Metal Testing Equipment

Standards

ISO 18625, ASTM A956, JIS B7731

Description

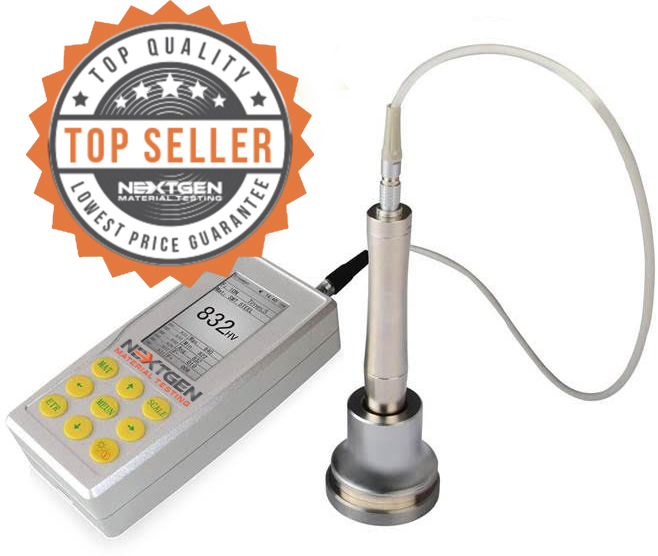

LeebGen3000 - Leeb Portable Rebound Tester is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

The Leeb Portable Rebound Tester LeebGen 3000 is designed to replace the traditional stationary metal hardness testers, such as Vickers, Brinell and Rockwell. Its portable design allows to draw the most accurate test data regardless of the direction of the hardness test measurement. This is accomplished with a built-in 360° automatic angle adjustment system. LeebGen 3000 utilizes the latest in advanced micro-electronic technology, and provides you with a fast, convenient and a cost effective quality testing solution. Read more in our latest MEGA BLOG!

Main Function and Features of Leeb Rebound Portable Hardness Tester

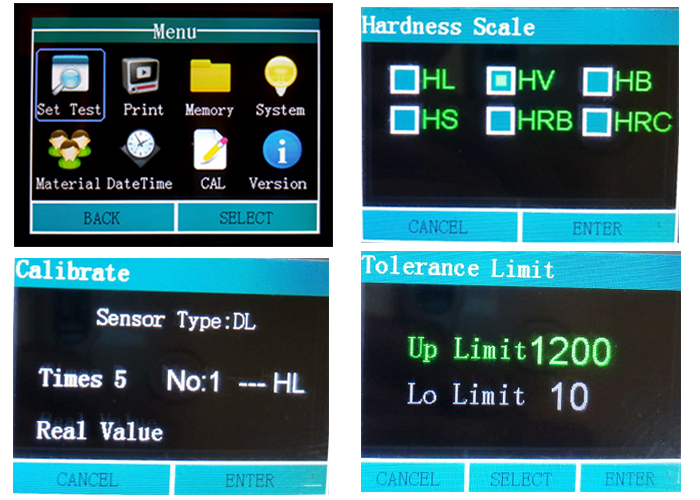

- A large, high contrast LCD screen for premium image quality in any condition

- The unit is equipped with a self-contained Universal D Impact device which eliminates the need for cables. Additionally, the unit is equipped with an impact direction sensor.

- High testing result with precision within +/-4HL in any impact direction with 360° automatic angle adjustment.

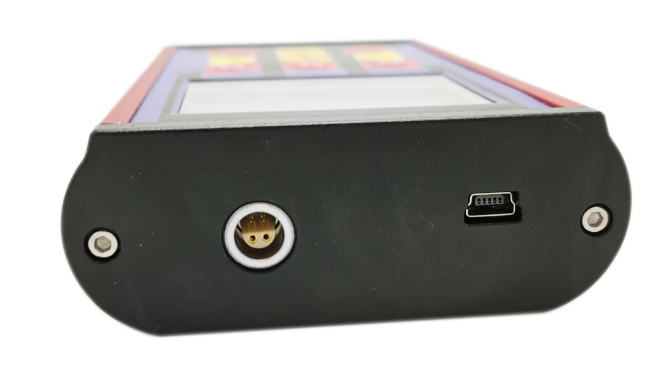

- Equipped with a USB port for ease of data transfer to a PC. Professional software is included at no extra cost.

