Metal Testing Equipment

Description

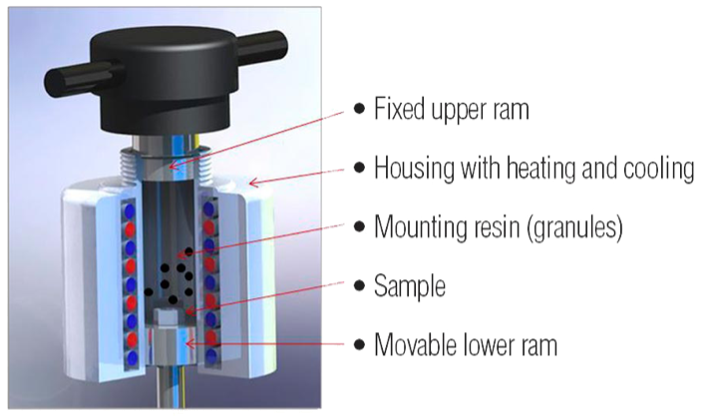

NextGen's GenPress MFA Dual HYD - Fully Automatic Mounting Presses for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples. The fully automatic mounting press system is controlled with a 7” touch screen controller where the parameters for heating, cooling and timing can all be adjusted and saved. GenPress - automatic hot mounting press can store up to 100 operator created programs which can be easily selected and repeated. The fully automatic metallographic mounting press system frees the operator to perform other tasks in the laboratory during the cycle and sounds an alarm when the cycle is completed. Read more in our MEGA blog!

The MFA series - mounting presses has an integrated motorized system to apply the necessary compression to form quality samples. The unit is conveniently sized to be configured for any laboratory or production setting. Sample sizes are available in 1”, 1.25", 1.5", 1.75”, 2" as well as 25mm, 30mm, 40mm and 50mm. With the use of optional sample spacers, the MFA series - hot mounting presses can prepare one to two mounted samples in a single cycle. This state-of-the-art automatic mounting press provides a cost effective option for a fully automatic metallography mounting press.

GenPress MFA Dual HYD Standard Configuration

-

Mounting Press

-

Mold Assembly (please identify which size of mold assembly upon ordering)

-

Powder Spoon

-

Funnel

-

Water Inlet Pipe

-

Drain Pipe

-

Cleaning Brush

-

2x Dual Spacers

-

Operation Manual

GenPress MFA Dual HYD Features

-

High Quality ABS Shell allowing for a modern appearance with ease of cleaning and maintenance

-

Touch Screen Control – 7” User Friendly Interface

-

Precision Hydraulic Operated Cycles with Silent Operation

-

Closed Loop Fully Automatic Process

-

Integrated Cooling System allows for more efficient sample preparation times

-

Molds can be customized depending on your size requirements

-

Operated Manually or Automatically – depending on your requirements

-

Up to 100 Sets of Cycle Memory

-

Up to 4 samples can be produced in one cycle

GenPress MFA Dual HYD Technical Specification

|

Model |

GenPress MFA Dual HYD |

|

Mold Diameter |

Ø22/25/30/40/45/50mm or Ø 1"/1.25"/1.5"/1.75"/2" |

|

Standard Features |

Programmable database with the ability to store over 100 programs |

|

System Pressure |

0-300Bar |

|

Pressure Setting Range |

0-60Bar |

|

Heater Power |

4KW |

|

Temperature Range |

0 - 200 ℃ adjustable |

|

Time Range |

0-99min |

|

Cooling Down Time Range |

0-99min |

|

Pressure Loading |

Automatic loading pressure (by hydraulic system) |

|

Cooling |

Water cooling (Chiller available as an optional purchase) |

|

Mounting Program |

Can edit and save over 100 mounting programs |

|

Operation and Display |

7-inch touch screen |

|

Working mode |

Automatic and/or Manual Operation |

|

Total Power |

4.5KW |

|

Power Supply |

AC220V 50/60 Hz |

|

Dimension & Weight |

30” x 23” x 22”; 209lbs / 760 x 580 x 550mm; 95kg |

FAQs

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press is a fully automatic dual hydraulic mounting press that has been designed with the primary purpose of facilitating the compression and mounting of material samples. In order to prepare metallographic samples, it is crucial to follow this procedure. Through this process, material samples are securely anchored and properly oriented, rendering them ready for microscopic observation and scrutiny.

