Metal Testing Equipment

Standards

ASTM E8, ASTM A370, ISO 6892-1, DIN 50125, JIS Z2201, ASTM E370

Description

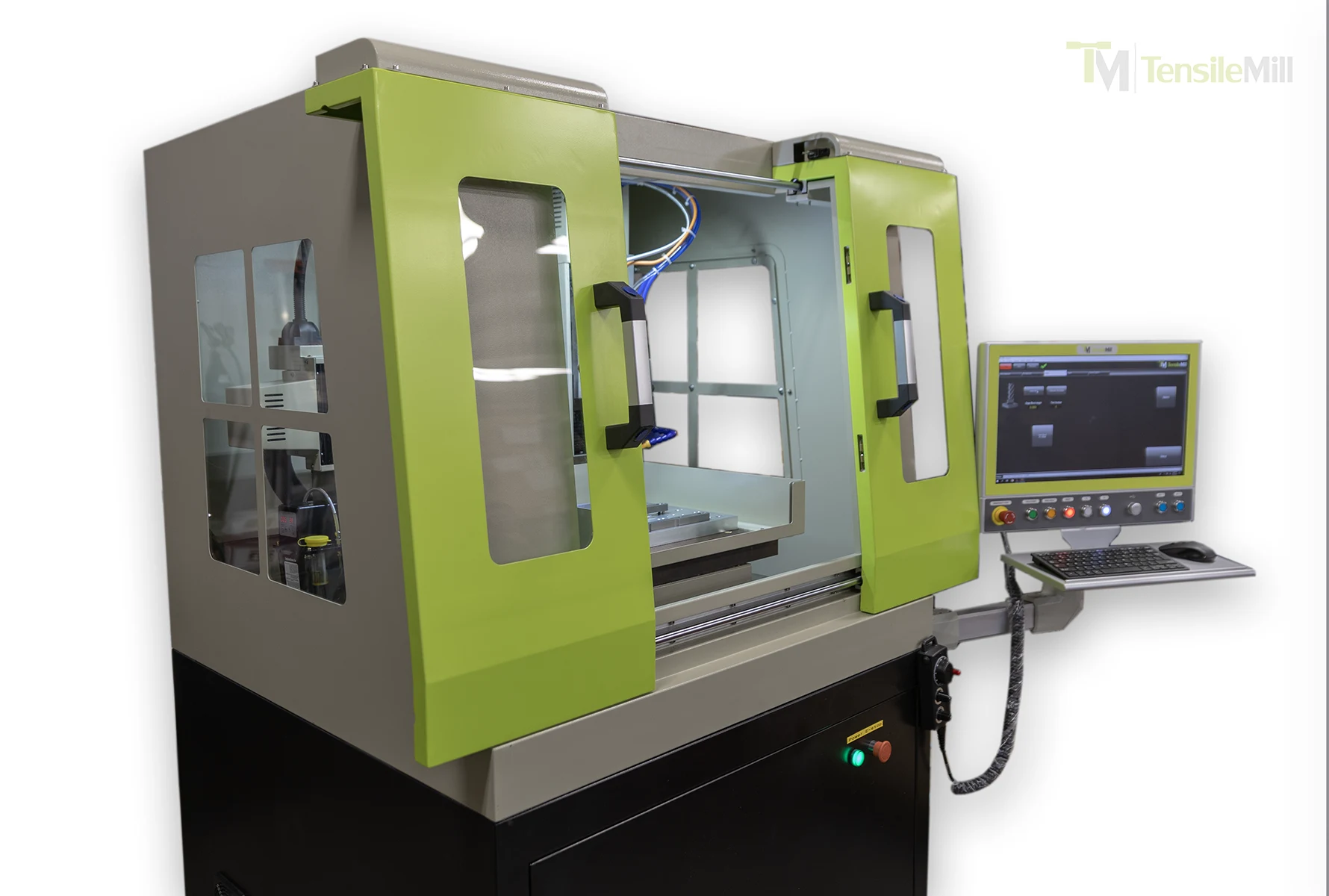

The TensileMill CNC MINI is a compact CNC system offered by our partner, TensileMill CNC, designed for preparing standardized flat tensile test specimens in laboratory and production environments. The system supports specimen geometries used in ASTM E8, ASTM A370 / E370, ISO 6892-1, DIN 50125, and JIS Z2201 standards. Operators can select preloaded specimen profiles within the TensileSoft™ interface or enter custom dimensions directly based on project requirements.

