Metal Testing Equipment

Description

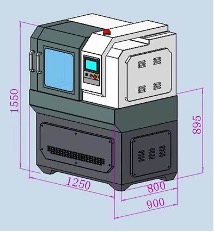

The GenCut GL 120XY has a large 120mm diameter maximum cutting capacity equipped with a fully automated XY table. Equipped with a double hood fully enclosed structure for the safest operation along with quick clamping mechanisms to achieve the most efficient cutting processes.

A powerful cooling system with two coolant lines reduce the ability for the specimen to get too hot during the cutting process. This ensures the specimen remains intact without any deformity or burn residue. It also allows the GenCut GL 120XY to achieve the best cutting quality while increasing the utilisation rate of the cutting wheel and maximizing the life of the blades. Read more in our MEGA BLOG!

GenCut GL 120XY Technical Specifications

|

Model |

GenCut GL120XY |

|

Cutting Wheel |

Φ350×2.5×Φ32mm |

|

Maximum Cutting Section |

Φ120mm |

|

Cutting Table Size |

400 x 300mm |

|

Z-Axis (Cutting Blade Spindle Drop Distance) |

150mm |

|

Y-Axis Movement Stroke |

300mm |

|

Y-Directional Speed of the Table |

0-300mm/min |

|

X-Axis Travel |

100mm |

|

Effective Tool Fed Distance |

300mm |

|

Variable Speed |

500-3000rpm |

|

Control System |

7” Colour Touch Screen Panel, PLC Controller |

|

Cutting Modes |

Flat Push Cutting, Intermittent Cutting

|

|

Cutting Speeds |

1-100mm/min

|

|

Resetting Mode |

Automatic

|

|

Cooling System |

Automatic Water Cooling - 2 Lines

|

|

Machine Type |

Vertical Cutting

|

|

Input Power |

4kW

|

|

Input Voltage |

380V 50/60Hz - 3Phase

|

GenCut GL 120XY Standard Configuration

-

GenCut GL120XY Cutting Saw

-

Coolant Chamber

-

Wrench 13#-15#

-

Wrench 17#-19#

-

Internal Hexagonal Wrench 6mm and 8mm

-

Water Inlet Tube

-

Drain Pipe

-

Diamond Cutting Wheel

-

Φ350 x 2.5 x Φ32mm

-

Water Tank and Pump and Operation Manual

FAQs

The main purpose of the GenCut GL 120XY – Multi-Function Abrasive Cut-Off Saw is to provide high-precision cutting of metal specimens for metallographic analysis. Equipped with a fully automated XY table, it offers a large cutting capacity of up to 120mm diameter.

The saw features a touchscreen user interface, making it user-friendly and easy to operate. Safety is prioritized with a double hood enclosed structure and quick clamping mechanisms, which facilitate secure and efficient sample fixation. The powerful cooling system, which includes two coolant lines, prevents overheating and maintains specimen integrity.

The GenCut GL 120XY is extremely flexible, with adjustable cutting speeds and modes, such as flat push cutting and intermittent cutting. This caters to an array of metallographic applications. This machine maximizes the cutting wheel's efficiency rate and extends the blades' life, making it a reliable tool for laboratory and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

The cutting wheel of the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw has specific dimensions: a diameter of 350mm, a thickness of 2.5mm, and a central bore diameter of 32mm (Φ350×2.5×Φ32mm). Specifications such as these are crucial for achieving precise and efficient cuts on various types of metal specimens, a requirement for accurate metallographic analysis.

The 350mm diameter allows for significant cutting depth, making it suitable for different types of sample sizes. The 2.5mm thickness provides wheel durability and stability during operation, providing clean and accurate cuts without compromising structural integrity. The 32mm bore diameter fits securely onto the spindle.

