Plastic Testing Equipment

Standards

Certified

Description

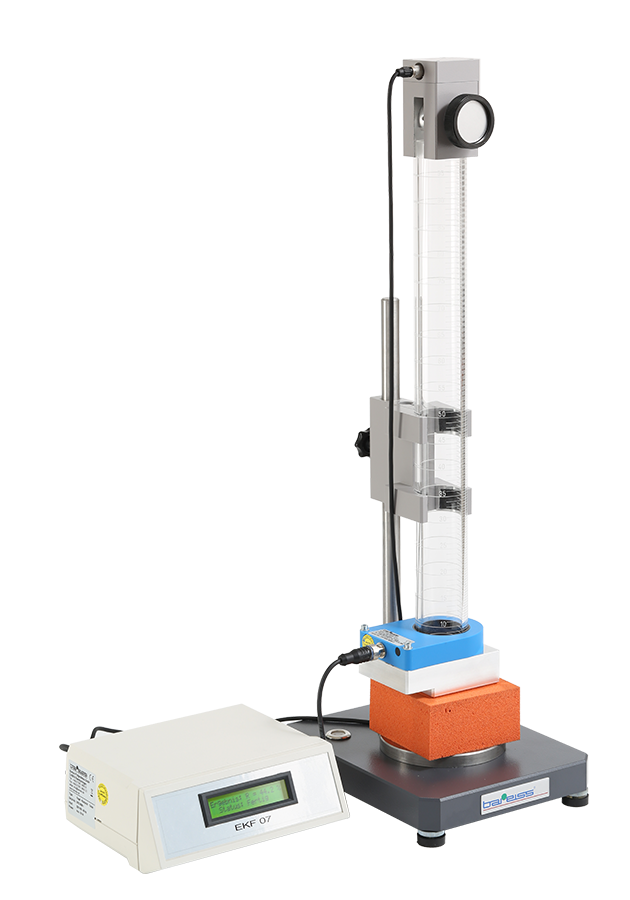

Ball Rebound Tester is a device designed to test resilience of materials such as foam, polyurethane and other similar materials. The unit comes certified in accordance with DIN EN ISO 8307 and ASTM D3574 industry standards. The test consists of a 16mm magnetic ball dropping freely onto a sample from a specified height of 500mm. The electronic console unit that comes standard with this instrument will show the measured value and calculate the proportion of the average value in %. After the test completion, a sensor placed close to the holder ensures that the ball is returns to the home position.

Standard Configurations

- Main Unit Test stand

- Electronic Console

- EKF 500 mm down-pipe with a magnetic system

- Works calibration certificate for 500 mm ball rebound

Features

- Plug-n-Play System

- Extremely Easy to Learn to Operate

- Short Measuring Cycle

- USB Port

- Test cycle, measured values, median value in %, status and operating instructions output to 4-line LCD

- No Calibration Requirements

Technical Specifications

| Model # | Ball Rebound Tester |

|---|---|

| Steel Ball | 16.3±0.2g |

| Ball Diameter | 16±0.2 |

| Sample Size | 100mm×100mm, height 50mm |

| Standards | DIN EN ISO 8307 and ASTM D3574 |

| Power Supply | 100 – 240 VAC; 50 / 60 Hz |

| IP Code | Electronic Unit IP 30 Down Pipe IP 20 |

| Data Output | V24 RS 232 – 9600 baud, 1 start bit, 8 data bits, 1 stop bit |

| Dimensions | Test Stand: 7.87 x 9.84 x 23.6" 200 x 250 x 600 mm Electronic Unit: 7.87 x 6.73 x 3.54" 200 x 171 x 90 mm |

Accessories

- EKF 460 mm down-pipe with a magnetic system

- Works calibration certificate for 460 mm ball rebound

- Data Output Cable

- USB adapter

- GKB03 software for data transmission to Excel

System Dimensions

FAQs

The Ball Rebound Tester is used to test the rebound resilience of plastic materials. It is commonly used in industries such as toy manufacturing, automotive parts, and sports equipment.

Elastomers, rubbers, and composite materials are among the materials that can be tested by Ball Rebound Tester. These materials are known for their resilience and ability to recover their shape after being subjected to external forces. By testing the rebound properties of these materials, manufacturers can ensure that their products meet the required quality standards and are fit for their intended use.

Nevertheless, Ball Rebound Tester is not appropriate for testing materials that are too soft or too hard, as the rebound height may not be accurately measured. Ball Rebound Tester from NextGen material Testing is It is a valuable tool for manufacturers looking to ensure the quality and performance of their products.

Click here to learn more about the product or here to receive a personalized quote.

The Ball Rebound Tester from Nextgen Material Testing is designed to measure the rebound height of a ball after being dropped onto a test material. However, the accuracy of the tester can be affected by various factors, including the properties of the material being tested, the height from which the ball is dropped, and the calibration of the equipment.