Despite its reduced footprint, the MINI integrates a cast iron machine frame, linear motion components, and a 2.2 kW water-cooled spindle, supporting stable cutting performance across a range of metallic and non-metallic materials, including heat-treated alloys and Inconel. The guided touchscreen control allows new users to become confident with the system in a short period of time, making the MINI well-suited for quality control labs and training environments where consistent repeatability is required.

The system provides a self-contained machining workflow for flat tensile specimens, allowing preparation to be carried out on-site with controlled dimensional accuracy and minimal setup adjustments.

CNC Control Platform

The TensileMill CNC MINI is operated through a guided touchscreen interface designed specifically for flat tensile specimen preparation. The controller includes the TensileSoft™ interface with direct parameter entry for standardized specimen geometries.

The system can be optionally upgraded to the Carbon CNC Software Package, which replaces the standard panel with a 21" industrial touchscreen, expanded memory and connectivity, and access to full G-Code machining functions. The Carbon package adds support for features such as macro programming, multiple tool and work offsets, helical and circular interpolation, trajectory control, scaling, mirroring, and access to MACH4 Industrial CNC capabilities when required for general CNC machining tasks.

System Architecture

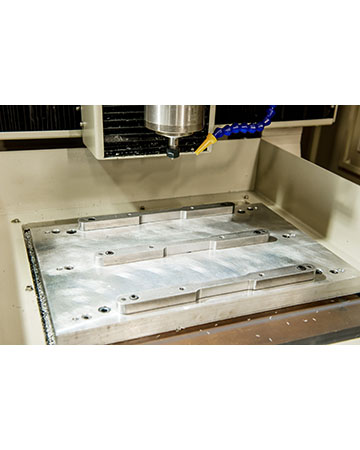

The MINI is built on a cast iron frame with linear rail motion components to support stable cutting conditions. A 2.2 kW (3 HP) water-cooled spindle operating at 24,000 RPM and high-precision servo drives allow the system to machine a wide range of metals and engineering materials, including heat-treated steels and nickel-based alloys.

Its compact footprint supports installation in small laboratory spaces while maintaining a full 400 × 400 × 200 mm (15.75 × 15.75 × 7.87 in) working envelope. The MINI is suitable for continuous flat tensile specimen preparation and routine quality control workflows where repeatable dimensional accuracy is required.

2026 Model Upgrade Option

Beginning July 2025, the MINI will be available with the updated 2026 control and motion platform. Orders placed before June 30, 2025 automatically receive the upgraded configuration at no additional cost.

The 2026 edition introduces:

- 21.6" industrial touchscreen interface

- Closed-loop drive system for improved motion stability

- Integrated diagnostic tools for streamlined troubleshooting

- Full G-Code compatibility included as standard

Service & Training Support

A maintenance and training support plan is available to assist with long-term operation. Routine preventative service schedules support consistent system performance over time. Training programs can be provided for new or existing operators to standardize workflow practices and maintain consistent specimen preparation across shifts or personnel changes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Working Area (X/Y/Z) | 15.75 × 15.75 × 7.87 in (400 × 400 × 200 mm) |

| Overall Dimensions – Closed Door (L × W × H) | 72 × 43 × 44 in (1829 × 1092 × 1321 mm) |

| Overall Dimensions – Open Door (L × W × H) | 72 × 73 × 52 in (1829 × 1855 × 1321 mm) |