The "Fully Automatic" designation of the GenPress MFA Dual HYD indicates its adeptness at executing the mounting task with minimal manual oversight. Such automation not only bolsters operational efficiency but also ensures consistent sample preparation, a factor paramount to achieving accurate and reproducible analytical outcomes.

GenPress MFA Dual HYD is the result of modern technological advancements in the metallography field, and was designed to optimize the phase of sample preparation while maintaining the highest levels of precision and dependability.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press incorporates a 7” touch screen controller, offering an intuitive interface for users. By using this advanced touchscreen mechanism, users are able to manipulate a wide range of operational parameters that are essential to the mounting process seamlessly.

Specifically, the controller facilitates heating, cooling, and timing adjustments. This ensures that the mounting conditions can be tailored to meet the unique needs of diverse material samples. This optimizes the preparation process for best results. Furthermore, these customized parameters can be stored on the controller, allowing users to save specific configurations for consistent and repeatable results in future sample preparations.

The GenPress MFA Dual HYD's 7-inch touchscreen controller serves as a central hub, centralizing all aspects of its operation and streamlining the overall process. As a result, it provides the users with the flexibility and precision they need in order to prepare expert metallographic samples.

Click here to learn more about the product or here to receive a personalized quote.

In addition to being a fully automatic dual hydraulic mounting press, the GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press has an advanced storage feature, making it suitable for automatic hot mounting. With this machine, you will be able to store as many as 100 different programs that have been crafted and configured by the operator. In situations where consistency and repeatability are required in the preparation of samples, such a feature becomes particularly valuable.

In order to avoid manual reentry of each process parameter, operators can conveniently select one of their previously saved programs instead of having to enter each parameter again. This ensures both accuracy and efficiency, as the press can repeatedly use the desired settings. This optimizes the preparation process and saves time for the operator. In a nutshell, the GenPress MFA Dual HYD exemplifies how modern machinery blends user-friendliness with high-end technical capabilities, resulting in a seamless metallographic sample preparation experience.

Click here to learn more about the product or here to receive a personalized quote.

With the GenPress MFA Dual HYD Hydraulic Mounting Press, users will be able to achieve maximum operational efficiency thanks to the fully automatic system. One of its most notable features is its full automation, which allows the mounting press system to run its cycle autonomously.

For operators, this autonomy translates into valuable time savings. Instead of being anchored to the device, they can engage in other pivotal tasks in the laboratory while the machine operates. This multitasking capability ensures optimal utilization of operator time, streamlining workflow in a busy laboratory environment.

Furthermore, to ensure operators are kept informed, the mounting press is equipped with an alert mechanism. Once the cycle concludes, an alarm sounds, notifying the operator. This alarm feature ensures that even while attending to other tasks, the operator remains informed about the press's completion status. The GenPress MFA Dual HYD seamlessly marries automation with user engagement, epitomizing laboratory efficiency.

Click here to learn more about the product or here to receive a personalized quote.

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press is equipped with an integrated motorized system, a crucial feature when it comes to ensuring the smooth running of the machine. This motorized system has been designed to apply the essential compression needed to shape material samples effectively.

The system ensures a consistent and accurate compression process. Such uniformity in pressure application is crucial to producing samples that are both uniform and of high quality. This is especially significant in metallographic sample preparation where precision and repeatability are of importance.

By utilizing a motorized system, the GenPress MFA Dual HYD provides enhanced control and reliability. It allows for consistent sample formation, minimizing potential variations from manual or less controlled processes. In essence, the integrated motorized system is a testament to the machine's commitment to excellence in sample preparation. This ensures that each sample meets the exacting standards set by field professionals.

Click here to learn more about the product or here to receive a personalized quote.

