Rock Mechanics Testing Equipment

Description

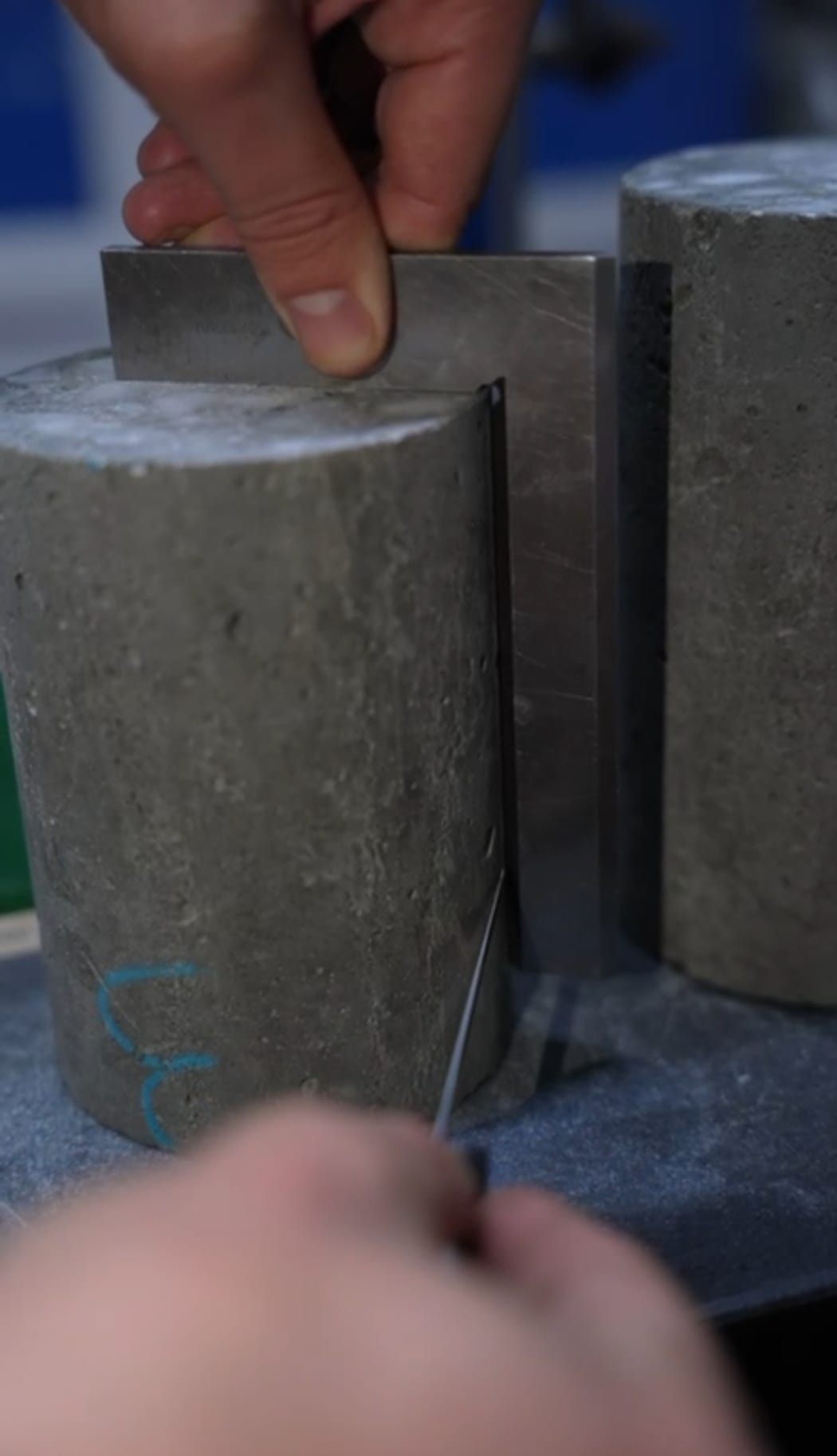

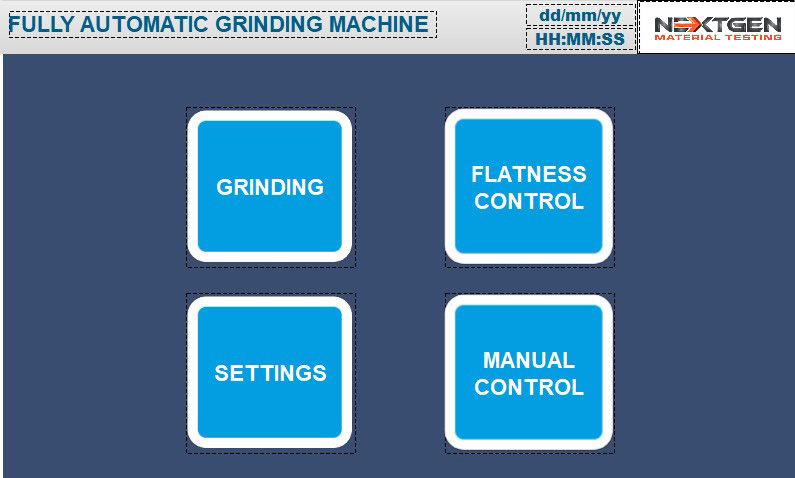

CoreGrind 3000 is a fully automatic rock core grinding machine used for sample preparation before laboratory testing. It grinds core specimens under electronic control, with a 7-inch touchscreen for setup and process monitoring.

