Materials and components do not fail under perfectly infusing conditions—they fail when struck, dropped, or exposed to unpredictable forces. This is why understanding how a material behaves under sudden impact is one of the most important aspects of product development and quality assurance. Drop weight impact testing provides the data needed to assess structural integrity, safety margins, and compliance with international standards.

At NextGen, we recognize the growing demand for precise, repeatable, and flexible impact testing solutions. Throughout this article, we present our own contribution to this field—the NG-FWT1 and NG-FWT2 low-capacity vertical drop weight testers. Built for energy levels up to 2000 joules and engineered to exceed expectations in both performance and safety. Our blog will also focus on the general key role played by vertical drop weight testing in modern laboratories, particularly in the context of low- and medium-energy applications.

What Is Drop Weight Impact Testing?

Drop weight impact testing involves releasing a known mass from a set height to strike a sample. The test calculates the energy absorbed by the specimen at impact. This type of testing is important for assessing ductile-to-brittle transitions, material toughness, and component durability under accidental or repeated shock loads.

Compared to Charpy and Izod methods, which use swinging pendulums, vertical drop weight testers provide direct, axial loading. This makes them ideal for testing non-standard shapes, larger parts, or assemblies that cannot be tested in traditional impact fixtures. Energy levels typically range from less than 1 joule to several thousand joules, depending on the material and application.

A Drop Weight Tester: What Is It and Why Is Capacity Important?

A drop weight tester is a vertical testing system used to simulate impact conditions by dropping a calibrated mass from a controlled height onto a test specimen. These machines are equipped with rigid frames, guided lifting mechanisms, interchangeable weights, and advanced measurement electronics to ensure accurate impact force delivery and data acquisition.

Modern systems often include touchscreen interfaces, programmable controls, and automated test sequences. A built-in or external software platform records impact speed, fall height, energy dissipation, and failure behavior in real time. Unlike pendulum systems, which apply lateral force, drop weight testers apply a purely vertical load, offering better control and a more realistic simulation of accidental impacts or falls.

Low-capacity drop weight testers—defined as systems with energy ranges up to approximately 2000 joules—are especially important in industries where materials are expected to perform under low to medium energy conditions. These include plastic pipes, automotive panels, packaging materials, composite sheets, and lightweight structural components.

