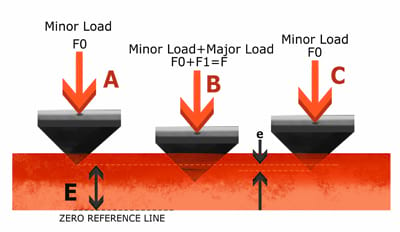

The Rockwell hardness test is a common method for determining the hardness of materials, particularly metals. It measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload. It is used frequently to assess the hardness and durability of steel, aluminum, and brass. This method is valued for its simplicity, speed, and ability to provide direct hardness readings.

The Rockwell hardness test involves pressing an indenter (a steel ball or diamond cone) into the material surface with a minor load, followed by a major load. The difference in penetration depth between the minor and major loads determines the hardness value, displayed directly on the machine. This test is standardized by several important standards to ensure consistency and accuracy. Rockwell hardness testing standards are ASTM E18 and ISO 6508. ASTM E18 provides detailed guidelines for testing metals, while ISO 6508 is the international standard for verifying the test’s applicability and consistency across different countries and industries.

There is an ever-increasing need for reliable and accurate equipment in the field of material testing. This need is critical for Rockwell hardness testing, as it directly influences the assessment of material properties. In this blog, we will present the best Rockwell hardness testers from NextGen Material Testing, which includes our top products and accessories that meet the highest standards of precision and reliability.

NG-RockGen DGEN Series – Digital Rockwell Hardness Tester

The first tester on our list is the NG-RockGen DGEN Series – Digital Rockwell Hardness Tester, which includes models for Rockwell Regular, Superficial, and TWIN scales. This advanced digital system measures metal hardness by evaluating the depth of penetration of an indenter under a large load, compared to a preload, in accordance with the Rockwell scale. This series complies with ASTM E18 standards.

Key Features and Capabilities of the DGEN Series

As a result of its high precision, user-friendly operation, and advanced digital capabilities, the NG-RockGen DGEN Series stands out as an excellent choice for a diverse selection of hardness testing applications.

-

High Precision and Accuracy: The system offers a resolution of 0.001, providing some of the highest accuracy available on the market

-

User-Friendly Digital Interface: Equipped with a large LCD display, the system removes human error by providing clear and direct hardness readings. In addition to being easy to use, the touchscreen interface provides smooth operation.

-

Automated Testing Procedures: The DGEN system automates the entire testing process, including indentation, reading, and resetting, which ensures high repeatability and reduces operator influence. Automatic loading, dwell time, and unloading provide greater consistency.

-

Versatile Scale Support: The series supports a comprehensive range of Rockwell scales, including HRA, HRB, HRC, HRD, HRF, and many others, as well as superficial scales such as HR15N, HR30N, and HR45T. The TWIN model combines both regular and superficial scales, offering unmatched versatility.

-

Data Management: The built-in printer and RS-232 port facilitate efficient data output and connectivity with computers for further analysis and record-keeping. The system also includes a data storage function that calculates and stores maximum, minimum, and average hardness values.\

Technical Specifications of the NG-RockGen DGEN Series

-

Indenter Types: Includes diamond Rockwell indenters and 1.588 mm ball indenters, suitable for different material hardness levels.

-

Loading Method: Features an automatic system for loading, dwelling, and unloading, ensuring consistent and precise testing.

-

Dwell Time: Adjustable dwell time from 1 to 60 seconds to meet different testing requirements.

-

Power Supply: Compatible with AC110V/60Hz or AC220V/50Hz power supplies.

-

Testing Space: The system provides a maximum specimen height of 8.5 inches (21.6 cm) and a throat depth of 15 cm, allowing for larger samples. Extension models are available for taller specimens.

-

Hardness Value Range: Covers a broad range of hardness values suitable for various materials, from HRA 20-88 to HR45T 12-72.

-

Dimensions and Weight: The instrument size is 18.15” x 6.2” x 26” / 45.7 x 15.7 x 66 cm with a net weight of 188 lbs (85 kg).