Grinding parameters can be set through recipe-based operation, and the pneumatic sample locking system secures specimens during the grinding cycle. An automatic recirculating water spray system is used during grinding to reduce dust and support a cleaner working process.

CoreGrind 3000 is typically used ahead of rock mechanics and geotechnical test programs where consistent specimen preparation is required. It is commonly paired with the CoreTrim 3000 fully automatic core trimmer and cutting machine as part of a complete sample preparation workflow.

Main Features And Capabilities

CoreGrind 3000 includes control, handling, and monitoring features for fully automatic core grinding in rock sample preparation workflows. Key features and capabilities include:

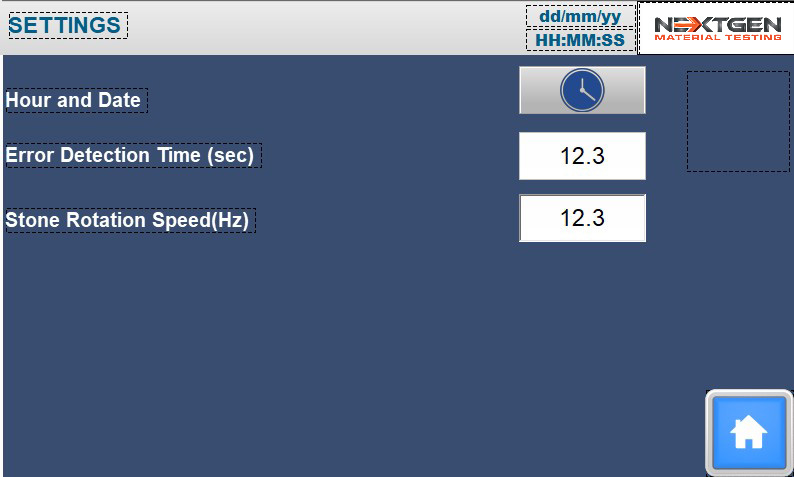

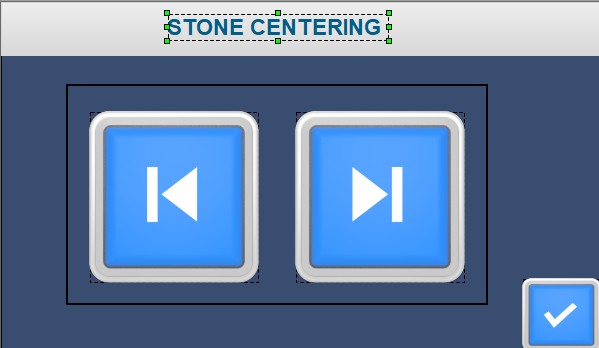

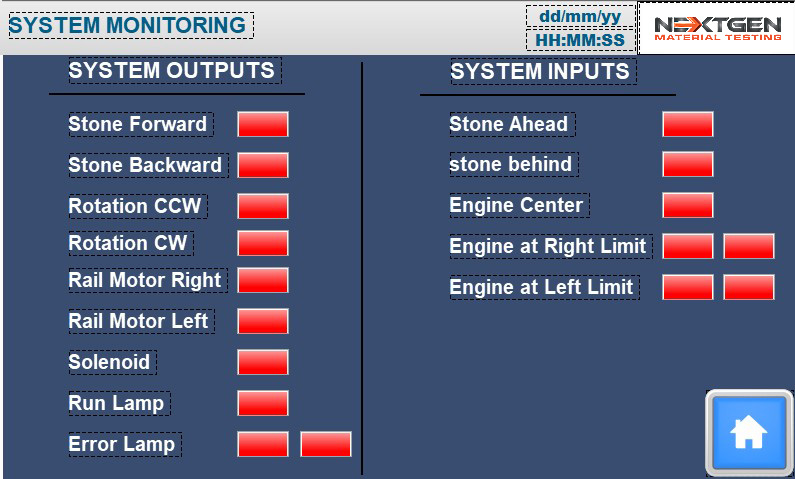

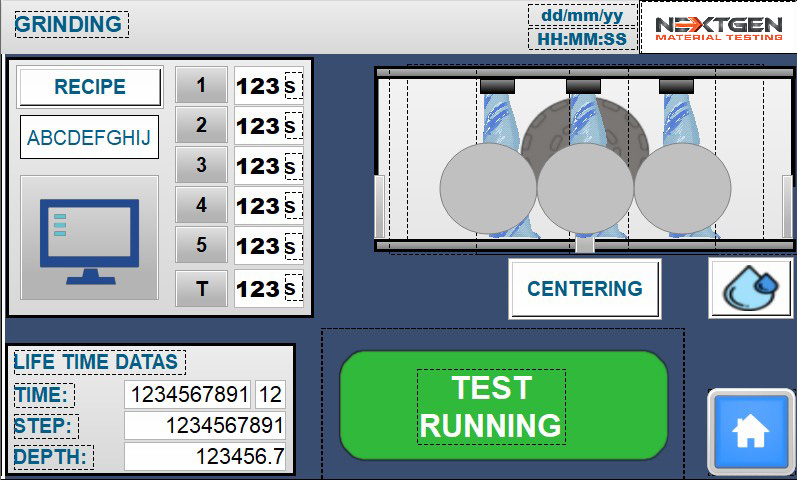

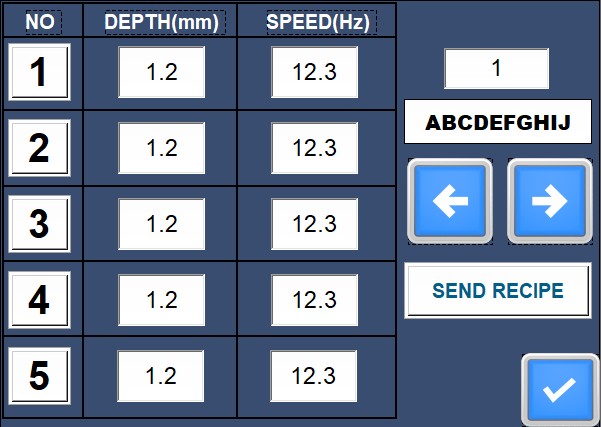

- 7-Inch Touchscreen Control: Sets parameters, runs programs, and monitors the grinding process from the operator interface.

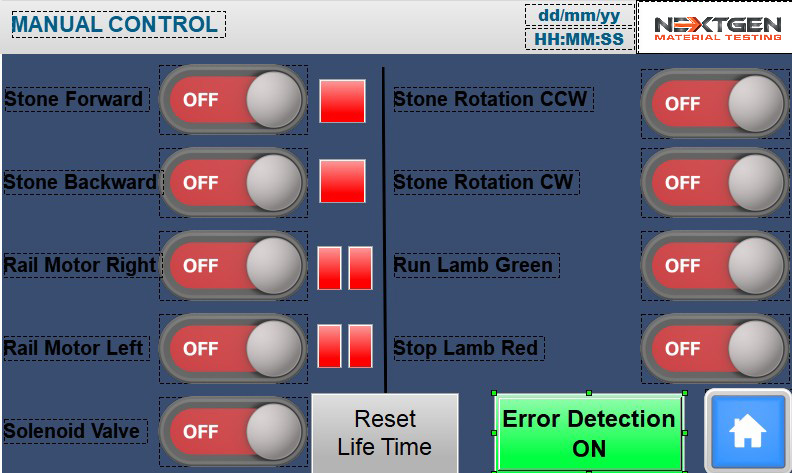

- Automatic Electronic Control System: Executes the grinding cycle automatically based on the selected settings.

- Pneumatic Sample Locking System: Holds core specimens securely during grinding.

