Rubber Testing Equipment

Standards

Description

Our aging oven is well-suited for performing drying, baking, wax melting, and sterilization experiments in industrial and mining enterprises, as well as in laboratories, colleges, and research institutions.

Aging Oven Technical Specifications

|

Aging Oven |

|

|

Operational Mode |

Microprocessor temperature control with LCD display, button type and fuzzy PID control technology |

|

High precision platinum resistance sensor |

|

|

Forced circulation convection duct |

|

|

Temperature Control Range |

Rt+10~200℃/Rt+10~300℃ |

|

Accuracy |

0.1℃ |

|

Volatility |

±1℃ |

|

Alarm |

SV+5℃ |

|

Uniformity |

±2℃ at 100℃ |

|

Power Consumtion |

2000W |

|

Interior Material |

304 stainless steel |

|

Exterior Material |

08F Cold rolled steel plat |

|

Inner Chamber Dimensions |

23.65" x 19.70" x 29.55" / 600 x 500 x 750mm |

|

Outer Chamber Dimensions |

34.65" x 28.35" x 36.65" / 880 x 720 x 930mm |

|

Weight |

199lbs / 90kg |

FAQs

Yes, the Aging Oven is designed to comply with QB/T 2920-2010 standard, which outlines the requirements for performing aging tests on rubber materials. The oven in which the aging test will be performed must meet the requirements outlined in this standard in order to assure consistency and reliability of the results.

Compliance with QB/T 2920-2010 means that the Aging Oven can accurately simulate the environmental conditions under which rubber materials age, providing data on their durability and performance over time. It is for this reason that the oven is a valuable tool for quality control, research, and development in industries that use rubber components in their production. In terms of material performance and product longevity, the Aging Oven meets this standard, providing reliable results that can be used to make informed decisions about material performance.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven is well-suited for a number of experiments, including drying, baking, wax melting, and sterilization. Considering its capabilities, it is a valuable tool in industrial and mining enterprises because of the way it operates.

For drying experiments, the oven provides controlled conditions to remove moisture from samples. It is ideal for quality control and product development in the baking industry since the precise temperature control of the oven allows it to heat materials evenly, thus making it ideal for quality control and product development. Wax melting is another key application, where the oven’s ability to maintain stable temperatures makes sure wax melts uniformly without overheating or burning.

As a result of the oven's high-temperature capabilities, sterilization experiments can benefit from the oven's ability to effectively kill bacteria and other microorganisms, which is important to maintain sterility in a laboratory setting.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven is designed for versatile use in many settings, including industrial and mining enterprises, laboratories, colleges, and research institutions. As a result of its robust and reliable performance, it is well-suited to a large assortment of applications in these types of environments.

In industries such as mining and industrial, ovens are used for a range of purposes, including drying, baking, and melting wax. These processes are necessary for material preparation and quality control. Laboratories use the oven for precise experiments that require controlled temperature conditions, such as aging tests on rubber materials or sterilization procedures.

As a result of this oven's capabilities, colleges and research institutions benefit from its use by using it in educational experiments and research projects that require a consistent and reliable temperature control system.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven features advanced microprocessor temperature control with an LCD, a button-type interface, and fuzzy PID control technology. The features mentioned above guarantee that reliable and precise temperature regulation is achieved, which is vital for conducting accurate experiments.

By using a microprocessor temperature control, it is possible to set and maintain the desired temperature with precision, thus increasing the reliability and reproducibility of the test results. The LCD provides a clear and easy-to-read interface for monitoring and adjusting temperature settings, making the oven user-friendly and efficient to operate.

Fuzzy PID control technology offers advanced temperature regulation by automatically adjusting heating parameters to maintain stable temperatures. This technology reduces temperature fluctuations and improves control accuracy, both of which are essential for sensitive experiments, such as those concerning aging tests, drying, baking, wax melting, and sterilization.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven uses a high-precision platinum resistance sensor for temperature measurement. This type of sensor is renowned for its accuracy and reliability, both of which are crucial for precise temperature control.