| Suggested Floor Space | 82.7 × 78.5 in (2100 × 2000 mm) |

| Machine Weight | 1500 lb (680 kg) |

| Frame Material | Cast iron |

| Table T-Slot Size | 0.472 in (12 mm) |

| Spindle Speed | 24,000 rpm |

| Spindle Motor Power | 3 hp (2.2 kW), water-cooled |

| Spindle Taper | ER20 collet (ISO20 optional) |

| Servo Motor Power | 0.54 hp (400 W) |

| Servo Torque | 566 oz-in (4.0 Nm) |

| Maximum Feedrate | 500 ipm (12.7 m/min) |

| Position Repeatability | ±0.0003 in (±0.01 mm) |

| Drive System | Precision ballscrew, servo drive |

| Maximum Tool Shank Diameter | 0.47 in (12 mm) |

| Input Voltage | 220 V, single-phase |

| Total Power Consumption | 15 A (3.3 kW) |

| Noise Level at Operator Position | 70–90 dB |

| Controller Interface | TensileSoft™ on 10-inch touchscreen |

| Optional Upgrade | Carbon CNC package with 21-inch industrial touchscreen and full G-code support |

| Connection Requirements | Pneumatic (optional) |

Included Turnkey Package

| Item | Details |

|---|---|

| Tooling | (1) 0.250" ER Collet + (1) 0.250" Shank Endmill |

| Clamping Fixture | Custom Tensile Clamp Fixture for ASTM, ISO, DIN, JIS, EN specimen preparation |

| Motion System Upgrade | 3-Axis Servo Package (Available as Upgrade) |

Note: The TensileMill CNC MINI is undergoing a door design update to support improved operator safety and enhanced workflow accessibility.

FAQs

TensileMill CNC Inc. takes pride in its ability to quickly and effectively communicate with clients to assist them in resolving any technical challenges with its flat tensile sample preparation equipment. Our skilled CNC consultants and a tried-and-true team of application engineers can answer virtually all technical and application queries you may have regarding the system.

Despite its small size, the MINI sample preparation machine includes a triple sample fixture as standard equipment. This fixture is made to reduce operator involvement time and increase production efficiency. The samples can be stacked three times (or sample stacks). The operator can start the machine by selecting a pre-set setting in the software, and leaving the workspace. At the same time, the samples are being prepared, and returned to find precise tensile specimens afterwards.

TensileMill CNC MINI – Compact Flat Tensile Sample Preparation Machine uses Precision Ballscrew driving mechanism.

Click here to request a personal quote.

The equipment is instantly ready to mill by just entering the necessary measurements. Despite the machine's small size, the conventional 2.2kW (3hp) Water Cooling Spindle and its approved tooling can prepare huge quantities of soft, hard, and Inconel materials.

A fluid chamber that circulates inside is included in the MINI. When the fluid emits a bad odour, it needs to be changed. Usually, this begins to happen around 6 to 12 months. In general, the cutting fluid must be topped off when it becomes low, and the spindle cooling fluid only needs to be replenished once per year.

According to the machine's X, Y, and Z travel criteria, the largest tensile sample specimen can be prepared with the TensileMIll CNC MINI - Compact flat tensile sample preparation machine. The MINI has a 400mm x 400mm x 200mm working travelling area (15.75 x 15.75 x 7.87 inches). The MINI tensile preparation machine can prepare almost any type of tensile sample in accordance with the relevant Industry requirements thanks to these features.

Click here to request a personal quote.

Better than ever, TensileMill CNC MINI - Compact Flat Tensile Test Sample Preparation. Do not allow the unit's seeming "size" to overwhelm you. The maximum freedom in tensile specimen preparation and complete CNC machining capabilities were especially considered when designing this small mill. Since the system's most recent updates, the MINI has largely outperformed our Classic model. Now, for less money, you can have a smaller footprint, bigger table area, more power, and improved precision & repeatability!

High-quality tensile specimen preparation has never been simpler. A 10" LCD screen with our renowned Tensile Software is included as standard equipment with the TensileMill CNC MINI. Our robust Carbon software, which has a friendly tensile milling interface, controls the machine. In accordance with the specifications mentioned in your ASTM, ISO, DIN, JIS, or other industry standards, the interface enables the operator to enter your preferred tensile specimen size swiftly.

