Metal Testing Equipment

Description

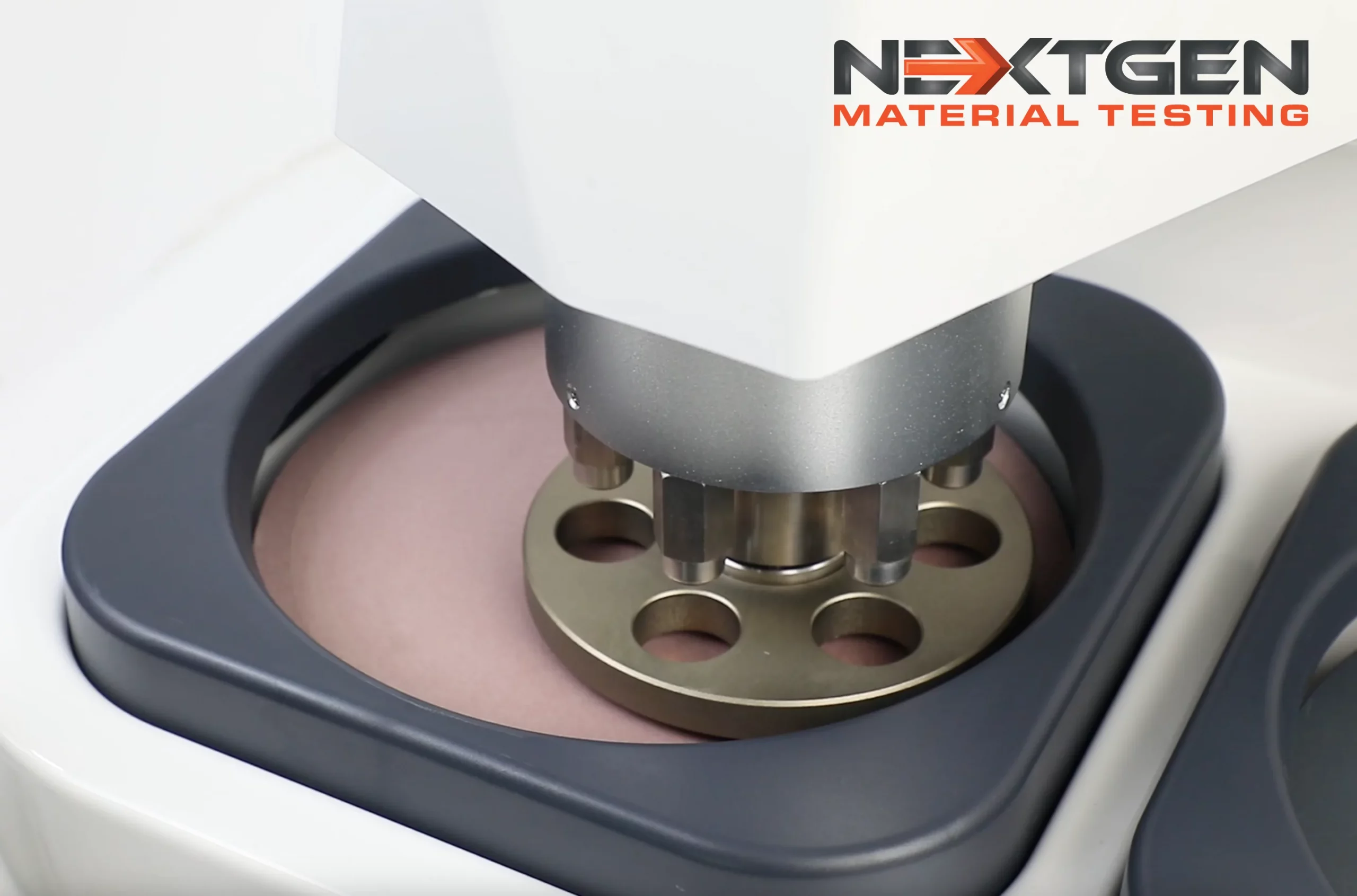

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine. This state-of-the-art equipment seamlessly integrates pre-grinding, grinding, and polishing processes to deliver exceptional results.