Platinum resistance sensors, also known as RTDs (Resistance Temperature Detectors), offer excellent stability and repeatability over a wide range of temperatures. The high precision of these sensors ensures that even slight temperature variations are accurately detected and adjusted. For experiments that require a high level of temperature regulation, this is particularly important.

By incorporating a high-precision platinum resistance sensor, the Aging Oven guarantees accurate temperature measurements, thus increasing the reliability of drying, baking, wax melting, sterilization, and other temperature-sensitive experiments. This and other features make the oven an ideal choice for applications in industrial settings, laboratories, colleges, and research institutions.

Click here to learn more about the product or here to receive a personalized quote.

The forced circulation convection duct in the Aging Oven greatly benefits its performance by providing uniform temperature distribution throughout the chamber. A feature such as this is required to maintain the most accurate and consistent conditions during testing.

The forced circulation system works by continually circulating heated air within the oven, which prevents hot spots and makes sure that all parts of the chamber reach and maintain the set temperature. This uniform heating is particularly important for experiments that require consistent thermal conditions, such as aging tests, drying, baking, wax melting, and sterilization.

By providing even temperature distribution, the forced circulation convection duct helps achieve reliable and repeatable results. This makes the Aging Oven an ideal tool for a wide variety of applications. This feature not only improves experimental outcomes but also enhances oven efficiency and effectiveness.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven offers an extensive temperature control range, which can be set from room temperature (RT) plus 10°C to 200°C or 300°C, depending on the specific model and application requirements.

Controlling the temperature within this range is a necessity for many scientific and industrial applications. For example, in rubber aging tests, the temperature must be accurately maintained to simulate real-life aging conditions and provide reliable data on material durability and performance.

The flexibility of temperature control makes the Aging Oven suitable for many materials and testing conditions, so that precise and consistent temperatures can be maintained for accurate and reliable results. This feature is particularly beneficial in research settings where different experiments might require unique temperature settings in the same equipment. Additionally, the oven’s ability to reach higher temperatures up to 300°C expands its applicability to more demanding processes that require elevated heat.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven offers a high-temperature accuracy of 0.1°C, making it exceptionally precise for different scientific and industrial applications. When it comes to experiments that require stringent temperature control to achieve reliable and repeatable results, this level of accuracy is crucial.

For instance, in rubber aging tests, maintaining such a precise temperature is essential to accurately simulate the aging process and obtain valid data on the material's durability and performance. Similarly, in processes like drying, baking, and sterilization, consistent temperature accuracy provides uniformity and consistency across all samples.

The precision of 0.1°C allows the Aging Oven to meet the demanding requirements of numerous standards and testing protocols. This makes it an indispensable tool in settings requiring careful thermal management. This high level of accuracy is achieved through advanced temperature control systems, including microprocessor controls and high-precision platinum resistance sensors, which continuously monitor and adjust the oven's temperature to maintain the set conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven features a temperature volatility of ±1°C, thereby minimizing temperature fluctuations within the oven. A high level of control is key to maintaining stable thermal conditions during experiments in order to obtain accurate and consistent results.

Temperature volatility refers to the degree to which the oven's temperature varies around the set point. In the case of the Aging Oven, a volatility of ±1°C means that the temperature can fluctuate no more than one degree Celsius above or below the desired temperature. This tight control is particularly important in processes such as aging tests, where even small temperature changes can affect the material properties being measured.

For drying, baking, wax melting, and sterilization experiments, maintaining a stable temperature ensures that all samples are subjected to the same conditions, leading to uniform outcomes. This consistency is vital for quality control and research, where reproducibility is a key requirement.

Click here to learn more about the product or here to receive a personalized quote

The Aging Oven offers 2°C temperature uniformity at 100°C. This specification indicates that the temperature variation within the oven chamber is kept within a 2°C range when set to 100°C, allowing all areas of the chamber to remain at the same temperature.