Introducing the NG-FWT1 and NG-FWT2 Drop Weight Testers

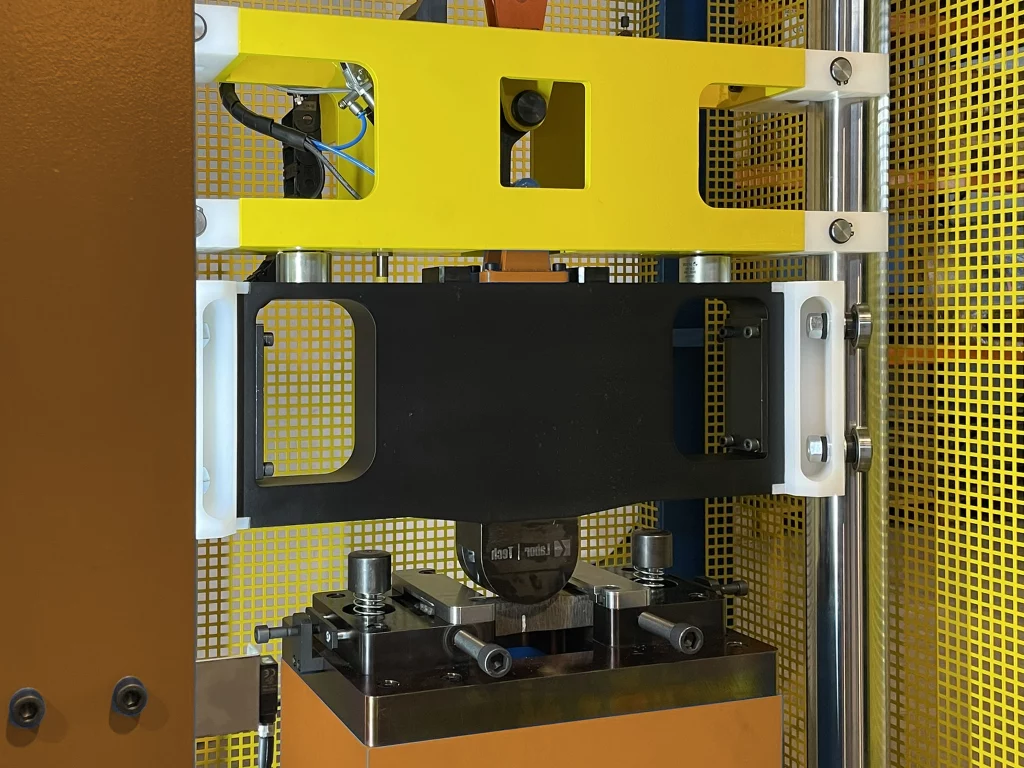

The NG-FWT1 and NG-FWT2 are part of NextGen’s FWT Series—precision-engineered drop weight testers developed for low- to medium-energy impact testing. With nominal energy capacities of up to 2000 joules, these systems simulate material and component behavior under a number of real-world conditions, including different drop heights, impact speeds, repeated strikes, collisions, and accidental falls.

The NG-FWT1 and NG-FWT2 are part of NextGen’s FWT Series—precision-engineered drop weight testers developed for low- to medium-energy impact testing. With nominal energy capacities of up to 2000 joules, these systems simulate material and component behavior under a number of real-world conditions, including different drop heights, impact speeds, repeated strikes, collisions, and accidental falls.

Both models support an array of test specimens and shapes, offering flexible configurations to meet diverse testing environments. Designed in full compliance with international standards such as EN, ISO, ASTM, GOST, BS, and NF, they provide dependable performance and meet regulatory requirements.

Each unit features a built-in touch-screen LCD monitor operating on DROPTest-S software or can be integrated with a standalone PC running DROPTest–BASIC software. These options allow users to meet specific testing and data management requirements while maintaining consistent accuracy and traceability.

NG-FWT1 and NG-FWT2 Drop Weight Testers Features

The NG-FWT1 and NG-FWT2 models are engineered to perform high-precision impact testing with a variety of technical and structural advantages. Their main features include:

-

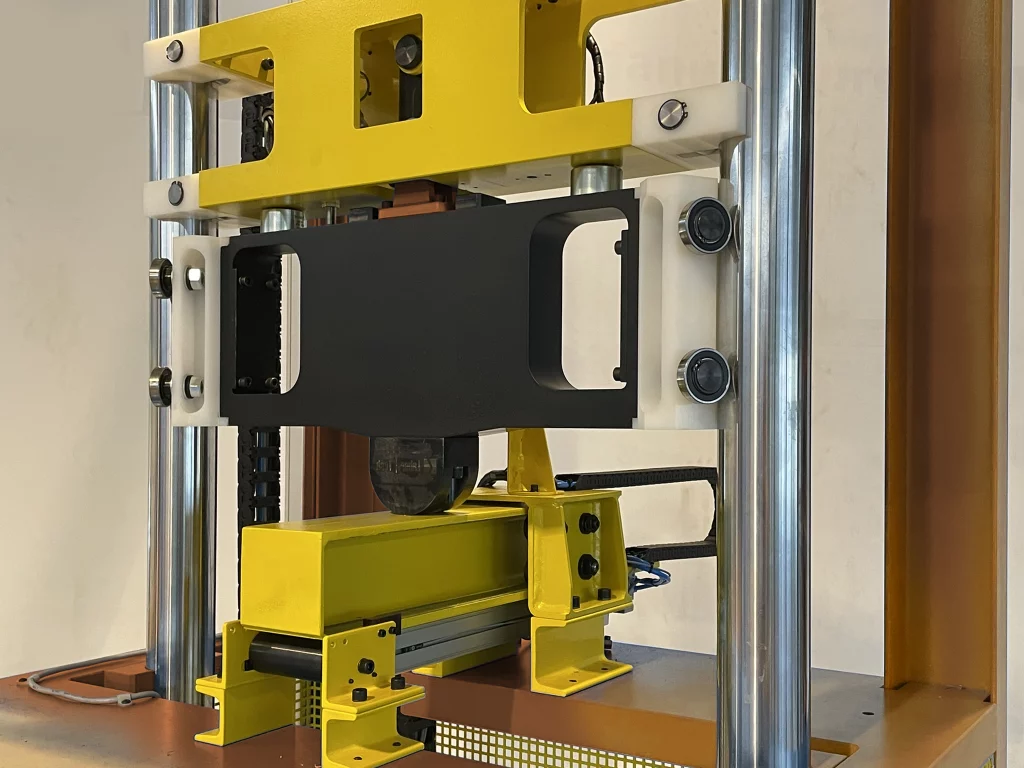

Robust Vertical Frames – High rigidity with resistance to dynamic interference for stable and maintenance-free operation.