- Internal data storage of dates and times of use

- Rechargeable battery through the USB port

- LeebGen 3000 has an integrated display of results for all common hardness scales including: Rockwell, Vickers, Knoop, Brinell, Shore and more.

- The unit comes standard with a wireless BlueTooth mini printer.

- LeebGen 3000 is designed for ease of calibration

- Equipped with an intelligent sleep mode

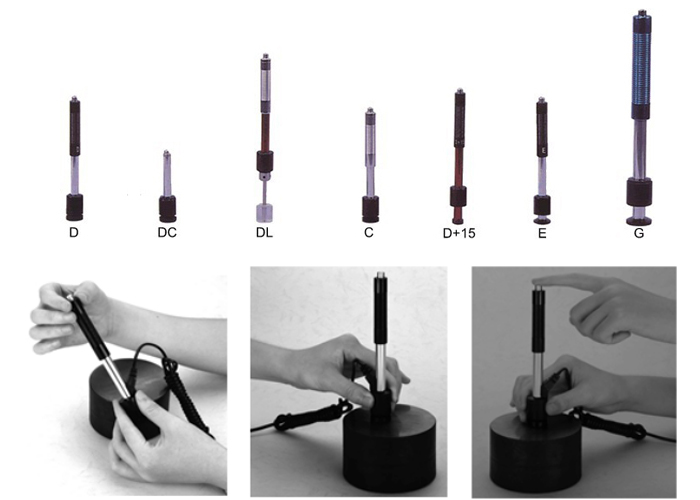

Impact Devices

| Impact Device | Image | Description | Commonly Tested Materials and Methods of Application |

|---|---|---|---|

| D |  |

Impact D is the universal unit for most hardness measurements. It is capable of a wide measuring range up to 68 HRC. | Steel and cast steel, cast iron, stainless steel, bronze, cast aluminum alloys, brass, wrought copper alloys and more. |

| DC |  |

Impact DC is designed for the harder to reach places. The device has similar properties and applications as the D, with testing components up to a maximum of 68 HRC. | Holes, cylinders, or measurements inside of an assembled machine and construction. |

| D+15 |  |

Impact D+15 is very similar to Impact D, the D+15 tests components up to a hardness of 68 HRC. Additionally, it has the same range of applications as the D and DC however has a different physical structure. The device is used with an elongated impact body and a coil which has a raised position of 0.6" or 15mm. | Holes and groves on a dipped surfaces |

| DL |  |

Impact DL can test a parts of up to a maximum of 68 HRC. The impact device has the same range of application as the D+15 with an exception of a more narrow front section. | Drill holes, gears and tight-to-reach spaces in the base of grooves. |

| G |  |

Impact G is designed with an increased impact energy of roughly 9X to that of the Impact D device. It can test materials of up to 646 HB. The larger diameter of the spherical tip allows for a more accurate measurement on a coarse microstructure. As a result, impact G does not need as much surface finish as the D device for an accurate readings. | Designed for rougher and heavier metals including: Cast aluminum, castings and forgings, cast iron, steel and cast steel. |

| C |  |

Impact C is equipped with a reduced impact energy. Relative to the Impact D, the energy impact is roughly 25% lower. The impact tests materials up to a maximum hardness value of 70 HRC. A better surface finish is required for Impact C then for Impact D. | Case hardness depth, coatings with a layer thickness of 0.1" or 0.3mm and impact sensitive materials requiring a small measuring indentation. Additionally uses: Cast steel, steel, cold work tool, and various cast aluminum alloys. |