Temperature uniformity is extremely important for several reasons. Firstly, it makes sure that all samples inside the oven are exposed to the same thermal conditions. In aging tests, drying, baking, wax melting, and sterilization experiments, uniform temperature distribution guarantees that the entire sample undergoes the same treatment.

Maintaining temperature uniformity is particularly important in quality control processes, where even slight changes in temperature can lead to significant differences in the properties and behavior of the tested materials. By providing a uniform temperature environment, the Aging Oven helps maintain valid and comparable test results across different batches and experiments.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven has a power consumption of 2000 watts (W). In addition to providing sufficient heating capacity for a variety of experiments and processes, such as drying, baking, wax melting, and sterilization, this level of power consumption ensures that the oven operates efficiently.

The 2000W power rating is indicative of the oven’s ability to maintain stable and precise temperature control over extended periods. This power capacity allows the oven to quickly reach and sustain the desired temperatures, minimizing warm-up times and optimizing overall operational efficiency.

In industrial and laboratory settings, power consumption is an important factor to consider as it impacts both operational costs and the oven’s compatibility with existing electrical systems. The 2000W power consumption of the Aging Oven makes it suitable for use in standard laboratory environments without significant modifications to the electrical infrastructure.

Additionally, the efficient power usage of the oven supports its advanced features, such as microprocessor temperature control with fuzzy PID technology, high-precision platinum resistance sensors, and forced circulation convection ducts.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven interior is made of 304 stainless steel. The use of this particular material is significant for a number of reasons, including the optimization of oven performance and durability.

304 stainless steel is renowned for its excellent corrosion resistance. This is extremely important in an environment where the oven may be exposed to various chemicals and high humidity levels during experiments such as drying, baking, wax melting, and sterilization. This resistance to corrosion ensures that the oven interior surfaces remain intact and free from rust, maintaining a clean and sterile environment for testing.

Moreover, 304 stainless steel is highly durable and can withstand high temperatures without deforming or degrading. This durability guarantees that the oven maintains structural integrity and performance for long periods, even under frequent and intense use. Stainless steel's robust nature also makes it easy to clean and maintain.

The smooth and non-reactive surface of stainless steel minimizes the risk of chemical reactions with the test materials so that the samples remain uncontaminated and the results are reliable. Additionally, the material's reflective properties help distribute heat evenly within the chamber, contributing to the oven's excellent temperature uniformity.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven exterior is made from an 08F cold rolled steel plate. This choice of material is important for several reasons, contributing to the oven's overall durability, strength, and aesthetic appeal.

08F cold rolled steel plate is known for its high strength and toughness. The oven is therefore capable of withstanding the rigors of daily use in industrial and laboratory settings. Cold-rolling enhances steel's mechanical properties, providing greater resistance to impacts and deformation than hot-rolled steel. This makes the oven's exterior robust and capable of protecting the internal components from physical damage.

In addition to its strength, 08F cold-rolled steel offers a smooth and uniform surface finish. This not only improves the oven's appearance but also makes it easier to clean and maintain. A smooth exterior surface prevents dust and contamination.

The material's excellent paint adhesion properties also allow for high-quality finishes, which protect the steel from corrosion and extend the oven's life. This protective coating provides exterior resilience to environmental factors such as humidity and temperature variations.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven's inner chamber dimensions are 23.65 inches in height, 19.70 inches in width, and 29.55 inches in depth. This is equivalent to 600 mm in height, 500 mm in width, and 750 mm in depth. These generous dimensions provide ample space for a variety of samples and experimental setups.

The spacious inner chamber allows multiple samples to be processed at once. This is particularly beneficial for applications such as drying, baking, wax melting, and sterilization, where large or numerous samples need to be uniformly treated under controlled temperature conditions.

The well-sized chamber allows for air circulation around the samples, contributing to even temperature distribution and consistent results. This uniformity is key to guaranteeing that all parts of the samples are exposed to the same thermal conditions.

