Metal Testing Equipment

Standards

ISO 148, EN10045, ASTM E23, DIN 50115, ASTM E74 (Class AA)

Description

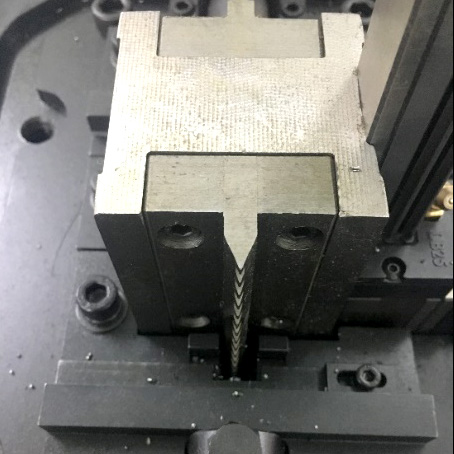

The GenNotch 4000 Series is a dual chamber motorized broaching / notching machine designed for Charpy Test notch specimens. This floor-mounted self-contained unit is equipped with a user-friendly interface for ease of operation. The GenNotch 4000 is designed for cutting Charpy and Izod V-type and U-type notches according to the latest industry standards, delivering the highest quality notching samples equivalent to that of a milling machine.

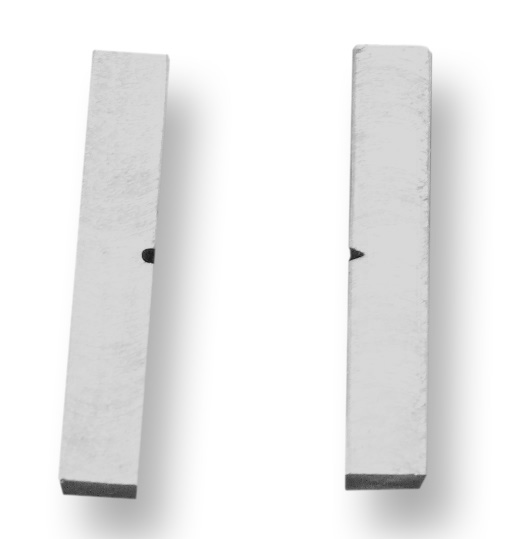

The GenNotch 4000 is able to prepare two specimens at one time due to its dual broaching system in mere seconds with exceptional accuracy and repeatability every time. The state-of-the art manufactured broaching knives can be purchased based on your preferred V or U types specimen preparation needs. The standard knives have been upgraded to prepare specimens up to 60 HRC.

GenNotch 4000 Series - Charpy / Izod Metal Impact Notching Machine

Technical Specifications

| GenNotch 4000 Series | |

|---|---|

| Broacher Travel | 340±10mm |

| Speed | 2-3m/min |

| Lubrication System | Lubricating oil circulation, the oil is interchangeable |

| Hydraulic Oil | L-HM46 (Anti-wear) |

| Oil Volume | 20L |

| Power Consumption | 350W |

| Power Requirements | 3-phase, 5-line, AC 220V±10%, 50Hz |

| Machine dimension (LxWxH) | 22.83 x 15.75 x 44.90-inches 58 x 40 x 114cm |

| Weight | 440lbs / 200kg |

Test Specimens

| GenNotch 4000 Series | |

|---|---|

| Specimen Size | 10x10(7.5, 5, 2.5)x55mm |

| Specimen Hardness | ≤HRC42 |

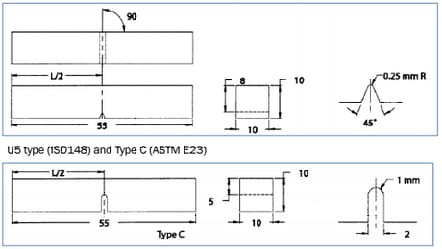

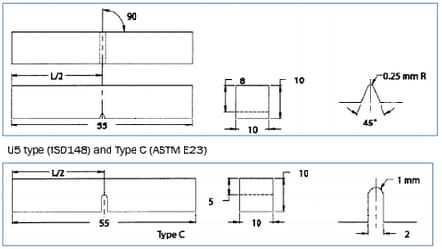

| Notch Type | V type: depth 2mm, 45°±2°, r=0.25mm±0.025mm |

| U2 type: depth 2mm, width 2mm, r=1mm±0.05mm | |

| U3 type: depth 3mm, width 2mm, r=1mm±0.05mm | |

| U5 type: depth 5mm, width 2mm, r=1mm±0.05mm | |

FAQs

GenNotch 4000 motorized specimen notching system complies virtually all North American and European standards including ASTM, E23-02a, EN10045, ISO148, ISO083, DIN 50115 and more.

The notching knives are custom designed with W18Cr4V material to guarantee the highest level of rigidity and slow wearable. Each impact broaching knive can be used approximately 20000 times.

The quoted system comes as a turnkey solution to include at least 2 specimen notching knives at no additional cost. Additional knives can be purchased separately.

Recently, GenNotch 4000 Notching System has been upgraded allowing the cutting capabilities of up to 60HRC.

Please specify the cutting requirements to your quality consultants for the most optimal impact V and U notching cutting solution for you.

Shavings and debris are simply collected on top of the machine. A simple brush or magnet is enough to clean the machine and keep it in top condition.

The NextGen broaching system requires little to no maintenance! The GenNotch system is equipped with an internal lubricating oil circulation system to reduce operator involvement on maintenance requirements.

The GenNotch is equipped with a dual broaching system and can prepare two samples in one pass!

The GenNotch 4000 series is a floor standing unit which is 43cm x 75cm x 125cm tall and weighs 200kg.

NextGen offers a variety of broaching tools to cover all international industry standards such as the Charpy and Izod V-type notch along with the U type notch as well!

A simple power requirement is all that is required to connect the GenNotch 4000 series Charpy notch broaching machine. A 3-phase, 5-line power requirement is needed. AC 380V 50/60Hz.

Absolutely! With a simple modification, both standard and sub-size Charpy and Izod Impact specimens can be prepared according to specification.

While we recommend an environment with laboratory standards, the GenNotch is robust and built to last for decades for Charpy V-notch and Charpy U-notch sample preparations.

Related Products

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.