The maximum engraving speed of TensileMill CNC MINI – Compact Flat Tensile Sample Preparation Machine is 10,000mm/min.

Click here to request a personal quote.

Upgrade to our full Carbon software is supported by our simple touchscreen controller. A 21" touch panel, 64 Gb of storage, WiFi, Ethernet, 4 Gb of RAM, USB ports, 126 work offsets, helical interpolation, scaling, and mirroring, cutting-edge dual mode cutter compensation, drilling canned cycles, improved trajectory planning, etc. are all included in the upgrade. The operator is given access by Carbon to the Industrial CNC Software (MACH4), which is used to control expert CNC functions and the software interface for tensile milling. Our Carbon software is continually getting updated, and every TensileMill CNC system comes with free updates.

The tensile software interface stores previously input specimen sizes and offers easy access. Additionally, it has a large collection of tensile specimens that have already been preprogrammed, enabling the user to immediately run a programme without entering any measurements. You may also update our Carbon software interface with your new TensileMill CNC MIN - Compact Flat Tensile Sample Preparation machine, turning it into a hybrid tensile sample and CNC machine. Our powerful and user-friendly CNC control technology offers practically limitless options.

Click here to request a personal quote.

The newest member of the family of CNC machining is the TensileMill CNC MINI - Compact Flat Tensile Sample Preparation. It makes the process of creating high-quality tensile specimens easier than before. Our robust Carbon software, which features a very user-friendly tensile milling interface, is used to operate our TensileMill CNC MINI. The interface enables the user to quickly select the necessary tensile specimen size in accordance with the parameters specified in your ISO, ASTM, JIS, DIN, or any other industry. The machine is prepared to begin milling several seconds after you enter your precise measurements.

Our tiny, portable TensileMill CNC MINI is an extremely quick machining centre that was created with consideration for market testing. Despite being compact, the axis of the TensileMill CNC MINI's hefty cast iron frame moves over linear rails with exceptional smoothness. High-powered servos and a 24,000 RPM ISO20 spindle give it outstanding machining power.

TensileMill CNC MINI – Compact Flat Tensile Sample Preparation machine has 1.5 KW Water Cooling spindle.

Click here to request a personal quote.

Yes, you can do the upgrade. You can request a quote from TensileMill CNC to receive a software upgrade option for your MINI. The upgrade will allow the MINI to operate as a CNC capable machine and tensile sample preparation machine.

The TensileMill CNC MINI has 400mm (15.75 in) x 400mm (15.75 in) x 200mm (7.87 in) working traveling area. The size of the tensile sample specimen that should be prepared using the MINI should not exceed the mentioned working traveling area. This allows the MINI to handle practically any type of tensile sample as long as they are within appropriate industry standards. Contact us today to know more.

The MINI has its own internal re-circulating fluid chamber. You need to change the fluid when it starts to give off a foul odor. This usually occurs after 6 to 12 months of use. Generally speaking, you only need to change the cooling fluid of the spindle, and you only need to do this once a year. You just need to add more cutting fluid when it gets low.

We made a series of YouTube videos regarding the process of tensile specimen preparation from aluminum blanks as well as carbon steel blanks. You can watch the videos and see.

If you want to see it with your own eyes, please contact us at +1 877 672-2622 so we can go about the details of your visit to our Maine facility.

The MINI is compact, but it is powerful enough to take on the task with its triple sample fixture. The fixture aims to maximize the efficiency of production and minimize human intervention. It allows you to stack thrice the usual number of samples that you prepare. All you need to do is click the chosen setting option, which is provided by the software. The operator can start the machine to commence the preparation, and then move on to do other tasks. The tensile specimens should be ready by the time he comes back.

The MINI has 200-240V voltage tolerance. You can use a step-down converter when you wish to bring down voltage and a step-up converter when you wish to elevate voltage. Stepping up or stepping down depends on the electrical requirements of your facilities.