NG-RockGen – Standard Digital Series Rockwell Hardness Tester

The second tester on our list is the NG-RockGen Standard Digital Series Rockwell Hardness Tester, available in both manual and electronic models. This multipurpose device is designed to evaluate metal hardness by measuring the depth of penetration of an indenter under a large load, following the standards set by ASTM E18.

The second tester on our list is the NG-RockGen Standard Digital Series Rockwell Hardness Tester, available in both manual and electronic models. This multipurpose device is designed to evaluate metal hardness by measuring the depth of penetration of an indenter under a large load, following the standards set by ASTM E18.

Manual Model: RockGen-MR

The manual version of the NG-RockGen Standard Digital Rockwell Hardness Tester offers a straightforward and economical hardness testing solution. It is particularly valued for its simplicity and reliability, requiring no electrical power.

-

Durability and Design: The tester features a high-gloss, scratch-resistant surface so that it maintains its original appearance even after years of use. Its cast molding shell provides a stable structure resistant to minor damage.

-

Ease of Use: The dial gauge directly reads the hardness value, offering a sensitive response and accurate measurement. The manual loading wheel allows easy adjustment with three loading test forces, catering to different hardness scales. This model’s lack of electronic components reduces potential technical issues.

-

Applications: Suitable for a range of materials including chilled steel, hardened and tempered steel, annealed steel, castings, malleable casts, hard alloys, hardened steel plates, aluminum alloys, and bearing steel.

Electronic Model: RockGen-ER

Electronic Model: RockGen-ER

The electronic version, RockGen-ER, extends the manual model’s features with automated controls for higher accuracy and efficiency. It is ideal for environments requiring precise and repeatable hardness measurements.

-

Advanced Automation: This model automates test force load, dwell time, and load release, eliminating human error and providing consistent results. It is particularly useful for testing thin parts and metal surfaces.

-

User Interface and Precision: Like the manual model, it has a high-gloss, scratch-resistant surface and a robust cast shell. The electronic version, however, provides additional precision with automated features, making it ideally suited to detailed and high-volume testing.

-

Operational Efficiency: The dial gauge reads hardness values directly with high sensitivity. The machine operates with high accuracy and is designed for long-term use, backed by trusted after-sales technical support and lifetime product support from the manufacturer.

Key Features and Specifications of NG-RockGen – Standard Digital Series Rockwell Hardness Tester

Both models share several features:

-

Standards Compliance: Meets ASTM E18 standards, guaranteeing industry-wide acceptance and reliability.

-

Testing Capability: Capable of testing various Rockwell Regular Scales (HRA, HRB, HRC, etc.) and Superficial Scales (HR15N, HR30N, etc.).

-

Robust Construction: Built with a stable, damage-resistant cast shell.

-

Accessories: Equipped with a diamond Rockwell indenter, steel ball indenters, different testing tables, and standard hardness blocks, among others.

The manual model is ideal for basic, cost-effective testing needs, while the electronic model is suitable for more demanding applications requiring greater precision and automation. As a result of their combined efforts, they provide a complete solution for Rockwell hardness testing in a range of industrial and laboratory environments.

GenRock NG-150 Series – Advanced Rockwell Hardness Tester

Our third test device is the GenRock NG-150 Series – Advanced Rockwell Hardness Tester, also available in both manual and automatic models. This advanced system evaluates metal hardness by measuring the depth of penetration of an indenter under a large load, consistent with the Rockwell scale. It complies with ASTM E18, EN ISO 6508, and GB/T230 international standards.

Main Features and Capabilities of the GenRock NG-150 Series

The GenRock NG-150 Series stands out for its high degree of automation and user-friendly interface, making it suitable for both regular and superficial Rockwell hardness testing. It offers a number of features aimed at enhancing accuracy and efficiency in hardness testing processes.

-

Rockwell Regular and Superficial Scales: This tester supports a broad range of scales, including HRA, HRB, HRC, and more, as well as superficial scales like HR15N, HR30N, and HR45T.

