Hardness testing of metallic materials is one of the most common methods for evaluating materials quality and performance in many industries. This type of testing is critical for verifying that metals meet specific standards for durability, reliability, and safety. Accurate hardness measurements are necessary for applications where material failure is not acceptable.

Nevertheless, there have been instances where incorrect hardness measurements have led to significant consequences. These errors are often traced back to the use of substandard testing equipment. Such equipment affects the accuracy and reliability of the results.

Throughout this article, we introduce our GenRock NG-150 Series – Advanced Rockwell Hardness Tester, a cutting-edge device engineered to deliver exceptional accuracy and efficiency in hardness testing. This blog will cover what the GenRock NG-150 is, its advanced features, and how it stands out as the ideal solution for Rockwell hardness testing.

What is Rockwell Hardness Tester and Rockwell Hardness Scale?

First, lets clarify what a Rockwell hardness tester is and the principles behind the Rockwell hardness scale. A thorough understanding of these concepts is necessary in order to appreciate the purpose and capabilities of this advanced testing equipment.

What is a Rockwell Hardness Tester?

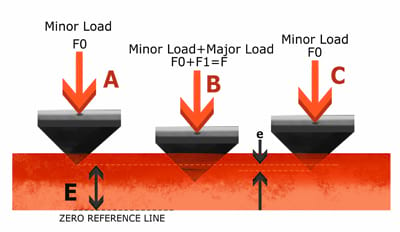

A Rockwell hardness tester, also called a Rockwell scale tester, measures materials’ hardness using the Rockwell scale. It works by applying a controlled force to an indenter, which is pressed into the surface of the material being tested.

This type of tester is widely regarded for its accuracy, ease of use, and flexibility. It is commonly used in industries such as manufacturing, automotive, aerospace, and research laboratories. By providing reliable hardness measurements, the tester guarantees that materials meet specific performance and safety standards, whether in the form of steel plates, aluminum alloys, or hardened components.

Rockwell Hardness Scale – What Is It?

The Rockwell hardness scale, often referred to as the Rockwell scale, is a quantitative method for determining material hardness by measuring the depth of an indenter’s penetration under a specified load. This scale is highly efficient, offering precise numerical values that are easy to interpret and broadly accepted. Unlike other methods like the Brinell or Vickers scales, the Rockwell scale is known for its speed, simplicity, and ability to handle a large variety of material types.

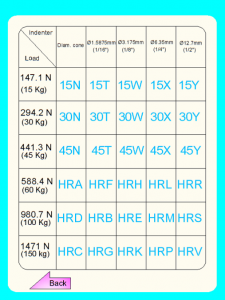

For example, the HRC scale (Rockwell C) is used for hardened steel and hard alloys, where the indenter is a diamond cone and the load applied is 150 kgf. The HRB scale (Rockwell B), on the other hand, is suitable for softer materials like brass or aluminum alloys, using a steel ball as the indenter with a load of 100 kgf. Superficial scales, such as HR15N, are used for thin materials or coatings, applying a lighter load of 15 kgf with a diamond cone indenter. The Rockwell scale is capable of adapting to a wide spectrum of testing circumstances due to these variations.

General Description of the GenRock NG-150 Series

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester is an automatic digital testing system created to measure metal hardness with exceptional accuracy. It operates based on the Rockwell scale, determining hardness by measuring the depth of penetration of an indenter under a large load, compared to the penetration caused by a preload.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester is an automatic digital testing system created to measure metal hardness with exceptional accuracy. It operates based on the Rockwell scale, determining hardness by measuring the depth of penetration of an indenter under a large load, compared to the penetration caused by a preload.

This system is available in variations according to Rockwell Regular and Superficial Testing Scales, allowing for compatibility with a broad selection of materials and testing requirements. Equipped with an easy-to-navigate operational menu, the GenRock NG-150 Series provides an easy-to-use testing experience. Its resolution of 0.001 guarantees the highest precision level available on the market, while the fully automated work table and user-friendly digital display optimize both accuracy and efficiency.

The GenRock NG-150 Series complies with the following international standards:

-

ASTM E18: This standard outlines the procedure for Rockwell hardness testing, assuring repeatability and accuracy in determining material hardness for metals. It is an internationally recognized benchmark in material testing for a broad range of industries.

-

EN ISO 6508: This European and international standard specifies the requirements for Rockwell and Rockwell Superficial hardness tests, including the testing method, acceptable tolerances, and calibration requirements.

-

GB/T230: This Chinese standard governs the Rockwell Hardness Testing method and is used extensively in the manufacturing and research sectors within China and beyond.