The dimensions also provide flexibility in experimental design, allowing users to configure the interior space according to their specific needs. Whether working with small individual samples or large batches, the inner chamber of the Aging Oven accommodates a wide range of testing requirements. This is why it is an ideal tool for industrial enterprises, laboratories, colleges, and research institutions.

Click here to learn more about the product or here to receive a personalized quote.

The outer chamber dimensions of the Aging Oven are 34.65 inches in height, 28.35 inches in width, and 36.65 inches in depth, or equivalently 880 mm in height, 720 mm in width, and 930 mm in depth. The oven's dimensions provide it with a robust and spacious exterior that houses its advanced features and components.

The substantial size of the outer chamber allows adequate space for the inner workings of the oven, including the microprocessor temperature control system, forced circulation convection ducts, and high-precision platinum resistance sensors. This ample space is necessary for maintaining the efficient operation of these components.

The exterior dimensions also make the oven stable and durable, capable of withstanding frequent use in industrial and laboratory environments. Despite its large size, the oven is designed to be practical for laboratory setups. It fits into typical lab benches and workspaces while providing the volume required for many testing applications.

Click here to learn more about the product or here to receive a personalized quote.

The Aging Oven weighs 199 pounds (90 kilograms). This substantial weight reflects the durable construction and high-quality materials used in its design, including the 304 stainless steel interior and the 08F cold rolled steel exterior.

The relatively heavy weight of the oven contributes to its stability during operation. This assures that it remains firmly in place even when handling high-temperature processes and housing different samples. The stability of the heating environment is vital for maintaining precise temperature control and preventing any movement that may disrupt the uniformity of the heating process.

Moreover, the weight indicates the oven's durable build, capable of withstanding frequent use in industrial and laboratory settings. Despite its heavy-duty construction, the oven is designed to be manageable within standard laboratory environments, allowing for ease of installation and integration into existing setups.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

ICI / Mace Snag Tester

Discover the Fabric Textile ICI / Mace Snag Tester, a reliable tool for assessing fabric snagging under normal wear conditions.