* Different Impact Devices - imeko.org

|

|

LeebGen 3000

|

|---|---|

|

Operating Environment

|

-10-+60°C; Humidity: 20%-85%. |

|

Storage Environment

|

-30-+80°C; Humidity: 5%-95%. |

|

Dimensions (LxWxH)

|

5.8” x 1.4” x 0.8” / 147x35x22mm |

|

Weight

|

0.22 lbs. / 100 g |

Measuring Range and Materials

|

Material

|

HLD

|

HRB

|

HRC

|

HB

|

HV

|

HSD

|

|---|---|---|---|---|---|---|

|

Steel and cast steel

|

300-900 | 39-100 | 20-68 | 81-654 | 81-955 | 32-100 |

|

Cold work tool steel

|

300-840 | - | 20-67 | - | 80-898 | - |

|

Stainless steel

|

300-800 | 46-101 | - | 85-655 | 85-802 | - |

|

Grey cast iron

|

360-650 | - | - | 93-334 | - | - |

|

Nodular cast iron

|

400-660 | - | - | 131-387 | - | - |

|

Cast aluminum alloys

|

170-570 | 23-84 | - | 19-164 | - | - |

|

Brass

|

200-550 | 13-95 | - | 40-173 | - | - |

|

Bronze

|

300-700 | - | - | 60-290 | - | - |

|

Copper

|

200-690 | - | - | 45-315 | - | - |

FAQs

The main purpose of the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester provide a portable, non-destructive method for testing metal hardness. Using the Leeb rebound principle, the tester measures the velocity of an impact body before and after it rebounds from the test material, which determines the material's hardness.

Designed to replace traditional stationary testers such as Vickers, Brinell, and Rockwell, the LeebGen 3000 offers high precision and versatility. Its 360° automatic angle adjustment allows for accurate readings regardless of testing direction. The device also converts hardness values into multiple scales, including Rockwell (HRB, HRC), Vickers (HV), Brinell (HB), and Shore (HSD). With its lightweight and compact design, the tester is perfect for on-site testing of a broad range of materials, such as steel, aluminum alloys, brass, bronze, and cast iron, helping industries assess metal hardness quickly and accurately.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester provides flexible measurements over multiple hardness scales, enabling it to be used with various types of materials and applications. Using the Leeb rebound principle, it measures hardness and converts the results into the following scales:

-

Leeb (HLD): Measures the impact body's rebound velocity for precise hardness readings.

-

Rockwell (HRB, HRC): Ideal for testing medium to hard metals such as steel and cast iron.

-

Brinell (HB): Used for soft metals like aluminum alloys and bronze.

-

Vickers (HV): Suitable for fine materials and thin coatings.

-

Shore (HSD): Common in plastics or soft materials.

The LeebGen 3000 supports a broad measurement range for different materials:

-

Steel and Cast Steel: 300-900 HLD, 20-68 HRC.

-

Stainless Steel: 300-800 HLD, 46-101 HRB.

-

Cast Aluminum Alloys: 170-570 HLD.

-

Brass, Bronze, and Copper: Includes specific ranges for each.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester complies with ISO 18625, the international standard for Leeb hardness testing. This standard specifies the requirements, testing procedures, and calibration protocols for rebound hardness measurements.

Compliance with ISO 18625 guarantees that the LeebGen 3000 provides precise, repeatable, and reliable hardness readings for metallic materials. By adhering to this globally recognized standard, the tester guarantees accuracy and consistency in numerous industrial applications, including manufacturing, quality control, and on-site inspections. Thus, it is an ideal choice for organizations that require high-quality hardness testing that is aligned with international standards.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester complies with ASTM A956, the standard practice for Leeb hardness testing of metallic materials. ASTM A956 outlines the requirements for conducting rebound hardness tests using portable devices and provides uniformity in testing procedures and results.

