Metal Testing Equipment

Standards

ISO 148, ASTM E23, ISO 179, ISO 180, ASTM D6110, ISO 8256, ASTM D256, ASTM D2444, ASTM D3763, ASTM D7192, ASTM E208

Description

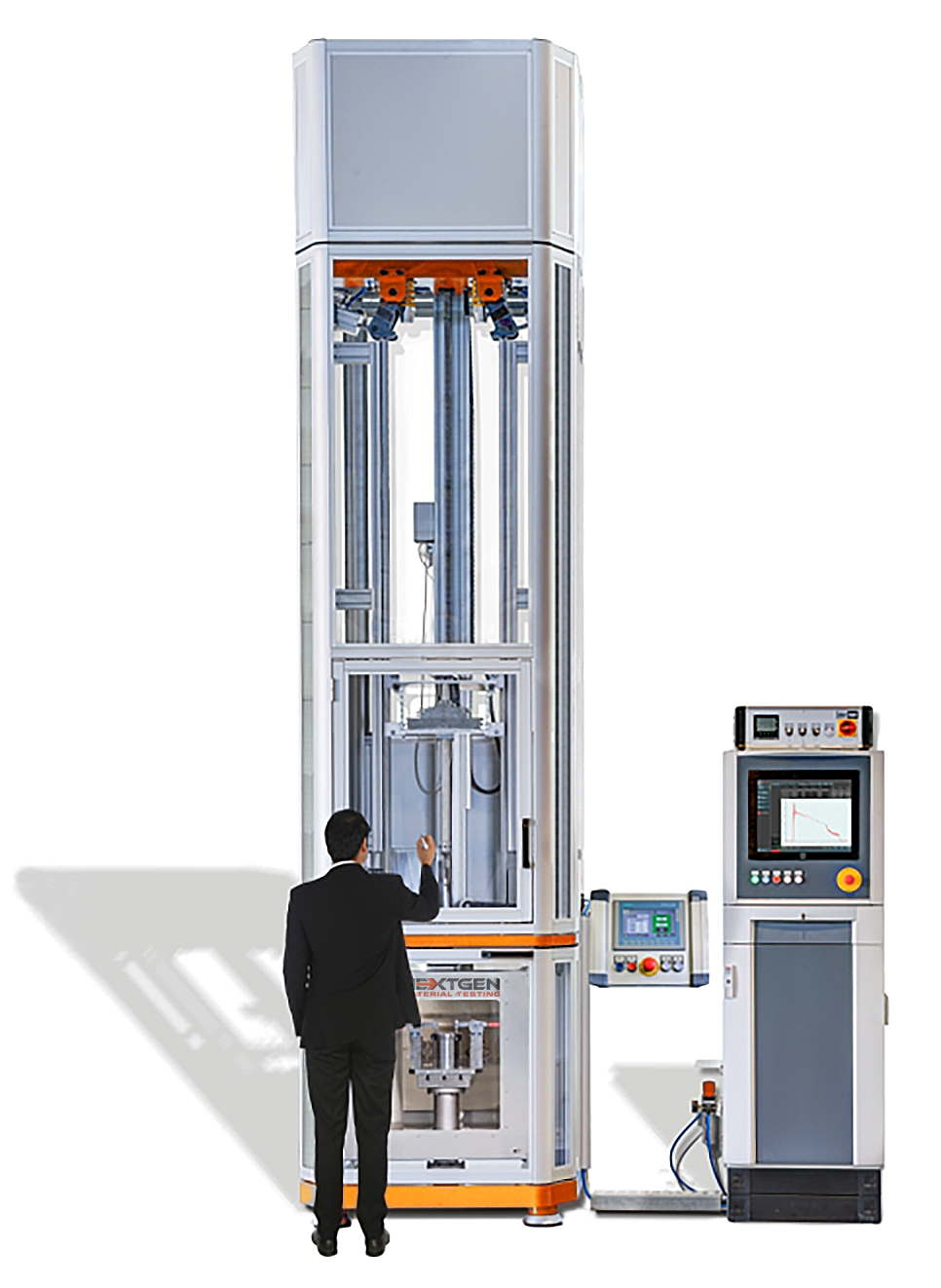

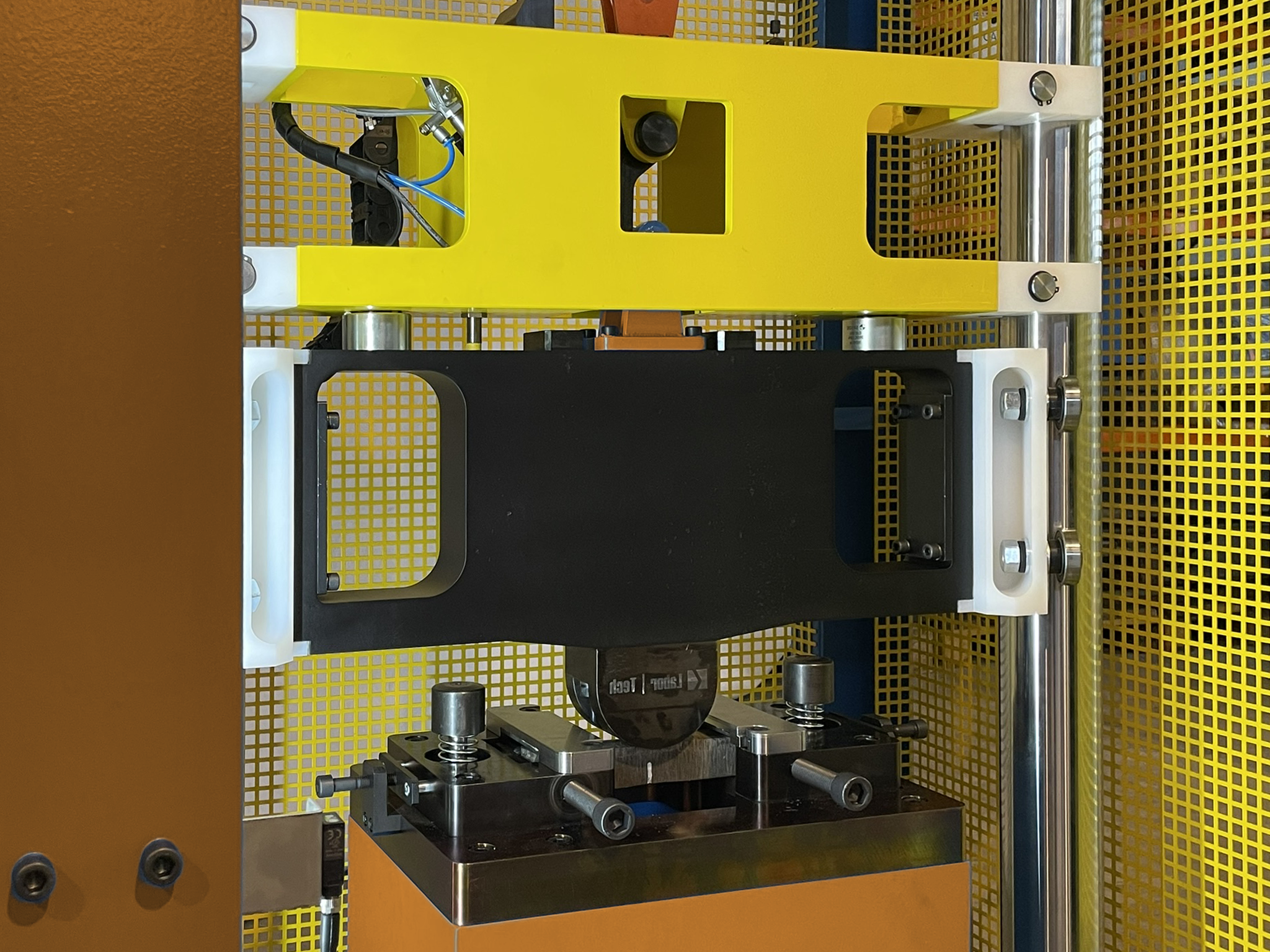