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

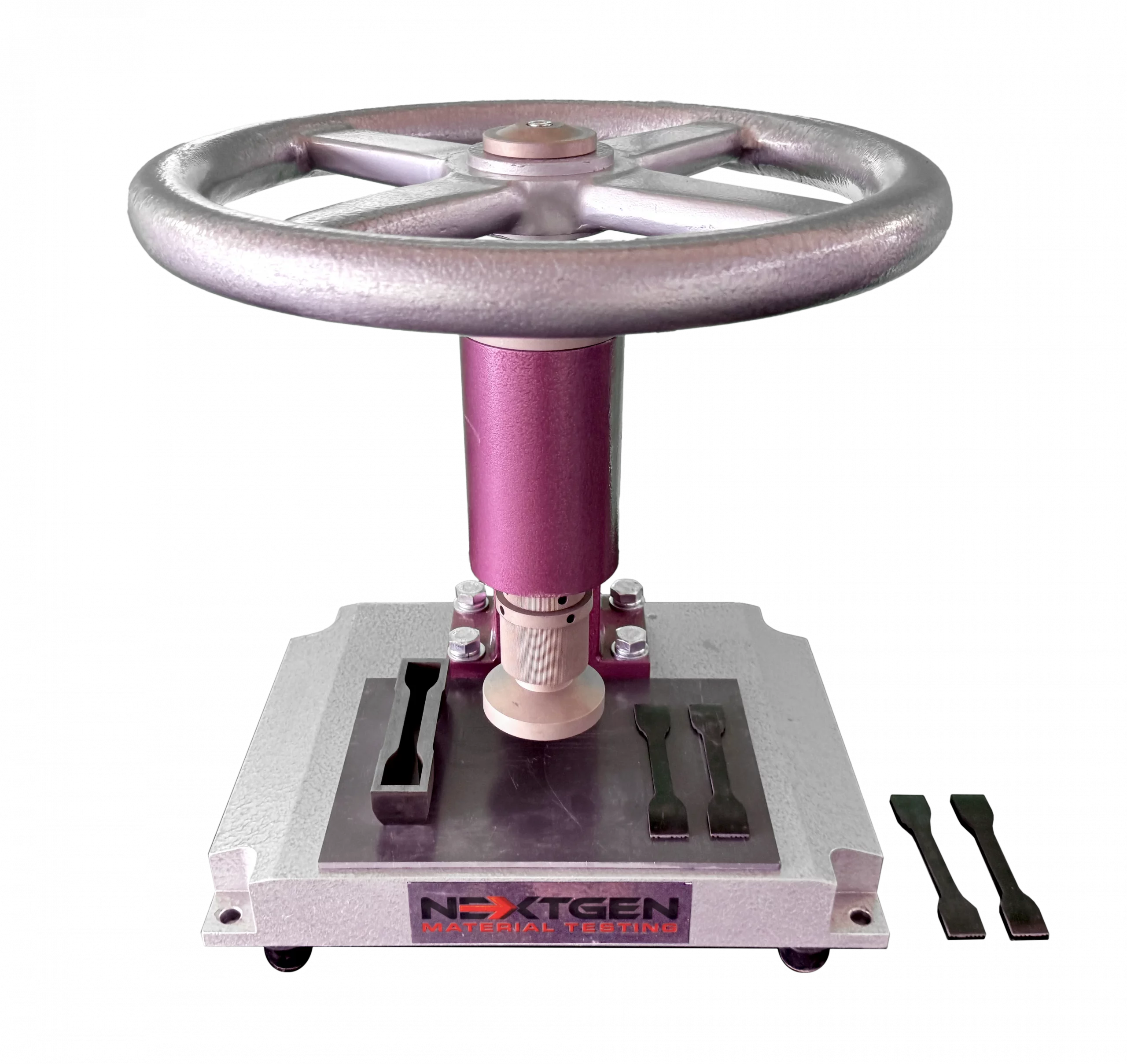

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

