Plastic Testing Equipment

Certified

Description

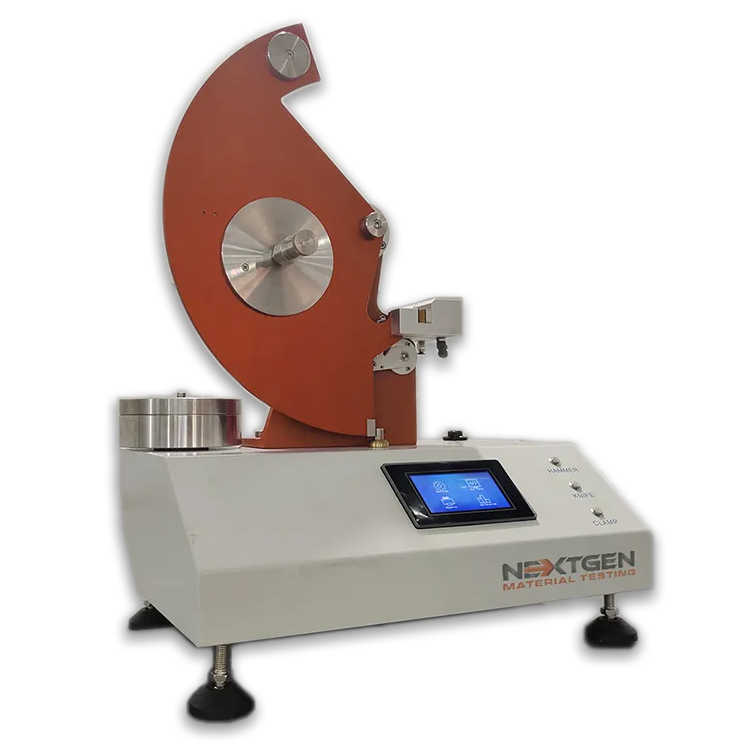

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

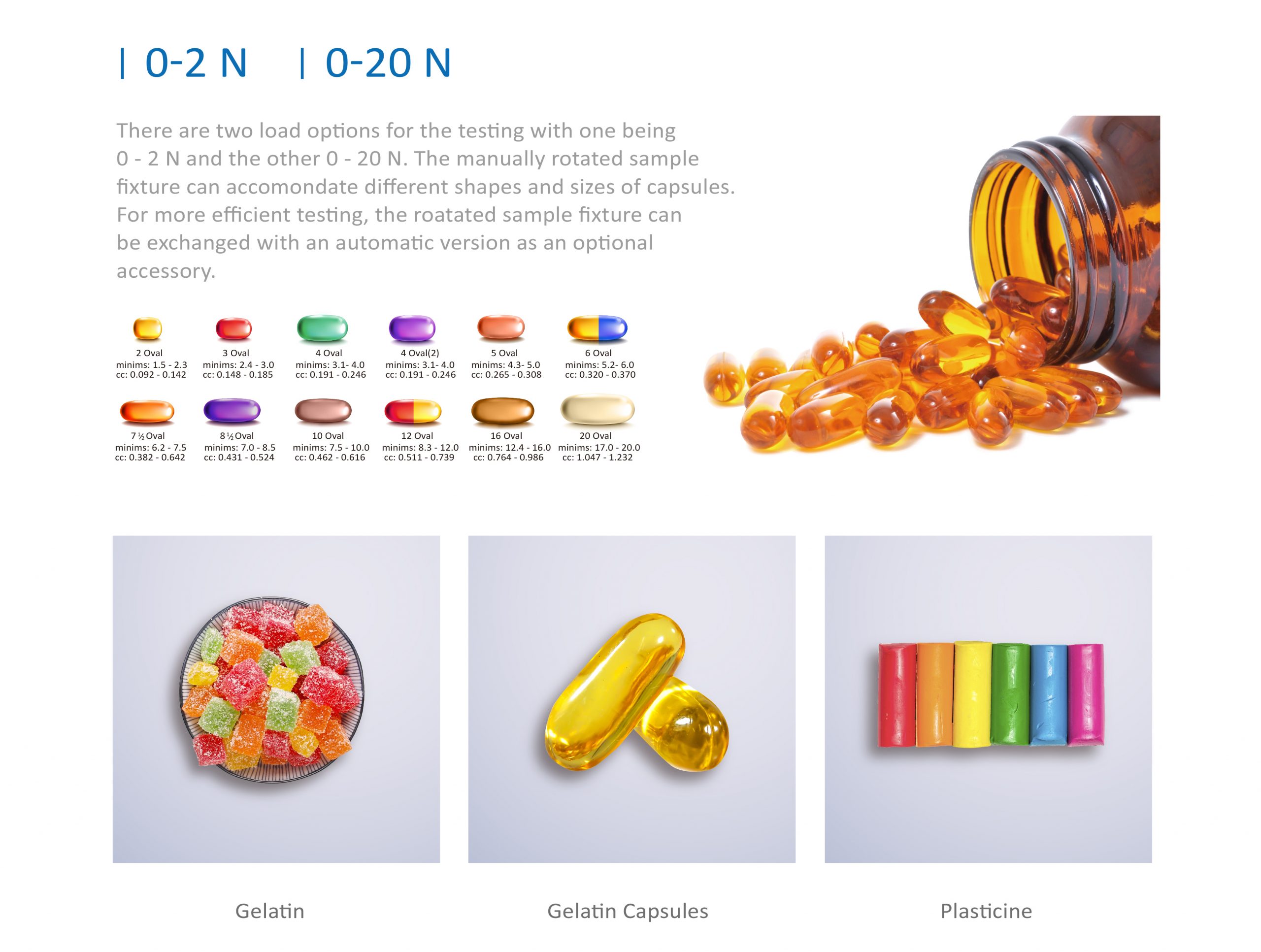

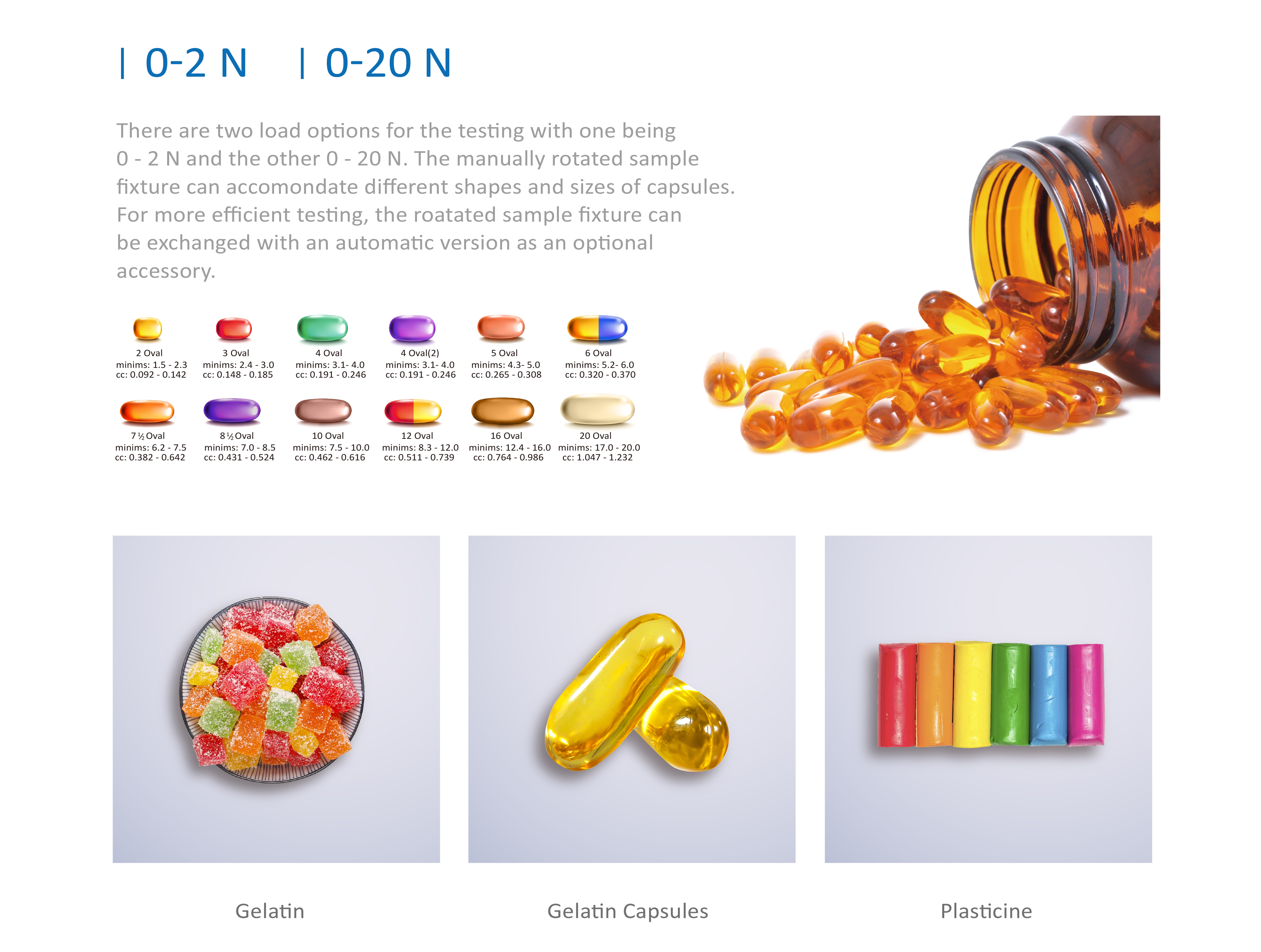

The Gelomat system is capable of performing hardness test procedure on materials such as gelatine capsule, plasticine, edible gelatine and more. The unique can be equipped with 