Its dimensions have been carefully chosen to ensure it is neither too bulky nor too compact. This deliberate size makes the unit versatile enough to seamlessly fit into a range of environments. This is whether it be a laboratory with space constraints or a large production setting.

Being "conveniently sized" means users can expect efficient space utilization without compromising device functionality. This becomes especially useful in laboratories or production settings where every inch of space matters and where equipment is frequently rearranged to optimize workflows.

Furthermore, this thoughtful sizing emphasizes the press's suitability for a wide spectrum of users, from research institutions to industrial production units. It underscores the design team's commitment to offering a mounting press that aligns with the varying spatial needs of professionals in different sectors. In essence, with the GenPress MFA Dual HYD, users invest in a device that promises flexibility in installation without compromising its performance capabilities.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press offers a versatile range of sample sizes to cater to diverse requirements. Users can choose between imperial and metric measurements. Imperial sizes include 1”, 1.25", 1.5", 1.75”, and 2". On the other hand, for those who prefer metric measurements, the sizes include 25mm, 30mm, 40mm, and 50mm.

This range of available sample sizes ensures that the mounting press can accommodate various sample dimensions. This makes it an ideal choice for professionals working on different types of projects or analyses. The flexibility in sample size further underscores the press's adaptability, ensuring it meets the specific demands of each task while maintaining high-quality results. In conclusion, with the GenPress MFA Dual HYD, users can expect a device designed to handle a broad spectrum of sample sizes. As a result, it can be utilized in a variety of metallographic sample preparation scenarios.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press boasts a well-rounded standard configuration to cater to diverse needs. At the heart of this setup lies the mounting press, a critical component that facilitates the primary functions of the equipment. As part of the press comes the mold assembly. Users should determine and communicate their specific size requirements for the mold assembly during order placement.

In addition to the primary components, accessories simplify mounting. These include a powder spoon for accurate material measurement, a funnel for seamless substance transfer, and a water inlet pipe feeding cooling water into the system. Additionally, the drain pipe is designed to efficiently expel waste water, ensuring cleanliness. A cleaning brush is also provided to maintain the system's cleanliness and longevity. The package is further enhanced with two dual spacers, which increase its adaptability to different sample preparations. Rounding up the configuration is an operation manual. This offers users a comprehensive guide to the equipment and its varied features, ensuring they make the most of their investment.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press is constructed with a high-quality ABS shell. This choice of material brings multiple advantages to the device.

Firstly, ABS, which stands for Acrylonitrile Butadiene Styrene, is a popular thermoplastic polymer known for its resilience and durability. The use of this material ensures that the mounting press remains protected against regular wear and tear, increasing its lifespan and consistent functionality.

In addition to its robust nature, the ABS shell gives the machine a contemporary and polished appearance. This aesthetic appeal complements its functionality, making it suitable for both modern laboratories and industrial production settings.

Another significant advantage of the ABS shell is its user-friendly design that simplifies cleaning and maintenance. Such a feature is essential in settings like metallographic laboratories where cleanliness is vital. Simple maintenance also ensures minimal operational downtime, contributing to efficiency and productivity.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press features precision hydraulic operated cycles, a key component that sets it apart in the realm of mounting presses.

This hydraulic system is designed to ensure that every press cycle is accurate, consistent, and reliable. By utilizing hydraulic mechanisms, the press can achieve the necessary compression forces for mounting samples with the utmost precision. Such precision ensures that samples remain intact, a critical requirement for metallographic sample preparation.

Moreover, while many hydraulic systems can be loud or disruptive, the GenPress MFA Dual HYD is engineered to operate silently. This silent operation is a boon, especially in laboratory environments, where maintaining a quiet atmosphere is often essential for concentration and precision in other tasks.

The integration of precision hydraulic operated cycles in the GenPress MFA Dual HYD provides optimal performance while maintaining a serene workspace. It epitomizes efficiency and user comfort, making it an indispensable tool for metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Closed-loop systems refer to feedback-controlled mechanisms. As a result, the press continuously monitors its operations, gathers data from various sensors, and makes real-time adjustments to maintain the desired operational parameters. The process runs in a "loop," with the system consistently checking and rechecking its performance against predefined standards.