- Recipe-Based Operation: Saves and runs grinding recipes based on sample characteristics.

- Adjustable Grinding Steps (0.5 To 1.5 mm): Controls material removal per step to match specimen requirements.

- Recirculating Water Spray Against Dust: Applies water during grinding to reduce dust and support a cleaner process.

- Multi-Language Interface: Supports operation in multiple languages.

- Process Memory And Tracking: Records the number of samples and total grinding completed.

- Diamond Grinding Blade Life Monitoring: Tracks grinding wheel condition to support planned maintenance.

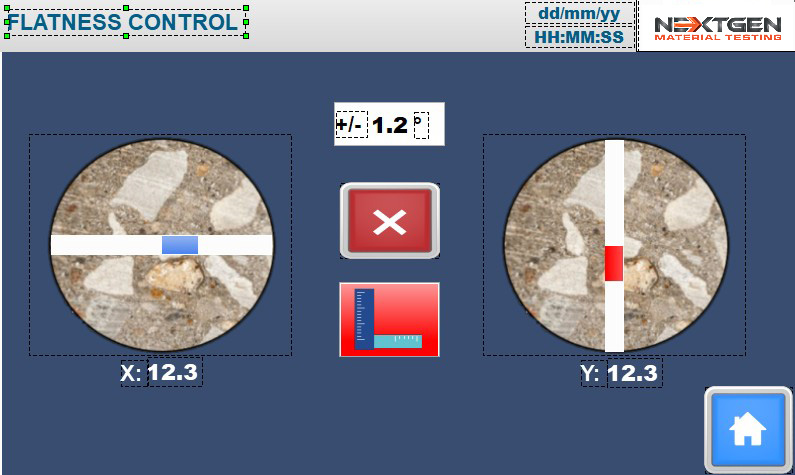

- Optional Surface Flatness Control (0.01 Degree): Checks surface flatness via touchscreen when the optional device is installed.

- Ethernet Remote Connection: Enables remote diagnostics and device data tracking via Ethernet.

How It Works

CoreGrind 3000 follows a simple operating sequence for fully automatic core grinding during rock sample preparation:

- Load the core specimens into position.

- Lock the specimens using the pneumatic sample locking system.

- Select a saved recipe or set grinding parameters on the 7-inch touchscreen.

- Start the cycle and monitor the grinding process while the unit runs automatically with recirculating water spray for dust control.

