Metal Testing Equipment

General

The optimal solution for all your requirements as regarding to your round tensile specimen production is our robust TensileTurn CNC XL. The XL is a boosted version from our original lathe machine giving a chance for preparing soft or tough square, round and irregular stock of materials with the right accuracy every time. The machine can keep remarkable turn times for various types of metals, composite materials, and alloys.

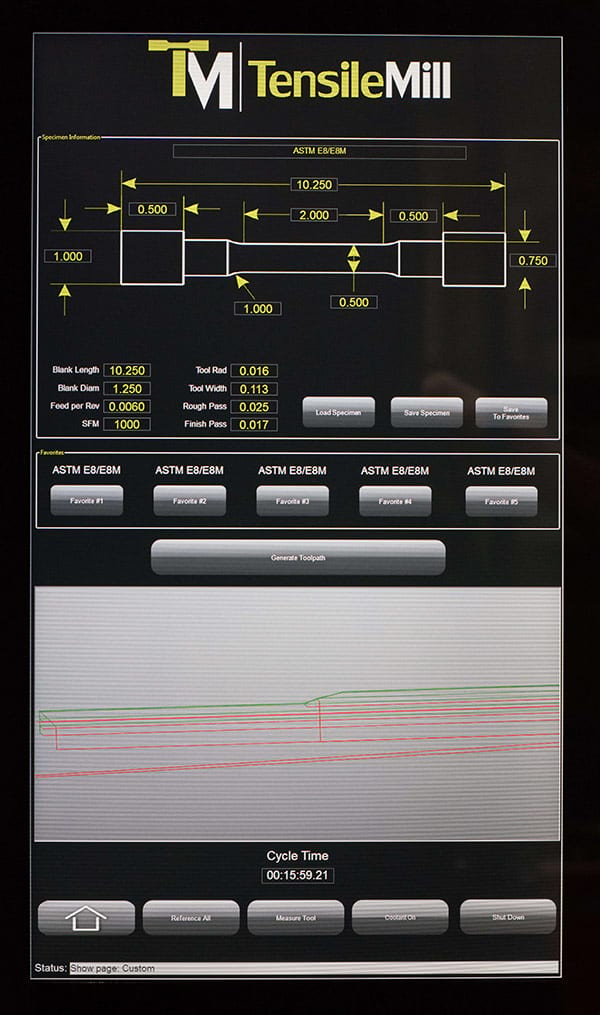

Similar to our original model, the XL comes standard with a big touchscreen interface that has our well known Tensile Software. The TensileSoft has a collection on common standards like (ASTM, DIN, ISO, etc.) letting you set up your round tensile test sample to speculation at all times. The software which is easy to use lets the XL to be controlled by almost any stage of engineering experience.

Also, the XL comes standard with our Carbon software that lets operators with more experience to program the machine for applications that are advanced such as knurling, drilling, sanding, turning or facing, cutting. Our group of expert CNC engineers will train your operators on how to utilize the machine properly for both tensile sample preparation and other machining requirements from CNC at the time of the suggested training and installation.

Similar to the original TensileTurn CNC, the XL can set up standard round tensile specimens, fatigue specimens, sub-size specimens, button-head tensile bars, threaded tensile specimens, and other round testing specimens. It is only required for the operator to just load the machine with stock that is either square, round or irregular.

This round tensile specimen preparation machine is the best solution for large and medium-sized laboratories. It is proficiently capable of keeping medium to high volume of day-to-day specimens while keeping to regular preparation correctness. The merging of user-friendliness, lightning-fast sample preparation speeds to speculate all the time, results in this gentle giant being a leader in the marketplace. The time and cost savings following the right operation of the machine saves tens of thousands of dollars per year for a facility of average size. The savings can be reflected in the notably reduced engagement of the operator and the removal of outsourcing tensile sample preparation needs for outside laboratories. Your facility is now able to make superior quality round tensile samples to spec in the comfort of your shop. The manufactured tensile samples can be immediately used for tensile testing proceedures.

Controller

The user-friendly 21"controller comes standard with our machine comprising of the Mach4 software with advanced CNC capabilities. The systems include 64 Gb of storage, Wi-Fi, 4 Gb of RAM Ethernet, macro B programming, 254 tool offsets, USB ports,126 work offsets, helical interpolation, mirroring and scaling, drilling canned cycles, advanced trajectory planning, sharp dual mode cutter compensation, and more. Also with the tensile milling software interface, Carbon also lets the operator get across the MACH4 industrial CNC Software used for professional CNC control functions. Our carbon software always has newly developed features, and every TensileMill CNC system includes updates at no extra cost.

Technical Specifications

|

TensileTurn CNC XL

|

|

|---|---|

| Capacity | |

| Max Swing Diameter |

450mm

|

| Standard Turning Diameter |

300mm

|

| Max Turning Length |

550mm

|

| Travel | |

| X Axis |

180mm

|

| Z Axis |

600mm

|

| Spindle | |

| Max RPM |

3500 RPM

|

| Spindle nose |

A2-6

|

| Spindle bore |

65mm

|

| Turret |

Servo Index

|

| Square Shank Height |

25mm

|

| Boring Bar Diameter |

40

|

| Speed | |

| Feed Rate |

X:20 / Z: 24 m/min

|

| Tailstock | |

| Taper |

MT4

|

| Quill Travel |

80mm

|

| Quill Diameter |

75mm

|

| Body Travel |

440mm

|

| Motor | |

| Spindle |

11 / 13Kw

|

| Axis Motor |

3 Kw

|

| Hydraulic Motor |

1.5 Kw

|

| Coolant Motor |

.55 Kw

|

| Power |

20 KVA

|

| Coolant |

140 L

|

| Dimensions | |

| Height |

87" / 2200mm

|

| Floor Space |

2600 x 1600mm

|

| Weight |

8818 lbs / 4000 kg

|

Related Products

TensileTurn CNC - Round Tensile Sample Preparation

Featuring a convenient size and high accuracy, the TensileTurn CNC can produce the highest accuracy in round tensile specimens. Able to prepare round tensile specimens, sub-size specimens, threaded tensile specimens, button-head tensile bars, fatigue specimens or any other round testing specimens, the TensileTurn CNC is easy to operate for both experienced and inexperienced operators.