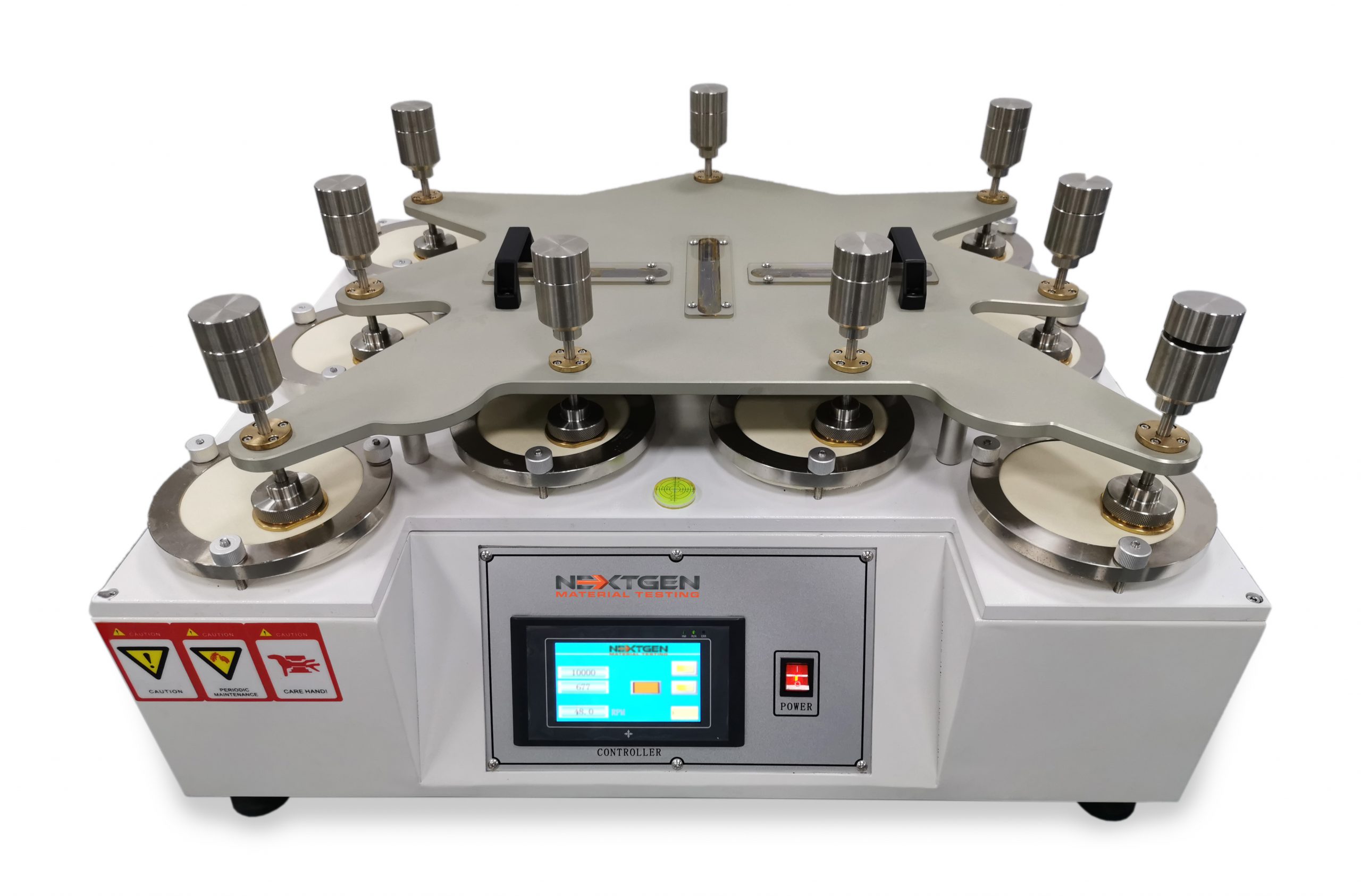

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

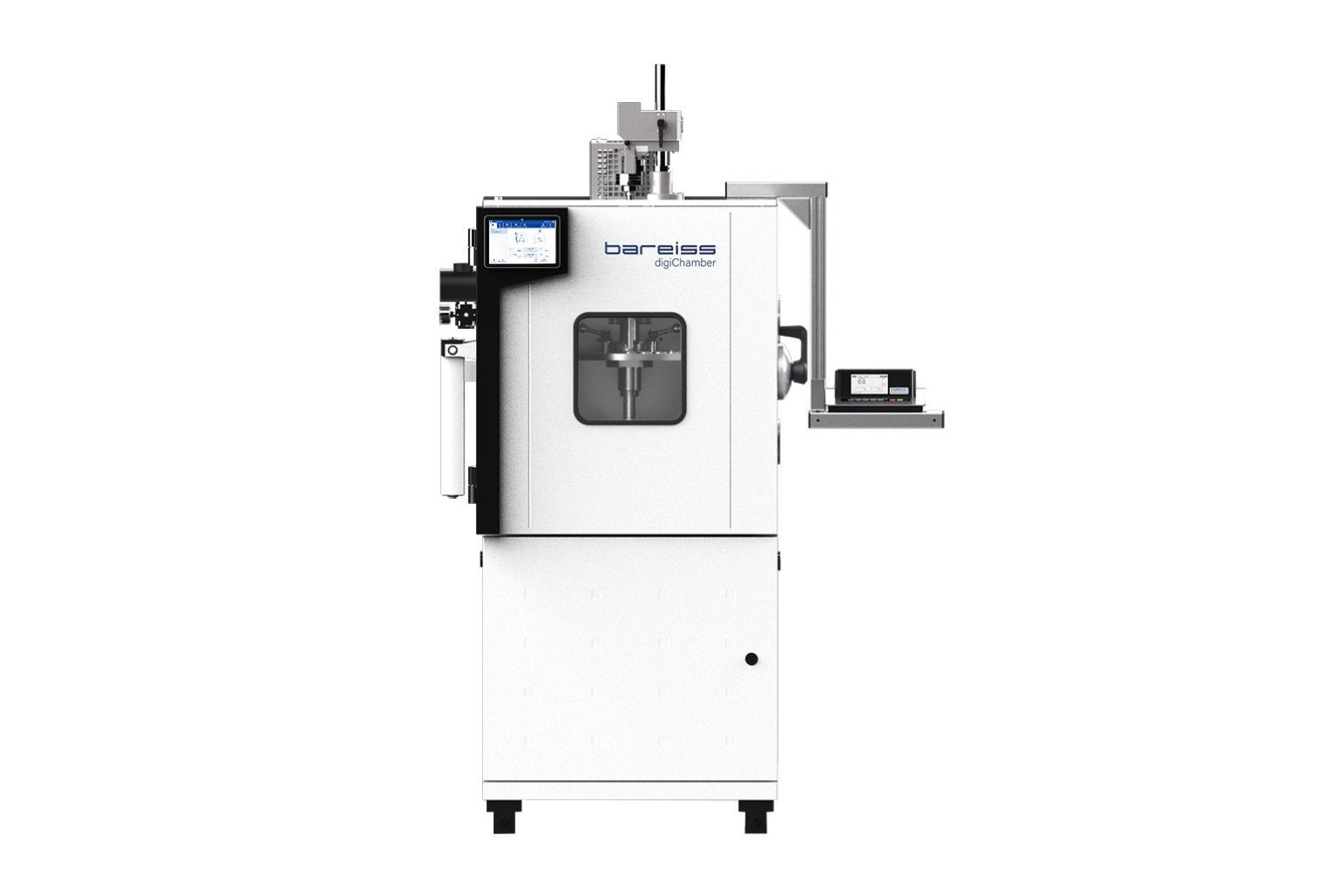

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is the Burst Strength Tester designed to test anti-rupture strength of variety of materials such as leather, paper and fabric.

