Rubber Testing Equipment

Standards

ASTM D3939/D3939M-2013 (2017), JIS L1058, GBIT11047-2008

Description

The Fabric Textile 4-position ICI / Mace Snag Tester from NextGen was created for manufacturers and quality control professionals, designed to quickly assess the likelihood of fabric snagging under normal wear conditions. Utilizing a precise and methodical approach, this tester simulates real-world scenarios where yarns are pulled from the fabric, providing an accurate measure of a fabric's durability.

ICI / Mace Snag Tester Features

-

Realistic Snag Simulation: Replicates the unpredictable snagging that fabrics might experience during regular use, ensuring a thorough evaluation.

-

Accurate Assessment: Through controlled rotation and hammer action, the tester creates snags on the fabric, allowing for a detailed comparison against standard reference fabrics.

-

Comprehensive Rating System: Provides a snagging rating that helps manufacturers understand the fabric’s performance, aiding in the selection of materials for high-traffic applications such as clothing and upholstery.

-

User-Friendly Operation: Designed for ease of use, the Mace Snag Tester allows for quick sample preparation and consistent results.

ICI / Mace Snag Tester Working Principle

The Mace Snag Tester is designed to simulate the snagging that fabrics might experience during regular use. Here's a simplified explanation of how it works:

-

Sample Preparation: A piece of fabric is cut to a specific size and placed on a rotating drum inside the tester.

-

Hammer Placement: A hammer, which is attached to the machine by a chain, is placed so that it rests on the surface of the fabric sample.

-

Drum Rotation: The drum starts rotating at a constant speed. As it turns, the hammer is dragged along the fabric, but because it's suspended by a chain, it flips and bounces around unpredictably.

-

Snagging Action: As the hammer moves across the fabric, it catches on the fabric's fibers, creating snags or pulls (i.e., it pulls threads out of the fabric).

-

Test Duration: The drum continues to rotate for a set number of cycles, allowing the hammer to create snags across the entire surface of the fabric sample.

-

Evaluation: Once the test is complete, the fabric is removed, and the number and severity of the snags are assessed. This is typically done by comparing the tested fabric to a set of standard reference fabrics that show different levels of snagging.

-

Rating: The fabric is then given a snagging rating based on how it compares to these standards, indicating how likely it is to snag during normal wear

ICI / Mace Snug Tester Technical Specifications

| Model | 4-position ICI / Mace Snag Tester |

| Number of positions | 4 |

| Rotary drum size | Diameter of 82mm (including outer rubber thickness of 3mm), width of 210mm |

| Rotation speed of the drum | 60 ± 2r/min |

| Total weight of the nail | 160+10g (including 11 equally spaced needles) |

| Needle | Exposed length 10mm, tip radius: R0.13mm |

| Fixed guide rod | Working width 125mm, diameter 10mm |

| Weight | 243 lbs / 110 kg |

FAQs

The Fabric Textile 4-position ICI / Mace Snag Tester from NextGen is specifically designed for manufacturers and quality control professionals to quickly and accurately assess the likelihood of fabric snagging under normal wear conditions. This tester simulates real-world scenarios where fabrics are subjected to conditions that may cause yarns to be pulled from the material, which is a common cause of fabric deterioration over time.

By taking a precise and methodical approach, the ICI / Mace Snag Tester replicates the unpredictable snagging fabrics might experience during everyday use, allowing for a detailed evaluation of the fabric's durability. This simulation provides an accurate measure of how well a fabric will perform in high-traffic applications, such as clothing, upholstery, and other textile products where durability is crucial. The results help manufacturers make informed decisions about material selection, making sure that their products meet quality standards for long-term use.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the ICI / Mace Snag Tester complies with ASTM D3939/D3939M-2013 (2017). The purpose of this standard is to determine the resistance of fabrics to snagging, as snagging is a common problem that can have an adverse effect on the durability and appearance of textiles. The ASTM D3939 standard details the method for the assessment of the tendency of yarns in fabrics to snag when exposed to conditions that simulate everyday wear and tear.

