The field of material testing is changing entire industries. In our times, it is becoming increasingly popular and indispensable. Testing methods like hardness testing, tensile testing, and abrasion testing are extensively used to guarantee the quality of the tools and everyday items we rely on. For example, hardness testing provides assurance that kitchen knives stay sharp and durable. Tensile testing verifies seat belt strength and flexibility. Abrasion testing is important for products like flooring materials and outdoor equipment, confirming they can withstand wear and tear over time.

Nevertheless, many manufacturers hesitate to fully embrace material testing, fearing the substantial costs they assume it will incur. This perception is misleading. When implemented correctly, material testing can significantly reduce manufacturing costs by preventing defects, optimizing material use, and improving process efficiency.

Now, we will discuss how material testing can reduce manufacturing costs and address common challenges. Let us explore several aspects including the importance of material testing, reducing resource waste, strengthening supplier relationships, process efficiency and maintenance. Through practical examples and strategies, we will present the profound impact of material testing on manufacturing efficiency and cost reduction.

What is Material Testing?

Material testing is the process of measuring materials’ properties and performance to verify that they meet the necessary standards for their intended applications. It is an integral part of manufacturing, used to guarantee materials’ quality, durability, and safety. All types of materials, including metals, polymers, ceramics, and composites, can be tested. Material testing is performed by engineers, manufacturers, and quality control professionals.

By testing materials, it is possible to confirm that materials can withstand stresses and conditions in real-world applications, preventing failures and improving product reliability. This process not only improves safety and performance but also optimizes material use, reduces waste, and ultimately lowers manufacturing costs.

Material Testing Process in Manufacturing

There are several key stages that are involved in the material testing process in manufacturing:

-

Sample Preparation

Materials are cut or machined into test specimens with precise dimensions. Test specimens are shaped in standardized forms, such as rods, bars, or plates.

-

Conducting Tests

Different tests are performed to evaluate material properties, such as strength, hardness, impact resistance, and fatigue life. Specialized equipment applies forces or stresses to the material, and its response is measured, providing information about its behavior.

-

Data Analysis

The results of these tests are analyzed to determine if the material meets the required specifications and standards for its intended use. This analysis compares observed properties with benchmarks to assess material suitability, identifying any deviations that may impact the final product.

-

Reporting

Detailed reports are generated, providing insights into the material’s properties and performance. These reports include test data, interpretations, and conclusions, aiding material selection and product design.

Key Ways Material Testing Lowers Manufacturing Expenses

Despite the initial investment in material testing and the time required to conduct it, manufacturers can achieve substantial cost savings throughout the production process. Here are some of the main factors that contribute to cost reduction:

Reducing Material Waste

First of all, by testing materials, manufacturers can identify the most efficient ways to use them, thereby reducing waste to a significant extent. For instance, manufacturers can optimize the design stage to minimize cut-offs and scraps. This process involves precise planning and design adjustments that make the most of raw materials, reducing waste generated. Additionally, recycling rejected parts and scraps can further cut down on raw material costs, turning potential waste into valuable resources. For example, additive manufacturing (3D printing) can precisely control material usage, reducing waste compared to traditional subtractive methods.

Material testing also helps identify cheaper alternatives that meet the same performance criteria as more expensive materials. Using high-strength polymers instead of metals in certain applications can reduce material costs and lower processing energy requirements. This switch is beneficial in applications where polymers’ lighter weight provides additional advantages, such as in automotive parts where reducing vehicle weight improves fuel efficiency.

Implementing these strategies can save money. Optimizing material usage not only reduces raw materials costs but also minimizes the environmental impact by decreasing waste production. Identifying and using alternative materials that are less costly and energy-intensive further increases these benefits.

Strengthening Supplier Relationships

Regularly testing suppliers’ materials provides consistent quality, reducing production delays and rework. By continuously assessing supplier performance against predefined metrics, manufacturers can identify reliable suppliers who regularly provide high-quality materials. This practice allows manufacturers to negotiate better terms and reduce overall costs by minimizing the risk of defective materials entering the production line. Effective performance evaluation fosters stronger partnerships and increases supply chain reliability, as consistent quality from suppliers leads to smoother production processes and fewer interruptions.

Working closely with suppliers to develop new materials or improve existing ones can save money. For instance, a supplier might innovate a new alloy that is cheaper and more durable than current options. This will reduce part replacement frequency and associated downtime. The collaborative approach enhances product quality and performance but also accelerates time-to-market for new products, giving manufacturers a competitive edge. Joint innovation initiatives tap into both parties’ expertise and resources, fostering a culture of creativity and continuous improvement within the supply chain.

By leveraging strong supplier relationships, manufacturers can maintain a steady supply of high-quality materials, optimize costs, and drive innovation, in turn leading to a more efficient and cost-effective manufacturing process.

Process Efficiency and Maintenance

The third factor is that the materials are well-suited to the production processes, resulting in fewer adjustments and reduced downtime. When materials are tested and selected based on their machinability, tools can be worn less, extending equipment life. Using easier to machine materials can significantly reduce tool changes and machine maintenance. This leads to more efficient production runs and lower operational costs.

Regular material testing can inform maintenance schedules by identifying wear and tear before equipment failure. By monitoring the condition of materials and components, manufacturers can schedule timely maintenance, avoiding unexpected breakdowns that disrupt production. Regularly testing and monitoring cutting tools’ wear allows manufacturers to replace them before they fail.