-

JIS Z2245: This Japanese Industrial Standard specifies the methods for Rockwell hardness testing, covering both regular and superficial scales.

Main Applications of the Advanced Rockwell Hardness Tester

As mentioned previously, the GenRock NG-150 Series is capable of testing the hardness of a wide selection of materials. These include, but are not limited to:

-

Chilled steel

-

Hardened and tempered steel

-

Annealed steel

-

Casting and malleable cast iron

-

Hard alloys

-

Hardened steel plates

-

Aluminum alloys

-

Bearing steel

Main Functions and Features of the GenRock NG-150 Series

Now, lets go over main functions and features. An innovative design of the GenRock NG-150 Series focuses on precision, speed, and ease of use. Among its key features are:

-

Rockwell Regular and Superficial Scale Testing: The system supports a broad range of Rockwell scales, allowing compatibility with diverse materials and testing requirements.

-

Conversion Scale Support: It offers smooth relative conversions between different scales, such as HRC, HRB, and others, streamlining material comparison and quality analysis.

-

Arc Correction Function: This feature improves accuracy by compensating for arc effects during testing, resulting in consistent and reliable results even with curved samples.

-

Dynamic Touchscreen Display: The intuitive interface provides real-time functionality, including dynamic visualization of the working table’s movements and operations, simplifying the testing process.

-

Fast Indentation Cycle: Engineered for efficiency, the system completes the full testing cycle—loading, dwell time, unloading, and displaying the hardness value—quickly and accurately.

-

One-Touch Operation: Operators can execute the entire specimen testing process with a single touch, including automatic homing for added convenience.

-

Comprehensive Data Management: Integrated data storage allows automatic calculation of maximum, minimum, and average hardness values. The results can be printed directly or transferred to a computer using the RS232 interface, facilitating easy documentation and analysis.

Technical Specifications of the GenRock NG-150 Series

Next, lets move on to our device’s technical specifications. In this section, we will take a closer look at its features and capabilities.

Next, lets move on to our device’s technical specifications. In this section, we will take a closer look at its features and capabilities.

-

Model: RockGen TWIN DGEN

-

Initial Test Force: 3kgf (29.4N) and 10kgf (98N)

-

Total Test Force:

-

15kgf (147.1N)

-

30kgf (294.2N)

-

45kgf (441.3N)

-

60kgf (588.4N)

-

100kgf (980.7N)

-

150kgf (1471N)

-

-

Indenter Options:

-

Diamond Rockwell indenter

-

ф1.588mm ball indenter

-

-

Operation: Fully automatic loading, dwell, and unloading cycles with automatic test table rising, homing, and one-key completion.

-

Hardness Reading: Touchscreen interface for real-time results.

-

Supported Test Scales: Extensive range including HRA, HRB, HRC, HRD, HRF, HR15N, HR30N, HR45T, and others.

-

Conversion Scales: HV, HK, HBW, and Rockwell scales for enhanced flexibility.

-

Data Management:

-

Built-in printer for immediate results.

-

RS232 interface for easy data transfer to a computer.

-

-

Resolution: 0.1HR with an adjustable dwell time of 0–99 seconds.

-

Testing Space: 320mm (12.6″) height and 150mm (5.9″) depth.

-

Power Supply: AC110V or AC220V, 50Hz.

-

Standards Compliance: ISO 6508, ASTM E-18, JIS Z2245, GB/T 230.2.

-

Dimensions and Weight:

-

Machine: 21.1x13x35 inches (535x330x890mm)

-

Packed: 32.3×18.1×46 inches (820x460x1170mm)

-

Net Weight: 176 lbs (80kg)

-

Gross Weight: 220 lbs (100kg)

-

Why the GenRock NG-150 Series is the Ideal Choice for Hardness Testing

In summary, the GenRock NG-150 Series – Advanced Rockwell Hardness Tester stands as a benchmark for precision, efficiency, and reliability in hardness testing. Its advanced features, compliance with international standards, and ability to test an array of materials make it an invaluable instrument for industries requiring accurate material analysis.

Our tester is particularly beneficial for industries such as automotive, aerospace, manufacturing, and research. Professionals in these fields rely on the GenRock NG-150 Series for its flexibility, user-friendly operation, and outstanding accuracy to verify that their materials meet performance and safety standards.

At NextGen Material Testing, we are committed to helping you select the right equipment for your specific needs. With years of experience and expertise, we can provide solutions customized to meet your industry demands.

If you have questions or need further information, feel free to contact us directly or request an online quote. We are here to help you find the right solution for your testing needs. Let us help you achieve remarkable results with the GenRock NG-150 Series and beyond.