The ICI/Mace Snag Tester from NextGen is designed to meet the requirements of this standard, providing a controlled and repeatable process for simulating real-world snagging conditions in order to meet the standards. With a rotating drum and hammer mechanism, the tester creates snags in fabric samples, which are then compared against standard reference fabrics to determine which fabric is the most suitable for this test.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the ICI / Mace Snag Tester complies with JIS L1058, a Japanese Industrial Standard that specifies methods for testing fabric snagging resistance. JIS L1058 outlines procedures similar to those in other international standards, focusing on how fabrics respond to snagging during normal wear and tear. This standard is critical for guaranteeing that textiles meet durability and quality expectations in markets that require Japanese standards.

The ICI / Mace Snag Tester from NextGen is designed to meet the rigorous requirements of JIS L1058. It provides a reliable and controlled testing environment where fabrics are subjected to snagging simulations. By complying with this standard, the tester makes certain that the results are consistent with industry expectations in Japan and other regions that recognize JIS standards. Having this compliance is crucial to manufacturers who need to validate the durability of their fabrics in accordance with the requirements of the Japanese market.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the ICI / Mace Snag Tester is fully compliant with GB/T 11047-2008, which is a Chinese national standard that describes the procedures for evaluating textile fabrics' snagging resistance. Having this standard in place is vital to making sure that fabrics can withstand everyday use without significant snagging, which could compromise their appearance and durability.

The ICI / Mace Snag Tester is designed to simulate real-world snagging conditions in a controlled environment, providing accurate and consistent results that align with the criteria set out in GB/T 11047-2008. This compliance is particularly significant for manufacturers who need to verify that their textiles meet Chinese durability standards. By complying with this standard, the ICI / Mace Snag Tester helps manufacturers verify the quality of their fabrics, making sure that they are robust enough to meet consumer expectations in markets where this standard is recognized.

Click here to learn more about the product or here to receive a personalized quote.

The ICI / Mace Snag Tester is engineered to realistically replicate the unpredictable snagging fabrics might encounter during everyday use. This simulation is necessary for thoroughly evaluating textile durability. The tester achieves this by using a rotating drum combined with a hammer mechanism that moves erratic, and unpredictable across the fabric sample. This motion mimics random forces and interactions fabrics endure in real-world settings, such as rubbing against other materials or catching sharp objects.

By replicating these real-life conditions, the ICI / Mace Snag Tester provides a comprehensive assessment of how likely a fabric is to snag under normal wear. This realistic snag simulation is critical for manufacturers who need to ensure that their fabrics can withstand everyday use, helping them make informed decisions about material selection and quality control.

Сlick here to learn more about the product or here to receive a personalized quote.

The ICI / Mace Snag Tester offers an accurate assessment of fabric snagging by using a combination of controlled rotation and hammer action. As the fabric sample is placed on a rotating drum, a hammer attached to a chain moves across the fabric in a controlled yet unpredictable manner. This action creates snags on the fabric that closely mimic those during regular use.

The accuracy of this process is improved by the ability to directly compare the snagged fabric against standard reference fabrics that exhibit known levels of snagging. This comparison allows for a detailed evaluation of the fabric's performance, providing manufacturers with a clear understanding of how their materials will hold up under typical wear conditions. The precision of this assessment helps make informed decisions about fabric quality and suitability for high-traffic applications.

Click here to learn more about the product or here to receive a personalized quote.

The ICI / Mace Snag Tester is equipped with a comprehensive rating system that assists in helping manufacturers evaluate the performance of their fabrics, particularly in terms of snagging resistance. After the fabric has been subjected to the controlled snagging process within the tester, it is compared against standard reference fabrics that represent various levels of snagging severity. This comparison allows the fabric to be assigned a specific snagging rating.

This rating provides manufacturers with a clear, quantifiable measure of how the fabric will perform under real-world conditions, especially in high-traffic applications such as clothing and upholstery. By understanding the fabric's snagging resistance, manufacturers can make informed decisions about material selection, making certain that they choose fabrics that meet the necessary durability standards for their intended use. This rating system is vital for maintaining product quality and customer satisfaction in industries where fabric durability is of utmost importance.

Click here to learn more about the product or here to receive a personalized quote.

How does the user-friendly design of the ICI / Mace Snag Tester benefit operators in fabric testing?