Implementing a systematic approach to maintenance, such as Total Productive Maintenance (TPM), can further optimize process efficiency. TPM focuses on proactive and preventative maintenance to improve equipment reliability and extend lifespan, reducing overall maintenance costs. Additionally, the use of data-driven maintenance strategies, such as condition-based monitoring, can optimize maintenance activities by predicting failures and scheduling maintenance at the most convenient times.

Maximizing Benefits with Quality Testing Equipment

All efforts in material testing can be negated if conducted with outdated, unsuitable, or poor-quality equipment. Hence, it is crucial to use reliable equipment to be certain that material testing provides accurate and useful results to verify the quality of the test.

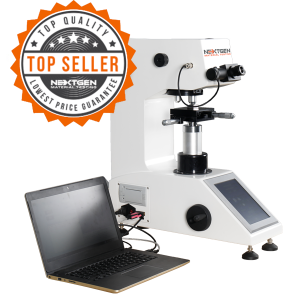

At NextGen Material Testing, we understand the importance of high-quality material testing equipment. We have supplied high-quality equipment to many satisfied customers over the years. Our offerings include maintenance services, necessary parts, accessories, consumables, and our readiness to provide other required services.

If you are searching for equipment that can reduce manufacturing costs, consider our equipment. Among our wide selection of tools across different categories, here are some bestsellers that could be exactly what you need.

NG-1000 – Micro Vickers and Knoop Hardness Tester

The NG-1000 – Micro Vickers and Knoop Hardness Tester is a cutting-edge device designed for precise and reliable hardness measurements, meeting ASTM E384, ASTM E92, and ISO 6507 standards. This advanced tester comes in three configurations: the Standard Digital Vickers Hardness Tester (AGEN), the Digital Vickers Hardness Tester (DGEN), and the Digital Vickers Hardness Tester with CCD Optical Analysis Software (CCD).

The NG-1000 – Micro Vickers and Knoop Hardness Tester is a cutting-edge device designed for precise and reliable hardness measurements, meeting ASTM E384, ASTM E92, and ISO 6507 standards. This advanced tester comes in three configurations: the Standard Digital Vickers Hardness Tester (AGEN), the Digital Vickers Hardness Tester (DGEN), and the Digital Vickers Hardness Tester with CCD Optical Analysis Software (CCD).

The tester features a motorized turret and optical cross rails for high guiding accuracy. Its advanced transmission system, equipped with a high transmission ratio worm gear, allows for stable and continuous lifting. The dual optical path allows for parallel use of the eyepiece and CCD camera, extending the optical system’s lifespan and simplifying the testing process.

The NG-1000 is fitted with a high-definition 8-inch touchscreen interface, complete with a digital eyepiece and built-in encoder. This allows for easy measurement of indentation diagonals and direct display of hardness values on the touch screen. The system also includes a hardness conversion function, enabling quick conversions from HV to other scales like HRA, HRB, HRC, and HBW.

With its Vickers (HV) and Knoop (HK) hardness testing capabilities, the NG-1000 can test a broad range of materials, from the softest to the hardest, using its included 10X and 40X lenses. It also features an OK/NG judgment function for quick pass/fail assessments. The NG-1000 is an ideal solution for industries requiring precise and dependable hardness testing.

GenDale – 9-Station Martindale Abrasion Tester

If you need abrasion testing equipment, we highly recommend the GenDale – 9-Station Martindale Abrasion Tester. This advanced tester meets several key standards, including ISO 12945-2, ASTM 4966 / 4970, BS EN 388, and ISO 20344.

GenDale is used to test shoe fabric, shoe lining, and other shoe-related materials. It can simultaneously test up to 9 specimens for abrasion, providing efficient and precise material assessment. The tester uses a complex back-and-forth rubbing motion to measure the fabric’s abrasion strength, determined by the number of cycles until a hole appears in the test area.

Ideal for footwear manufacturers, the textile industry, and quality assurance departments, the GenDale Martindale Abrasion Tester is a useful addition to any material testing process.

Achieving Maximum Manufacturing Efficiency with Material Testing

The role of material testing in reducing manufacturing costs can be attributed to several key factors. First of all, it reduces material waste by identifying the most efficient methods of using materials, optimizing design stages, and facilitating the recycling of rejected parts. Secondly, it promotes collaboration among suppliers by ensuring consistent material quality, reducing production delays, and fostering collaborative innovation. The third benefit is increased efficiency and maintenance by guaranteeing that materials are well-suited to production processes, extending the life of equipment, and enabling proactive maintenance.

Consider NextGen Material Testing. if you are seeking reliable equipment to reduce your manufacturing costs. Our products can be customized to meet your specific needs. For instance, our NG-1000 – Micro Vickers and Knoop Hardness Tester delivers precise hardness measurements and meets multiple industry standards. Additionally, our GenDale – 9-Station Martindale Abrasion Tester is ideal for testing different materials’ abrasion resistance. To learn more about these products, please visit their product pages.

At NextGen we are ready to assist you with all your material testing needs. With our high-quality equipment, you will be able to improve your manufacturing processes in a significant manner. Please do not hesitate to contact us directly or request an online quote for answers to all your questions.