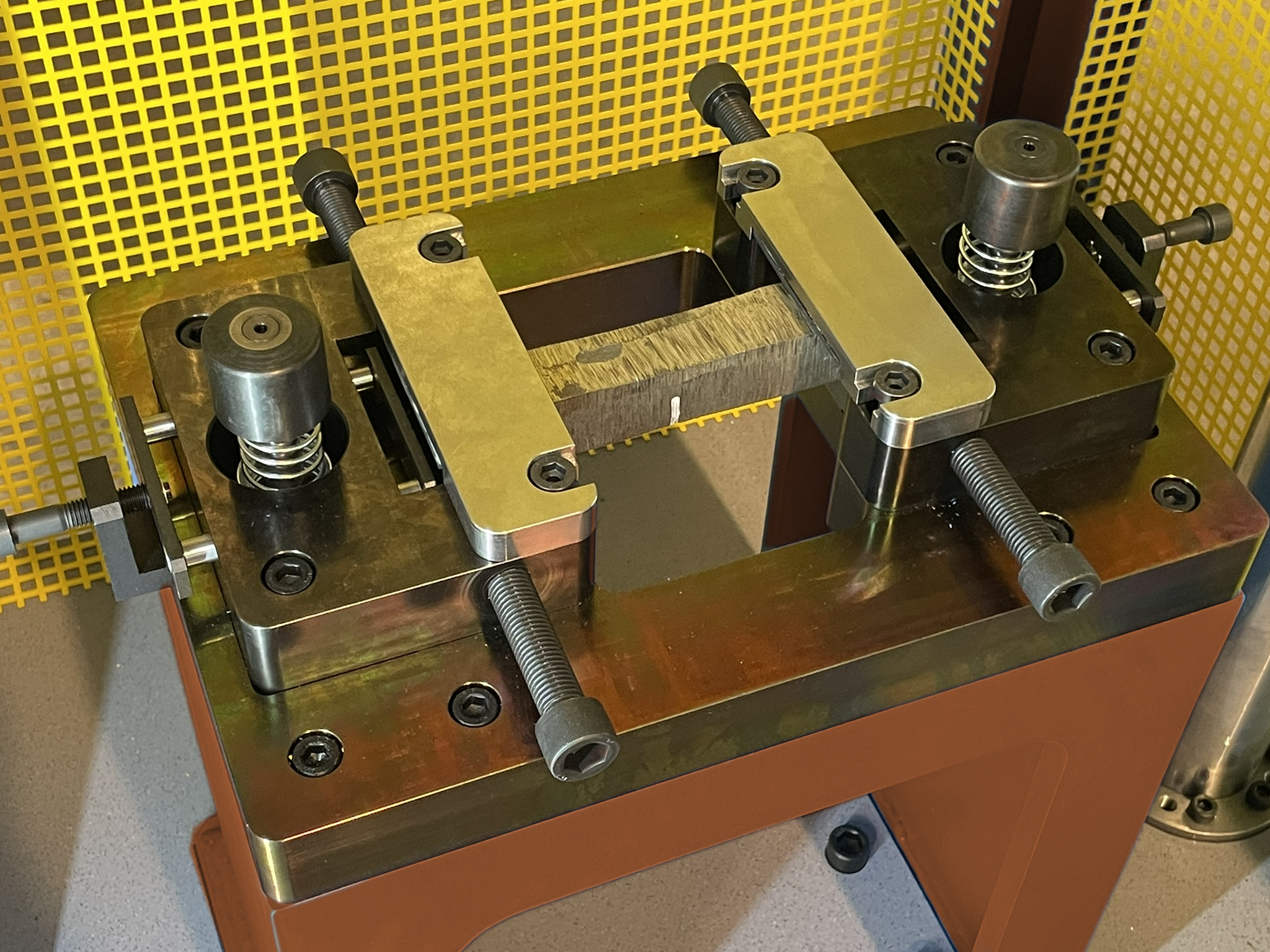

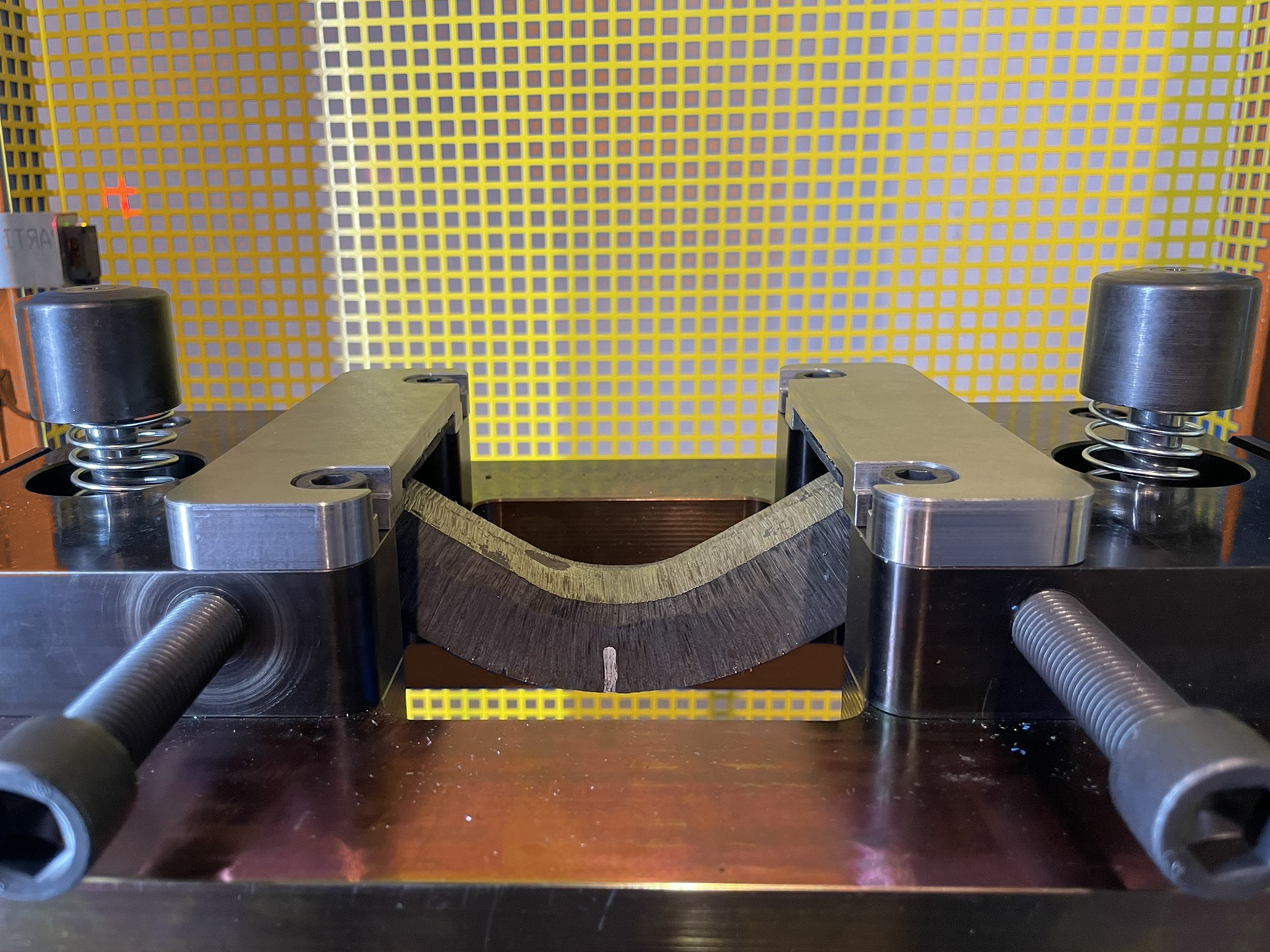

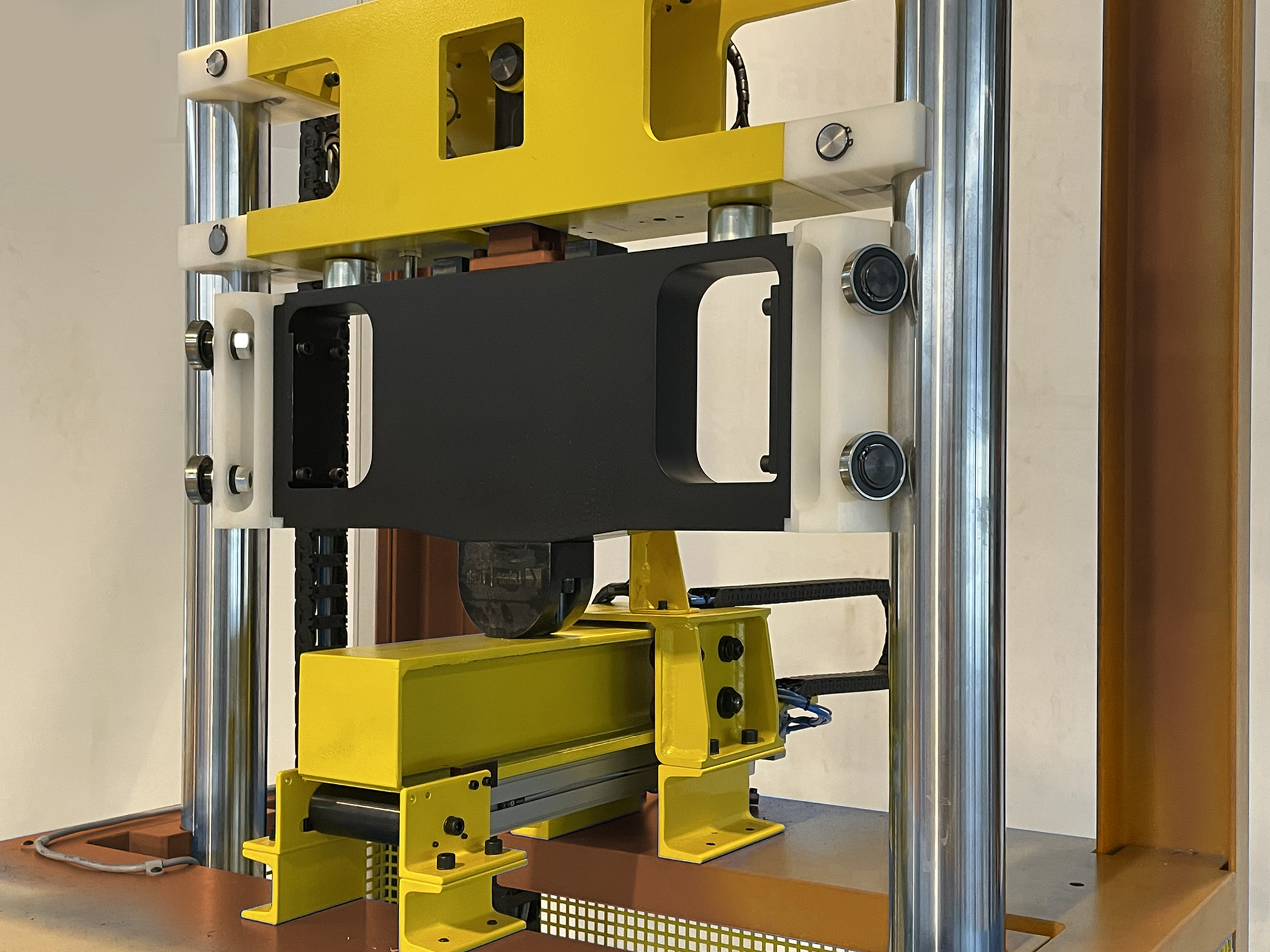

NextGen's FWT Series low-capacity drop weight testers, including models NG-FWT1 and NG-FWT2, are engineered for testing materials, samples, and components of various shapes across a broad spectrum of low to medium energy levels, with nominal energy capacities up to 2000J. Our advanced equipment enables precise simulation of material and component behavior under diverse conditions, including varying speeds, energy impacts, drop heights, collisions, accidental falls, and repeated impacts. Our newest drop weight testers are available in multiple configurations and are designed to comply with the stringent testing standards such as EN, ISO, ASTM, GOST, BS, and NF. They feature an integrated touch LCD monitor with DROPTest-S software or can be paired with a full-fledged PC running DROPTest – BASIC software, ensuring comprehensive compliance with customer requirements and industry standards. Read more in our Mega Blog!