The ICI / Mace Snag Tester is built with user-friendliness in mind, making it easy for operators to perform fabric testing efficiently. One of the key benefits of its design is the ability to prepare fabric samples for testing quickly. The machine's straightforward setup and operation reduces the time required to get the machine ready, allowing users to focus more on testing and less on preparation.

Additionally, the tester is engineered to deliver consistent results, which is necessary for fabric performance assessment reliability. The simplicity of operation makes it possible for even those with minimal technical experience to operate the machine effectively, reducing the likelihood of user error and increasing the overall accuracy of the tests. This user-friendly design makes the ICI / Mace Snag Tester an ideal tool for manufacturers and quality control professionals who need to conduct frequent and reliable snagging tests on fabrics.

Click here to learn more about the product or here to receive a personalized quote.

The ICI / Mace Snag Tester simulates fabric snagging during regular use. The process begins with sample preparation, where a piece of fabric is cut to a specific size and placed on a rotating drum inside the tester. A hammer, attached to the machine by a chain, is then positioned to rest on the fabric sample surface.

As the drum rotates at a constant speed, the hammer drags along the fabric. Due to its suspension by a chain, the hammer flips and bounces unpredictably, emulating the random snagging conditions fabrics encounter every day. This action causes the hammer to catch on the fabric’s fibers, creating snags or pulls by pulling threads out of the material.

The drum continues to rotate for a predetermined number of cycles so that the entire fabric surface is exposed to snagging action. After the test duration is complete, the fabric is removed, and the number and severity of snags are assessed by comparing the tested fabric to standard reference fabrics that display different levels of snagging. The fabric is then given a snagging rating based on how it compares to these standards, providing a clear indication of how likely it is to snag during normal wear. This process allows manufacturers to evaluate and select fabrics that offer better resistance to snagging.

Click here to learn more about the product or here to receive a personalized quote.

How many positions does the ICI / Mace Snag Tester have, and what does this mean for fabric testing?

The ICI / Mace Snag Tester is designed with 4 positions, meaning it can in parallel test up to four fabric samples at once. This multi-position capability is particularly beneficial for laboratories and manufacturers that need to perform multiple tests in a short period. By allowing four samples to be tested concurrently, the tester increases efficiency and throughput, enabling quicker comparisons and assessments of different fabrics under identical conditions.

This feature is especially useful in quality control processes where large batches of fabric need to be evaluated for snag resistance. The ability to test multiple samples at the same time allows for consistent results and helps manufacturers make informed decisions about fabric selection and production. The 4-position design of the ICI / Mace Snag Tester increases its functionality, making it a powerful tool for comprehensive fabric durability testing.

Click here to learn more about the product or here to receive a personalized quote.

The rotary drum in the ICI / Mace Snag Tester has a diameter of 82mm, which includes an outer rubber thickness of 3mm, and a width of 210mm. The use of these dimensions is critical in order to make certain that the snagging simulation will be consistent and reliable across all fabric samples.

The drum's size allows it to be used with a variety of fabric types and sizes while providing enough surface area for the hammer to create snags along the fabric. The 82mm diameter guarantees that the drum rotates smoothly, maintaining a consistent speed and applying even pressure as the hammer moves unpredictably across the fabric. The 210mm width offers sufficient space for the fabric to be tested thoroughly, allowing multiple snags to form during the test.

These dimensions are designed to replicate real-world conditions where fabrics might encounter similar snagging scenarios, making certain that the testing process accurately reflects how the fabric will perform in everyday use. The size of the rotary drum is, therefore, a key component in providing accurate and meaningful results in snag resistance testing.

Click here to learn more about the product or here to receive a personalized quote.

The drum in the ICI / Mace Snag Tester rotates at 60 ± 2 revolutions per minute (r/min). This controlled rotation speed is essential for achieving consistent and accurate snagging results during testing. The speed is carefully calibrated to replicate real-world conditions.

Maintaining a precise rotation speed guarantees that the hammer, which moves across the fabric as the drum rotates, applies consistent force and pressure to the fabric samples. This consistency is essential for creating repeatable snags that can be accurately assessed for their severity. The ± 2 r/min tolerance allows for slight variations in speed without compromising the reliability of the test results, ensuring that each test provides a true representation of the fabric's durability.