Applications

CoreGrind 3000 is used for rock core sample preparation where specimens must be ground before laboratory testing.

- Rock Mechanics Testing Laboratories

- Core Specimen Preparation For Routine Testing

- Geological And Research Sample Preparation Workflows

Technical Specifications And Versions

CoreGrind 3000 is available in two versions. V1 covers standard core diameters and includes a published throughput reference for common specimen sizes, while V2 expands the diameter range for larger cores and references sample abrasion strength up to 200 MPa.

| Specification | CoreGrind 3000 V1 | CoreGrind 3000 V2 |

|---|---|---|

| Machine Type | Fully Automatic Core Grinding Machine For Sample Preparation | |

| Control System | 7-Inch Touchscreen Electronic Control | |

| Sample Locking | Pneumatic Sample Locking System | |

| Recipe-Based Operation | Yes | |

| Grinding Step Setting | 0.5 To 1.5 mm | |

| Dust Control | Recirculating Water Spray Against Dust | |

| Multi-Language Support | Yes | |

| Data Recording | Number Of Samples And Grinding Amount Stored In Memory | |

| Diamond Grinding Blade Life Monitoring | Yes | |

| Optional Flatness Control | 0.01 Degree Precision (Optional) | |

| Remote Connection | Ethernet Remote Connection | |

| Core Diameter Range | 1.50 To 3.94 in (38 To 100 mm) | 1.97 To 6.30 in (50 To 160 mm) |

| Throughput Reference | 3 × 100 × 200 mm + 2 × 150 × 300 mm In 62 s | Depends On Specimen Size And Setup |

| Sample Strength Reference | Depends On Sample Material And Abrasion Conditions | Up To 200 MPa |

| Power Supply | 220 V, 50 To 60 Hz | |

Optional Accessories And Add-Ons

CoreGrind 3000 can be supplied with optional accessories to support the grinding process and site setup:

- Water Tank With Filtration And Circulation: Optional tank and recirculation system for CoreGrind 3000 (V1 and V2).

- Grinding Wheel: Optional grinding wheel for CoreGrind 3000 (V1 and V2).

Request A Quote For CoreGrind 3000

For pricing, lead time, and configuration details, request a quote or contact us directly. Please include the required version (V1 or V2), core diameter range, specimen sizes, target throughput, and local power standard, or get the catalogue for full product information.

FAQs

This system is used to grind and finish rock core ends as a standardized sample preparation step before laboratory rock mechanics and geotechnical testing.

In a typical workflow, cores are recovered and cut or trimmed to length, then the specimen ends are ground so they are ready for downstream tests such as compressive strength and deformation measurements. Consistent end preparation helps reduce variability tied to manual technique and supports more repeatable results across operators and shifts.

CoreGrind 3000 is designed to make that step consistent by running the grinding cycle under electronic control through a 7-inch touchscreen, securing specimens with a pneumatic locking system, and using recipe-based programs for repeat jobs. It also supports wet grinding with a recirculating water spray for dust control, process memory and tracking, and diamond grinding blade life monitoring.

If you want to confirm the best version and options for your specimen sizes and prep targets, you can learn more or request a quote.

This system is more consistent than manual core grinding because it runs a programmed, fully automatic grinding cycle under electronic control, instead of relying on hand pressure, timing, and operator technique during rock core sample preparation.

In day-to-day use, repeatability comes from process controls that standardize how each specimen is held and how each cycle is executed:

- 7-inch touchscreen control for setup and real-time process monitoring

- Recipe-based operation to save and rerun proven grinding parameters

- Pneumatic sample locking to keep core specimens stable during grinding

- Adjustable grinding steps from 0.5 to 1.5 mm to control material removal per step

- Recirculating water spray during grinding to reduce dust and support a cleaner process

- Process memory and tracking, plus diamond grinding blade life monitoring to help manage wear-related drift

If your method requires tighter end-condition checks, optional surface flatness control can be added, and the Ethernet remote connection supports remote diagnostics and data tracking.

If you want to confirm the right configuration for your core diameters, recipes, and optional controls, you can learn more or request a quote.

You use this system after the core has been recovered and cut to length, and before you run rock mechanics or geotechnical tests, to grind and finish the ends as a controlled sample preparation step.

In a typical workflow, core cutting or trimming establishes the specimen length, then end grinding brings the end condition under tighter control for downstream measurements like strength and deformation. Doing this step consistently helps reduce test-to-test scatter caused by manual grinding technique.

In day-to-day use, the sequence is straightforward:

- Load the core and secure it with the pneumatic sample locking system

- Select a saved recipe or set parameters on the 7-inch touchscreen

- Run the automatic grinding cycle with recirculating water spray for dust control, with process tracking and diamond blade life monitoring supporting routine lab control

If you want to confirm the right configuration for your core sizes and preparation targets, you can learn more or request a quote.

A fully automatic core grinder is often unnecessary when your lab has low sample volume, limited variation in specimen types, and you can meet your test method’s end-condition needs without automated recipes, tracking, or cycle control.