NG-FWT1 & NG-FWT2 Drop Weight Testers Features

The NG-FWT1 and NG-FWT2 drop weight testers are engineered for high-precision impact testing, featuring:

-

Robust Vertical Frames – Designed with high rigidity and resistance to dynamic interference, ensuring durability, an ergonomic layout, and maintenance-free operation.

-

SIEMENS PLC Control – Integrated with an LCD touch screen running DROPTest-S software, enabling seamless operation at the machine base.

-

Comprehensive Test Management – The DROPTest-BASIC software provides full evaluation and test data management for impact testing applications.

-

Automated Lifting System – Precisely controlled electronic positioning adjusts the support to the required energy level or defined position.

-

Advanced Measuring Electronics – Expandable with 4MHz measurement speed, ideal for force and impact instrumentation.

-

Instrumented Test Mandrel Identification – Automatic recognition of test mandrels operating within EN ISO 7500-1 and ASTM E4 accuracy classes, with linearization capability.

-

Multi-Axis Expansion – Optional horizontal axis control for impact energy measurement at multiple points, along with an anti-reflection system for enhanced accuracy.

-

Regulatory Compliance – Fully meets EC machinery directives and incorporates the latest EN ISO 13850-SIL 1 safety features.

-

Calibrated Weights & Accreditation – Weights calibrated per the Metrology Act 505/1990 and certified by an EN ISO / IEC 17025 accredited laboratory.

-

Custom Test Preparations – Configurable for specialized test setups in accordance with industry standards.

-

Extreme Condition Testing – Compatible with temperature chambers or high-temperature furnaces for high-precision testing under varying thermal conditions.

NG-FWT Drop Weight Tester Machine Control

-

Centralized Control System – Ergonomically positioned controls for smooth operation and precise test execution.

-

Integrated Electronics & Safety Management – The NG-FWT1 and NG-FWT2 feature a Rittal central enclosure, housing all electronics and machine control components. The system runs on DROPTest-S-XXX safety software within a Simatic S7 safety PLC, utilizing electromechanical interlocking and modular expansion options.

-

Advanced Touchscreen Interface – Displays real-time test parameters, including fall height, energy dissipation, drop weight, and impact speed, ensuring precise monitoring and repeatability.

Security and Update Requirements

-

Compliance with European Safety Standards – The NG-FWT1 and NG-FWT2 meet all requirements of the European Machinery Directive (89/392/EEC and 91/368/EEC – Machinery Safety) for high-impact testing systems.

-

Certified TÜV Safety Circuit – Equipped with a certified safety control and monitoring system.

-

Advanced Safety Features – Designed in compliance with EN ISO 13849-1/2, guaranteeing high safety performance.

-

Dual-Layer Protection – All critical safety systems feature double-fused safeguards for maximum operational security.

-

Continuous Safety Monitoring – Real-time inspection of safety guards and access doors, integrating the latest EN ISO 13850-SIL 1 safety functions.

NG-FWT Drop Weight Tester Extensions

-

Advanced Instrumentation Expansion – Optional force measurement and impact trajectory analysis with high-speed 4 MHz electronics, integrated digital control, and the SPEED measurement unit for precise data acquisition. Powered by DROPTest-BASIC software with modular enhancements for expanded functionality.

-

Temperature-Controlled Testing – Optional cooling system expansion allows for temperature-controlled impact testing, supporting a maximum cooling capacity of up to 90°C for enhanced material behavior analysis.

-

Robotic System Integration – Fully automated robotic systems enable autonomous control, allowing the NG-FWT1 and NG-FWT2 to operate without human intervention for high-efficiency, repeatable testing.

DROPTest Software Features

DROPTest software is a core component of all NG-FWT1 and NG-FWT2 vertical impact testing systems, designed to improve productivity and testing accuracy in laboratories and quality control environments. Below, are the main features of the DROPTest software:

-

Purpose-Built for Drop Weight Testing – Engineered for precise and efficient impact analysis.

-

Customizable Sample & Test Standards – Edit sample types, modify item names, and adjust test parameters with ease.

-

Graphical Test Preparation – Visual guidance for individual standards and step-by-step work procedures.

-

Real-Time Digital Display – Live monitoring of impact force, velocity, and other key parameters.

