The variety of elastomers, rubbers, and plastics available enables designers and manufacturers to make the best possible choice of material for new products. The hardness of such materials ensures reliability and wear resistance, while ductility is essential for functionality. Accurate hardness measurements require the right equipment to provide reliable measurement results. NextGen’s Digi Test II & Barofix 4 entering device are the perfect solution for this test. This device provides accurate results and is easy to use thanks to its automated measurement.

Hardness measurements are available in the ranges of all Shore scales (virtually all materials except metals) commonly used in the United States and the IRHD scale, which is popular in Europe. The device’s advantages include the ability to measure the hardness of convex and concave samples. In addition, it has a unique VLRH (Very Low Rubber Hardness) test scale, which is designed specifically to provide accurate results for ultra-soft materials (such as foam, sponge rubber, silicone, etc.). In addition, it is the only device on the market that allows you to measure the hysteresis of rubbers and plastics in an automated mode. Let’s take a closer look at what hysteresis is and what knowledge of the hysteresis of rubber, plastics, and other elastomers can provide.

Manifestations of Elastic Hysteresis

The effect of elastic hysteresis is manifested in the difference between the tensile and elastic energy. That is, the energy required to deform the material may be greater than the energy released when the external stress is removed. In this process, the material absorbs part of the energy and dissipates as heat. The geometric manifestation of hysteresis can be the length of a rubber band stretched under the weight: with increasing weight, the length gradually increases and decreases with decreasing weight. But the length remains slightly longer when the weight decreases than when the weight increases. It looks like the ribbon has a memory of its previous states. This factor characterizes the viscoelastic characteristics of rubber and plastics.

The understanding of hysteresis is very important for rational material selection and, in some cases, for ongoing product quality control. For example, in the production of memory mattresses, elastomers with a high hysteresis value, such as polyurethane sponge, are used. Such orthopedic mattresses seem to adapt to the human body and slowly return to their original shape when a person gets up from it, which looks like the mattress’s “memory.” Here we understand that the value of the material’s hysteresis will depend on the time interval between the change in load and the acquisition of data on the geometric parameters of the material. Consequently, the key factors for obtaining reliable hysteresis data are the automatic measurement and the use of several cycles of measurement, consisting of increasing and decreasing the gradual load on the material.

The hysteresis of the tire rubber determines the resistance to movement on the road. In fact, the higher the rubber hysteresis, the greater the energy loss. In addition to reducing the vehicle’s fuel efficiency, it also affects the wear resistance of the wheel coating and traction properties. But high rubber hysteresis also contributes to the shock absorption properties of wheel tires. By determining hysteresis data, tire manufacturers are trying to find a balance between driving resistance and rubber wear resistance – to provide high-quality, long-lasting tires with minimal fuel consumption and maximum user comfort. Of course, solving such a complex problem is based on many other factors, such as the shape of the tire surface, vehicle load, average driving speed, road and temperature conditions, tire air pressure, and many others.

Rubber hysteresis is important for O-rings because it affects their behaviour during deformation and tension. If the rubber has a high level of hysteresis, it can cause the O-rings to wear out faster and lose their sealing ability.

So even from this brief overview, we can see that knowledge of material hysteresis can give manufacturers important information to improve the quality of new products or maintain a consistent level of quality in current production. Therefore, the reliability of the hardness test data obtained from the samples becomes a key factor.

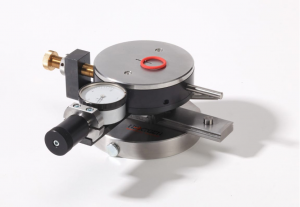

Barofix 4: Automatic Sample Centering Ensures Reliable Data

As mentioned above, the accuracy of rubber and plastic hardness measurement with the Digitest II hardness tester is ensured, among other factors, by the automatic operation of the device. However, when comparing the results of hardness measurements obtained even with such modern and accurate devices as the Digitest II, you may still encounter discrepancies. These can, of course, be due to product defects, but there is another source of error: operator mistake. This is especially true for concave and convex samples, such as O-rings. A small inaccuracy in the position of the ring under the indenter of the hardness tester can significantly affect the measurement result, i.e. lead to discrepancies that have no relation to product defects.

To minimize such operator influence on the measurement procedure, NextGen offers an effective solution. The Barofix 4 device, which can be added to the standard equipment of the Digitest II measuring system. It is designed to quickly and automatically centre the rings to be measured for hardness exactly under the indenter. This is achieved with the help of Barofix 4 optical detection and a movable measuring table with a length of 120 mm and a stroke length of 90 mm. It allows multiple ring hardness sequential measurements in two locations of each ring point in one operation in automatic mode. The thickness of the rings can range from 0.6 mm to 10 mm.

The Barofix 4 also has the ability to measure the thickness and height of the sample, which can be an additional controlling factor during the measurements. It is used in conjunction with a BS 09 test stand with an IRHD M or Micro Shore A measuring head.

The Barofix 4 also has the ability to measure the thickness and height of the sample, which can be an additional controlling factor during the measurements. It is used in conjunction with a BS 09 test stand with an IRHD M or Micro Shore A measuring head.

Thus, the Digitest II is a modern answer to the needs of rubber and plastic manufacturers in various production areas. With a set of unique features, including an ultra-precise VLRH scale, the ability to work with flat and non-flat samples, and a hysteresis measurement function. This system is indispensable in the relevant laboratories for new product development and ongoing quality control of production. In combination with the Barofix 4 autosampler, it provides reliable hardness test results for all rubber and plastic samples. These measurements have never been easier and more accurate than with the Digitest II and Barofix 4 tandem! And the fast hysteresis tests that are automatically available only with Digitest II equipment will give you an in-depth understanding of the material properties you are working with.

Contact NextGen Material Testing to always benefit from the reliability and quality of the German manufacturer of the world’s best rubber and plastic hardness testing equipment.