Compliance with this standard guarantees that the LeebGen 3000 delivers accurate, repeatable, and reliable hardness measurements for a broad range of metals and alloys. By meeting ASTM A956 requirements, the tester is a trusted tool for industries and laboratories that demand adherence to international testing protocols. This standardization also guarantees compatibility with quality control and certification processes, which makes LeebGen 3000 a valuable asset for diverse applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester complies with JIS B7731, the Japanese Industrial Standard for Leeb hardness testing. This standard specifies the procedures, requirements, and calibration methods for rebound hardness tests on metallic materials.

Compliance with JIS B7731 guarantees that the LeebGen 3000 meets the high precision and reliability expected in Japanese industrial and laboratory settings. By adhering to this standard, the tester provides consistent and repeatable results, enabling it to be used for a variety of applications, including material quality control and on-site testing. The ability to comply with multiple international standards, such as JIS B7731, underscores LeebGen 3000’s flexibility and reliability on global markets.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester was developed as a modern alternative to traditional stationary testers like Vickers, Brinell, and Rockwell systems. Its portable design offers unmatched flexibility by allowing hardness testing in various locations and environments without compromising accuracy.

One standout feature is its 360° automatic angle adjustment system, which allows for precise measurements regardless of impact direction. This advanced functionality minimizes errors caused by test orientation, providing consistent and reliable results under all conditions. Additionally, the tester leverages cutting-edge micro-electronic technology to deliver rapid, accurate readings, resulting in a cost-effective and time-saving quality control solution.

The LeebGen 3000 is an innovative tool that combines portability with high precision and ease of use in order to meet the demands of modern industries requiring efficient and flexible hardness testing methods.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester was developed as a modern alternative to traditional stationary testers like Vickers, Brinell, and Rockwell systems. Its portable design offers unmatched flexibility by allowing hardness testing in various locations and environments without compromising accuracy.

One standout feature is its 360° automatic angle adjustment system, which allows for precise measurements regardless of impact direction. This advanced functionality minimizes errors caused by test orientation, providing consistent and reliable results under all conditions. Additionally, the tester leverages cutting-edge micro-electronic technology to deliver rapid, accurate readings, resulting in a cost-effective and time-saving quality control solution.

The LeebGen 3000 is an innovative tool that combines portability with high precision and ease of use in order to meet the demands of modern industries requiring efficient and flexible hardness testing methods.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester features a large, high-contrast LCD screen, enabling it to deliver premium image quality and enhance usability under different conditions.

This screen allows for clear visibility of test results, even in challenging environments with poor lighting. High contrast allows users to easily read values, minimizing errors and improving operational efficiency. Its size and clarity provide ample space to display multiple parameters at once, offering a comprehensive overview of the test data.

The user-friendly display simplifies the testing process by making it easier to navigate through menus, view hardness measurements, and monitor test conditions. Whether used in a laboratory or on-site, the LCD screen significantly increases the reliability and convenience of the LeebGen 3000, delivering accurate and efficient hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is equipped with a self-contained Universal D Impact device, which significantly improves its functionality and ease of use. This impact device is fully integrated into the tester, eliminating external cables. The cable-free design improves portability and reduces the risk of damage or tangling during operation, allowing for on-site and field testing.

Additionally, the device includes an impact direction sensor, which detects and adjusts to impact angle. This feature ensures precise hardness measurements, regardless of orientation, and works perfectly with the tester’s 360° automatic angle adjustment system. Together, these features provide unmatched accuracy and convenience, making the LeebGen 3000 an effective and reliable tool for modern hardness testing applications.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester guarantees high precision within ±4HL in any impact direction, thanks to its advanced 360° automatic angle adjustment system. This innovative feature guarantees that hardness measurements remain consistent and accurate, regardless of the test orientation.