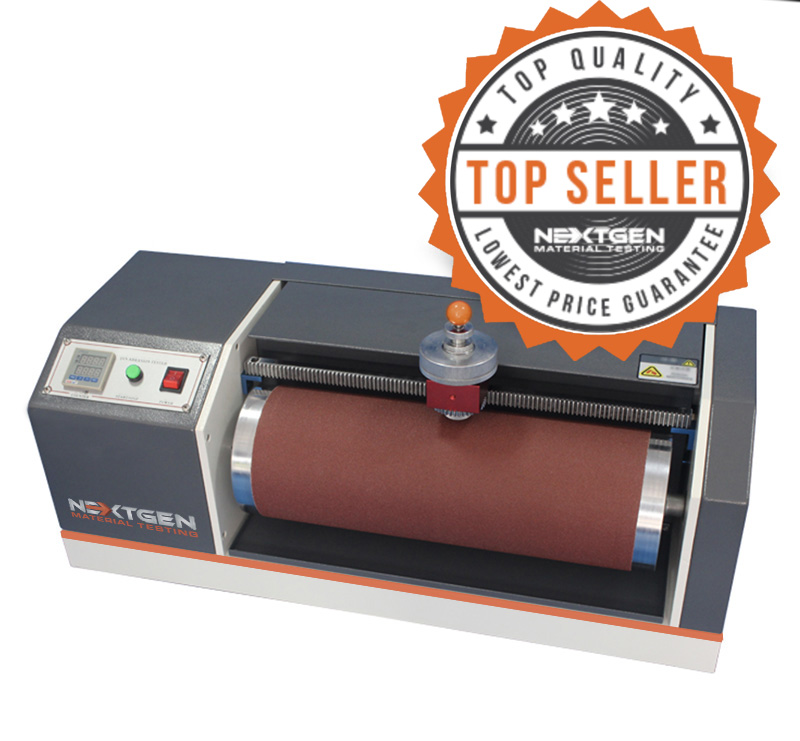

DIN Abrasion Tester

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

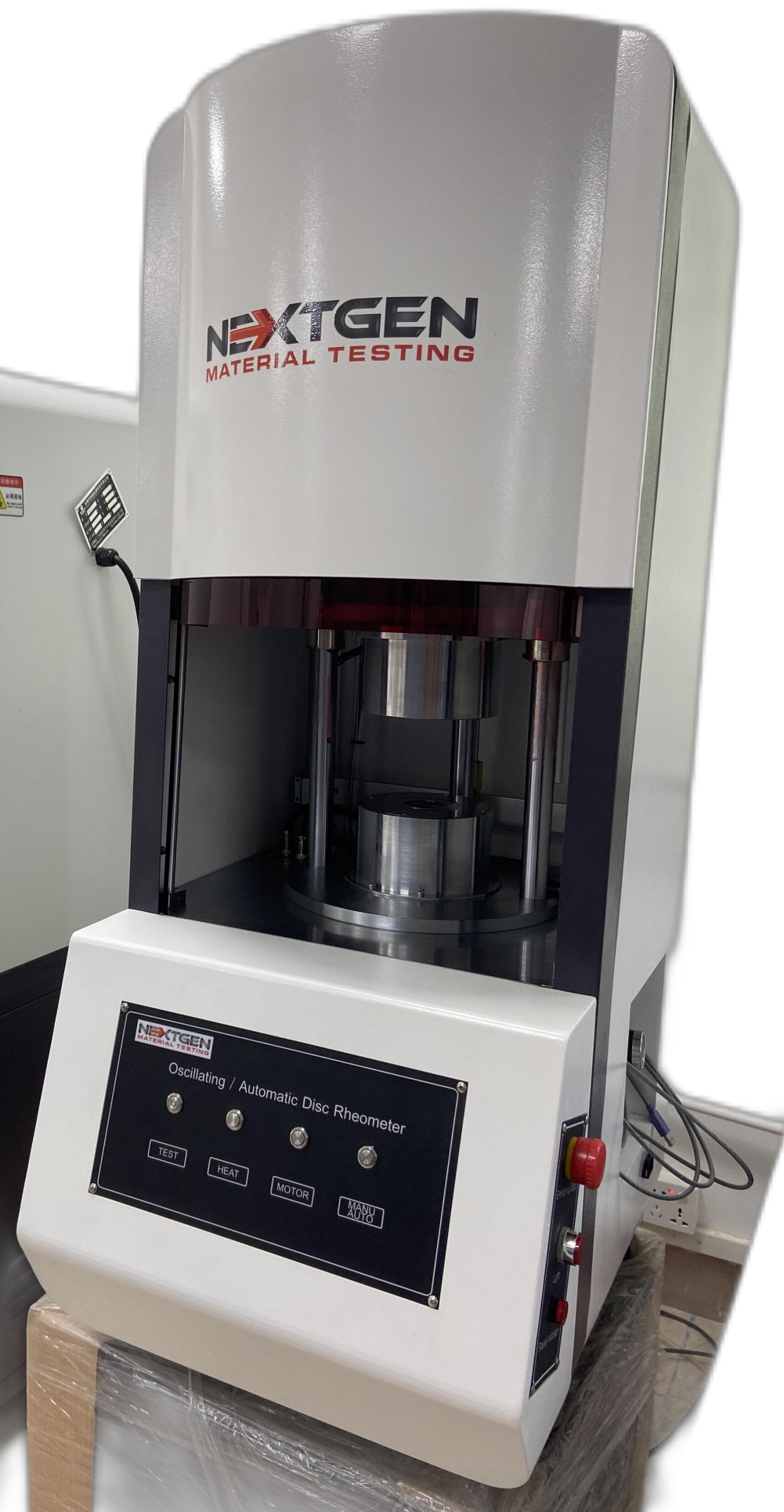

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.