These design features contribute to the overall performance and reliability of the GenCut GL120XY, enabling it to deliver high-quality cuts consistently. The robust construction of the cutting wheel also extends its lifespan, making it a cost-effective component for frequent use in both laboratory and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

In terms of cutting section capacity, the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw can cut products with a maximum diameter of 120 millimeters (Φ120mm). As a result of its substantial capacity, the machine can handle larger metal specimens.

The ability to cut specimens up to 120mm means that the GenCut GL120XY can accommodate a range of sample sizes, providing flexibility for different cutting needs. This is particularly beneficial in laboratories and industrial settings where diverse sample dimensions are common.

The robust cutting wheel design and powerful motor enable the machine to perform precise and efficient cuts on larger specimens while maintaining high-quality results. This large cutting capacity, combined with the machine's advanced features, makes the GenCut GL120XY an ideal tool for precise metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

GenCut GL120XY Multi-Function Abrasive Cut-Off Saw cutting table size is 400mm by 300mm. This generously sized table provides ample space for positioning and securing different types of metal specimens during cutting.

The cutting table's dimensions increase the machine's versatility, allowing it to accommodate a large range of sample sizes and shapes. This is beneficial in laboratories and industrial environments where diverse samples are frequently handled. The large table surface ensures that specimens can be easily and securely fixed, contributing to precise and stable cutting operations.

In addition to providing a stable platform, the cutting table size also facilitates better manipulation and adjustment of samples. This feature is necessary for high-quality results in metallographic sample preparation. The spacious cutting table of the GenCut GL120XY thus plays a central role in its overall functionality and performance.

Click here to learn more about the product or here to receive a personalized quote.

The Z-axis (cutting blade spindle drop distance) capacity of the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is 150 millimeters. This specification indicates the maximum vertical travel distance of the cutting blade spindle, allowing the blade to drop down to 150mm.

This substantial Z-axis movement increases the machine's flexibility by enabling it to handle thicker and larger specimens effectively. The ability to adjust the spindle drop distance allows for precise cutting depth control, which is crucial for accurate and clean cuts. This feature is valuable in metallographic sample preparation, where maintaining the quality and integrity of cut specimens is of paramount importance. The 150mm Z-axis capacity allows users to work with a range of sample sizes and shapes, providing flexibility and precision in cutting operations.

Click here to learn more about the product or here to receive a personalized quote.

In terms of the stroke capacity of the Y-axis movement, the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw has a stroke capacity of 300 millimeters. The specifications indicate the maximum horizontal travel distance of the cutting table along the Y-axis, enabling the workpiece to be moved precisely and extensively during the cutting process along this axis.

This significant Y-axis movement enhances the machine’s versatility and flexibility, enabling it to handle larger and more complex specimens effectively. The ability to move the table 300mm along the Y-axis means that users can position and adjust their samples accurately, achieving precise cuts. The extended Y-axis stroke is particularly beneficial for metallographic sample preparation, as it allows for detailed cutting of different sample sizes and shapes.

Click here to learn more about the product or here to receive a personalized quote.

The Y-directional speed range of the table on the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is from 0 to 300 millimeters per minute (mm/min). This adjustable speed range allows for precise control over the table movement during the cutting process, which allows the cutting operation to be adapted to the specific requirements of different materials and samples.

The ability to adjust table Y-directional speed enhances machine versatility and precision. Slower speeds can be used for harder materials or more delicate cuts, reducing the risk of damage to the sample and providing high-quality results. Faster speeds are suitable for softer materials or when a quicker cutting process is needed, improving efficiency without compromising cut quality.

This range of speeds provides significant flexibility, allowing users to optimize the cutting process for various applications in metallographic sample preparation. The precise control over table movement guarantees consistent and accurate cuts.

Click here to learn more about the product or here to receive a personalized quote.

The X-axis travel capacity of the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is 100 millimeters. This specification indicates the maximum horizontal movement of the cutting table along the X-axis, allowing for precise adjustments and positioning of the workpiece during the cutting process.

