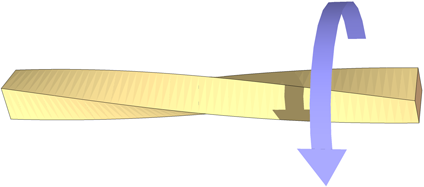

Torsion testing, a method in materials science, determines how materials respond to twisting forces. This testing measures properties such as shear strength and modulus by applying rotational stress. For instance, understanding a material’s torsional characteristics is crucial in the design of components like drive shafts and springs, which regularly experience twisting forces during operation.

The purpose of this article is to provide a detailed look into GenTor Horizontal Torsion Tester. We will discuss the product’s key features, technical specifications, and provide information on who can benefit the most from incorporating this equipment into their testing processes.

Getting to Know Torsion Testing Equipment

To begin with, it is necessary to understand the type of testers it belongs to, namely torsion testers and horizontal torsion testers.

What is a Torsion Tester?

A torsion tester is a mechanical device used to evaluate how materials respond to twisting or rotational forces. This type of tester measures properties such as shear strength, torsional rigidity, and torsion angle to determine a material’s performance under torsional stress. Torsion testers are crucial in verifying that materials and components can withstand real-world rotational loads.

What is a Horizontal Torsion Tester?

There are horizontal torsion testers, which are a specific type of torsion testing machine where the specimen is positioned horizontally during testing. This design provides greater stability, especially when working with long specimens or components naturally oriented horizontally. Horizontal torsion testers are particularly suitable for applications where space constraints make vertical testers less practical.

How Do Torsion Testers Work?

Torsion testers operate by securely holding a specimen at both ends. One end remains fixed, while the other is subjected to controlled rotational forces. The tester measures the torque applied and the resulting angular deformation or twist of the specimen. These measurements provide data to calculate the material’s shear strength and torsional modulus.

Horizontal torsion testers allow easier loading and alignment of longer specimens. Additionally, the horizontal setup reduces gravity influence, which can impact the accuracy of vertical testers in certain testing scenarios.

What Are They Used For?

Torsion testers are commonly used in many industries to assess materials and components’ performance under twisting or rotational forces. They are used to guarantee that critical parts such as drive shafts, axles, springs, fasteners, and surgical instruments meet performance and safety requirements.

Applications include quality control, research and development, and product validation. For instance, automotive manufacturers use torsion testers to evaluate drive shaft durability, while the aerospace industry relies on them to test components like wing spars and control rods that experience torsional loads during flight.

Materials Tested with Torsion Testers

Torsion testers evaluate a broad range of materials. Commonly tested materials include:

-

Metals: Such as steel, aluminum, and titanium, used in structural and mechanical applications.

-

Polymers: Including plastics and rubber, often used in flexible components.

-

Composites: Materials made from two or more constituent materials with different properties, often used in lightweight, high-strength applications.

-

Wires and Cables: Used to evaluate electrical wiring and mechanical cables’ torsional durability.

Introducing the GenTor Horizontal Torsion Tester

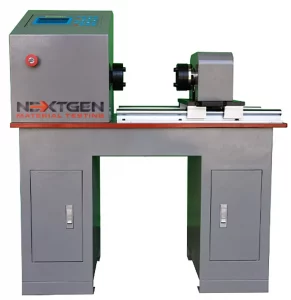

The GenTor Torsion Tester is a modern computerized machine specifically created for torsion testing of a range of materials, including metals, non-metals, composite materials, and component parts. This testing machine features a horizontal-type load frame with high stiffness, providing precise and consistent test results.

Equipped with a high-precision torque sensor, the GenTor Torsion Tester measures torque applied to a specimen with exceptional accuracy. Additionally, the machine includes a high-precision torsion angle meter, allowing for precise measurement of the torsion angle during testing.

With its multiple control modes, the machine offers maximum flexibility for testing different materials under a range of conditions. Computerized real-time display of testing data and curves provides users with a detailed and comprehensive view of test results.

Working Principle of the GenTor Torsion Tester

The GenTor Torsion Tester includes a host machine, a torsion angle measuring device, a dedicated measuring system, and a computer. When a test is initiated, the computer sends instructions to the control unit, which drives the servo motor to operate. The moving grip rotates along with the reducer, causing the sample to experience torque. This torque is then transmitted to the fixed grip, and the torque sensor detects it, sending a signal to the amplifying circuit of the control unit.

The amplified signal is converted from analog to digital and displayed in real time on the computer screen. The torque angle is measured using an optical encoder, providing precise torsion angle measurements during testing.

The machine’s computer-controlled testing software allows users to control numerous parameters, such as torque control, torsion angle control, and deformation control. The software enables the setting of testing speeds and other control parameters while displaying real-time data, including torque, yield torque, maximum torque, torque strength, angle, and torsion speed.