Both models have several technical differences that you see in the comparison table, which you can obtain upon request. The major differences between the two models include costs, volume capacity, and size. Between the two, the MINI is smaller in size that's just right for small to medium scale of sample preparation. It is also a more affordable solution if used as standalone equipment for tensile sample preparation.

You can make a full upgrade to turn your TensileMill CNC MINI into an extremely cost-effective solution when it comes to preparing tensile samples. You can request for a detailed quotation to know more about the flat tensile preparation machines and determine the best one for your facility.

The 10-gallon re-circulating water-based coolant comes standard with the MINI. The coolant has been formulated based on the particular materials that must be cut. We recommend brands like Blaser, Hocut, and Cim Cool for the preparation of tensile specimens as well as other CNC machining needs.

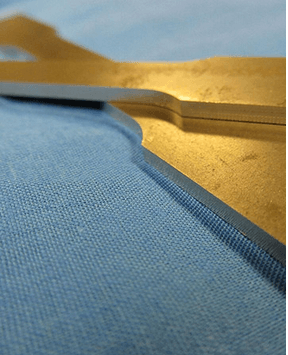

The flat tensile specimen prep systems, including the TensileMill CNC MINI, can prepare the tensile specimens from sheets and strips. To save time, it is best to prepare tensile dog bone samples from sheets. However, you can still prepare specimens from strips if you prefer it that way. Take a look at these options:

- First Option

You may cut the tensile specimen blanks initially into strips before loading them into the clamping fixture, which comes with the unit. Try cutting down the specimens to 2-inch thickness (or less) to make it work more efficiently. You may load up to half-inch thick specimens per clamp, then get them all ready in a single cycle.

- Second Option

You may cut the tensile specimens directly from the sheets. The custom clamping fixture setup, which is included in all standard quotations, allows you to cut from the sheet tops. This gives you the advantage of preparing some specimens from one sheet in a single cycle. The number of specimens that you can cut depends on the size of the sheet that you are using.

The main difference between cutting from sheets and cutting from strips is the manner the cut is created. For sheets, the cuts start from the top, then the outline is made. For strips, the cuts are made from the specimens' side. If you prefer to cut from sheets, you need to inform our technical team regarding the dimensions of the sheet that you want to use.

You can hasten the preparation when you stack your tensile samples. The TensileMill CNC MINI has a clamping device that makes it possible to stack the tensile samples, which could be of any material, for fast preparation. You can stack samples with a thickness of 1-inch and below using the clamping device, which can hold the specimens firmly in place. This allows the machine to run smoothly and produce perfect tensile samples. If you have unique specimens, there are available specialty clamps that you can use. You can visit our site to know more about the quick tensile sample preparation or you may also request a quote.

The TensileMill CNC MINI tensile preparation machine has taken the market by storm. The huge volume of orders that the company continuously receives is causing some delays in the expected delivery of the unit. You can contact us first to know how fast we can ship your MINI to your facility.

The triple-position clamping fixture base comes standard with the MINI. It has a one size clamp for every position that lets the user mill at least 3 samples at once. The maximum length of starting samples that the turnkey solution allows is 12 inches. There are also available custom solutions.

Additionally, the unit also comes with endmill and ER collet that you can use for a long time. If you need additional endmills, ER collet, clamping fixtures, and base fixtures, you can submit a request to order anytime.

Sometimes, you need a little bit of trial and error to find the material's feed rate and optimal speed. Of course, it is necessary to use the right endmills that your material is compatible with. This process may take a while but will still not consume too much of your time. TensileMill CNC MINI Inc. offers free tensile dog bone preparation as one of the unique benefits.

All you need to do is send the specimens to us. Our engineers are the ones who prepare the specimens. They can usually identify the feed rate and suitable speed on the second or third cycle run. Once the specimens are prepared, our technical engineers will present to you the most fitting recommendations. Also during the training and installation process, we cover the feed rate and speed optimization to ensure that you will be able to perfectly prepare your tensile specimens each time.