-

SIEMENS PLC Control – Integrated with an LCD touchscreen to operate DROPTest-S software at the machine base.

-

Comprehensive Test Management – DROPTest-BASIC software offers full data evaluation and test control functions.

-

Automated Lifting System – Electronically controlled positioning for setting accurate energy levels and drop heights.

-

Advanced Measuring Electronics – Expandable with 4 MHz sampling rate for precise force and velocity measurements.

-

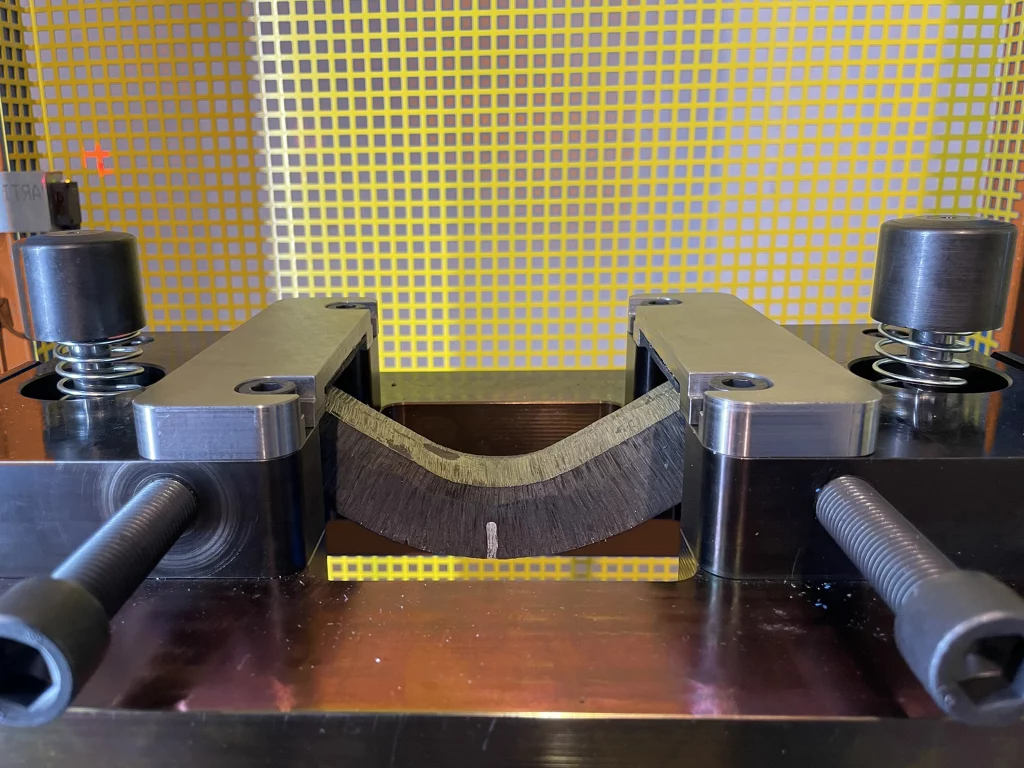

Instrumented Test Mandrel Identification – Automatic mandrel recognition per EN ISO 7500-1 and ASTM E4 accuracy standards.

-

Multi-Axis Expansion – Optional horizontal axis control and anti-reflection system for impact energy measurements from multiple directions.

-

Regulatory Compliance – Built in accordance with EC machinery directives and EN ISO 13850-SIL 1.

-

Calibrated Weights and Accreditation – Calibrated according to the Metrology Act 505/1990 and certified by an EN ISO / IEC 17025 laboratory.

-

Custom Test Preparations – Supports specialized test configurations for numerous materials and industry standards.

-

Extreme Condition Testing – Compatible with temperature chambers and high-temperature furnaces for diverse testing environments.

NG-FWT Drop Weight Tester Machine Control

The models are equipped with advanced control systems. Here is more information:

-

Centralized Control System – Ergonomic layout for user-friendly and accurate test setup and control.

-

Integrated Electronics & Safety Management – Rittal enclosure with machine control components; powered by Simatic S7 safety PLC with electromechanical interlocking and modular expansion.