2 load capacity option of 0-2N and 0-20N. These testing heads can be easily interchanged as per the operator’s requirements. The supporting electronic unit offers a clearly arranged display with an easy menu navigation, USB-interface for data transfer modular, digital test system automatic recognition of the measuring range and measuring time functions.

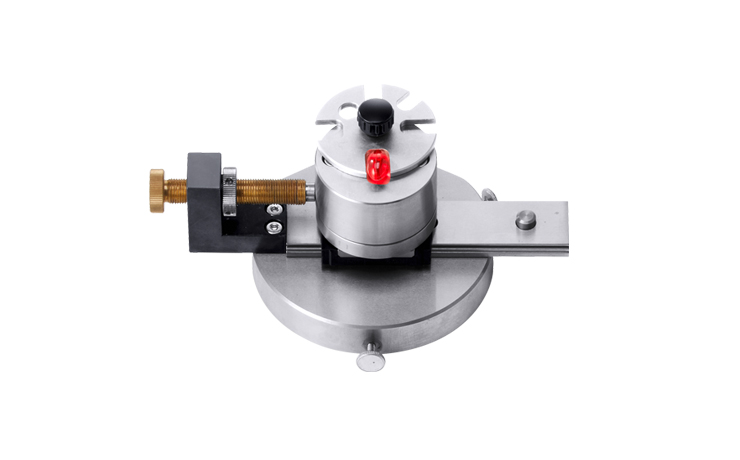

Should a customized holding fixture for gelatine and capsule specimens be required, we have got you covered. Our Centrofix offers the optimal solution based on your required template for different shapes of capsules and the precise centring of gelatine capsules Simply confirm the specific dimensions and the quantity of capsules that you are looking to test in a single test cycle and we will take care of the rest.