-

Comprehensive Data Management – Store measured data in a searchable database with filters for order, date, and custom definitions.

-

Built-In Calibration Mode – Includes an extensive calibration suite for enhanced accuracy.

-

Automated Cooling Timing – Pre-programmed cooling cycles in accordance with EN ISO 148-1 and ASTM E23.

-

Data Integration – Supports data transfer from temperature chambers, thermometers, and other peripherals.

-

Multi-Language Support

-

Advanced Reporting & Export Options – Generate PDF reports, export data to CSV, MySQL, or MS SQL databases.

-

Unlimited Licensing – No restrictions on installations, allowing deployment on any system without licensing limitations.

NG-FWT Drop Weight Testers Technical Specifications

| Technical Data | Units | NG-FWT 200VP | NG-FWT 400VP | NG-FWT 600VP | NG-FWT 800VP | NG-FWT 1000VP | NG-FWT 2000VP |

| Energy Range | J | 0.3 - 294 | 0.3 - 405 | 0.3 - 588 | 0.3 - 757 | 2.5 - 882 | 2.5 - 1814 |

| Impact Speed | m/s | 0.7-4.42 | 0.7-4.646 | 0.7-6.26 | 0.7-4.645 | 1-7.67 | 1-8.52 |

| Fall height range | mm | 25-1000 | 25-1100 | 25-2000 | 25-1100 | 25-3000 | 25-3700 |

| Position accuracy | mm | 0.5 | |||||

| Weights Dimensions | kg | 0.5-30 | 0.5-37.5 | 0.5-30 | 0.5-70 | 0.5-30 | 0.5-50 |

| Accuracy weights classes | % | According to OIML | |||||

| Weight | lbs/kg | 798/362 | 873/396 | 913/414 | 1098/498 | 1098/498 | 1358/616 |

| Color finish | RAL | 1015, 5015 | |||||

| Dimensions | |||||||

| Height | in/mm | 104"/2620 | 104"/2620 | 144"/3650 | 105"/2650 | 184"/4680 | 222"/5650 |

| Width | in/mm | 31.5"/800 | 31.5"/800 | 31.5"/800 | 31.5"/800 | 31.5"/800 | 35.5"/900 |

| Length | in/mm | 22.5"/570 | 22.5"/570 | 22.5"/570 | 22.5"/570 | 22.5"/570 | 26.5"/670 |

| Environmental conditions | |||||||

| Operating temperature | °C | 10 to 35 | |||||

| Storage Temperature | °C | -35 to 55 | |||||

| Working space humidity | % | < 90 | |||||

| Noise level | dB | < 65 | |||||

| Electrical Connection | |||||||

| Supply voltage | V | 230...240/50-60Hz | |||||

| Fuse | A | 16 | |||||

| Power rating (without accessories) | VA | 820 | 820 | 820 | 1000 | 1000 | 2000 |

NG-FWT Drop Weight Tester International Standards Compliance

ISO & EN ISO Standards:

-

EN ISO 179-1

-

EN ISO 148-1

-

ISO 179-1

-

ISO 179-2

-

ISO 180

-

ISO 03-2

-

ISO 8256

-

EN ISO 6603-2

-

ISO 7765-2

-

EN ISO 179-1/-2

-

ISO 18352

ASTM Standards:

-

ASTM D2444

-

ASTM D256

-

ASTM D3763

-

ASTM D6110

-

ASTM D7136/D7136M-05

-

ASTM D7192

-

ASTM E208

-

ASTM E23

-

ASTM A370

-

ASTM F1614

-

ASTM F2412

-

ASTM E436

-

ASTM D5628

GOST Standards:

-

GOST 9454-78

-

GOST 30456-97

DIN & EN Standards:

-

DIN EN ISO 12100

-

DIN EN ISO 14120

-

DIN EN 60204-1 ed.2

-

EN 6038

Aerospace Standards:

-

Airbus AITM 1.0010

-

Boeing BSS 7260

-

DIN 65561

Related Products

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J, and lzod test from 1J to 22J.

Class D Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class D – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150J and a maximum capacity of 750J. The system comes standard with a digital display with software upgrade function for data plotting. The Class D impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J, 450J, 600J and a maximum of 750J capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.