Incorporating a fully automatic process into this closed-loop mechanism means that, once set, the GenPress MFA Dual HYD can complete its sample preparation tasks with minimal manual intervention. The press handles every step, from adjusting pressures and temperatures to timing the mounting cycle. This is done while constantly maintaining the desired parameters.

The benefits of such a system are numerous. It guarantees consistent and high-quality results each time, reduces human error, and saves time for operators. By automating the intricate steps involved in sample preparation and ensuring they adhere strictly to set guidelines, the GenPress MFA Dual HYD stands out as a reliable and efficient tool in metallography labs.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press offers a significant degree of adaptability when it comes to mold sizes. This caters to the varied requirements of metallographic sample preparation. Recognizing that different samples and applications might have unique size demands, the press provides the option to customize molds.

This customization feature ensures that laboratories and production settings can obtain the exact mold dimensions they require for their specific tasks. This enhances the precision and quality of mounted samples. Whether for specialized research, unique materials, or particular analysis methods, having the right mold size is crucial.

By offering customizable mold options, the GenPress MFA Dual HYD accommodates a wide range of sample sizes and ensures a more efficient and tailored mounting process. This flexibility demonstrates the press's commitment to meeting diverse needs and ensuring optimal results in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Using the GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press, you will be able to choose between manual and automatic operation modes. The manual mode allows users to directly control the mounting process, allowing hands-on management of each step during the mounting process. It is especially useful when operators need to make precise adjustments during specific tasks or when they want immediate oversight of the process in order to make nuanced adjustments.

The automatic mode, on the other hand, facilitates a more streamlined operation, as compared to the manual mode. Once the necessary parameters are set, the mounting press completes the process without further intervention. This is ideal for routine tasks, batch operations, or when consistency across multiple samples is desired.

It is important for users to understand that by providing both manual and automatic operation modes, the GenPress MFA Dual HYD allows users to choose the mode that best meets their needs.

Click here to learn more about the product or here to receive a personalized quote.

With this device, up to four samples can be accommodated and prepared within a single operation cycle. As a result of the multi-sample capability, laboratories and production settings can achieve higher throughput, which is crucial in environments where time is of utmost importance. Instead of processing samples sequentially, which could be time-consuming, the GenPress MFA Dual HYD allows batch processing. By doing this, not only does the preparation process go faster, but it also ensures a consistent level of quality for all the samples.

Further, the mounting press is able to handle multiple samples at the same time, which allows it to maximize its operational efficiency as well as reduce potential downtimes and ensure a smooth workflow in the process. Together with its other advanced features, this capability makes the GenPress MFA Dual HYD an invaluable asset for professionals seeking to prepare metallographic samples with precision and productivity at the same time.

Click here to learn more about the product or here to receive a personalized quote.

GenPress's MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press has a wide range of pressures set for this mounting press as it is fully automatic and dual-hydraulic. In the beginning, it starts at 0 Bar and rises to a maximum of 300 Bar.

Such a wide pressure range allows the press to adapt to different sample types and mounting requirements. Whether dealing with delicate samples that require minimal pressure or more robust samples that necessitate higher pressure for proper mounting, this equipment can handle it all.

Having the flexibility to adjust the system pressure ensures that each sample is treated with the precise amount of pressure it requires. This ensures the integrity of the sample and the quality of the mounting. The comprehensive pressure range of the GenPress MFA Dual HYD is one of the features that make it a versatile and valuable tool for metallography professionals.

Click here to learn more about the product or here to receive a personalized quote.

GenPress MFA Dual HYD is a fully automatic dual hydraulic mounting press that offers a pressure setting range of 0 Bar to 60 Bar when using dual cylinders.

Operators can set the specific pressure values that can be used for the mounting process within this range. By doing so, one is able to tailor the pressure applied to the material sample based on the nature and requirements of the material sample. It ensures that delicate samples are not exposed to excessive pressure while more robust samples receive adequate compression for optimal mounting.