You can prepare both tapered edge and regular (standard) tensile specimens. We have clients who prepare tensile dog bones based on the standards of ASTM and ISO. See the illustration below to serve as guide:

You can contact us today for further explanation or learn more when you request a free quote.

We aim to make the training and setup process as easy as possible. We offer onsite installation, and we provide training to guide your people. We also put together a few videos demonstrating the entire process from beginning to end. If you don't have a budget for training your people, here are the links that can help you:

- https://youtu.be/KXEHxwTJX6I - this is about the proper use of TensileMill CNC MINI

- https://youtu.be/NL8-L8Mznxk - this is about TensileMill CNC MINI's loading and unloading

- https://youtu.be/vLTGg8jNYEg - this is about control panel operation

If you have more questions about how to operate your TensileMill CNC MINI, feel free to contact us today. You can proceed to our support page if you need assistance.

We have a Turnkey Package that includes a custom fixture, shank endmill, and ER collet. The full Carbon CNC Package gives the MINI the ability to handle advanced applications and to function as an advanced CNC machine. You can upgrade the spindle to a 2.2kW ISO20 holder that allows the machine to cut through samples, which are thicker than usual, with ease. Also, the 3-axis servo motor upgrade gives your unit the power to have higher precision and accuracy as well as faster turnaround time.

The wait is over, and you now have the solution regarding the enhancement of your system - the TensileMill CNC MINI. It is the market's leading tensile test specimen preparation today. Your lab will surely benefit from it for a long time. You can contact us now to find out the other wonderful things that MINI can do for you.

Your TensileMill CNC MINI needs a 20A, 3-prong receptacle. All you need to do is plug the receptacle. You may also choose to hardwire to a disconnect. You may also contact us anytime if you want to know more.

The unit itself approximately has the following dimensions in inches: 48 (width) x 48 (depth) x 75 (height). Take note that the controller requires an additional 12 to 14 inches space since it goes on the left-hand side. Make sure to follow the recommended safe distance and other safety regulations being implemented to avoid untoward incidents. If your facility demands specific space requirements, you may contact us at any time so we can give you the most suitable suggestion.

The usual price of the endmills is between $30 and $85, and you can place your order at TensileMill CNC. After using the spindle rigorously for a few years, it may already need to be replaced. Before the replacement, we have seen some spindles work for more than a decade. Some spindles that constantly ran in heavy production environments only lasted for 6 years. The replacement cost of the spindle is around $1,400.

Most consumables and spare parts can be obtained in-house or you can have them delivered in a few weeks. You can contact us today or go online to place a request.

The following are the requirements of TensileMill CNC MINI:

- 15amp

- 220V power supply

The unit comes with the standard way lube system and re-circulating coolant. You don't need any special connections to make the unit run. There's also an optional pneumatic connection.

This is a floor-standing system, which can be installed according to your preference. We suggest tilting the machine slightly to the front right side to gain a more efficient circulation of the fluid.

An open roof is provided to this enclosed unit. You may choose to put a hood range over the unit if you prefer - it is not mandatory to do so.

It is recommended to have starting blanks that are almost as thick as the net size. This means each clamping fixture can easily accommodate blank widths of 38mm or 1.5 inches thick. In case your sample is wider, you can consult our staff in the engineering section to get the best solution for the milling process.

The MINI has a standard spindle between 1.5kW and 2hP. If you are going to use a tougher material for tensile sample preparation, the ISO 20 spindle can give you the optimal benefit. This gives you a choice between 2.2kW and 3hP. You can actually prolong the lifespan of your machine even if you are milling materials that are tough.

To give you an accurate quantity of specimens that you can prepare in one cycle, you should speak with one of our Product Consultants to further discuss your application. The material's thickness, hardness, and type are the things that affect the time it takes to finish the machining process as well as the quantity of flat tensile milling samples. You are welcome to call us today or submit your request for further details.

When you purchase your TensileMill CNC MINI you will also receive the clamp fixture and designated endmills as part of the standard package. The soft and hard materials require different endmill bits. The engineers of TensileMill CNC MINI present the most suitable endmill bits recommendation according to the hardness or softness and type of material that you'll use. This also includes the total milling volume.

