Accurate hardness testing is a key requirement in metallic materials analysis. It provides valuable insights into a material’s resistance to deformation, wear, and long-term performance under stress. Whether assessing surface integrity or examining heat treatment effects, the ability to perform consistent and precise measurements is critical in ensuring both product quality and operational reliability.

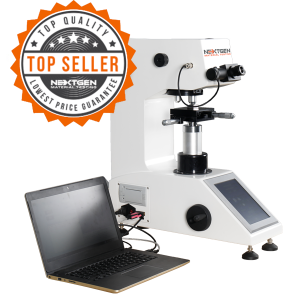

At NextGen, we fully understand the significance of dependable and efficient testing instruments in place. Our extensive experience in the field has shown that reliable test results are only possible when supported by high-quality, well-engineered equipment. With this in mind, we are pleased to introduce two of our most advanced Vickers hardness testing systems, carefully developed to support an array of industrial and research applications.

Before we explore the details of these solutions, it would be useful to first examine the Vickers hardness testers themselves. The following section will provide a detailed overview of these instruments, including their working principles, key benefits, and their role within today’s testing environment.

What is a Vickers Hardness Tester?

Vickers hardness testers are highly precise instruments used to measure solid materials’ hardness by measuring their resistance to surface deformation. Also known as a microhardness tester or diamond pyramid hardness tester, this device has an important role to play in laboratories and production environments where accuracy and repeatability are key factors for quality control and material characterization.

The testing process involves pressing a diamond-shaped indenter into the material surface under a specific load. The resulting square-shaped indentation is then measured using an optical system. The size of the indentation reflects the material’s hardness. Smaller impressions indicate higher hardness levels. The Vickers method is particularly valued for its ability to provide a single, continuous measurement scale across a broad load range, which allows users to test both extremely soft and very hard materials with the same instrument.

This tester is suitable for a broad spectrum of applications. It can be used on ferrous and non-ferrous metals such as steel, aluminum, and copper, as well as ceramics, thin coatings, surface-treated layers, and small precision components. Because it leaves only a minimal mark on the test surface, the method is also ideal for analyzing cross-sections or microstructures without radically altering the sample.

A Vickers hardness tester offers critical insights into a material’s resistance to wear, its durability under mechanical stress, and the effectiveness of surface treatments such as carburizing or nitriding. These insights help engineers and technicians confirm compliance with manufacturing standards, evaluate treatment processes, and guarantee product performance in demanding industrial environments.

Introducing NextGen’s Premier Vickers Hardness Testers

Our Vickers hardness testers have been engineered not only to provide accurate and repeatable results but also to optimize operator workflow, reduce human error, and support an extensive range of applications ranging from fine microstructure analyses to full-scale macro evaluations. This section introduces our two flagship solutions: the NG-1000 Series for micro Vickers and Knoop tests and the NG-5000 Series for macro Vickers tests.

NG-1000 Series – Micro Vickers and Knoop Hardness Tester

NG-1000 Series – Micro Vickers and Knoop Hardness Tester

The NG-1000 Series represents a comprehensive solution for micro Vickers and Knoop hardness testing. It is built to deliver high-resolution results with minimal user input, making it ideal for laboratories that require precision and productivity. This series is available in multiple configurations—AGEN, DGEN, CCD, SEMI, and FA—to suit different operational needs, from basic digital readout systems to fully automated testing workflows.

Each tester within the NG-1000 Series is equipped with a motorized turret that automatically shifts between the objective lenses and the indenter. This feature significantly reduces the testing time and minimizes manual positioning errors. The optical system allows the operator to observe and measure indentations at magnifications up to 600x, supporting precise evaluation of very fine features, coatings, and surface treatments.

What sets this system apart is its ability to conduct both Vickers and Knoop tests with ease, making it ideal for soft metals, ceramics, coatings, and microstructures that demand a gentle but accurate approach. The NG-1000CCD configuration integrates a high-resolution CCD camera along with VickSoft software, which automates the measurement process and generates statistical reports. Users can sort results by part or sample ID, export them in different formats, and even map a series of indentations across a cross-section to evaluate surface treatment depths.