-

Advanced Automation: The automatic model features a fully automated test cycle, including loading, dwell time, and unloading, which minimizes human error and enhances repeatability. The automatic rising and homing test table further simplifies operations.

-

Touch Screen Interface: The user-friendly touchscreen dynamically displays the working table functionality, enabling easy navigation through the operational menu. With this digital display, test parameters can be read and adjusted precisely.

-

Data Management: Equipped with a built-in printer and RS232 interface, the tester allows for efficient data storage, calculation of statistical metrics (maximum, minimum, average hardness values), and easy data transfer to a computer for further analysis.

Technical Specifications of the GenRock NG-150 Series

-

Indenter Types: Includes a diamond Rockwell indenter and a 1.588 mm ball indenter, suitable for different material hardness levels.

-

Loading Method: Automatic system for loading, dwelling, and unloading, ensuring consistency and precision.

-

Resolution: High resolution of 0.1 HR for accurate hardness readings.

-

Dwell Time: Adjustable dwell time from 0 to 99 seconds to accommodate various testing needs.

-

Power Supply: Operates on AC110V or AC220V, 50Hz.

-

Testing Space: Offers a generous test space of 320mm height by 150mm depth, accommodating larger specimens.

NG-150 Rockwell Hardness Tester Applications

The GenRock NG-150 Series is suitable for a broad range of materials, including chilled steel, hardened and tempered steel, annealed steel, castings, malleable cast iron, hard alloys, hardened steel plates, aluminum alloys, and bearing steel. Due to its robust design and comprehensive features, it is an outstanding choice for quality control, research, and development, as well as industrial applications that require precise hardness measurements.

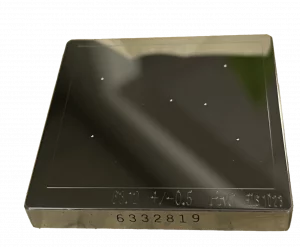

Hardness Test Blocks, Indenters, and Hardness Testing Accessories

NextGen Material Testing provides a wide selection of hardness test blocks and accessories required for accurate metal hardness testing. Certified Test Blocks are important reference materials for hardness testing precision. According to industry standards such as ASTM, it is necessary to use a test block every time when your testing apparatus is in operation and whenever there is a change in the indenter, anvil, or load force.

NextGen stocks the full range of Brinell and Rockwell test blocks. We also offer Knoop and Vickers micro blocks, as well as heavy-load Vickers blocks. Additionally, we supply a complete collection of certified indenters compatible with Rockwell, Brinell, Vickers, and Knoop testing methods. Our extensive selection of test anvils is designed to work with most hardness testers available on the market. For more information or to discuss your specific requirements, please contact us today.

Improving Hardness Testing with NextGen

The three Rockwell hardness testers offered by NextGen exemplify the highest level of precision and efficiency in hardness testing. The NG-RockGen DGEN Series features cutting-edge digital technology, automating the entire testing process and providing high precision and extensive data management capabilities, making it suitable for the most demanding applications. The GenRock NG-150 Series stands out with its advanced automation and adaptability, supporting a wide selection of Rockwell regular and superficial scales. Lastly, NG-RockGen Standard Digital Series provides both manual and electronic models that are robust and user-friendly, ideal for many industrial and laboratory settings.

In addition to these exceptional hardness testers, NextGen offers a comprehensive lineup of hardness test blocks, indenters, and accessories. These certified reference materials are a necessity for hardness testing accuracy. We offer a wide variety of test blocks, including Brinell, Rockwell, Knoop, and Vickers. Moreover, full range of certified indenters and test anvils compatible with most hardness testers is available. These accessories meet industry standards and are crucial for maintaining hardness testing equipment reliability.

At NextGen Material Testing we are dedicated to meeting all your material testing needs. Whether you need state-of-the-art hardness testers or basic accessories and consumables, we are here to help. Contact us directly or request an online quote, and let us provide you with the best solutions to your hardness testing requirements.