In modern production and research, the quality of a material is closely tied to its hardness. But how can you be sure that a metal, coating, or alloy truly meets the required standards? The challenge is that many traditional testing methods don’t always deliver the precision needed. Some systems require large samples and are not suitable for thin coatings. Others are limited in their load range and increase the risk of inaccurate results. This leads to delays, repeated tests, and unnecessary costs.

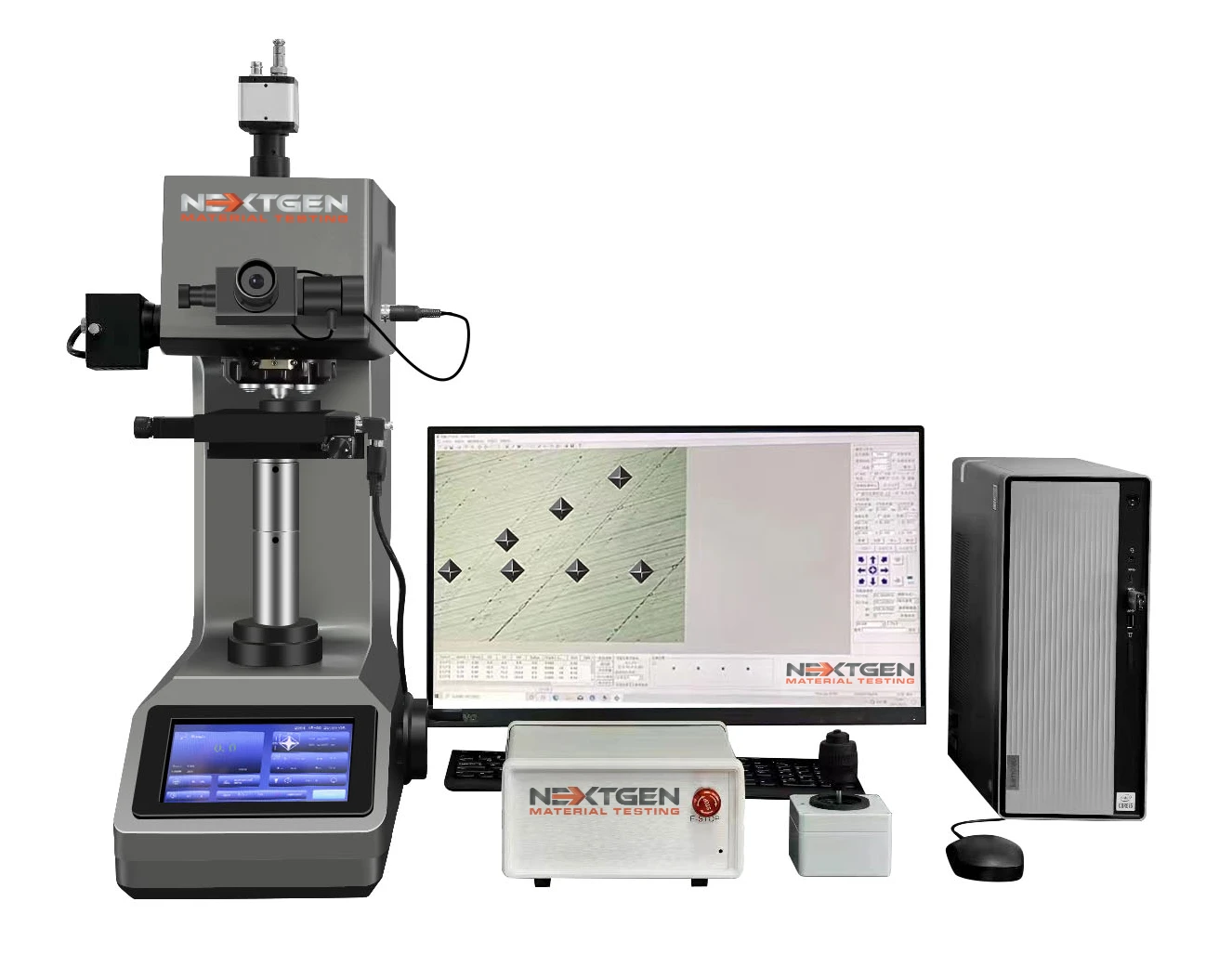

We at NextGen Material Testing, Inc. have been in the material testing equipment market for many years and understand that users need solutions that combine accuracy, convenience, and flexibility. That is why we offer the NG-1000 Series Micro Vickers and Knoop Hardness Testers. This series has become a benchmark in its class by bringing together modern electronics, automation, and compliance with international standards.

In this blog, we will take a closer look at the NG-1000 Series. We will explain how the system works, outline the available configurations and their differences, and highlight the key features and specifications that make this model stand out.