A simpler solution is usually enough when:

- You only grind cores occasionally and throughput is not a bottleneck

- One or two trained users handle preparation consistently, with minimal shift-to-shift variation

- Your reporting and QA/QC program does not require stored counts, grinding totals, or traceability features

- You do not need advanced monitoring features like blade life tracking or optional flatness checks

In those cases, many teams choose a semi-automatic or manual-style end grinding approach and put budget into upstream cutting, training, and a repeatable inspection routine for end condition.

If you want to confirm what level of automation fits your specimen sizes, throughput targets, and repeatability goals, you can learn more or request a quote.

This system is built for rock core end grinding and uses diamond grinding blades, so it is well-suited to demanding rock core sample preparation, including harder materials. For highly abrasive cores, the key consideration is not whether the grinder can run, but how grinding rate and consumable life behave with your specific rock type and end-condition requirement.

For the best consistency on hard or abrasive cores, focus on the setup variables that drive results and wheel wear:

- Rock mineralogy and how abrasive the cuttings are

- Your target end condition, including whether optional surface flatness control is needed

- The grinding step setting (0.5 to 1.5 mm) and overall material removal

- Diamond wheel condition, supported by blade life monitoring and process tracking

If you want to match the right CoreGrind 3000 version and options to your core sizes and material, you can learn more or request a quote.

CoreGrind 3000 is available in two diameter-range versions. V1 supports 1.50 to 3.94 in (38 to 100 mm) cores, and V2 supports 1.97 to 6.30 in (50 to 160 mm) cores.

If most of your work falls in the common mid-range, both versions cover the overlap from 50 to 100 mm. Labs typically choose V1 when they stay within 100 mm, and move to V2 when larger diameter cores are part of the program or expected in the future.

Final version selection can also depend on your specimen geometry, how much end material you need to remove, and any method-driven end-condition requirements that influence the preferred setup.

If you want to confirm the best version for your core diameters and workflow targets, you can learn more or request a quote.

An optional surface flatness control package is available for this system, allowing you to check flatness on the touchscreen when the optional device is installed.

This option is typically used when your rock mechanics or geotechnical method requires tighter control of end conditions and you want an on-machine check as part of the grinding workflow. The flatness control is specified at 0.01 degree on the product configuration.

When selecting the option, it helps to align the setup with your specific workflow requirements:

- Your method or internal acceptance criteria for end surface condition

- Your core diameter range and whether you are configuring V1 or V2

- How you want to use the check, for process confirmation or for documented QA/QC

If you want to confirm the right configuration for your core sizes and flatness verification needs, you can learn more or request a quote.

Yes. This system supports recipe-based operation, so you can save grinding parameter sets and recall them for different rock categories and specimen conditions.

In a rock core sample preparation workflow, recipes help you standardize the end-grinding step across operators and shifts. Instead of re-entering settings each time, you select the appropriate saved recipe on the 7-inch touchscreen and run the automatic cycle under electronic control.

Labs typically build recipes around the practical differences that affect end grinding consistency, for example:

- Rock type and expected abrasiveness

- Core diameter and specimen geometry

- How much end material needs to be removed to achieve the required end condition

- Internal QA/QC preferences for repeatability and traceability using the system’s process memory and tracking

If you want to confirm the best recipe approach and configuration for your core sizes and preparation targets, you can learn more or request a quote.

The pneumatic sample locking mechanism secures the core by using air power to clamp the specimen in a fixed position during the grinding cycle, helping prevent slip or rotation while material is being removed.

In practical use, the operator loads the core, activates the pneumatic lock, then runs the automatic cycle from the touchscreen. Using pneumatic locking helps keep the holding force consistent from sample to sample, which is one reason fully automatic core grinding is typically more repeatable than manual preparation. It also supports smoother operation when you are running saved recipes and tracking totals in memory.

If you want to confirm the right CoreGrind 3000 version and locking setup for your core diameters and workflow, you can learn more or request a quote.

Yes. This system uses an automatic recirculating water spray during grinding to reduce dust and support a cleaner grinding process.

In rock core sample preparation, wet grinding helps capture fine particles at the source and flush grinding debris away from the contact area. That typically supports a more uniform end condition and surface appearance, especially when you are trying to keep results consistent across operators and shifts.

How much the spray contributes to end-surface quality depends on practical factors such as:

- Rock type and abrasiveness

- Grinding step setting and total material removal

- Diamond grinding blade condition and wear state

- Your saved recipe parameters and how consistently they are applied

If you want to confirm the best CoreGrind 3000 configuration for your specimens and cleanliness requirements, you can learn more or request a quote.

The 7-inch touchscreen is the main operator interface for controlling the automatic grinding cycle and monitoring the process during rock core sample preparation.

It is where the operator sets parameters, selects a saved recipe or enters new settings, and runs the program. Because the grinding cycle is executed under electronic control based on these inputs, the touchscreen helps keep preparation consistent from sample to sample.

It also supports routine lab oversight by giving you a single place to manage key monitoring functions:

- Monitor the grinding process from the operator interface while the cycle runs

- Review process memory and tracking for sample counts and total grinding completed

- Check diamond grinding blade life monitoring for planned maintenance

- View surface flatness checks on-screen when the optional flatness control device is installed

If you want to confirm the right configuration for your workflow, recipes, and monitoring needs, you can learn more or request a quote.