Testing Software for the GenTor Tester

The GenTor Horizontal Torsion Tester is equipped with highly advanced testing software designed for precise and efficient control. The software features closed-loop control, which supports multiple testing modes, including constant rotation angle, constant torque control, target hold, and hold time. This flexibility allows for customized testing procedures that can be adjusted to suit a broad spectrum of testing needs.

The software also enables real-time monitoring and visualization of testing data, so that users have a clear understanding of test results as they occur. This makes the GenTor Torsion Tester an ideal choice for laboratories and facilities that require accurate, data-driven insights for torsion testing.

Industry Standards for the GenTor Horizontal Torsion Tester

GenTor Torsion Tester is designed to meet the following international standards that govern the testing of torsion:

-

ASTM A938: This standard outlines the method for torsion testing of wire, providing guidelines for measuring properties like ultimate torsional strength and ductility.

-

ASTM E143: Describes the method for torsion testing of metallic materials to determine mechanical properties such as shear modulus.

-

ISO 7800: It specifies the method for torsion testing metallic wire, describing procedures for measuring twists and guaranteeing consistent results.

-

GB10128: This standard specifies the method for torsion testing metallic materials, including the procedure for evaluating mechanical properties under torsional stress.

Technical Overview of the GenTor Horizontal Torsion Tester

The GenTor Horizontal Torsion Tester offers a range of technical specifications. Take a closer look at them to gain a better understanding of what this machine can accomplish:

-

Maximum Torque Capacity: 200 N.m, 500 N.m, 1,000 N.m, 2,000 N.m, 6,000 N.m

-

Torque Measuring Range: 4-200 N.m, 10-500 N.m, 20-1,000 N.m, 40-2,000 N.m, 24-6,000 N.m

-

Distance Between Grips: 0-500 mm, up to 1,000 mm for higher capacities

-

Minimum Torque Reading: 0.01 N.m

-

Relative Error of Torque: ≤±1.0% (from 20% of each full range)

-

Relative Repeatability Error of Torque: ≤±1.0%

-

Maximum Torsion Angle Reading: 9,999.9°

-

Resolution of Torque Angle: 0.1°

-

Horizontal Opening Without Grips: 675 mm

-

Maximum Test Speed: 1.5 RPM

-

Torsion Speed: 0.1-1,000°/min (stepless)

Who Will Benefit from the GenTor Horizontal Torsion Tester

Knowing the potential applications of the GenTor Horizontal Torsion Tester is key to determining its value in a broad range of industries. This equipment is engineered to meet the needs of professionals in different sectors by providing accurate and reliable torsion testing results. Here are some of the key beneficiaries of this advanced testing machine and how it supports their specific needs:

Automotive Industry

In the automotive sector, the GenTor Horizontal Torsion Tester evaluates critical components such as drive shafts, axles, and steering mechanisms. Accurate torsion testing guarantees that these parts withstand real-world operational stresses. For example, a tested drive shaft can resist sudden twists during acceleration, preventing premature failure and improving vehicle safety and performance.

Aerospace Industry

In aerospace, components like wing spars, control rods, and fasteners undergo torsional loads during flight. The NextGen GenTor tester helps to verify that these parts have sufficient torsional strength. A properly tested control rod can endure high-altitude turbulence without losing structural integrity, reducing safety risks during flight.

Manufacturing Sector

In manufacturing, torsion testers are essential for the quality control of springs, fasteners, and tools. Torsion testing, for example, confirms that industrial machinery springs perform consistently under repeated twisting, preventing equipment malfunctions or breakdowns.

Medical Device Industry

Medical devices, including surgical instruments and implants, often experience torsional forces during use. The NextGen GenTor tester verifies the durability and strength of these components. For instance, a tested orthopedic screw can maintain its shape and stability during surgical procedures, improving patient outcomes.

Research and Development

Research institutions use torsion testers to study the mechanical properties of new materials and develop innovative solutions. Researchers can test the torsional strength of a newly developed composite material to determine its potential applications in lightweight, high-strength structures.

Driving Quality and Innovation with Reliable Torsion Testing

The GenTor Horizontal Torsion Tester stands out as an excellent addition to any testing laboratory or facility where the need to perform accurate torsion tests is a necessity. By providing reliable data on how materials perform under twisting forces, this machine supports better decision-making in design, quality control, and research. With its advanced technical features and ability to process different types of materials and testing scenarios, the GenTor is built to produce accurate results in a variety of settings.

Whether you are in the automotive sector verifying the safety of drive shafts, in the aerospace industry testing the integrity of structural components, or part of a manufacturing or research team assessing material properties, the GenTor Horizontal Torsion Tester can meet your testing requirements with its performance and accuracy.

We are here to help you. If you have questions regarding our product or need additional information, please contact us directly or request an online quote. It is our goal to make your material testing better and more effective by providing you with the best services available.