The rotation speed of 60 ± 2 r/min is a key factor in the effectiveness of the ICI / Mace Snag Tester, as it helps simulate realistic snagging conditions, providing manufacturers with valuable data on fabric performance under normal wear and tear.

Click here to learn more about the product or here to receive a personalized quote.

The total weight of the nail mechanism in the ICI / Mace Snag Tester is 160+10 grams, including 11 equally spaced needles. This weight is significant because it directly influences the interaction between the fabric sample and the nail mechanism during the snag test. The carefully calibrated weight makes certain that the needles exert the right amount of pressure on the fabric as they move across it, creating snags that closely reflect those that could occur during everyday use.

The inclusion of 11 equally spaced needles ensures that snagging is distributed uniformly over the fabric sample, providing a comprehensive assessment of the fabric's durability. The combined weight and spacing of the needles replicate real-world snagging conditions, allowing manufacturers to accurately evaluate how their fabrics will perform under normal wear.

Click here to learn more about the product or here to receive a personalized quote.

The needle used in the ICI / Mace Snag Tester has an exposed length of 10mm and a tip radius of R0.13mm. These precise specifications are crucial for replicating realistic snag conditions during fabric testing. The needle's exposed length guarantees that the needle penetrates the fabric surface at an optimal depth, creating snags that accurately reflect those that might occur during regular use.

The tip radius of R0.13mm is carefully designed to balance sharpness and durability. A finer tip radius allows the needle to catch and pull fabric fibers more effectively, simulating the kind of snags that happen when fabrics rub against sharp objects or rough surfaces. The combination of the needle’s length and tip radius assures that the snagging action is both realistic and consistent.

Click here to learn more about the product or here to receive a personalized quote.

The fixed guide rod in the ICI / Mace Snag Tester has a working width of 125mm and a diameter of 10mm. These specifications are significant because they serve an important role in guiding the hammer's movement as it moves across the fabric sample during the snagging test.

The 125mm working width allows the rod to accommodate a variety of fabric sample sizes, providing enough space for the hammer to move freely and create snags along the fabric's surface. This width is essential for allowing the fabric to be tested thoroughly so that the snagging action covers a significant portion of the material.

The 10mm diameter of the guide rod provides the necessary stability and support for the hammer mechanism, making sure that the hammer moves consistently and predictably during the test. This stability is crucial for maintaining the accuracy of the snagging simulation, leading to reliable and repeatable test results. The dimensions of the fixed guide rod are, therefore, integral to the overall performance and accuracy of the ICI / Mace Snag Tester.

Click here to learn more about the product or here to receive a personalized quote.

The ICI / Mace Snag Tester weighs 243 lbs (110 kg). This weight is significant for several reasons. First, the substantial weight provides stability during operation, assuring that the machine remains securely in place while testing is conducted. Stability is crucial for maintaining the accuracy of the snagging tests, as any movement or vibration could affect the interaction between the fabric sample and the hammer, leading to inconsistent results.

Additionally, the tester's weight reflects its robust construction, designed to withstand repeated use in laboratories or manufacturing environments. The solid build guarantees that the tester can handle frequent testing over long periods without compromising performance or precision.

This weight also implies that the machine is durable and capable of delivering consistent, high-quality results, making it a reliable tool for manufacturers and quality control professionals.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

Aging Oven

Our aging oven is well-suited for performing drying, baking, wax melting, and sterilization experiments in industrial and mining enterprises, as well as in laboratories, colleges, and research institutions.