The 100mm X-axis travel provides significant flexibility, enabling users to handle many different sample sizes and shapes with accuracy. This feature is particularly useful for metallographic sample preparation, where precise positioning is a necessity for high-quality cuts. The ability to move the table along the X-axis guarantees accurate cuts, improving the overall efficiency and effectiveness of the cutting process.

With its 100mm travel capacity, the GenCut GL120XY is capable of making precise and flexible adjustments, making it an essential feature for metallographic applications in which precise and accurate cuts are required.

Click here to learn more about the product or here to receive a personalized quote.

A GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is equipped with an effective tool-feeding distance of 300 millimeters. In this case, the maximum distance that the cutting tool can travel during the process of cutting is what is meant by this distance.

As a result of the machine's 300mm tool-fed distance, the machine has the capability of making precise and extended cuts, which allows it to handle a variety of sample sizes and shapes. By using this tool, users are able to perform detailed and accurate cutting operations, which is essential when preparing samples for metallographic analysis. Having the ability to cover a significant length in a single cut results in a more efficient process and provides a better result for the customer.

Click here to learn more about the product or here to receive a personalized quote.

The variable speed range of the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is from 500 to 3000 revolutions per minute (RPM). This selection of speeds allows precise control of the cutting process. This allows users to adjust the speed according to the material being cut and the specific requirements of each sample.

The lower end of the speed range, 500 RPM, is ideal for cutting harder materials or when slow, controlled cuts are necessary to maintain sample integrity. This reduces overheating risk and produces smooth, accurate cuts.

The upper end of the speed range, 3000 RPM, allows for faster cutting of soft materials, improving efficiency without compromising quality. As a result of its versatility, the GenCut GL120XY is capable of handling a broad range of metallographic cutting tasks, providing high-quality results every time.

Click here to learn more about the product or here to receive a personalized quote.

GenCut GL120XY Multi-Function Abrasive Cut-Off Saw comes with an innovative control system that features a 7-inch color touchscreen panel and a PLC (Programmable Logic Controller) as part of its control system. With the help of the advanced control system, operators can easily set and adjust cutting parameters such as speed, mode, and movement with an intuitive and user-friendly interface.

By using the touchscreen panel, users are able to interact with the machine in a more intuitive manner, offering clear and easy-to-understand controls that increase operational efficiency. The PLC controller provides precise and reliable automation of cutting processes, improving consistency and accuracy in sample preparation. This combination of touchscreen and PLC control makes the GenCut GL120XY highly adaptable and efficient for an array of metallographic cutting tasks.

Click here to learn more about the product or here to receive a personalized quote.

There are two different cutting modes available with the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw: Flat Push Cutting and Intermittent Cutting.

Flat Push Cutting is a straightforward mode where the cutting wheel moves continuously through the specimen, ideal for clean, uniform cuts. This mode is typically used for simple, straight-through cuts where consistent pressure and movement are required.

Intermittent Cutting, on the other hand, involves the cutting wheel making periodic stops during the cutting process. This mode is beneficial for cutting harder materials or complex shapes. The method allows for cooling periods to prevent overheating and to reduce the risks of damage to the specimen as a result of overheating.

As a result of these cutting modes, users are able to select the most appropriate method of cutting according to their specific requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL120XY Multi-Function Abrasive Cut-Off Saw features automatic resetting. In this mode, the cutting components are automatically returned to their initial positions after a cut is completed, which simplifies the operation of the machine. It is through the use of this automation that efficiency and ease of use are increased, resulting in a reduction in manual intervention and minimizing downtime between cuts.

It is important to note that the automatic reset mode ensures that the machine is ready for the next cutting task as quickly and efficiently as possible, simplifying workflow and improving productivity at the same time. In high-throughput environments where speed and efficiency are of greater importance, this feature is particularly useful.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL120XY Multi-Function Abrasive Cut-Off Saw uses an automatic water cooling system with two coolant lines. This system is designed to efficiently manage the cutting area temperature, preventing specimens from overheating during the cutting process. As a result of continuously circulating cooling water, specimen integrity is maintained and high-quality cuts can be achieved.

