Soil Mechanics Testing Equipment

Standards

NF P94-071, CEN-ISO/TS 17892-10, AASHTO T236, BS 1377:7, ASTM D3080

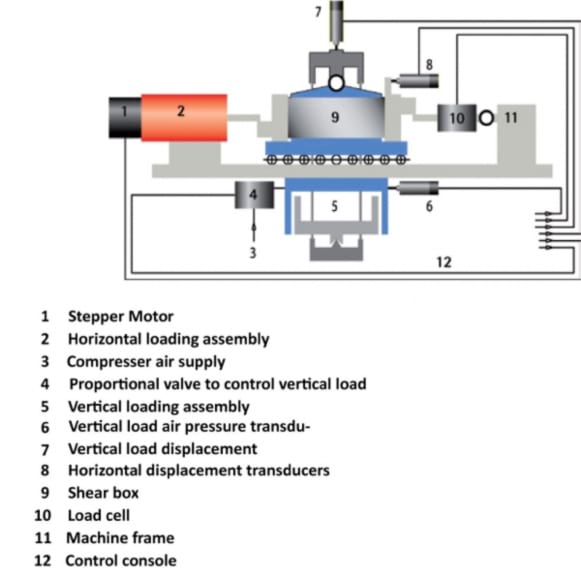

This microprocessor-based advanced model is a stand-alone machine, driven by a high-resolution stepper motor with epicyclical reduction gear with reduced backlash. Incorporate a pneumatic closed loop system for the automatic application of the axial pressure by a high-performance pressure regulator, with the main advantage of eliminating the manual loading of the dead weights. Excellent and high-resistance techno-polymeric material has been adopted for the carriage of the shear box. It offers excellent resistance to corrosion, wear, and tear and is resistant to all chemicals found in a soil specimen. The carriage is lightweight and easy to clean.

The microprocessor system reads and processes the force, axial pressure, and displacement readings, and manages the motor, the pressure valve, the safety system, and the test steps through the closed loop system. Scratchproof membrane keyboard with large monochromatic graphic display. The machine is supplied complete with the following electronic transducers:

- ±5 kN capacity load cell, bi-directional type (compression and tension), nominal sensitivity 2mV/V, accuracy ±0.003%

- 10 mm displacement transducer, 1 kOhm nominal resistance, ±0.25% linearity, 0.002 mm repeatability

- 25 mm displacement transducer, 1 kOhm nominal resistance, ±0.25% linearity, 0.002 mm repeatability

- 1000 kPa pressure transducer, 0.1 kPa accuracy, nominal sensitivity 2mV/V

The Shear box assemblies have to be selected and ordered separately. See accessories. The machine requires compressed air, 10 bar max. Pressure. For a suitable Air compressor, laboratory model, see accessories. A more detailed description, a Schematic layout, and an example of displays are given in the Widening. The shear testing can also be performed with other traditional machines such as a Digital shear testing machine, a Digital shear testing machine with data acquisition, a large shear testing machine for 300x300 square samples, and a Bromhead ring shear apparatus.

Main Features

- Automatic pneumatic application of pre-set consolidation steps (up to 50)

- Automatic test management from consolidation to failure: the operator is only requested to remove the clamping screws of the shear box

- No dead weights and lever arms are requested

- Vertical force was positively applied to the shear box without friction

- The straight connection between the shear box, drive unit, and load cell for the axial transmission of the horizontal force along the shearing plane, instead of the classic "swan neck"

- High-resistance techno-polymeric carriage

- Easy and immediate setup of the test parameters via the large digital graphic display

- Possibility to set different speeds and travel (forward and reverse) in the residual shear tests

- Each single step of axial force can be applied instantaneously or by means of a linear ramp in a pre-set time interval

- Different and independent data recording for consolidation and failure

- Different protocols of data downloading via RS 232 serial port

Specifications

| NG-Shearmatic | |

|---|---|

| Motor | High-accuracy stepper motor 1/10000 resolution |

| Test Speed | Infinitely variable from 0.00001 to 11.00000 mm/min |

| Maximum Horizontal Force | 5 kN |

| Maximum Vertical Force | 8 kN = 800 kPA on 100x100 mm square specimens |

| Maximum Shear Cycles | 10 (forward and reverse) |

| Maximum Travel | 20 mm |

| Maximum Air Pressure Supply | 10 bar |

| Maximum Working Air Pressure | 8 bar |

| PC Connection | RS 232 Serial Port |

| Overall Dimensions | 97 x 42 x 42 cm |

| Approximate Weight | 100 kg |

Related Products

Moisture Determination Balance - GenMoist

GenMoist is designed to automatically and simultaneously dry and weight a solid sample for the determination of moisture content. The machine provides a continuous direct readout for both the weight and the percentage moisture loss through the entire cycle. It has a build-in timer.

MULTISPEED Digital Automatic Universal Tester for Displacement Controlled Tests

The new MULTISPEED tester is the ideal solution for Road testing laboratory. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control. The machine can be equipped with analogical or digital load/displacement measurement systems as well as with the specific accessories, to suit either the field or central laboratory requirement.

Dynamic Triaxial Systems 1000 kPa

Dynatriax systems are ideal for commercial and research laboratories for the following applications: Liquefaction potential, Strength degradation due to cyclic loading, Shear modulus and damping ratio, resilient modulus, Effects of blasting in mines and quarries, Effect of ocean waves on costal and off shore structures.

Automatic Triaxial Testing System

Automatic Triaxial Testing System for soil mechanics laboratory testing in compliance with the latest industry standards.

NG-Oedometer - Front Loading Oedometers - Consolidation Test

This test determines the rate and magnitude of consolidation of a soil specimen restrained laterally and subjected to a number of successive increments of vertical loads.

ACE - Automatic Computerized Oedometer

ACE - is the most advanced automatic computerized oedometer for testing soil consolidation that can measure the response of soil specimens.

Shearmatic 300 - Large Shear Testing Machine

The SHEARMATIC 300 automatic machine is ideal for testing geosyntetics and also soil and other materials that contain large particles of up to 20 mm largest dimension. Sample size up to 300 mm square can be tested, with inserts allowing the testing of smaller sample sizes. See accessories.

Resonant Column and Torsional Shear Tester

RESONANT COLUMN combines the features of both resonant column and torsional shear into a single unit including the current driven motor to apply torsional load to sample, a series of transducers with signal conditioning, a cell and back pressure electro-pneumatic control system and a data logger.

Automatic Shear Testing Machine

The microprocessor control system, therefore, allows the machine to work as an automatic stand-alone unit: the test measurements (force and displacements) a re directly displayed and stored in memory according to pre-set recording modes. The PC is only temporary required to download the test data via the RS 232 port once the test is completed. The data can be processed by the Direct and residual shear Geo-Analysis templates. See accessories.

Laboratory Vane Apparatus

The laboratory vane apparatus is based on an original concept of the Transport and Road Research Laboratory of the United Kingdom. It offers versatility with a variety of vane sizes available. Typically it comes with the standard 12.7 mm square vane along with a set of four calibrated springs. Testing can be conducted either directly on the sample or within the sampling tube. For the latter, the NG-WF1738 Attachment for 38 and 100 mm diameter sampling tubes is recommended for optimal performance.