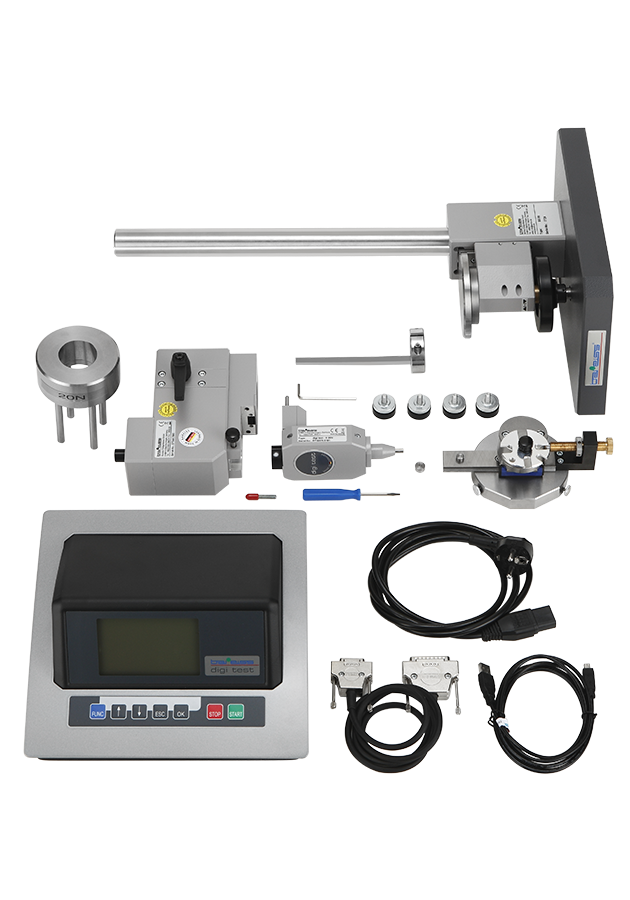

Standard Configurations

- Gelomat Main Unit Test Stand

- Electronic Console

- Gelomat - Loading Unit

- Gelomat Measuring Device 0-20 N, test stamp Ø10 mm OR test stamp Ø3.569 = 10 mm2

- Official DAkkS/DKD-calibration certificate for 0 - 2 N or 0 - 20 N

Features

- The Softgel capsule hardness tester is a non-destructive solution providing the ultimate value of preserving inventory

- The Gelatine hardness tester is highly reproductible and built for the highest standard accuracy German-manufactured equipment has to offer

- The digital display unit offers clear convenient display and functionality including measuring range and measuring time function.

- Auto correction function built into the digital display for when measured values are above or below the limit value.

- User-friendly system designed to meet and exceed the highest standards of accuracy and repeatability in the Global marketplace

- USB Port for convenient data transfer.

- Customized holding fixtures to meet highest level of accuracy and testing efficienct

- Hysteresis function

- Fully integrated automatic measuring process

- The tablet hardness tester is the ideal solution for the pharmaceutical, paintball, and cosmetic industries.

Technical Specifications

| Model # | NG-Gelomat |

|---|---|

| Test Method | Newton |

| Measuring Ranges | 0-20 n / 0-2 n |

| Power Supply | 100 - 240 VAC; 50 / 60 Hz |

| Fuse | 2 pieces of fuse 3.15 a (3.15 at) |

| Power Consumption | max. 20 VA |

| IP Code | IP 30 |

| Reading Output | LCD-graphic display (240x128 pixel) with brightness selectable led illumination |

