Metal Testing Equipment

Description

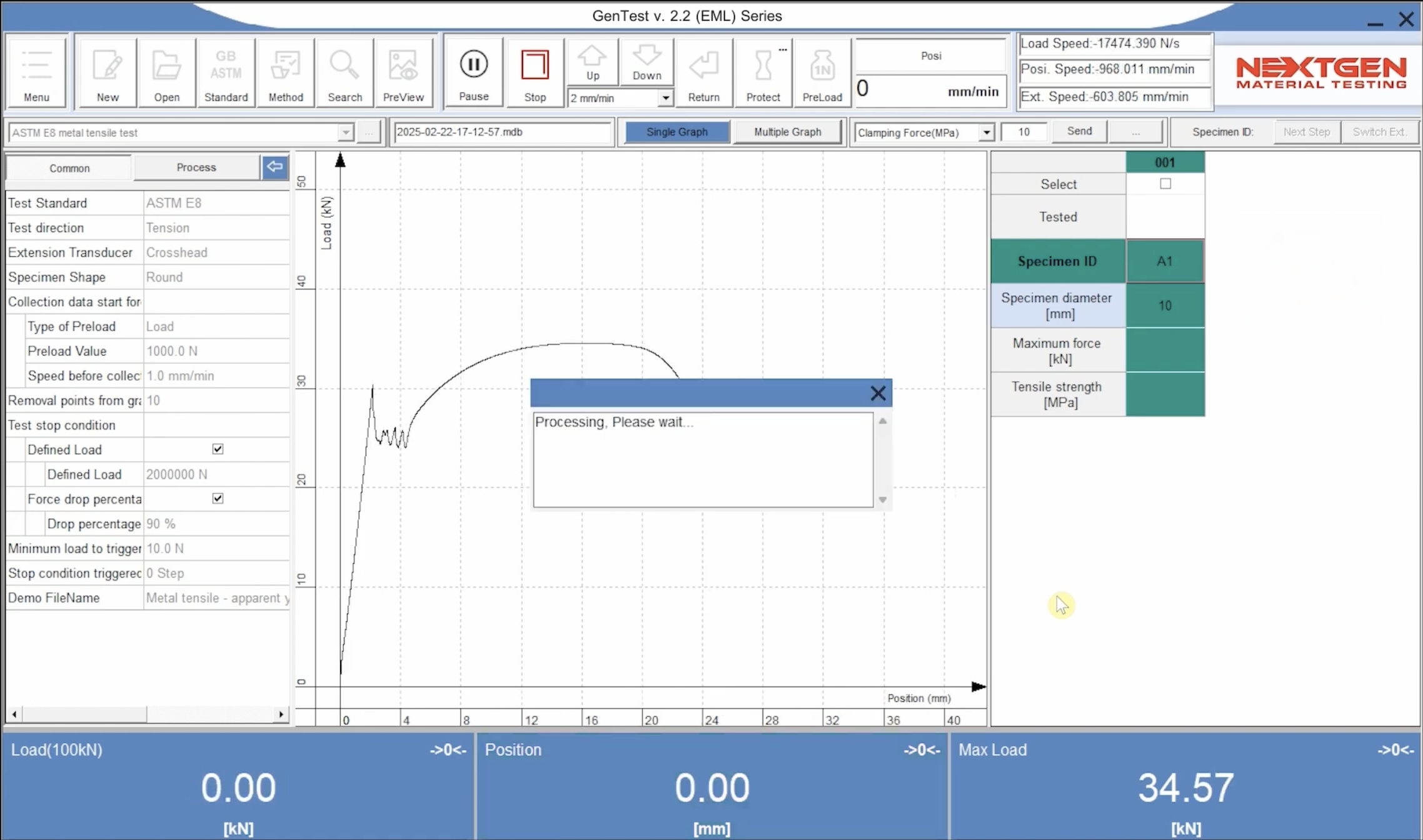

GenTest is the latest and most advanced data acquisition software designed for universal testing machines, offering seamless, precise, and repeatable mechanical testing across a wide range of materials and applications. Engineered for quality assurance (QA) and quality control (QC) environments, GenTest provides an intuitive interface, powerful analysis tools, and flexible reporting capabilities to meet the stringent requirements of global testing standards such as ASTM, ISO, DIN, EN, and BS. Fully compatible with NextGen’s NG-EML Series Electromechanical Universal Testing Machines, GenTest ensures efficiency, accuracy, and compliance for industries including metals, polymers, construction materials, biomedical products, and more.