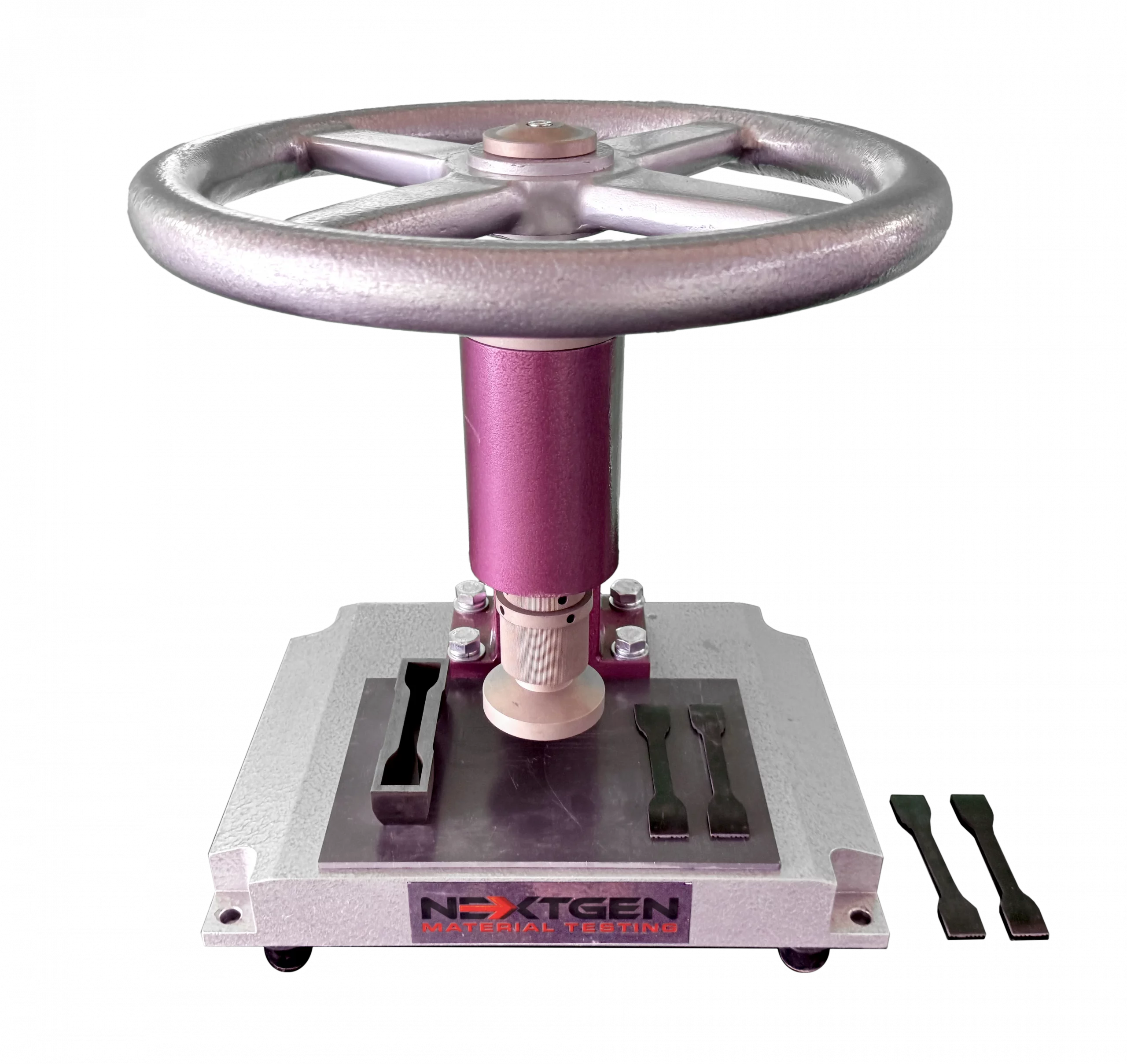

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

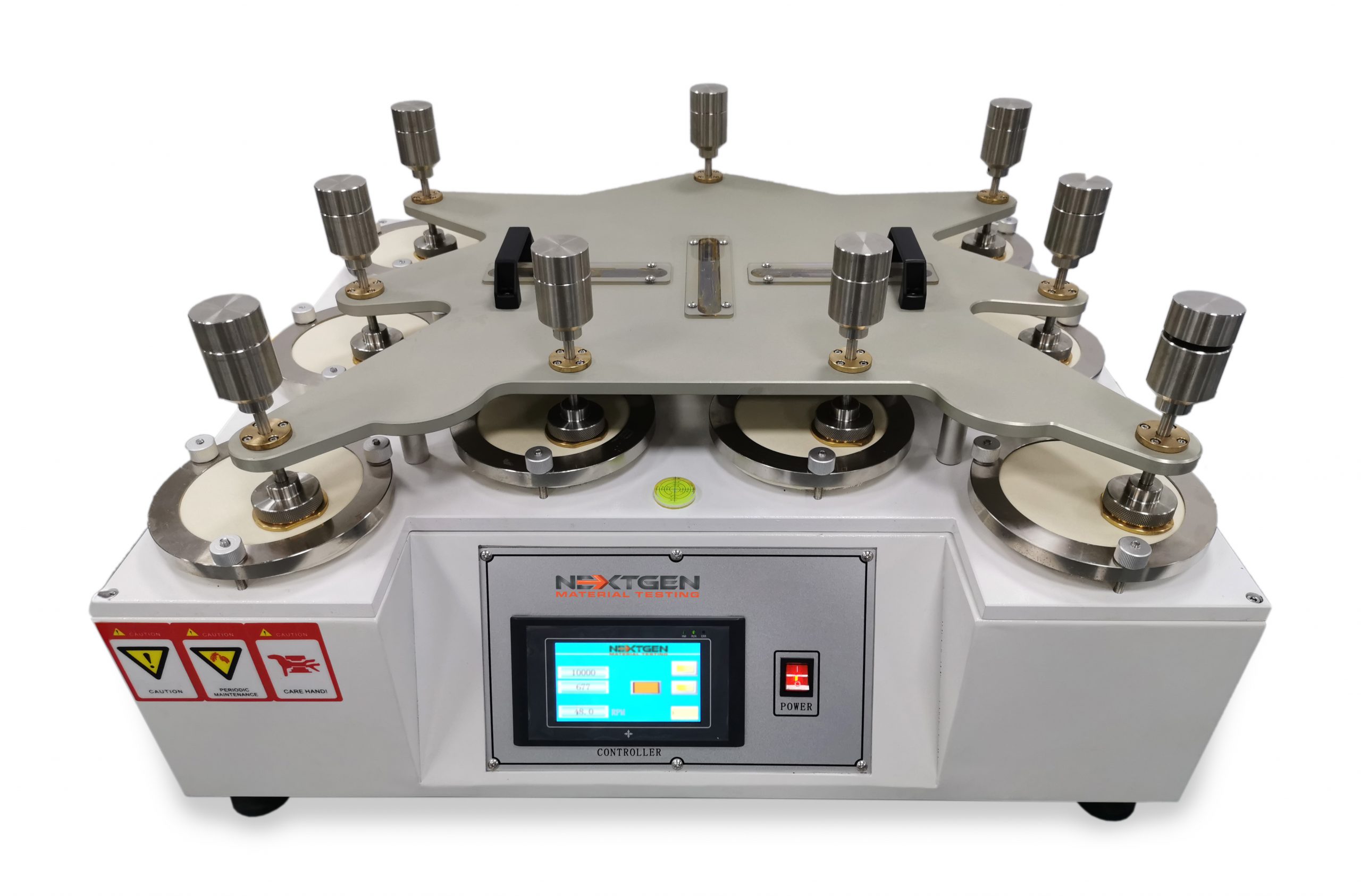

