Plastic Testing Equipment

Standards

ISO 179, ISO 180, ASTM D6110, ASTM D 256, GB/T1043, GB/T 1843

Description

The GenNotch 2000 Series is a motorized broaching machine designed for Charpy Test notch specimens. This floor-mounted self-contained unit is equipped with a user-friendly interface for ease of operation. The GenNotch 2000 is designed for cutting Charpy and Izod V-type and U-type notches according to the latest industry standards, delivering the highest quality notching samples equivalent to that of a milling machine.

Alternative models including variable motor speeds for wider material ranges are available at your request.

Technical Specifications

| GenNotch 2000 Series | |

|---|---|

| Motor Speed | N=1440r/min |

| Machine Dimensions (LxWxH) | 12.8 x 14.8 x 18.1" 326 x 376 x 460mm |

| Maximum Specimen Thickness | 1" 25mm |

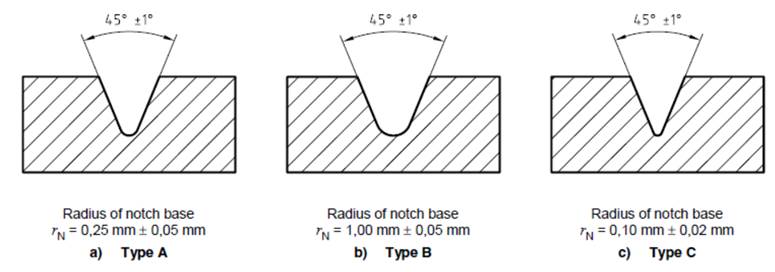

| Cutting Tooth | Type A comply with ISO 179, ISO 180, ASTM D6110, ASTM D256, GB/T1043, GB/T 1843, Type B, Comply with GB/T1043, GB/T 1843, ISO 179, ISO 180 Type C, comply with GB/T1043, ISO 179 |

| Weight | 66lbs / 30kg |

| Standard Accessories | 1. Main Unit: 1 set 2. Cutting Knife: 1 set 3. Fixture: 1 set |

Related Products

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J, and lzod test from 1J to 22J.

Advanced Motorized Multi-Specimen Notching and Broaching Machine for Impact Testing on Plastic Specimens GenNotch 3000

Description The GenNotch 3000 machine is designed for creating notches in plastic specimens for Charpy impact testing. It has a capacity to hold 20 samples simultaneously and can process 60 samples within a 10-minute timeframe. With its high processing accuracy, […]