Having a defined pressure setting range helps operators achieve consistent and high-quality results. It underscores the press's capability to offer both versatility and precision, ensuring that the metallographic sample preparation process is as accurate and efficient as possible. With the GenPress MFA Dual HYD, operators can confidently set the right pressure for each sample, further enhancing their quality and reliability.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press is equipped with a robust heating system to facilitate optimal sample preparation. There is a 4KW motor in this mounting press which provides the necessary power.

Due to this significant heating capacity, mounting samples can be heated rapidly and uniformly, enabling an efficient compression mounting process. A heater with a power output of 4KW ensures that the device is able to attain the required temperature in a short period of time. This reduces users' wait time and ensures the mounting process is efficient.

Such substantial heater power is crucial for metallographic sample preparation precision and speed. It not only helps achieve the desired sample mounting conditions promptly but also supports consistent performance across multiple mounting cycles. With a 4KW heater power, the GenPress MFA Dual HYD is well-suited to handling a wide variety of samples, ensuring they are adequately prepared and ready for subsequent analyses.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press boasts a versatile temperature range to cater for a range of sample preparation needs. Temperatures can be easily changed from a minimum of 0°C to a maximum of 200°C within the adjustable range.

This wide temperature spectrum provides users with the flexibility to set the desired temperature based on the specific requirements of their samples and the materials they are working with. The ability to adjust the temperature up to 200°C ensures that samples can be mounted under optimal conditions, resulting in high-quality preparations.

Moreover, the lower limit of 0°C is particularly beneficial when samples require cooler conditions or when the machine needs to revert to resting or standby mode. This comprehensive temperature range underscores the press's commitment to precision and adaptability in metallographic sample preparation.

The GenPress MFA Dual HYD's adjustable temperature range of 0°C to 200°C enhances its versatility. This ensures that it can cater to a broad spectrum of mounting needs in varied laboratory and production settings.

Click here to learn more about the product or here to receive a personalized quote.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press is designed with energy efficiency and robust capabilities. It has a total power consumption of 4.5KW. This power rating is a testament to the machine's capability to efficiently handle mounting material samples while maintaining optimal performance.

The 4.5KW power rating ensures that the mounting press has adequate energy to perform all its functions. This includes heating and cooling to operate the motorized system for compression and hydraulic operations. Press power consumption has been optimized to ensure consistent results without unnecessary energy waste.

Furthermore, the 4.5KW power consumption indicates that the mounting press, while powerful, does not require excessive energy. This can be a significant advantage in laboratories and production settings where energy efficiency and cost-saving are paramount.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press, with its 4.5KW total power consumption, strikes a balance between providing the necessary energy for high-quality sample preparation and being mindful of energy use and costs.

Click here to learn more about the product or here to receive a personalized quote.

The dimensions of this mounting press are 760mm in length, 580mm in width, and 550mm in height. Alternatively, this can be represented as being 30 inches by 23 inches by 22 inches. Because of its compact design, the mounting press is able to occupy minimal space while performing at an efficient level.

Considering weight, the mounting press weighs 95 kilograms, or approximately 209 pounds. This weight reflects the robust construction and integration of quality materials and components within the press, ensuring stability and durability. Such a weight ensures that the device remains stationary during operations, minimizing any potential disturbances or vibrations that could affect the mounting process.

The GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press is designed with a footprint of 760 x 580 x 550mm and a weight of 95kg. It provides both compactness and stability in its operation, making it a suitable choice for various settings.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenPress MFA MOT - Fully Automatic Motorized Mounting Press – Motor Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA MOT mounting press system frees the operator to perform other tasks in the laboratory during the cycle allowing better efficiency

GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly

GenPress Mounting Press for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material sample

GenVac MP3 Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

Experience our enhanced version of the GenVac MP Series. Our user-friendly touch screen interface along with automatic unit conversion and memory modes holds the title of one of the most advanced systems in the marketplace.

GenVac MP Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

GenVac MP2 - Vacuum Impregnator is designed for precision sample impregnation for porous materials. Common applications for vacuum impregnation systems include rocks and minerals, ceramics, electronic circuit boards and other composite materials.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.