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

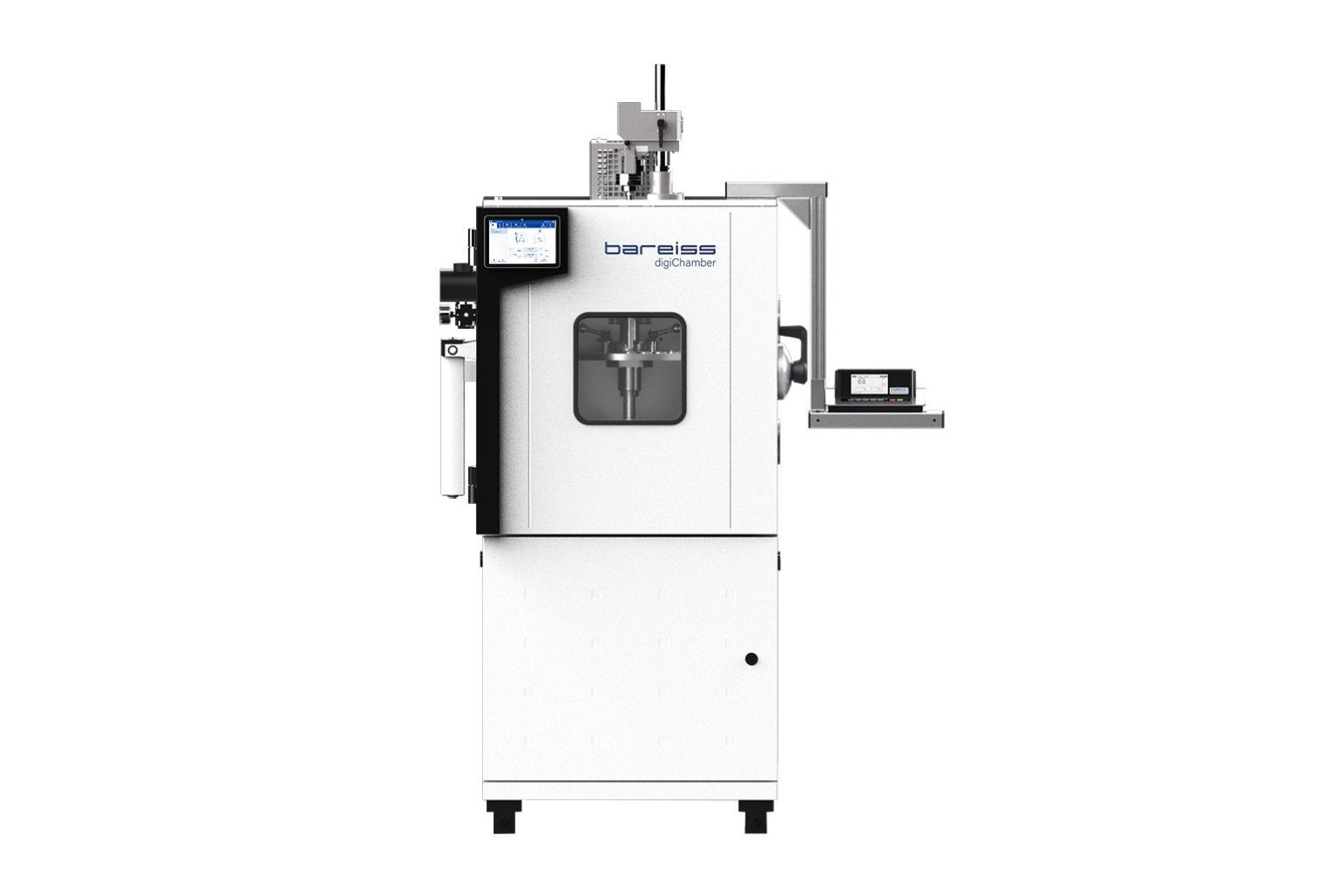

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is the Burst Strength Tester designed to test anti-rupture strength of variety of materials such as leather, paper and fabric.