| Resolution | 0.1 |

| Data Output | USB / RS 232 - 9600 baud, 1 start bit, 8 data bits, 1 stop bit |

| Dimensions (L x W x H) | |

| Test Stand | 7..87 x 9.8 x 22.44" / 200 x 250 x 570 mm |

| Electronic unit | 7.87 x 6.73 x 3.54" / 200 x 171 x 90 mm |

| Weight | |

| Test Stand | 20 lbs / 9 kg |

| Electronic unit | 4.4 lbs / 2 kg |

Accessories

- Centrofix Base DTZ CFB - Customized Centrofix for different configurations

- Capsule-attachment for gelatine capsule specimens

- HardTest - software for digital output and data export capabilities

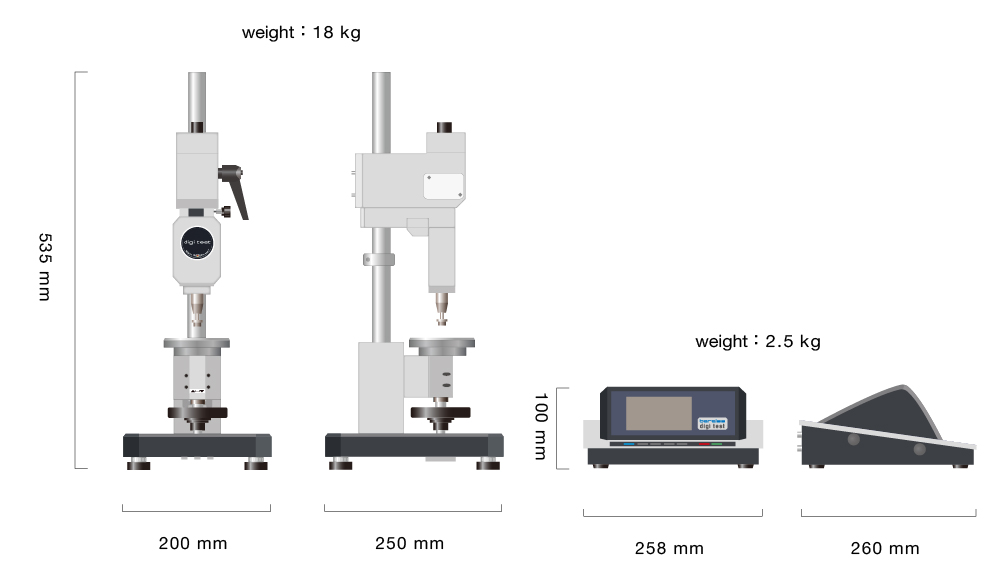

System Dimensions

FAQs

The main purpose of the Automatic Capsule and Soft Gel Hardness Tester is to provide precise and efficient testing of the hardness of soft gel and regular gelatin capsules. This system delivers consistent, accurate results for pharmaceutical, cosmetic, and related industries where capsule quality is extremely important.

The Automatic Capsule and Soft Gel Hardness Tester supports non-destructive testing, preserving valuable inventory while delivering highly reproducible results. It can test an array of materials such as gelatine capsules, plasticine, and edible gelatine with interchangeable testing heads for load capacities ranging from 0-2N to 0-20N. Its advanced features, including a digital display, USB connectivity for data transfer, and an auto-correction function for errors, allow for ease of use and reliable performance.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is built to perform precise hardness tests on a broad range of materials, thus being highly useful in multiple industries. It tests gelatin capsules, plasticine, edible gelatine, and other similar materials that require detailed hardness evaluations. This functionality supports industries such as pharmaceuticals, cosmetics, and food production, which are highly dependent on the quality and consistency of materials.

Its ability to test different types of materials allows the Automatic Capsule and Soft Gel Hardness Tester to provide reliable and repeatable results. Whether testing the durability of soft gel capsules, evaluating edible gelatine used in confectionery, or analyzing plasticine for specialized applications, this system delivers high precision. The adaptability of the system guarantees that it meets numerous testing requirements, helping industries maintain stringent quality control standards while enhancing hardness measurement efficiency.

Click here to learn more about the product or here to receive a personalized quote

Yes, the Automatic Capsule and Soft Gel Hardness Tester has two load capacity options, 0-2N and 0-20N. This flexibility allows the system to meet a broad range of testing requirements, catering to both delicate materials and those requiring higher force measurements.

The unit is designed with interchangeable testing heads, enabling operators to switch between two load capacities easily. This adaptability makes the Automatic Capsule and Soft Gel Hardness Tester an ideal choice for industries needing precise hardness measurements for many types of capsules and materials. By offering this customization, the system ensures reliable results tailored to specific testing needs.

Click here to learn more about the product or here to receive a personalized quote.