The Ball Rebound Tester typically has a measuring range between 0 and 100 percent rebound height. The accuracy of the tester is expressed as a percentage of the full-scale range. For instance, a tester with an accuracy of ±1 percent of the full-scale range can measure the rebound height within a range of ±1 unit for every 100 units of the full-scale range.

Equipment calibration is crucial to ensure the accuracy of the Ball Rebound Tester. Calibration involves adjusting the tester to ensure it provides accurate and consistent results. The calibration procedure typically involves dropping the ball onto a standard reference material with a known rebound height and adjusting the tester to match the known value.

Click here to learn more about the product or here to receive a personalized quote.

The time required to perform a test with the Ball Rebound Tester depends on the type of material being tested, the number of samples to be tested, and the specific test method being used.

The Ball Rebound Tester is a versatile piece of equipment that may be used to assess the resilience of various materials such as plastic, rubber, and elastomers. Dropping a ball from a given height onto the material and measuring the height of the ball rebound is the testing procedure. A test can take anywhere from a few seconds to many minutes to perform, depending on the precise testing needs.

With the Ball Rebound Tester, the ASTM D-5276 standard is often used to assess the rebound resilience of polymers. The ball shall be dropped from a height of 50 inches onto the material being tested, and the rebound height should be measured within 5 seconds of the impact, according to this specification. This testing method is completed in less than a minute.

The time required to perform a test depends on the number of samples being tested. For instance, if several samples need to be tested, the time required will increase accordingly.

Click here to learn more about the product or here to receive a personalized quote.

ASTM D 3574 international standard defines the procedure for determining the indentation force deflection (IFD) of a material by applying a specified amount of force to a circular indenter foot, which compresses the material to a specified thickness. The amount of force required to compress the material is measured and used to calculate the IFD value.

The ASTM D 3574 standard provides specific guidelines for the preparation of test samples, the selection of test equipment, and the testing procedure to ensure accurate and consistent results. The test method is useful in determining the load-bearing characteristics of a material, such as its ability to support weight and resist deformation.

This standard is widely used in various industries, including the automotive, furniture, and bedding industries, where flexible cellular materials are commonly used. The IFD values obtained through this standard are used to determine the appropriate level of firmness for a particular application.

NextGen’s Ball Rebound Tester complies with ASTM D 3574 standard.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s Ball Rebound Tester complies with the DIN EN ISO 8307 standard. This standard is also known as the "Rubber, vulcanized or thermoplastic - Determination of resilience by vertical rebound," and it is used to measure the resilience of rubber and plastic materials.

The DIN EN ISO 8307 standard defines the test method for determining the rebound resilience of rubber and plastic materials by measuring the height of a rebounding ball dropped from a specific height onto a sample of the material. The height of the rebound is used to calculate the rebound resilience of the material, which measures its ability to recover its original shape after deformation.

The Ball Rebound Tester from NextGen Test Solutions is designed and manufactured to comply with DIN EN ISO 8307 standard. The tester is designed to be accurate, precise, and reliable, and it is calibrated to ensure that it provides consistent and repeatable results.

Click here to learn more about the product or here to receive a personalized quote.

Here are the technical specifications of NextGen’s Ball Rebound Tester:

|

Model # |

Ball Rebound Tester |

|

Steel Ball |

16.3±0.2g |

|

Ball Diameter |

16±0.2 |

|

Sample Size |

100mm×100mm, height 50mm |

|

Standards |

|

|

Power Supply |

100 – 240 VAC; 50 / 60 Hz |

|

IP Code |

Electronic Unit IP 30 |

|

Data Output |

V24 RS 232 – 9600 baud, 1 start bit, 8 data bits, 1 stop bit |

|

Dimensions |

Test Stand: |

Click here to learn more about the product or here to receive a personalized quote.

The Ball Rebound Tester is a device used to assess the resilience of materials such as foam, polyurethane, and others. The unit is certified in compliance with the industry standards DIN EN ISO 8307 and ASTM D3574. A 16mm magnetic ball is dropped freely onto a sample from a set height of 500mm. The instrument's standard electronic console unit will display the measured value and calculate the percentage of the average value in %. After the test, a sensor next to the holder guarantees that the ball returns to its original location.

Here are some available accessories for NextGen’s Ball Rebound Tester:

- EKF 460 mm down-pipe with a magnetic system

- Works calibration certificate for 460 mm ball rebound

- Data Output Cable

- USB adapter

- GKB03 software for data transmission to Excel

Click here to learn more about the product or here to receive a personalized quote.

The Ball Rebound Tester is a device used to assess the resilience of materials such as foam, polyurethane, and other similar materials. The unit is approved in compliance with DIN EN ISO 8307 and ASTM D3574 industrial standards. A 16mm magnetic ball is dropped freely onto a sample from a height of 500mm. The electronic console unit that comes standard with this instrument will display the measured value and calculate the percentage of the average value in %. After the test, a sensor near the holder guarantees that the ball returns to its original location.