-

Advanced Touchscreen Interface – Displays real-time values for impact speed, fall height, energy dissipation, and drop weight with high repeatability.

Security and Update Requirements

Engineered for maximum safety and compliance, the NG-FWT1 and NG-FWT2 integrate multiple certified safety layers and monitoring systems. The following are some of them:

-

Compliance with European Safety Standards – Fully aligned with Machinery Directives 89/392/EEC and 91/368/EEC.

-

Certified TÜV Safety Circuit – Embedded control and monitoring system certified by TÜV.

-

Advanced Safety Features – Built to EN ISO 13849-1/2 mechanical safety standards.

-

Dual-Layer Protection – All critical systems are protected with double-fuses safety mechanisms.

-

Continuous Safety Monitoring – Real-time system monitoring of safety guards and access doors with EN ISO 13850-SIL 1 compliance.

NG-FWT Drop Weight Tester Extensions

For extended functionality, NG-FWT systems offer optional upgrades:

-

Advanced Instrumentation Expansion – Force and impact trajectory measurement using 4 MHz electronics and SPEED unit, fully controlled via DROPTest-BASIC.

-

Temperature-Controlled Testing – An optional cooling system supports testing at temperatures as low as -90°C.

-

Robotic System Integration – Enables fully autonomous testing with robotic arms in high-throughput environments.

DROPTest Software Features

The DROPTest software suite is central to every NG-FWT system. This software has the following features:

-

Purpose-Built for Drop Weight Testing – Engineered for accurate and efficient test setup and execution.

-

Customizable Sample and Test Standards – Easily edit sample types, item names, and all test parameters.

-

Graphical Test Preparation – Step-by-step guidance with visual support for standardized procedures.

-

Real-Time Digital Display – Live values for impact force, velocity, and energy output during testing.

-

Comprehensive Data Management – All results are stored in a searchable database, filterable by date, order, and custom tags.

-

Built-In Calibration Mode – Includes full calibration tools to maintain test consistency and accuracy.

-

Automated Cooling Timing – Programmed thermal cycles in line with EN ISO 148-1 and ASTM E23 requirements.

-

Data Integration – Supports external device connectivity such as temperature sensors and chambers.

-

Multi-Language Support – Software interface is accessible in multiple languages for global usability.

-

Advanced Reporting & Export Options – Generate reports in PDF, export to CSV, MySQL, or MS SQL databases.

-

Unlimited Licensing – Software can be installed on any number of systems without licensing limitations.

NG-FWT Drop Weight Tester International Standards Compliance

The NG-FWT1 and NG-FWT2 drop weight testers were developed to comply with an impressive number of international testing standards. The following is a brief overview of each standard supported by the NG-FWT series:

ISO & EN ISO Standards

-

EN ISO 179-1 / ISO 179-1 – Specifies the method for determining the Charpy impact strength of plastic specimens using non-instrumented equipment.

-

EN ISO 148-1 – Defines procedures for Charpy pendulum impact testing on metallic materials.

-

ISO 179-2 – Covers instrumented impact testing for plastics to analyze force-time and energy-time characteristics.

-

ISO 180 – Specifies Izod-type impact testing methods for plastic materials.

-

ISO 03-2 – Relates to general standardization rules and classifications used in testing.

-

ISO 8256 – Provides methods for testing plastics by instrumented and non-instrumented falling weight impact tests.

-

EN ISO 6603-2 – Describes instrumented falling weight impact testing of plastic films and sheets.

-

ISO 7765-2 – Covers impact testing for plastic film and sheeting using the falling dart method.

-

EN ISO 179-1/-2 – Combines standard and instrumented impact tests on plastics for comprehensive energy analysis.

-

ISO 18352 – Specifies impact test methods for determining fracture behavior of materials under low temperature and high strain rate conditions.

ASTM Standards

-

ASTM D2444 – Falling weight impact resistance testing for thermoplastic pipe and tubing.

-

ASTM D256 – Defines procedures for Izod impact testing of plastics.

-

ASTM D3763 – Instrumented drop weight testing for plastic materials under high-speed impact.

-

ASTM D6110 – Charpy impact testing of unnotched and notched rigid plastic specimens.

-

ASTM D7136/D7136M-05 – Measurement of fiber-reinforced composite damage tolerance after drop weight impact.

-

ASTM D7192 – Provides methods for determining impact resistance of plastics at low temperatures using a drop weight tester.