The testing heads of the Automatic Capsule and Soft Gel Hardness Tester are constructed for flexibility and efficiency. They can be easily interchanged based on the operator’s requirements, allowing the system to adapt to different materials and testing conditions. This allows for precise and reliable hardness measurements for a wide selection of specimens.

The electronic unit provides enhanced usability with a clearly arranged display and intuitive menu navigation. It also features a USB interface for smooth data transfer and supports automatic recognition of both the measuring range and the measuring time. These features simplify operation and improve testing accuracy, which makes the Automatic Capsule and Soft Gel Hardness Tester a highly efficient and user-friendly solution for capsule hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Capsule and Soft Gel Hardness Tester offers customized holding fixtures to meet specific testing needs for gelatine and capsule specimens. The system includes the Centrofix solution, which provides precise centering and secure holding of capsules, regardless of their shape or size.

To use a customized holding fixture, you simply need to provide the required dimensions and the number of capsules you wish to test in a single cycle. Based on this information, the appropriate configuration will be selected to meet your requirements. This results in optimal accuracy and efficiency in testing, making the Automatic Capsule and Soft Gel Hardness Tester an effective tool for handling diverse capsule shapes and sizes.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is supplied with comprehensive standard configurations to guarantee precise and efficient operation. These configurations include:

-

Gelomat Main Unit Test Stand: The primary component for capsule hardness testing.

-

Electronic Console: Provides intuitive control and display for easy operation.

-

Gelomat Loading Unit: Facilitates accurate load application during testing.

-

Gelomat Measuring Device: Includes options for 0-20 N capacity with either a test stamp Ø10 mm or a test stamp Ø3.569, providing flexibility for numerous testing needs.

-

Official DAkkS/DKD-Calibration Certificate: Guarantees accurate measurement and calibration, available for load capacities of 0-2 N or 0-20 N.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is a non-destructive testing solution, meaning it evaluates capsule hardness without damaging or altering it. With this approach, it is possible to preserve valuable inventory by making sure that the capsules that have been tested remain intact and usable after the process has been completed.

This feature is particularly beneficial in industries like pharmaceuticals and cosmetics, where minimizing waste is vital for maintaining cost efficiency and product availability. By verifying that testing does not compromise the integrity of the capsules, the tester delivers reliable hardness measurements while maximizing inventory use.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester provides highly reproducible results with exceptional accuracy. Its design reflects German-manufactured equipment's precision and quality standards, resulting in consistent and reliable performance across all tests.

This commitment to accuracy is achieved through advanced engineering, high-quality materials, and rigorous manufacturing standards. The system’s ability to provide precise and repeatable hardness measurements can make it a valuable tool for industries requiring high standards of quality control, such as pharmaceuticals and cosmetics. This reliability supports high-quality capsule production and guarantees compliance with global industry standards.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Capsule and Soft Gel Hardness Tester is equipped with a USB port, making it convenient for data transfer to be done. This functionality allows users to easily export test results to a computer or external storage device for further analysis, reporting, or record-keeping.

USB connectivity allows for greater efficiency by simplifying data management and sharing. This feature is particularly useful in industries like pharmaceuticals and cosmetics, where accurate documentation and analysis of testing data are crucial for quality control and compliance with industry standards.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Capsule and Soft Gel Hardness Tester is equipped with a hysteresis function, which is used to measure materials' behavior during both loading and unloading cycles. This feature provides valuable insights into the elastic and plastic properties of test specimens, such as gelatin capsules or other materials.

The hysteresis function is involved in identifying how a material responds to applied force and its ability to return to its original shape or deform permanently. By capturing these nuances, the tester delivers more comprehensive and reliable results than basic hardness testing alone. This functionality is particularly beneficial in industries where understanding material characteristics is critical for quality control and product development.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Automatic Capsule and Soft Gel Hardness Tester features a fully integrated automatic measuring process. This advanced functionality makes sure that all aspects of the hardness testing cycle, from the application of force to the recording and analysis of results, are carried out automatically without manual intervention.