Yes. An optional surface flatness control package is available for this system, specified at 0.01 degree, and the flatness check can be viewed on the touchscreen when the optional device is installed.

In a rock core sample preparation workflow, this option is used when you want an on-machine confirmation step for end condition, rather than relying only on external checks. It can help labs tighten control of specimen preparation before rock mechanics and geotechnical testing.

Whether you need the flatness option typically depends on your test method requirements, your internal QA/QC acceptance criteria, and how you want to document preparation results across operators and shifts.

If you want to confirm the right CoreGrind 3000 configuration for your core diameters and flatness verification needs, you can learn more or request a quote.

Yes. This system includes process memory and tracking that records the number of samples and the total grinding completed, and it also includes diamond grinding blade life monitoring.

These tracking features are designed to support day-to-day lab control and repeatability in rock core sample preparation:

- Number of samples processed

- Total grinding completed, stored in memory

- Diamond grinding blade life monitoring to help manage wheel condition and maintenance timing

In practical terms, this makes it easier to keep preparation consistent across shifts, spot when consumable wear may be influencing results, and support internal QA/QC traceability without relying on manual log sheets.

If you want to confirm how these tracking functions fit your workflow and reporting needs, you can learn more or request a quote.

This system requires a 220 V power supply, 50 to 60 Hz, for installation and operation.

For a smooth install, the main goal is to provide a stable, correctly wired 220 V feed that matches your facility’s local electrical practices, including proper grounding and protection per site code.

Electrical details are typically finalized based on facility and site requirements such as:

- Your local power standard and the receptacle or disconnect style used in your lab

- How you want the unit integrated into your prep area, including cable routing and safety access

- Any internal QA or EHS requirements for dedicated circuits and lockout procedures

If you want to confirm the right installation requirements for your facility and configuration, you can learn more or request a quote.

This system uses a pneumatic sample locking system, so you will need a facility compressed air connection to actuate the clamp during the grinding cycle. The exact air supply requirements depend on your site utilities and how you plan to plumb and regulate air at the machine.

For reliable day-to-day locking and repeatability, labs generally focus on providing clean, dry, regulated air and a stable supply so clamping force and cycle behavior stay consistent.

When planning the air drop for installation, the most important factors are:

- Your available plant air stability and how you regulate pressure at the point of use

- Air quality, including filtration and moisture control to protect pneumatic components

- Hose and fitting style, plus how you route air safely in the prep area

- Duty cycle expectations, based on sample volume and shift usage

If you want to confirm the right utility connections and installation setup for your lab, you can learn more or request a quote.

Yes. This system can be supplied with an optional water tank accessory that includes water circulation and filtration to support the recirculating spray used during grinding.

This option is commonly selected when you want a more self-contained wet-grinding setup for rock core sample preparation, with water management handled at the machine rather than relying entirely on building plumbing. It can also help keep the spray system running consistently by removing suspended grinding debris from the recirculating loop.

How well a recirculating, filtered tank fits your workflow typically depends on factors like the amount of fines your rock produces, your daily throughput, and how your lab prefers to handle slurry disposal and cleanup routines.

If you want to confirm the best water-management configuration for your site and whether the optional tank is the right fit for your V1 or V2 setup, you can learn more or request a quote.

Recommended floor space and clearances depend on how you plan to operate the system in your core prep area, including how you load cores, manage splash and slurry from wet grinding, and route utilities for power, compressed air, and water recirculation.

Most labs plan space so an operator can comfortably load and unload specimens, access the touchscreen, and clean the work zone without obstruction. It is also good practice to leave access for service and for removing covers or consumables during routine maintenance.

When laying out the footprint, the main factors are:

- Whether you add the optional water tank with filtration and circulation

- Where you place water management and slurry handling, including containment and cleanup space

- How you route 220 V power and the facility air line to avoid trip hazards

- How much staging room you need for incoming cores, finished specimens, and trays

If you want to confirm the best layout for your lab and options package, you can learn more or request a quote.

For a complete, lab-ready CoreGrind 3000 setup, the most useful add-ons are the ones that simplify water management, support repeatable grinding, and help you verify end condition when your method requires it.

Commonly recommended options include:

- Water tank with filtration and circulation, for a more self-contained recirculating wet-grinding setup and cleaner water handling

- Optional grinding wheel, so you have a spare ready and can minimize downtime when consumables wear

- Optional surface flatness control (0.01 degree), when you want an on-machine flatness check displayed through the touchscreen

The best bundle depends on your daily throughput, how much fine material your rock produces, and how tightly your QA/QC program controls end condition and documentation.

If you want to confirm the right options package for your V1 or V2 diameter range and workflow, you can learn more or request a quote.

Yes. This system is commonly paired with the CoreTrim 3000 as part of a complete rock core sample preparation workflow, with cutting or trimming handled first and end grinding completed next before rock mechanics and geotechnical testing.

In practical terms, the trimmer establishes specimen length and produces clean cut ends, then the grinder finishes those ends in a controlled, repeatable way. Pairing the two steps helps labs reduce operator-dependent variability and keep throughput steady when running routine programs or multi-shift testing.

