Consumables for material testing are expendable items used in the preparation, testing, and analysis of materials. They include items such as indenters, anvils, test blocks, grips, fixtures, extensometers, cutting blades, mounting powders, resins, grinding papers, polishing cloths, and etchants. These consumables are necessary for verifying the accuracy and reliability of different material examination methods, including hardness testing, tensile testing, and metallography.

Unfortunately, consumables do not always receive the attention they deserve. Sometimes they are used until the laboratory machine fails due to consumable degradation. In other cases, items wear out quickly and need constant replacement or even the newest products can yield incorrect test results.

The key to a successful material testing process is to choose the right consumables for material analysis. Inappropriate supplies cost too much-excessive spending, inaccurate test results, damaged samples, or broken testers. Throughout this blog, we will cover the most important aspects of selecting the right resources for testing, allowing you to make an informed and effective decision.

The Importance of Proper Consumables for Material Testing

Many factors highlight the importance of proper consumables in material testing. Just a few of them include accuracy, equipment longevity, cost efficiency, and regulatory compliance. Let us take a closer look at these factors to get a better understanding of how important it is to use the correct products on a daily basis.

Accuracy and Reliability

High-quality consumables are vital to accurate test results. For instance, using the correct indenter for hardness measurements ensures the indentation properly reflects the material’s hardness. In tensile testing, appropriate grips and fixtures hold the material securely, preventing slippage and providing exact measurements of tensile strength and elongation. In metallography, using the right cutting blades, mounting powders, and polishing cloths is crucial for preparing samples that represent the material’s microstructure.

Avoiding Equipment Damage

Using substandard or inappropriate consumables can damage expensive testing equipment. For example, a poorly manufactured cutting blade can lead to uneven cuts or damage to the cutting machine. In tensile testing, incorrect grips can cause excessive wear on the measuring machine or even break it if the material slips or the grips fail.

Cost Efficiency

While high-quality materials may have a higher initial cost, they save significant costs in the long run. Proper consumables reduce repeated tests, saving time and resources. They also minimize equipment damage risk and the associated repair or replacement costs. Obtaining accurate and reliable test results helps make informed decisions and prevent costly errors in material selection and application.

Compliance with Standards

In many industries, material testing is governed by strict standards and regulations. Proper consumables make certain that tests comply with these standards. By way of example, construction projects must meet regulatory requirements to ensure structure safety and performance. Using compliant consumables helps achieve the necessary quality and safety standards, avoiding legal liabilities and increasing the credibility of the research process.

How to Select the Correct Consumables for Material Testing

There is a huge selection of supplies for all kinds of testing. Each type often requires a unique approach and verification steps, but the basic steps are generally the same. The following information will help you comprehend how to choose the correct consumables by using some types of items as examples.

Performance Testing

Conducting performance tests using known reference materials is crucial to verifying consumable quality. For instance, regularly testing a set of certified test blocks with your hardness tester guarantees that the indenters, anvils, and test blocks produce accurate results. Thus, it is possible to identify deviations that may indicate a problem with the consumables.

Visual and Microscopic Inspection

Regular visual and microscopic inspection of items detects signs of wear, deformation, or damage. For example, inspecting the tip of an indenter under a microscope can reveal wear that might not be visible to the naked eye.

Regular Calibration and Verification

Regular calibration and verification of testing equipment with certified reference materials ensures that both equipment and consumables function correctly. For tensile testing, this involves using certified grips and fixtures and periodically verifying their performance with standardized materials.

Chemical and Physical Analysis

For consumables like mounting resins and polishing cloths used in metallography, chemical and physical analyses can verify that they meet the required specifications. This may include checking the chemical composition of resins or the abrasiveness of polishing cloths to make sure they provide the desired finish without introducing contaminants.

Consistency and Repeatability

A reliable material test always requires using materials that are consistent and repeatable, crucial to achieving a reliable result. Items such as grinding papers and diamond suspensions should consistently produce the same results across multiple uses. Testing these consumables under controlled conditions and comparing the results is an important step in guaranteeing their performance.

The Supplier’s Role in Choosing Consumables

There are many different ways of making sure that the correct consumables are being used. However, verifying all components through these methods can be very costly and time-consuming. Therefore, finding a reliable supplier is the best way to be certain of the quality of all the products you use.

NextGen Material Testing is a well-known company that provides all necessary services and products, including laboratory equipment and accessories. Our inventory of consumables is large enough to meet all your needs when it comes to these items. Our offerings include:

-

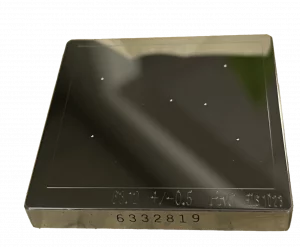

Hardness Testing Consumables: Indenters, anvils, and test blocks.

-

Tensile Testing Consumables: Grips, fixtures, and extensometers.

-

Metallography Consumables: Cutting blades, mounting powders, resins, grinding papers, polishing cloths, and etchants.

There is more information about the consumables we offer on their respective pages if you wish to learn more about them. Moreover, request a quote if you would like to learn more specific information.

Additional Considerations for Selecting Material Testing Consumables

A few other factors need to be considered when it comes to selecting the right consumables for material testing for maximum effectiveness. Among them are:

Supplier Certification and Quality Assurance

Choosing a supplier with recognized certifications and a robust quality assurance program can significantly impact consumable reliability. Make sure the supplier follows international standards like ISO 9001 for quality management. Certifications indicate the supplier’s commitment to maintaining high standards and consistent quality in their products.

Customization Options

Depending on the specific requirements of your material analysis, you might need customized consumables. Working with a supplier that offers customization can provide assurance that everything matches your specific needs. For example, special grips for unusual sample shapes in tensile tests or custom polishing cloths for specific metallographic applications can improve testing efficiency.

Technical Support and Expertise

A supplier that provides strong technical support can resolve issues quickly and facilitate smooth operations. Access to experts who can offer advice on the right consumables for your specific applications and troubleshooting support when problems arise is invaluable. This support can range from detailed product information to on-site training for your staff.

Sustainability and Environmental Impact

Think carefully about the environmental impact of your consumables. NextGen offer eco-friendly options and sustainable practices can reduce your testing lab’s carbon footprint. Hence, choosing biodegradable mounting resins or recyclable grinding papers can contribute to sustainable testing.

Cost-Benefit Analysis

While high-quality consumables may have a higher upfront cost, a cost-benefit analysis can help determine their long-term value. Assess factors such as lifespan, replacement frequency, and the potential impact on testing accuracy and equipment maintenance. Investing in high-quality consumables can save money by reducing downtime and improving test reliability.

Achieving Correct and Trustworthy Material Testing

Selecting the right consumables for material testing is an essential step for accurate and reliable results. Proper test supplies enhance your tests’ precision, protect your equipment from damage, and contribute to cost efficiency by reducing repeated tests. Additionally, using the correct components guarantees compliance with industry standards.

High-quality test supplies are required for correct measurements in hardness, tensile, and metallography testing. Conducting performance tests, regular visual and microscopic inspections, and maintaining consistent calibration and verification processes help select the right consumables. Moreover, working with a reliable supplier can significantly simplify this process.

NextGen Material Testing offer a comprehensive range of consumables to meet all your testing needs. We offer a comprehensive range of hardness testing supplies, tensile testing consumables, and metallography products as part of our product line. Please feel free to contact us directly or request a quote online. You can count on us to provide you with all the consumables you need to perform high-quality tests in order to satisfy your needs.