The automatic measuring process not only saves time but also enhances accuracy and repeatability by reducing potential errors associated with manual operation. This integration is particularly valuable in environments where high throughput and consistency are required, such as in the pharmaceutical, cosmetic, and food production industries. By automating the testing process, the system delivers reliable results while improving overall efficiency.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is highly beneficial for professionals and organizations in the pharmaceutical, paintball, and cosmetic industries.

Pharmaceutical companies can rely on this tester to verify capsule hardness and quality standards, improving safety and regulatory compliance. In the paintball industry, manufacturers benefit from the tester’s ability to analyze the durability and consistency of gel-based paintballs, resulting in superior product performance. Cosmetic producers use the tester to maintain the quality of soft gels and other gel-based products, assuring a reliable and satisfying consumer experience.

This powerful system helps these industries achieve precise, repeatable results while optimizing quality control processes, providing a valuable resource for improving product reliability and customer satisfaction.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester offers two measuring ranges: 0-20 N and 0-2 N. These measuring ranges offer flexibility in testing, allowing different materials with varying degrees of hardness levels to be tested.

The 0-2 N range is ideal for testing delicate materials, such as soft gel capsules or other specimens requiring low-force measurement. The 0-20 N range, on the other hand, is suitable for more robust capsules or materials that require higher force evaluation. The interchangeable testing heads allow users to easily switch between these ranges, resulting in precise and tailored measurements for diverse testing requirements within industries like pharmaceuticals, cosmetics, and food production.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester requires a power supply of 100-240 VAC and operates at 50/60 Hz. This wide voltage range guarantees compatibility with global power standards, allowing it to be used in many regions without the need for additional power conversion equipment.

This flexibility in power supply supports easy integration into laboratories and manufacturing facilities worldwide, guaranteeing reliable and consistent operation regardless of location. As a result of the tester's compatibility with standard electrical systems, it makes a practical and convenient solution for industries that require a high degree of accuracy in testing capsule hardness.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is equipped with two fuses, each rated at 3.15 A. These fuses provide important protection for the system by preventing damage from electrical surges or overloads, thus maintaining the safety and reliability of the tester during operation.

The inclusion of these fuses highlights the system's adherence to safety standards, making it suitable for use in laboratories and industrial settings. By safeguarding the device's components, the fuses contribute to the longevity and consistent performance of the tester, offering users peace of mind during regular testing procedures.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester consumes a power consumption of 20 volts. With such a low power requirement, it is possible to maximize the energy efficiency of the system, making it economically advantageous to operate over an extended period of time.

The tester’s minimal energy usage is particularly advantageous in laboratories and manufacturing facilities, where multiple devices run simultaneously. By maintaining low power consumption while delivering precise and reliable performance, the Automatic Capsule and Soft Gel Hardness Tester combines efficiency with functionality, supporting sustainable and cost-effective operation.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester has an IP code of IP 30. This rating indicates the device's protection against solids and liquids:

-

3 (first digit): The device is protected against solid objects larger than 2.5 mm, such as tools or thick wires.

-

0 (second digit): The device has no specific protection against water ingress.

This IP rating is suitable for laboratory and controlled indoor environments where exposure to liquids or dust is minimal. While the IP 30 rating offers adequate protection for typical use, users should avoid exposure to water or excessive dust to maintain tester performance and longevity.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is equipped with an LCD graphic display featuring a resolution of 240x128 pixels. The display includes selectable LED illumination for adjustable brightness, providing clear visibility of test results under changing lighting conditions.

With this advanced display, the user is provided with a user-friendly interface, which makes it easy for the user to read and interpret the measurements that are displayed on the display. The high resolution and customizable brightness enhance the overall usability of the tester, allowing operators to perform tests with precision and efficiency, even in challenging laboratory environments.

Click here to learn more about the product or here to receive a personalized quote.