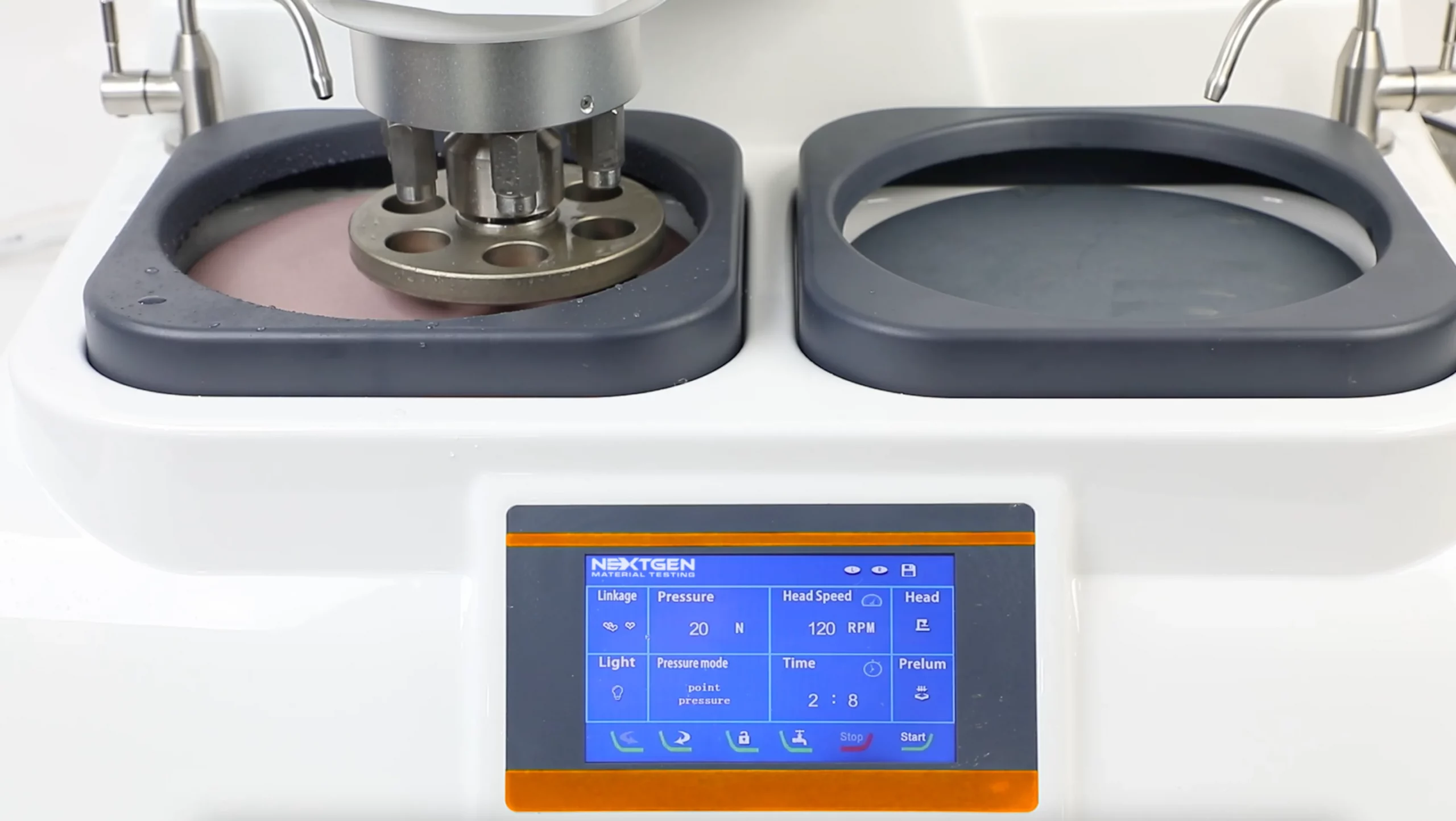

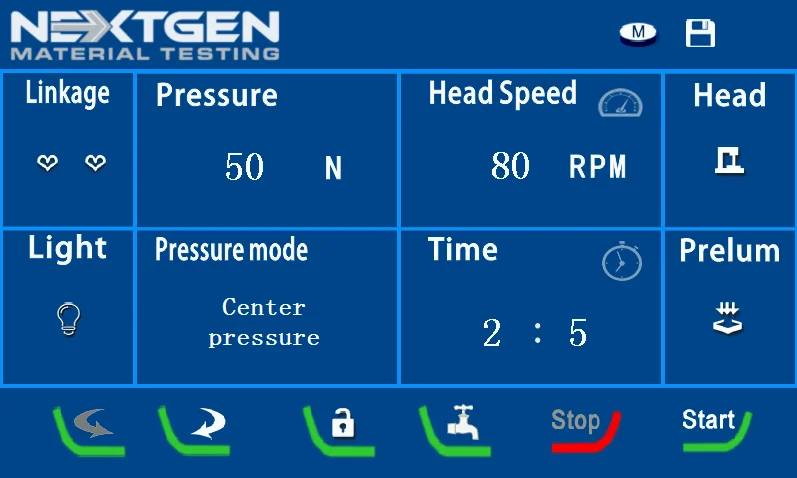

Controlled through a user-friendly touch screen interface, the GenGrind FA-IC features a DC brushless motor driving the grinding and polishing plate, while the grinding head is efficiently powered by a stepper motor. This design ensures stable rotation, low noise levels, and utmost safety and reliability during operation.

The machine allows users to customize various settings such as rotational speed, pressure, and sample preparation time according to their specific requirements. These adjustments are effortlessly made through the intuitive touch screen, enabling users to cater to different needs with ease.

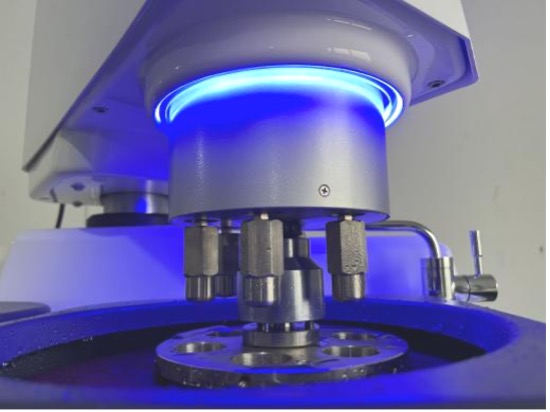

Incorporating its own lighting system, the GenGrind FA-IC provides convenient sample handling and placement. Additionally, its cooling device effectively prevents overheating during grinding, safeguarding the integrity of the metallographic structure. This feature is particularly beneficial in preserving the quality of metallographic samples.

Whether in metallographic laboratories within factories, colleges, or research institutes, the GenGrind FA-IC Single Wheel Polisher and Grinder stands as the ultimate choice for precision grinding and polishing applications. Its cutting-edge capabilities and reliable performance make it the preferred solution for achieving impeccable metallographic results.

GenGrind FA-IC 250D Features

-

Super cost-effective, offering outstanding value for money.

-

Dual working plates with standard dimensions of 254mm, providing 50% more working area compared to regular grinding and polishing machines.

-

Capable of polishing 6 pieces of 30mm diameter samples in a single operation, maximizing productivity.

-

High-end ABS shell, giving it a sophisticated and modern appearance.

-

User-friendly touch screen display for clear and intuitive interface, ensuring simple operation.

-

Adjustable testing time, rotating speed, and pressure to suit specific needs.

-

The grinding head is equipped with an electromagnetic clutch for convenient and quick operation, automatically locking when needed.

-

Offers stepless speed regulation from 100 to 1400rpm or four constant speed options, with the ability to define three common speeds for pre-grinding, grinding, and polishing.

-

Allows storage of up to 100 groups of grinding and polishing programs for quick recall and efficient workflow.

-

Features a magnetic disc design for swift disc changes, enhancing the replacement of sandpaper and polishing cloth.