With a growing library of pre-configured test methods, GenTest allows operators to quickly select industry-specific testing protocols, optimizing tensile, compression, impact, and fatigue testing with minimal setup time. Whether testing metals for aerospace durability, plastics for automotive safety, or composites for structural applications, GenTest streamlines the entire process, ensuring faster results, standardized reporting, and unmatched reliability. Upgrade to GenTest and experience the future of material testing software—where precision meets innovation.

GenTest Features

-

Comprehensive Test Method Library: Access a vast and continually expanding collection of pre-configured test methods, ensuring compliance with the latest industry standards.

-

User-Friendly Interface: GenTest's intuitive design allows to streamline test setup, execution, and data analysis.

-

Real-Time Data Acquisition: Monitor tests as they happen with high-speed data capture, providing immediate insights into material performance.

-

Advanced Analysis Tools: Utilize sophisticated algorithms for in-depth data analysis, enabling precise evaluation of material properties.

-

Customizable Reporting: Generate detailed, tailored reports that meet specific requirements, facilitating clear communication of test results.

-

Seamless Integration: Ensure compatibility with a wide range of testing equipment and systems, enhancing laboratory efficiency.

Related Products

NG-EML Single Column Bench Top - Universal Testing Machine (50N-5kN)

The single column Class A testing systems are suited for tension, compression, flexure and other testing applications where specimens require less than 5 kN and where lab space is limited. The system is equipped with 1/500,000 Force Resolution the system is capable to providing +/-1% down to 0.2N.

NG-EML Dual Column Bench Top - Universal Testing Machine (10N-20kN)

The dual column Class B testing systems are suited for tension, compression, flexure and other testing applications where load range requirements are between 10N to 20kN. This bench top model offer a user-friendly compact solution for your universal testing needs.

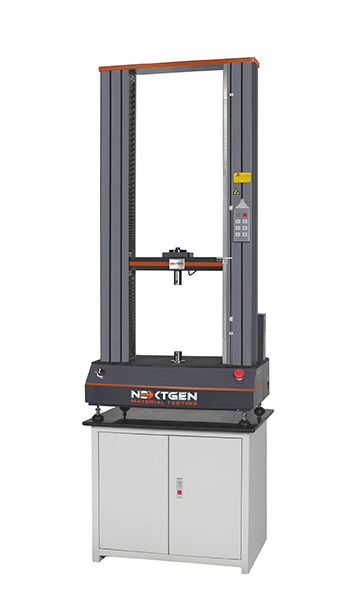

NG-EML - Dual Column Bench Top and Floor Standing - Universal Testing Machine (20kN-50kN)

The dual column Class C testing systems are suited for tension, compression, flexure and other testing applications where load range requirements are between 20kN to 50kN. The advanced load cell system offers ±0.5% accuracy down to 0.4% of capacity.

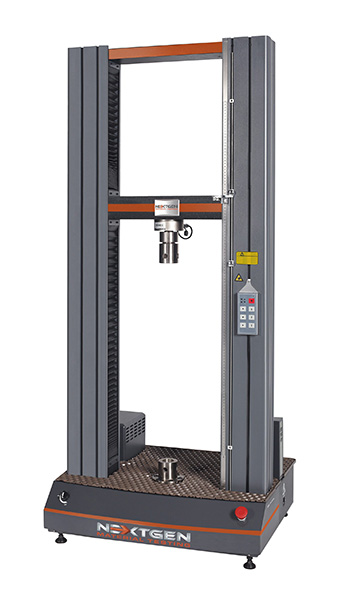

NG-EML Floor Standing - Universal Testing Machine (50kN-600kN)

The NG-EML Floor Standing - Universal Testing Machine (50kN-600kN) are suited for tension, compression, flexure and other testing applications where load range requirements are between 50kN to 600kN. This heavy duty system offers ±0.5% reading accuracy as well as position accuracy down to 0.021μm.