-

ASTM E208 – Drop weight test for determining nil-ductility transition temperature (NDTT) of ferritic steels.

-

ASTM E23 – Standard for Charpy impact testing of metallic materials.

-

ASTM A370 – Defines mechanical testing methods for steel products, including drop weight testing.

-

ASTM F1614 – Measures cushioning materials’ compressive impact performance.

-

ASTM F2412 – Standard test methods for foot protection impact testing.

-

ASTM E436 – Drop weight testing for fracture appearance transition temperature and upper shelf energy of ferritic steels.

-

ASTM D5628 – Instrumented impact resistance testing of flat plastic specimens.

GOST Standards

-

GOST 9454-78 – Soviet-era standard for drop weight metal fracture resistance testing.

-

GOST 30456-97 – Specifies procedures for impact testing of plastics and composites.

DIN EN Standards

-

DIN EN ISO 12100 – Fundamental principles for machine safety and risk assessment.

-

DIN EN ISO 14120 – Specifies requirements for fixed and movable guards for machinery safety.

-

DIN EN 60204-1 ed.2 – Electrical equipment safety requirements for machinery.

-

EN 6038 – Aerospace series standard for testing impact resistance in materials and assemblies.

Aerospace Standards

-

Airbus AITM 1.0010 – Airbus test method for determining impact damage resistance in composite materials.

-

Boeing BSS 7260 – Boeing standard for impact resistance of aircraft materials and structures.

-

DIN 65561 – Aerospace guideline for assessing mechanical strength under impact and load conditions.

NG-FWT Drop Weight Testers Technical Specifications

| Technical Data | Units | NG-FWT 200VP | NG-FWT 400VP | NG-FWT 600VP | NG-FWT 800VP | NG-FWT 1000VP | NG-FWT 2000VP |

| Energy Range | J | 0.3 – 294 | 0.3 – 405 | 0.3 – 588 | 0.3 – 757 | 2.5 – 882 | 2.5 – 1814 |

| Impact Speed | m/s | 0.7-4.42 | 0.7-4.646 | 0.7-6.26 | 0.7-4.645 | 1-7.67 | 1-8.52 |

| Fall height range | mm | 25-1000 | 25-1100 | 25-2000 | 25-1100 | 25-3000 | 25-3700 |

| Position accuracy | mm | 0.5 | |||||

| Weights Dimensions | kg | 0.5-30 | 0.5-37.5 | 0.5-30 | 0.5-70 | 0.5-30 | 0.5-50 |

| Accuracy weights classes | % | According to OIML | |||||

| Weight | lbs/kg | 798/362 | 873/396 | 913/414 | 1098/498 | 1098/498 | 1358/616 |

| Color finish | RAL | 1015, 5015 | |||||

| Dimensions | |||||||

| Height | in/mm | 104″/2620 | 104″/2620 | 144″/3650 | 105″/2650 | 184″/4680 | 222″/5650 |

| Width | in/mm | 31.5″/800 | 31.5″/800 | 31.5″/800 | 31.5″/800 | 31.5″/800 | 35.5″/900 |

| Length | in/mm | 22.5″/570 | 22.5″/570 | 22.5″/570 | 22.5″/570 | 22.5″/570 | 26.5″/670 |

| Environmental conditions | |||||||

| Operating temperature | °C | 10 to 35 | |||||

| Storage Temperature | °C | -35 to 55 | |||||

| Working space humidity | % | < 90 | |||||

| Noise level | dB | < 65 | |||||

| Electrical Connection | |||||||

| Supply voltage | V | 230…240/50-60Hz | |||||

| Fuse | A | 16 | |||||

| Power rating (without accessories) | VA | 820 | 820 | 820 | 1000 | 1000 | 2000 |

A Trusted Solution for Accurate and Compliant Impact Testing

The NG-FWT1 and NG-FWT2 drop weight testers reflect NextGen’s commitment to quality, precision, and industry-wide compatibility. With advanced features, robust control systems, software flexibility, and compliance with an exceptional range of international standards, these systems are purpose-built for laboratories that require reliable and repeatable impact data.

Whether your goal is to verify product safety, meet regulatory benchmarks, or support research and development, our NG-FWT series delivers consistent results for an array of materials and testing conditions.

If you have questions or would like to explore the full capabilities of our drop weight impact testing solutions, please contact us directly or request a quote online. We are here to help you select the right material testing equipment specific to your technical and industry-specific needs.