NG-5000 Series – Macro Vickers Hardness Tester

The NG-5000 Series is specifically developed for macro Vickers testing, where higher test forces and larger sample sizes are involved. This system is suitable for evaluating hard metals, thicker coatings, and bulk components that require a more robust assessment. As with the NG-1000, this series includes multiple models, each offering increasing levels of automation and data processing—from the manually operated AGEN version to the fully automatic FA system.

One of the key strengths of the NG-5000 Series lies in its flexibility in handling an array of load settings, extending from 300g up to 50kg. This makes it appropriate for a broad number of applications, such as measuring hardness gradients in treated steels, assessing structural homogeneity in forgings, or verifying mechanical properties in castings. The system features solid construction with a reinforced test frame, allowing stable operation even under high loads without compromising accuracy.

One of the key strengths of the NG-5000 Series lies in its flexibility in handling an array of load settings, extending from 300g up to 50kg. This makes it appropriate for a broad number of applications, such as measuring hardness gradients in treated steels, assessing structural homogeneity in forgings, or verifying mechanical properties in castings. The system features solid construction with a reinforced test frame, allowing stable operation even under high loads without compromising accuracy.

Digital models within this series include an internal encoder that transmits measurements directly to the system, enabling fast calculation and display of hardness values on a large LCD screen. The NG-5000CCD model includes a camera and software package that mirrors the automation capabilities found in the NG-1000CCD while also offering enhanced measurement depth and support for thicker test pieces.

Unlike the NG-1000 Series, which focuses on micro-level surface evaluation, the NG-5000 Series excels at bulk material testing and deep analysis of mechanical properties. In laboratories where both macro and microhardness testing is required, these two systems can easily complement one another. The macro tester can be used for the initial assessment of structural consistency and general hardness, while the micro tester can perform detailed surface and edge analyses with high resolution.

Who Can Benefit From Using NextGen’s Vickers Hardness Testers

The adaptability of NextGen’s Vickers hardness testers to both micro and macro testing makes them highly valuable in environments where accuracy, consistency, and compliance with international standards are essential. We will take a look at who would benefit from the use of these devices:

Quality Control Laboratories

Facilities responsible for verifying production materials’ consistency rely on hardness testing as a core part of their inspection routines. Both the NG-1000 and NG-5000 Series help ensure that components meet specifications, detect inconsistencies in heat treatment, and confirm surface treatments.

Research and Development Centers

R&D teams benefit from the precision and flexibility of Vickers hardness testers when analyzing new alloys, composite materials, or surface coatings. The ability to perform both micro and macro evaluations allows researchers to study structural changes at different scales and validate results with reliable data.

Aerospace and Automotive Manufacturers

In high-performance industries where safety and endurance are non-negotiable, hardness testing is used to monitor treatment effects on metals and coatings. NextGen’s systems support the testing of critical components such as gears, engine parts, and turbine blades by providing accurate readings even in complex geometries.

Heat Treatment and Surface Engineering Facilities

Companies specializing in carburizing, nitriding, or other surface treatments depend on microhardness testing to confirm the depth and effectiveness of hardened layers. The NG-1000 Series, in particular, is ideal for case-depth profiling and verification of treated zones with minimal damage to the sample.

Universities and Technical Institutions

Educational and research institutions use Vickers hardness testers to train students, conduct material studies, and perform standard experiments. The intuitive software, automated capabilities, and multi-scale load options make NextGen systems well-suited to academic environments.

The Right Solution for Reliable Hardness Testing

Choosing the correct hardness testing system is essential for ensuring the accuracy of your material evaluations, the efficiency of your workflow, and the reliability of your results. Whether your focus is on delicate surface analysis or deep structural testing, NextGen’s NG-1000 and NG-5000 Series provide comprehensive solutions that meet research and industry demands.

These systems combine user-friendly operation with advanced functionality, allowing operators to work with confidence in different types of testing situations. From detailed microstructure examination to robust macro testing of treated components, NextGen’s Vickers hardness testers deliver precision, repeatability, and compliance with recognized international standards.

Should you have additional questions about this product or would like to learn more, please request an online quote or contact us directly. If you would like assistance in selecting the right material-testing equipment for your specific application, we are here to help.