By compensating for variations in impact direction, the tester eliminates potential errors commonly associated with traditional hardness testing methods. This capability makes the LeebGen 3000 particularly useful for on-site testing, where test orientations often vary. Combined with its precise rebound velocity measurement, the device delivers reliable results for a wide array of materials, including metals like steel, cast iron, and aluminum alloys, offering accurate and repeatable hardness evaluations in diverse environments.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is equipped with a USB port, allowing convenient data transfer to a PC. This feature makes it possible for test results can be easily exported for further analysis, reporting, and record-keeping.

Additionally, the tester includes professional software at no extra cost. This software simplifies data management by enabling users to organize, process, and generate detailed reports of test results. The combination of a USB port and advanced software enhances workflow efficiency, making the LeebGen 3000 an excellent choice for laboratories and industries that require seamless integration of test data into their quality control processes.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester includes internal data storage capabilities, allowing it to save test results along with dates and times of use. This feature guarantees that critical test data is securely stored for later retrieval and analysis.

The ability to timestamp each test increases traceability and simplifies data management, making it easier for operators to organize and review results. This functionality is particularly valuable in quality control environments where accurate record-keeping is essential for audits, certifications, and reporting. By integrating internal storage with advanced features like USB connectivity, the LeebGen 3000 provides a comprehensive solution for efficient and reliable hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is powered by a rechargeable battery, which can be conveniently recharged through its USB port. This design allows for portability and eliminates frequent battery replacements, resulting in a practical solution for on-site and field testing.

The USB charging capability allows users to charge the device using various power sources, such as a computer, power bank, or wall adapter, enhancing flexibility and usability. The rechargeable battery provides reliable power for extended testing sessions, guaranteeing consistent performance even in remote locations. This feature makes the LeebGen 3000 a user-friendly and efficient tool for portable hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester comes standard with a wireless Bluetooth mini printer. This printer allows users to conveniently print test results on-site without additional cables or connections.

Bluetooth functionality allows for easy and quick pairing with the tester, enabling immediate printing of hardness data for record-keeping, quality control, or reporting purposes. This feature is particularly valuable in field testing environments, where documentation needs to be generated instantly. By including a wireless mini printer, the LeebGen 3000 enhances usability and efficiency, offering a complete solution for portable hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is equipped with an intelligent sleep mode designed to optimize energy efficiency and prolong battery life. This feature automatically puts the device into a low-power state when idle for a specified period, reducing unnecessary power consumption.

The intelligent sleep mode guarantees that the tester remains ready for use while conserving energy during downtime, which is especially useful for extended testing sessions or on-site applications. By reducing the frequency of recharging, this feature enhances the device's convenience and reliability, making sure it is always available when needed. This thoughtful addition contributes to the overall efficiency and user-friendliness of the LeebGen 3000.

Click here to learn more about the product or here to receive a personalized quote.

The Impact D tester is the universal impact device included with the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester, which is suitable for most general-purpose hardness measurements. It offers a broad measuring range of up to 68 HRC, allowing it to be used for a variety of materials, including steel, cast steel, cast iron, stainless steel, bronze, brass, cast aluminum alloys, and wrought copper alloys.

This flexibility makes the Impact D tester ideal for routine hardness testing in industries such as construction, manufacturing, and metalworking. It provides consistent and reliable results for diverse material types, resulting in accurate measurements for structural components, machine parts, automotive applications, and more. The Impact D tester is particularly valued for its adaptability and precision, making it a valuable tool for both field and laboratory testing scenarios.

Click here to learn more about the product or here to receive a personalized quote.

The Impact DC tester is specifically designed for hard-to-reach areas, which makes it suitable for situations where traditional testers may not fit. While it shares similar properties and applications with the Impact D tester, the Impact DC is particularly suited to testing components up to 68 HRC in confined spaces such as holes, cylinders, and assembled machinery.

This device is commonly used in industrial and construction environments where precise hardness measurements are required in challenging locations. Its design allows for accurate results even in areas with restricted access, making it an ideal accessory for comprehensive and flexible hardness testing with the NG – LeebGen 3000.

Click here to learn more about the product or here to receive a personalized quote.