To build a complete workflow, the best pairing usually depends on factors such as core diameter range, expected daily volume, end-condition requirements, and how you plan to manage wet cutting and wet grinding water and cleanup.

If you want to confirm the best pairing for your specimen sizes and prep targets, you can learn more, learn more, or request a quote.

Yes. This system includes an Ethernet remote connection that can be used for remote diagnostics and device data tracking.

In a production-style rock core sample preparation workflow, Ethernet connectivity can make it easier to support the grinder without being on-site and to keep better visibility into how the machine is being used over time.

How you implement remote access and tracking will depend on your facility’s IT and QA requirements, including:

- Whether the machine is allowed on your network, and how remote access is approved

- What device data you want to capture for internal reporting or traceability

- How you want service support to connect, on-demand or scheduled

If you want to confirm the best setup for your site network and reporting needs, you can learn more or request a quote.

This system supports recipe-based operation, so grinding parameter sets can be saved and reused to keep rock core sample preparation consistent. How you handle recipe backups or parameter exports for documentation control depends on your lab’s QA requirements and how you want to manage records across shifts and sites.

For documentation control, many labs treat the on-machine recipe as the operational tool, then control the official record through controlled work instructions and approved parameter sheets. The system also includes process memory and tracking, plus an Ethernet remote connection for remote diagnostics and device data tracking, which can support broader traceability workflows.

When choosing a documentation approach, the key decision points are:

- Whether you need formal version control and change approval for recipe parameters

- What you need to archive, such as recipe settings, usage totals, or maintenance history

- How your IT team prefers to handle network connectivity and data access

If you want to confirm the best configuration and documentation workflow for your QA program, you can learn more or request a quote.

In a rock core sample preparation workflow, this system supports safer, more controlled grinding by automating the cycle and keeping the specimen secured during material removal, instead of relying on manual hand grinding techniques.

Safety-related features and design elements include:

- Pneumatic sample locking to hold the core securely during grinding

- Electronic control through a 7-inch touchscreen, so the operator runs the programmed cycle from the interface

- Recirculating water spray for wet grinding, which helps control dust and keep the process cleaner

- Process memory and tracking, plus diamond grinding blade life monitoring to support planned maintenance and reduce wear-related issues

- Ethernet remote connection for remote diagnostics and device data tracking, which can reduce on-site troubleshooting time

Overall safety performance also depends on your lab’s procedures, PPE, utility setup, splash and slurry handling, and lockout practices around rotating equipment.

If you want to confirm the best configuration and options for your EHS requirements and workflow, you can learn more or request a quote.

Slurry and residual water are managed through the machine’s wet-grinding approach, where a recirculating water spray is used during grinding to control dust and keep the process cleaner.

In day-to-day operation, the water carries fine grinding debris away from the contact area and into your water-management setup. If you add the optional water tank with filtration and circulation, it supports a more self-contained recirculation loop and helps keep the spray supply cleaner over repeated cycles.

Cleanup frequency and how you handle slurry typically depend on:

- How much fine material your rock produces and how abrasive it is

- Your daily throughput and how long you run wet grinding per shift

- Whether you use the optional tank, or manage water and disposal through site utilities

- Your internal QA and EHS procedures for slurry handling and housekeeping

If you want to confirm the best water-management configuration for your site and workflow, you can learn more or request a quote.

This system includes diamond grinding blade life monitoring to track grinding wheel condition and support planned maintenance, instead of waiting for end quality to drift during rock core sample preparation.

In practice, wheel life management is handled through the machine’s built-in monitoring functions, supported by process memory and tracking that records the number of samples processed and the total grinding completed. This gives the lab a consistent way to review usage trends and schedule wheel changes proactively.

Wheel replacement timing depends on your specimens and method requirements, especially:

- Rock hardness and abrasiveness

- How much material you remove per specimen, including the grinding step setting (0.5 to 1.5 mm)

- Your required end condition, especially if you rely on optional on-machine flatness checks

- Whether you see changes in cycle behavior, surface appearance, or repeatability that indicate wear

If you want to match wheel selection and replacement planning to your core diameters and rock types, you can learn more or request a quote.

For reliable day-to-day core grinding, routine maintenance is mainly about keeping the wet-grinding system clean, monitoring diamond wheel condition, and making sure the pneumatic locking and controls operate consistently from cycle to cycle.

Most labs build a simple routine around the machine’s core subsystems:

- Rinse and wipe down the grinding area after use to prevent slurry buildup, and keep the recirculating water spray path clear

- If your system includes the optional water tank with filtration and circulation, clean out collected fines and service the filtration components on a schedule that matches your rock and throughput

- Use diamond grinding blade life monitoring, plus process memory and tracking totals, to plan wheel changes before end condition starts to drift

- Check the pneumatic sample locking for secure clamping, and keep the facility air supply clean, dry, and leak-free

If you want to align a maintenance routine with your rock types, throughput, and options package, you can learn more or request a quote.

To verify end-face flatness over time, the most practical approach is to combine a consistent grinding recipe with periodic flatness checks, then use wheel-life and usage tracking to spot drift before it affects your rock mechanics results.

If your workflow requires on-machine verification, an optional surface flatness control package (0.01 degree) can be added, with flatness checked via the touchscreen when the optional device is installed.