Ball Rebound Tester Standard Configurations:

- Main Unit Test stand

- Electronic Console

- EKF 500 mm down-pipe with a magnetic system

- Works calibration certificate for 500 mm ball rebound

Ball Rebound Tester Features:

- Plug-n-Play System

- Extremely Easy to Learn to Operate

- Short Measuring Cycle

- USB Port

- Test cycle, measured values, median value in %, status and operating instructions output to 4-line LCD

- No Calibration Requirements

Click here to learn more about the product or here to receive a personalized quote.

The ability of a foam or polyurethane material to bounce back to its original shape after being squeezed or distorted is measured by foam and polyurethane resilience testing. This is a test for materials that will be subjected to repetitive compressive forces over time in applications such as furniture, bedding, and automobile components.

The ball rebound test is one of the most used procedures for measuring the durability of foam and polyurethane. This test is dropping a certain weight ball onto the material and measuring the height of the rebound. The height of the rebound is used to calculate the material's resilience.

In addition to the ball rebound test, other foam and polyurethane resilience testing methods include the constant-force indentation test and the compression set test. Each method has its advantages and disadvantages, and the choice of testing method will depend on the application's specific needs.

NextGen’s Ball Rebound Tester Ball Diameter is 16±0.2

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Ball Rebound Tester from NextGen Test Solutions can be used for research and development (R&D) purposes. In fact, the Ball Rebound Tester is designed to provide accurate and reliable results, making it an ideal tool for R&D applications where precise measurements and consistent performance are required.

Materials are typically tested under various settings in R&D applications to identify their qualities and performance characteristics. The Ball Rebound Tester can be used to assess the resilience of foam and polyurethane materials under a variety of situations such as temperature, humidity, and compression pressures.

Furthermore, researchers can utilize the Ball Rebound Tester to analyze the performance of various foam and polyurethane materials, allowing them to determine the optimum materials for certain applications. This is especially important for R&D projects that involve the development of new products or the improvement of existing ones.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

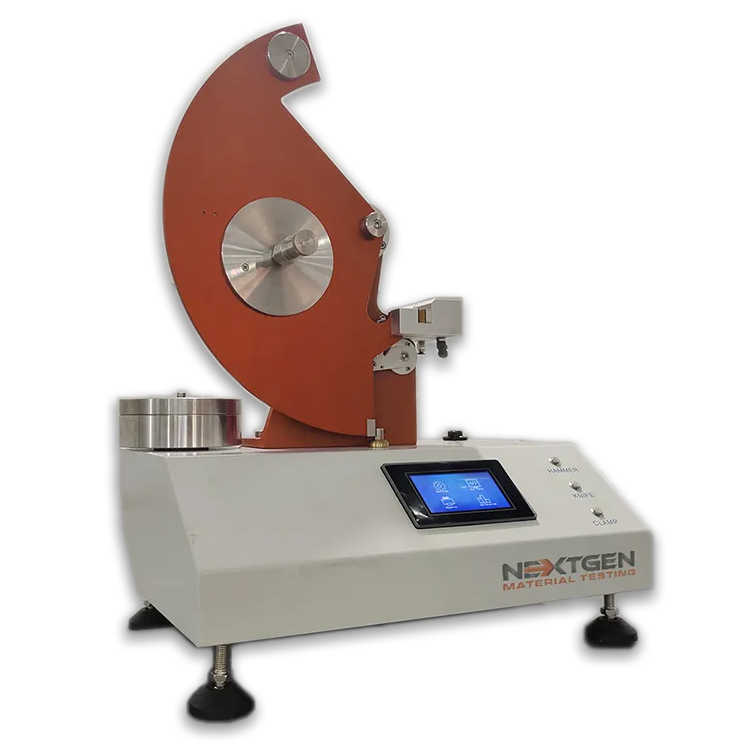

GenElm Series Elmendorf Tearing Tester – 64N and 128N Models

The GenElm Series Elmendorf Tearing Tester is designed for precise measurement of tear strength in fabrics, plastic films, paper, nonwovens, and technical textiles. Available in 64 N and 128 N models, it complies with ASTM, ISO, and DIN standards to provide accurate and comparable results across laboratories. The system features a touch-screen interface, pneumatic clamping, automatic specimen cutting, and data export via RS232, combining usability with consistent performance.

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

The NG-HDT HDT/Vicat testing machine measures HDT and Vicat softening temperature (VST) for thermoplastics, including pipes and fittings. It supports common ISO, ASTM, and GB/T methods run under constant load with controlled heating. The system is available in 3-station and 6-station configurations with touchscreen control for the full test sequence. Measurement uses Class A PT100 temperature sensing and LVDT displacement monitoring, with an immersion oil bath rated up to 300°C (572°F). Results can be saved and exported over Ethernet, with options such as a chiller and external oil-vapor extraction/filtration.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.