The Impact D+15 tester is a specialized version of the Impact D, created specifically for hardness testing in specific environments. It retains the ability to test components up to 68 HRC and shares the same range of applications as the Impact D and DC testers. However, its elongated impact body and raised coil position of 0.6 inches (15 mm) make it uniquely suited to measuring holes, grooves, and dipped surfaces.

This design allows for accurate testing in areas where standard testers may not be effective, particularly in industries dealing with intricate parts or surfaces. The Impact D+15 tester offers precision and reliability in challenging testing conditions, thus serving as a valuable tool for users requiring flexibility and adaptability in their hardness measurements.

Click here to learn more about the product or here to receive a personalized quote.

The Impact DL tester is intended for testing parts with a hardness of up to 68 HRC, particularly in narrow or confined spaces. While it shares the same range of applications as the Impact D+15, its narrow front section makes it ideal for measuring drill holes, gears, and tight-reach spaces at the base of grooves.

This unique feature of the Impact DL tester provides accurate hardness measurements in areas where standard devices may struggle to access. It is particularly valuable in industries that require testing of intricate or compact components, offering precision and flexibility for comprehensive hardness testing solutions.

Click here to learn more about the product or here to receive a personalized quote.

The Impact G tester is engineered for testing rough and heavy metals, which makes it particularly suitable for materials with coarse microstructures. With an impact energy approximately nine times greater than that of the Impact D device, it is capable of testing materials up to 646 HB. This increased energy, combined with the larger diameter of its spherical tip, allows for accurate hardness measurements even on surfaces with minimal finishing.

The Impact G tester is ideal for use on cast aluminum, castings and forgings, cast iron, steel, and cast steel, where traditional devices may require finer surface preparation. Its ability to deliver precise results on rough surfaces provides a valuable tool for industries dealing with heavy-duty and structural materials, assuring reliable hardness testing in challenging conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Impact C tester is designed with reduced impact energy, approximately 25% lower than the Impact D device, which makes it suitable for testing materials with a maximum hardness of 70 HRC. This lower impact energy is particularly suitable for applications that require a better surface finish than Impact D.

The Impact C tester is commonly used for evaluating case hardness depth, coatings with a thickness of 0.1 inches or 0.3 mm, and impact-sensitive materials where only a small indentation is acceptable. It is well-suited to materials such as cast steel, cold work tool steel, various cast aluminum alloys, and other delicate components

By offering precise hardness measurements for coatings and sensitive materials, the Impact C tester is an ideal solution for industries that demand non-destructive testing with minimal surface damage, ensuring accurate results and preserving the integrity of the tested material.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is engineered to operate reliably within a temperature range of -10°C to +60°C and a humidity range of 20% to 85%. This comprehensive operational range makes the tester suitable for diverse environments, including industrial sites, laboratories, and outdoor field applications.

The ability to function under varying conditions guarantees tester accuracy and performance even in challenging settings, such as extreme temperatures or moderate humidity. This flexibility makes the LeebGen 3000 an excellent choice for hardness testing in global industrial and research environments.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester can be safely stored in a temperature span of -30°C to +80°C and a humidity range of 5% to 95%. This robust storage capability guarantees that the device remains protected and functional even under extreme environmental conditions.

Such flexibility in storage conditions allows the tester to be securely transported and kept in a variety of industrial and field settings. This is without compromising accuracy or performance. This feature is particularly beneficial for organizations that operate in diverse and challenging climates, making the LeebGen 3000 a reliable and durable solution for long-term use.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester has compact dimensions of 5.79 x 1.38 x 0.87 inches (length x width x height) or 147 x 35 x 22 mm. Its small size allows for excellent portability, making it easy to handle and transport for on-site testing or field applications.

The compact design of this unit makes it ideal for use in tight spaces or remote locations while maintaining full functionality at the same time. As a result of its lightweight design, the LeebGen 3000 is capable of providing greater convenience without compromising precision or reliability due to its space-saving construction.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester weighs approximately 3.5 ounces (100 grams). Its lightweight design makes it highly portable and easy to use, particularly in field applications or on-site testing.