For ongoing control, labs typically build a simple check routine around:

- Running periodic confirmation checks on representative specimens and comparing results shift to shift

- Reviewing process memory and tracking totals, alongside diamond grinding blade life monitoring, to time wheel changes before end condition degrades

- Verifying the pneumatic sample locking is holding cores consistently and recipes are being applied correctly

If you want to confirm the best flatness verification approach and options for your method requirements, you can learn more or request a quote.

Yes. NextGen can provide on-site installation and basic operator training for this system, with the scope tailored to your facility, utilities, and workflow.

Installation support typically focuses on getting the grinder set in place, completing required physical and electrical connections, verifying that key functions operate correctly, and confirming the system is ready for your rock core sample preparation routine.

Basic operator training is usually structured to get technicians running consistent cycles safely and repeatably, including:

- Safe startup, shutdown, and general operating practices around wet grinding

- Specimen loading and use of the pneumatic locking system

- Recipe selection and parameter entry on the touchscreen

- Water spray and slurry housekeeping routines, including optional tank use when equipped

- Using process tracking and blade life monitoring to support routine QA/QC

If you want to confirm the right installation and training package for your site and configuration, you can learn more or request a quote.

After commissioning, ongoing support for this system typically centers on after-sales technical assistance for operation questions, troubleshooting, and keeping your rock core sample preparation process running consistently.

Support options commonly include:

- After-sales technical support by phone or email for operating guidance and issue triage

- Warranty support for covered issues, based on the warranty package supplied with your order

- Service inquiry support for maintenance questions, consumables planning, and general service coordination

- Ethernet-based remote diagnostics and device data tracking when the machine is connected and your site allows remote access

What the best support path looks like depends on your internal QA and IT requirements, how you manage recipes and traceability, and whether remote connectivity is permitted on your network.

If you want to confirm the best support and remote-diagnostics setup for your site, you can learn more or reach our service team through contact us.

The standard warranty for this system is a minimum of 12 months, covering the machine from top to bottom against defects in materials and workmanship, starting from shipment or delivery as defined in your order documentation.

Coverage is intended to protect the equipment itself, while normal wear items and consumables are not covered. Warranty claims can also be declined when issues are tied to misuse, abuse, improper maintenance, or customer modification.

For smooth warranty handling, it is good practice to complete and document a full incoming inspection soon after delivery and report any shipping damage or nonconformance promptly, since those items are time-sensitive in most procurement terms.

If you want to confirm warranty details for your exact configuration and delivery terms, you can learn more or reach our team through contact us.

NextGen supports this system with an ongoing spare-parts and accessories supply program, and many labs can get fast turnaround by ordering commonly used items that are kept in inventory.

Actual delivery speed depends on the part type and your location, since some items are higher-turnover consumables while others are less common service components. For core grinding uptime, labs typically plan around the items most likely to stop production:

- Keeping a spare diamond grinding wheel on hand for quick changeovers

- Stocking water-management items when using a recirculating setup, such as filtration-related components

- Ordering wear items proactively based on blade life monitoring and tracking totals

If you want to confirm what is currently stocked for your CoreGrind 3000 configuration and the fastest shipping option to your site, you can learn more or contact us.

Related Products

Semi-Automatic Core Grinding Machine - NG-CoreGrind 1000

Our Semi-Automatic Core Grinding Machine (also known as Coregrinder or Core Grinder) is the preferred alternative to the traditional rubber / sulfur capping methods used by Quality Labs

West Cerchar Abrasivity Index Tester

Description The West Cerchar Abrasivity Index Tester is designed to determine the rock abrasivity index (CAI) for the purpose of quantifying the classification of rock materials abrasivity. This type of test is especially valuable in the mining industries, underground construction […]

Rock Core Cutter and Masonry Saw

Our Rock Core Cutter and Masonry Saw designed for preparing concrete, rock, or natural stone cores and test specimens.

Rock Shear Box Apparatus

This apparatus was originally developed at Imperial College, London, by Professor E. Hoek. It is a simple and practical method of determining the strength and slope stability of rock, both in the field and in the laboratory.

Point Load Tester: Portable Rock Strength Testing for Field Applications

Discover the high-precision Point Load Tester for fast and reliable rock strength testing as a cost-effective solution for geotechnical and construction projects.

Core Cutting Machine for Sample Preparation – CoreTrim 3000

CoreTrim 3000 is a fully automatic core cutting machine for rock sample preparation. It cuts cylindrical core samples from 1.50 to 3.94 in (38 to 100 mm) and supports up to 3 samples per cycle for 3.94 × 7.87 in (100 × 200 mm) specimens. The cutting cycle is electronically controlled and completes automatically, including blade return to Home Position. An integrated water spray is applied during cutting to reduce dust. CoreTrim 3000 is used in rock mechanics testing laboratories and other workflows where core specimens must be cut before testing.

Laboratory Coring Machine and Bits

This machine is specifically used in the laboratory for cutting core samples from hard materials such as rock and concrete.

Double Faced Rock Core Grinder Machine NG-CoreGrind 2000

CoreGrind Double faced core grinder machine is designed to grind and polish the end surfaces of concrete & rock cube and cylinder specimens.