-

Boasts a sample chuck with free-rotating design, complemented by an internal lighting system, ensuring ease in sample handling.

-

Equipped with a built-in nozzle, sewage collection tank, and automatic cleaning, streamlining maintenance tasks.

-

Utilizes DC brushless and stepper motors for stable rotation, low noise levels, and prolonged machine life.

-

The base is made of a single-piece aluminum alloy material, offering lightweight construction, excellent shock absorption, and corrosion resistance.

7" Touch Screen User Friendly Control Display

GenGrind FA-IC 250D Technical Specification

| Model | GenGrind FA-IC 250D |

| Working Plate | Standard Ø254mm with magnetic disc; 2.2KW |

| Speed of working plate |

100-1400 r/min stepless speed Support clockwise / anticlockwise direction rotating |

| Four level constant speeds (stepless speed) | V1=300r/min, V2=500r/min, V3=800r/min, V4=1000r/min (each speed can be set between 100-1400r/min) |

| Grinding head speed | 0-200r/min |

| Grinding head power | 0.2kw (clockwise rotating) |

| Grinding head lock mode | Automatic electronic lock |

| Sample holder | Standard Ø30mm 6 pieces of samples |

| Automatic mode | Can be programmed. Speed, running time and grinding wheel steering switch, with timing function |

| Samples pressure range |

Center load: 0-150N (Commonly used 40-120N) Single point load: 0-90N |

| Pressure loading type |

Single point pneumatic pressurization + Central pressure |

| Pressure adjustment |

Digital voltage regulation |

| Timing function |

0-99 minutes |

| Power supply |

AC220V, 50/60Hz, 2.8kW |

| Dimensions |

30.31" x 28.74" x 27.56" / 770 x 730 x 700 mm |

| Weight |

220 lbs / 100 kg |

GenGrind FA-IC 250D Standard Configuration

-

GenGrind FA-IC 250S Single Wheel Fully Automatic Grinder and Polisher with Individual and Central Pneumatic Force Control

-

Grinding Plate 254mm

-

Polishing Cloth with PSA (250mm) (4)

-

Grinding Papers 400# (4)

-

Grinding Papers 800# (4)

-

Grinding Paper 1200# (4)

-

Waterproofing Ring (On Machine)

-

Paper Disc

-

Magnetic Disc

-

Water Inlet Hose 0.75”

-

Water Outlet Hose 32mm

-

Power Line and Operational Manual

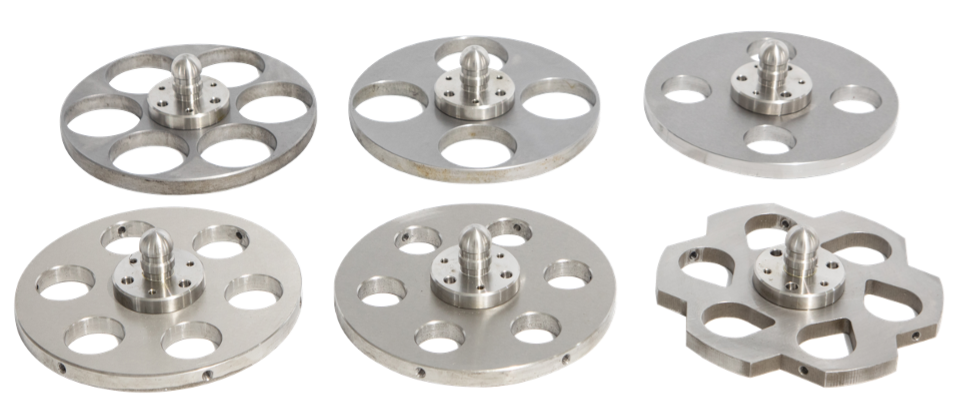

Specimen Sample Examples

Important Note: Sample Specimen Size to be indicated at time of order!

Related Products

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenGrind Belt BF - Floor Standing Heavy Duty Dual Stage Belt Grinder for Metallographic Sample Preparation

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations.

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

GenGrind FA-IC Dual Wheel Fully Automatic

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.