This low weight allows for minimal user fatigue during extended testing sessions and enhances the device's practicality for technicians and engineers who require a portable yet reliable hardness testing solution. Despite its compact size and lightweight construction, the LeebGen 3000 maintains precision and durability, which makes it an indispensable tool for hardness testing in many different industries.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester delivers accurate hardness measurements regardless of material type by taking advantage of advanced calibration options and material-specific settings. It is capable of testing a broad variety of metals, including steel, cast iron, stainless steel, aluminum alloys, bronze, brass, and copper.

The device allows users to select material-specific settings that adjust for unique material properties, such as density and surface hardness, to deliver precise and consistent results. Additionally, its 360° automatic angle adjustment system compensates for test direction variations, providing uniform accuracy regardless of orientation. This capability is particularly important for field applications, where material types and conditions vary significantly.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is exceptionally well-suited to field testing due to its portable and lightweight design, weighing only 3.5 ounces (100 grams). Its compact dimensions of 5.79 x 1.38 x 0.87 inches (147 x 35 x 22 mm) make it easy to carry and operate in numerous locations, including remote or challenging environments.

The device’s robust construction ensures durability and reliable performance under extreme conditions, with an operating temperature range of -10°C to +60°C and humidity tolerance of 20% to 85%. Its rechargeable battery, combined with the intelligent sleep mode, provides extended usage without frequent recharging, this device is practical for on-site applications.

Additionally, the 360° automatic angle adjustment system and versatile impact devices enable accurate testing of diverse materials and structures, even in tight or irregular spaces. These features make the LeebGen 3000 an indispensable tool for professionals conducting hardness testing in the field.

Click here to learn more about the product or here to receive a personalized quote.

The 360° automatic angle adjustment system in the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester significantly improves test accuracy by compensating for variations in impact direction. This innovative feature allows for precise and consistent hardness measurements, regardless of whether the test is conducted vertically, horizontally, or at an angle.

This capability is particularly beneficial in field applications where the test surface orientation may vary. By automatically adjusting for the direction of impact, the system eliminates potential errors caused by testing angle inconsistencies, providing reliable results every time. This feature, combined with the device’s advanced technology, makes the LeebGen 3000 a versatile and trustworthy tool for professionals requiring accurate hardness measurements under diverse testing conditions.

Click here to learn more about the product or here to receive a personalized quote.

The NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is powered by a rechargeable battery that offers long-lasting operation, which makes it ideal for extended testing sessions in the field or laboratory. The device is designed with an intelligent sleep mode that automatically reduces power consumption during inactivity. This feature significantly extends battery life by conserving energy when the device is not in use.

The battery is easily recharged via the built-in USB port, allowing convenient charging from a variety of sources, such as laptops, power banks, or wall adapters. This results in minimal downtime and enhances portability, enabling testers to remain operational in diverse environments. The combination of a reliable rechargeable battery and power-saving technology makes the LeebGen 3000 an ideal choice for efficient and uninterrupted hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG – LeebGen 3000 – Leeb Rebound Portable Hardness Tester is specifically configured to handle small or irregularly shaped objects through its range of flexible impact devices. For instance, the DL impact device is ideal for narrow spaces such as drill holes and gear bases, while the D+15 impact device is suited to grooved and dipped surfaces with its elongated body.

The tester’s compact size and precise calibration capabilities ensure accurate hardness measurements, even in challenging testing scenarios. Whether dealing with intricate shapes, confined spaces, or delicate components, the LeebGen 3000 adapts smoothly, providing reliable results. This flexibility makes it an indispensable tool for industries that require accurate testing of unique or complex parts.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Ultrasonic Contact Impedance Hardness Tester - UH200

Welcome to our most advanced and cost-effective Ultrasonic Hardness Testing System. This portable machine is all you need and more!

