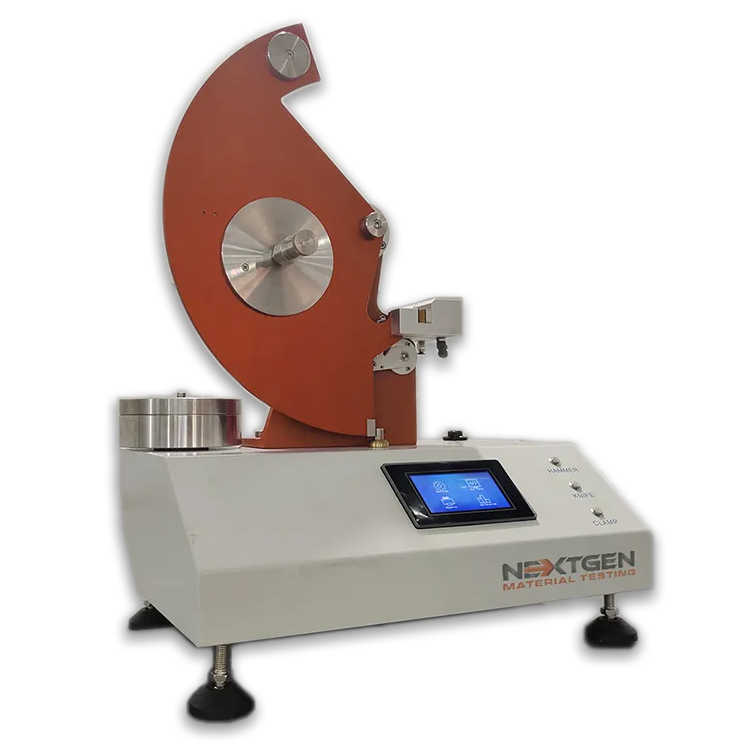

GenElm Series Elmendorf Tearing Tester – 64N and 128N Models

The GenElm Series Elmendorf Tearing Tester is designed for precise measurement of tear strength in fabrics, plastic films, paper, nonwovens, and technical textiles. Available in 64 N and 128 N models, it complies with ASTM, ISO, and DIN standards to provide accurate and comparable results across laboratories. The system features a touch-screen interface, pneumatic clamping, automatic specimen cutting, and data export via RS232, combining usability with consistent performance.

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

The NG-HDT HDT/Vicat testing machine measures HDT and Vicat softening temperature (VST) for thermoplastics, including pipes and fittings. It supports common ISO, ASTM, and GB/T methods run under constant load with controlled heating. The system is available in 3-station and 6-station configurations with touchscreen control for the full test sequence. Measurement uses Class A PT100 temperature sensing and LVDT displacement monitoring, with an immersion oil bath rated up to 300°C (572°F). Results can be saved and exported over Ethernet, with options such as a chiller and external oil-vapor extraction/filtration.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.