The resolution of the Automatic Capsule and Soft Gel Hardness Tester is 0.1, resulting in high precision and accuracy in hardness measurements. This level of detail allows the tester to detect subtle variations in material properties, providing valuable information for industries such as pharmaceuticals, cosmetics, and food production, where product consistency is paramount.

A resolution of 0.1 enables the tester to deliver reliable and repeatable results, even for delicate specimens like soft gel capsules. This precision guarantees that every test meets stringent quality control requirements, helping manufacturers maintain the highest product performance standards. Whether testing capsules for durability or evaluating gel-based materials for uniformity, the tester’s fine resolution provides critical insights into quality assurance and compliance with industry standards.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester offers several data output options, including USB and RS 232 interfaces. The RS 232 output operates at a baud rate of 9600 with 1 start bit, 8 data bits, and 1 stop bit, guaranteeing reliable and standardized data communication.

These output options allow seamless transfer of test data to computers or external devices for further analysis, documentation, or integration with laboratory management systems. The USB interface provides a quick and user-friendly connection, while RS 232 allows compatibility with a wide range of devices and systems. These features make data management efficient and support quality assurance processes by enabling accurate and easily accessible test records.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester consists of two main components with the following dimensions:

-

Test Stand: 7.87 x 9.8 x 22.44 inches (200 x 250 x 570 mm), built to provide a sturdy and stable platform for accurate hardness testing.

-

Electronic Unit: 7.87 x 6.73 x 3.54 inches (200 x 171 x 90 mm), compact and user-friendly for easy placement and operation in laboratory environments.

These dimensions make the system space-efficient while keeping functionality and precision. The compact electronic unit allows convenient positioning, while the robust test stand provides stability during testing. Together, these components offer a practical and efficient design for laboratories and production facilities requiring reliable capsule hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester is composed of two main components with the following weights:

-

Test Stand: 20 lbs (9 kg), providing a stable and robust foundation for precise hardness testing. During operation, its weight provides minimal vibrations and reliable performance.

-

Electronic Unit: 4.4 lbs (2 kg), designed to be lightweight and compact, making it easy to place and manage in laboratory or production settings.

The combined weight of these components strikes a balance between portability and stability, allowing for flexible integration into different testing environments while maintaining precision for consistent and repeatable results. This thoughtful design supports ease of use and dependable performance across diverse applications.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Capsule and Soft Gel Hardness Tester offers a range of accessories designed to increase its functionality and adaptability to different testing requirements. These include:

-

Centrofix Base DTZ CFB: A customized holding fixture that supports different configurations, providing precision and stability for a variety of capsule shapes and sizes during testing.

-

Capsule-Attachment for Gelatine Capsule Specimens: Specifically designed for secure and accurate placement of gelatine capsules, providing consistent and reliable hardness measurements.

-

HardTest Software: A powerful tool for digital data output and export, enabling seamless transfer of test results to a computer for further analysis and documentation.

Providing a reliable and user-friendly solution for diverse hardness testing needs, these accessories extend the versatility and efficiency of the Automatic Capsule and Soft Gel Hardness Tester.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenElm Series Elmendorf Tearing Tester – 64N and 128N Models

The GenElm Series Elmendorf Tearing Tester is designed for precise measurement of tear strength in fabrics, plastic films, paper, nonwovens, and technical textiles. Available in 64 N and 128 N models, it complies with ASTM, ISO, and DIN standards to provide accurate and comparable results across laboratories. The system features a touch-screen interface, pneumatic clamping, automatic specimen cutting, and data export via RS232, combining usability with consistent performance.

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

The NG-HDT HDT/Vicat testing machine measures HDT and Vicat softening temperature (VST) for thermoplastics, including pipes and fittings. It supports common ISO, ASTM, and GB/T methods run under constant load with controlled heating. The system is available in 3-station and 6-station configurations with touchscreen control for the full test sequence. Measurement uses Class A PT100 temperature sensing and LVDT displacement monitoring, with an immersion oil bath rated up to 300°C (572°F). Results can be saved and exported over Ethernet, with options such as a chiller and external oil-vapor extraction/filtration.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.