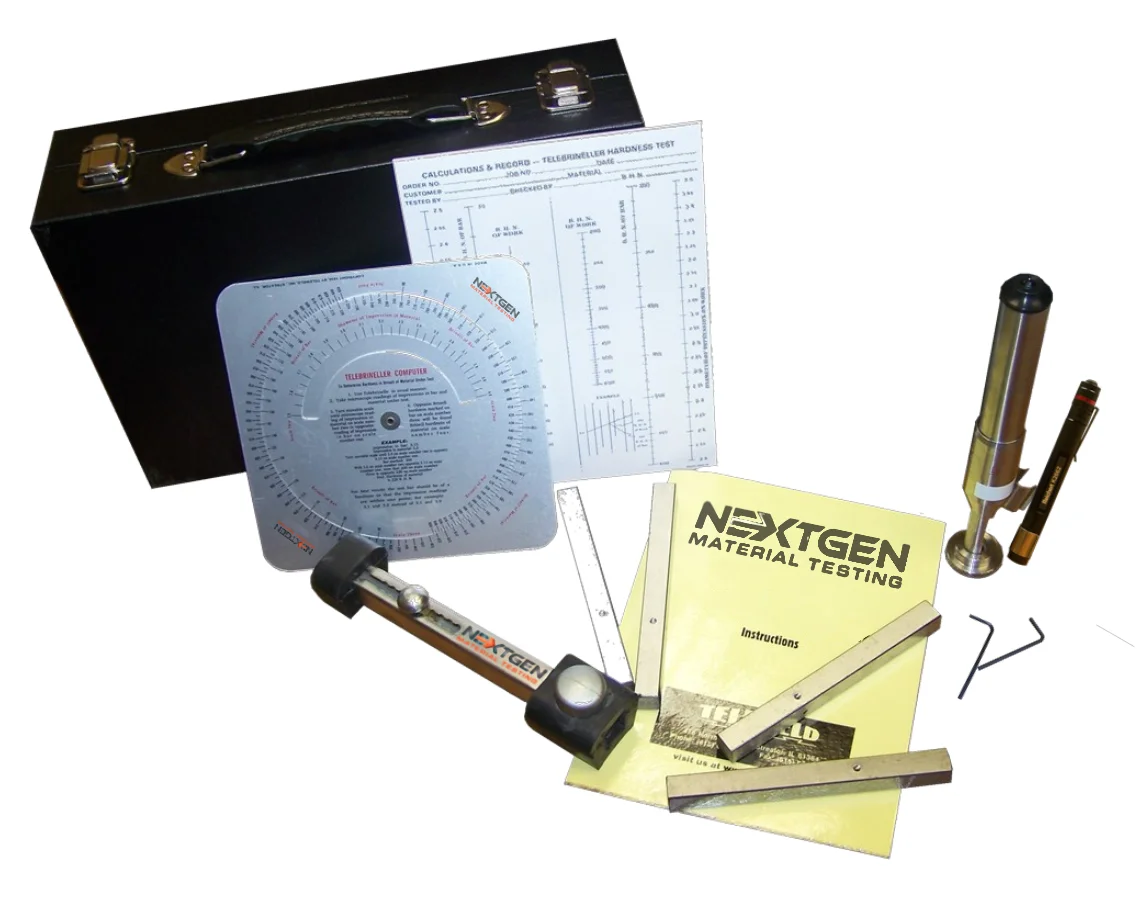

NextGen Telebrineller Brinell Hardness Testing System

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch quality. Developed specifically for welding crews, Telebrineller draws on over fifty years of field experience and solid metallurgical knowledge. Portable and practical, the entire Telebrineller system, housed in a case, weighs less than ten pounds. It's an ideal choice for Brinell hardness testing in any situation.

Surface Roughness Testers

High accuracy surface roughness testing systems for material surface analysis and statistical processing of data. Multiple model variations to help fit your technical and budgetary expectations.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.