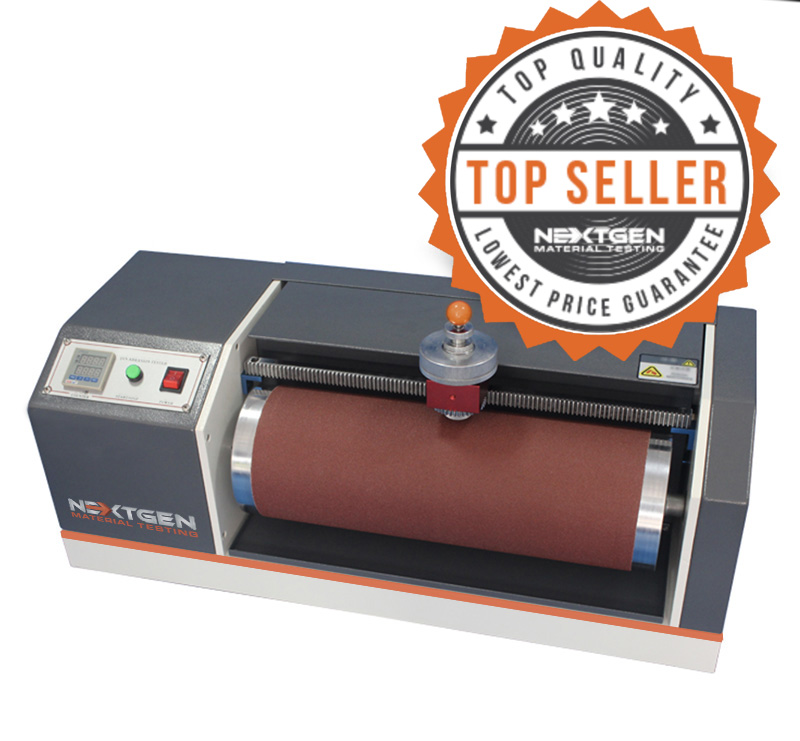

DIN Abrasion Tester

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

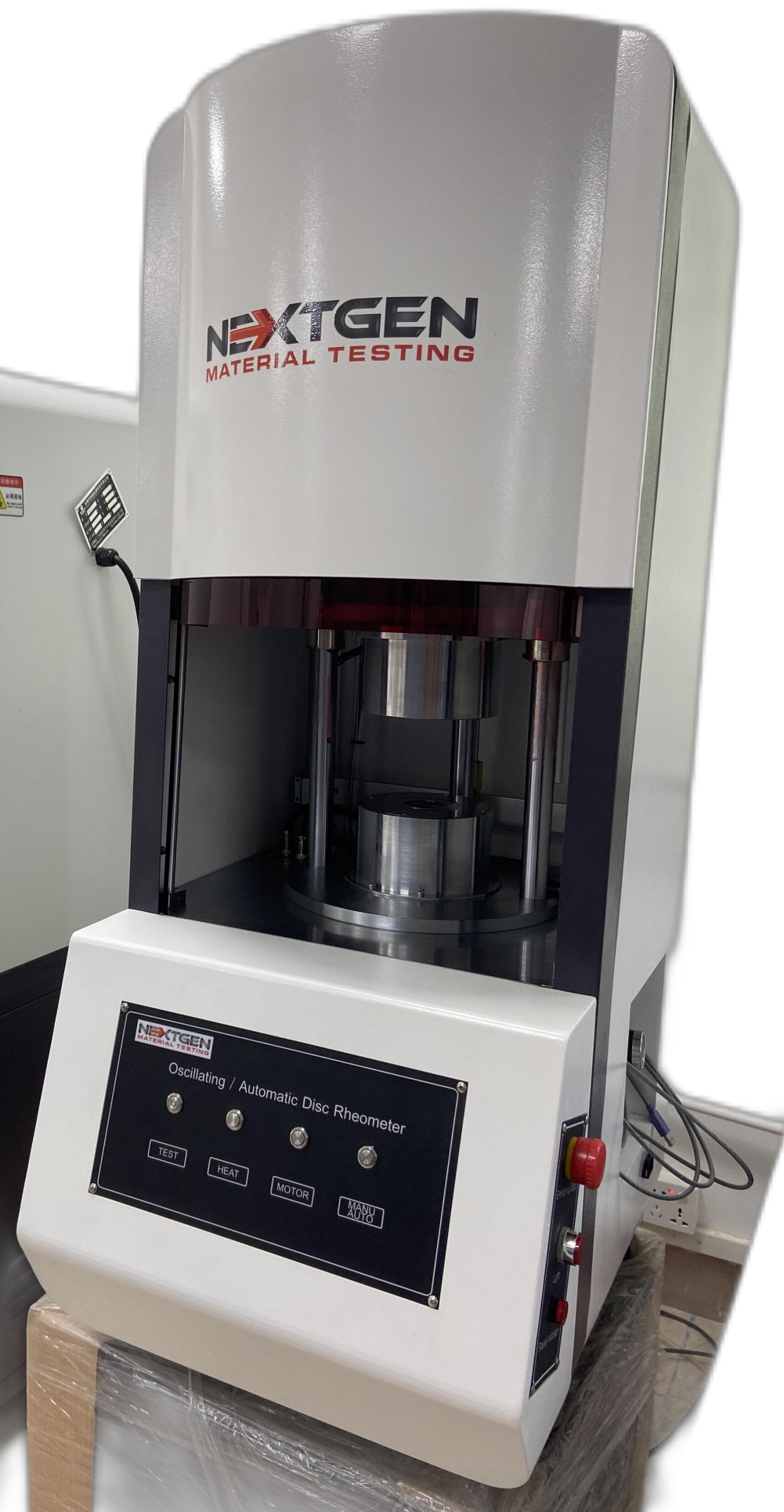

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.