All endmills are uniquely designed and created to address the need to prepare tensile samples. This makes up for a longer or superior lifespan for each unit as compared to the other endmills in the market.

The average cost of endmills per bit is between $35 and $80. There are also bulk options that can save you more money. You can directly buy the bits from TensileMill CNC. You can request a quote today when you want to buy the consumables you need.

The tooling fixtures, which receive proper maintenance, are created to last for decades. During the one day installation and training, our engineers will provide proper guidance and knowledge to your operators regarding the preventative maintenance. Preventative maintenance is vital in the proper and smooth functioning of the unit. The equipment's manual provides more preventative maintenance instructions that can hinder or delay any problem from occurring.

If you upgrade to a 3-axis servo motor, you will gain a more accurate and faster axis movement for your TensileMill CNC MINI. This is considered an excellent upgrade so you can deal with advanced CNC machining requirements with ease.

The unit comes with the standard Way Lube system that uses ISO 68 way lubricant, which is designed to reduce drag and friction. Other brand suggestions include Irving, Shell, Mobil, and others with similar quality. If you have other questions in mind, do reach out to us and talk to one of our qualified representatives to discuss things. We will always be glad to extend some assistance.

A laboratory that only requires a low quantity of tensile sample preparation needs (around 5 to 45) per day will benefit a lot from TensileMill CNC MINI. The compact yet tough TensileMill CNC MINI can handle different types of composite materials and metals. It has a high-tech design that your laboratory requires, and the price won?t hurt your budget. The unit is equipped with our own tensile software interface that provides ease of use, which the larger machines typically give. When you upgrade to the full Mach4 Carbon package, your TensileMill CNC MINI can also handle the additional CNC machining requirements. Your tensile preparation is made easy with help from your reliable TensileMill CNC MINI. Ask for a quote today to get started.

When you request a quote, ask for TensileMill CNC MINI with a vise option. This makes it possible to prepare Charpy Specimens, which have sub size or standard dimensions, for impact testing. Take note that an experienced operator is the best personnel for the task.

There are several ways to troubleshoot your compact flat tensile sample preparation system's coolant pump. First, take a look at some of the reasons the coolant system may be causing trouble:

- The motor may overload due to a jammed pump impeller or the resistance to turning is too much. The corrosion from sitting idly, sludge build-up, etc. could be the culprit.

- The problem could be due to a wiring problem from the breaker to the pump. If there is a bad connection or the wire is chafed, a short could occur and cause the breaker to trip.

- Although it is not common or likely to happen, an issue in the internal motor might also cause some problems.

Before the units leave the facility, they are all tested for function and also during installation. There is highly likely an issue with the unit when it is running and pumping liquid for 10 seconds, especially if it has not been running for quite a while. We recommend submerging the belt in fluid during the time when it is sitting idle. You may contact us right now so we can assist you and bring light to the questions that you have in mind.

Related Products

TensileMill CNC Classic Upgrade – Flat Tensile and Charpy/Izod Impact Specimen Preparation System

The TensileMill CNC Classic Upgrade is a hybrid CNC system for preparing standardized flat tensile and Charpy/Izod impact test specimens in-house. It supports ASTM E8, ASTM E23, ISO, DIN, and JIS geometry formats and provides stable machining accuracy for consistent batch-to-batch results.

TensileMill CNC XL – Flat Tensile Specimen Preparation Machine

The TensileMill CNC XL – Flat Tensile Specimen Preparation Machine is an advanced CNC system built for accurate and repeatable flat specimen machining. Designed for high-volume testing environments, it supports ASTM E8, ASTM A370, ISO 6892-1, and DIN 50125 standards. Its powerful 5 hp spindle, Mach4-based Carbon™ control, and automatic tool changer deliver fast material processing across metals, polymers, and composites. The heavy cast iron frame ensures vibration-free precision, while the intuitive TensileSoft™ interface allows both trained and new operators to achieve consistent results.