The dual coolant lines provide greater cooling efficiency, allowing for better temperature control and reducing the risk of burning residue on samples. The GenCut GL120XY was designed with this feature in mind to preserve the quality and accuracy of metallographic cuts, making it a reliable tool for precise sampling preparation, as well as preserving the quality of metallographic cuts. In addition to simplifying the operation of the automatic cooling system, it also ensures that it continuously manages cooling without the need for manual adjustments.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is designed for vertical cutting. This vertical cutting capability allows the saw to make precise, downward cuts through metal specimens. During the cutting process, this is essential in order to maintain control and accuracy.

Vertical cutting is advantageous in metallographic sample preparation as it provides straight and clean cuts, preserving the sample's integrity. The vertical orientation helps manage cutting forces more effectively, reducing the risk of deflection or deviation with other cutting orientations.

This type of cutting is ideal for a number of applications, providing consistent and reliable results in both laboratory and industrial settings. The vertical cutting design of the GenCut GL120XY, combined with its other advanced features like automated XY table movement and precise control systems, ensures high-quality, repeatable cuts essential for detailed metallographic analysis.

Click here to learn more about the product or here to receive a personalized quote.

The input power of the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is 4 kilowatts (kW). This substantial power rating guarantees that the machine operates efficiently and effectively. It provides the necessary strength to cut through many different metal specimens with precision and consistency.

The 4kW input power supports robust performance for high-precision metallographic sample preparation. It allows the cutting wheel to maintain a stable and consistent speed, even when cutting through tougher or thicker materials. This power capacity also contributes to the machine's ability to handle demanding tasks without significant power fluctuations or performance reductions.

Furthermore, the high input power is essential for driving the automated features of the GenCut GL120XY. This includes the automated XY table movement, variable speed control, and a powerful cooling system. These features work together to ensure that each cut is precise, clean, and free from thermal damage.

Click here to learn more about the product or here to receive a personalized quote.

The input voltage requirement for the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw is 380 volts (V), with a frequency of 50/60 hertz (Hz), and it operates on a 3-phase power supply. With this industrial-grade voltage and power configuration, the machine receives a stable and adequate power supply to provide high performance.

Operating at 380V and utilizing a 3-phase power supply allows the GenCut GL120XY to deliver consistent power to its components, including the 4kW motor. This setup supports the machine's robust performance, enabling it to handle demanding cutting tasks with precision and efficiency. The 3-phase power supply is particularly beneficial in industrial applications as it provides a more balanced and reliable electricity flow.

This configuration also provides compatibility with standard industrial electrical systems. This makes it easier to integrate the GenCut GL120XY into existing setups without extensive modifications. The specified voltage and frequency support the machine's advanced features, such as automated table movements and variable speed control.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenCut GL120XY Multi-Function Abrasive Cut-Off Saw includes several components that are designed for efficient and precise cutting operations. These components are:

-

GenCut GL120XY Cutting Saw: The main unit is designed for high-precision metallographic cutting.

-

Coolant Chamber: Ensures effective cooling during cutting.

-

Wrenches (13#-15# and 17#-19#): For assembly, maintenance, and adjustment.

-

Internal Hexagonal Wrenches (6mm and 8mm): For secure fastening and adjustment of different parts.

-

Water Inlet Tube and Drain Pipe: For the cooling system, ensuring continuous water supply and drainage.

-

Diamond Cutting Wheel (Φ350 x 2.5 x Φ32mm): Precision-engineered for clean and accurate cuts.

-

Water Tank and Pump: Part of the cooling system to maintain optimal cutting conditions.

-

Operation Manual: Provides detailed instructions on machine setup, operation, and maintenance.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenCut GL 170XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity – Φ170mm

The GenCut GL 170XY has a large 170mm diameter maximum cutting capacity equipped with a fully automated XY table.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.