What are Micro Vickers and Knoop Hardness Testers?

Before going into the details of the NG-1000 Series, it is better to first look at the basics. Micro Vickers and Knoop testers are used to measure hardness on a very small scale. They are two different methods, each with its own type of indenter and calculation. In many modern systems, including the NG-1000, both are combined in one unit to make the process more practical.

Before going into the details of the NG-1000 Series, it is better to first look at the basics. Micro Vickers and Knoop testers are used to measure hardness on a very small scale. They are two different methods, each with its own type of indenter and calculation. In many modern systems, including the NG-1000, both are combined in one unit to make the process more practical.

How Micro Vickers and Knoop Testers Work

Both methods press a diamond indenter into the surface with a controlled low force.

- Vickers (HV): a square pyramid. The length of both diagonals is measured.

- Knoop (HK): a stretched pyramid. Only the long diagonal is measured. This makes Vickers more universal, while Knoop is better for thin layers and brittle materials.

Typical Use

These testers are chosen when standard hardness machines cannot deliver accurate results. Common tasks include:

- Checking hardness of coatings and surface treatments

- Testing case-hardened layers and weld zones

- Measuring small samples or micro-parts

- Working with glass, ceramics, or other brittle materials

Data You Get

Results are given as HV (Vickers) or HK (Knoop) values. Advanced systems can also:

- Store and average results

- Show min/max ranges

- Build hardness profiles across a surface or depth

- Convert values into other hardness scales if required

Introducing the NG-1000 Series Micro Vickers and Knoop Hardness Testers

The NG-1000 Series is designed to give precise and repeatable hardness results on a wide range of materials. It offers a motorized turret that changes the indenter and lenses automatically, and the load cycle is fully controlled with dwell times set between 1 and 99 seconds. This saves time and reduces operator error.

The NG-1000 Series is designed to give precise and repeatable hardness results on a wide range of materials. It offers a motorized turret that changes the indenter and lenses automatically, and the load cycle is fully controlled with dwell times set between 1 and 99 seconds. This saves time and reduces operator error.

Operation is straightforward. A large LCD screen with a simple menu gives access to all test functions, while a built-in printer makes it easy to keep a record of hardness values. For advanced analysis, the system can be equipped with a CCD camera and VickSoft software. This setup captures images of indentations, calculates hardness directly, and generates clear test reports.

The NG-1000 uses a stable rack-and-pinion system with a high-precision worm gear to apply force smoothly. Dual optical paths allow both eyepiece and CCD camera to work at the same time, which makes daily use faster and extends the life of the optical system.

A high-resolution 8″ touchscreen with encoder input further improves workflow. With one button, the operator can record diagonal values and view the hardness result instantly. The system also includes hardness conversion, giving results in Vickers, Knoop, Rockwell, or Brinell scales when needed.

Each NG-1000 comes with 10X and 40X objectives, covering a broad hardness range from very soft metals to high-strength alloys. Both Vickers (HV) and Knoop (HK) testing are standard features, making this model a complete solution for laboratories and production environments.

NG-1000 Configurations at a Glance

The NG-1000 Series is available in several configurations for different workflows. Core mechanics and optics stay the same. The difference is how you capture and process the indent.

AGEN is the straightforward digital model. You read the diagonals and enter values on the keypad. DGEN adds an encoder. You read through the eyepiece and send the numbers with one click. CCD adds a camera and VickSoft. The software reads the indent image, calculates hardness, stores data, and builds reports.

Any NG-1000 can be upgraded to Semi-Automatic. A motorized XY stage moves between points; you set focus by hand, then the software runs the sequence, measures, and plots curves.

For full hands-off runs, CCD FA adds motorized Z with autofocus during testing.

NG-1000CCD – Digital With CCD Optical Analysis

The NG-1000CCD is the most advanced configuration in the series. It uses a high-quality CCD camera together with VickSoft software to measure hardness automatically from the indentation image. Operators can still work through the eyepiece if preferred, but the camera and software make the process faster and more consistent.

The NG-1000CCD is the most advanced configuration in the series. It uses a high-quality CCD camera together with VickSoft software to measure hardness automatically from the indentation image. Operators can still work through the eyepiece if preferred, but the camera and software make the process faster and more consistent.

This model comes with a motorized turret for automatic switching between lenses and the indenter. A built-in printer allows quick documentation of results, while the software stores data, calculates hardness values, and generates full reports. With its high accuracy and ease of operation, the NG-1000CCD is a preferred choice for quality control and research laboratories that need reliable and repeatable results.

NG-1000DGEN – Digital With Encoder Support

The NG-1000DGEN is a digital configuration designed for users who prefer direct measurement through the eyepiece. After measuring the diagonals with the micrometers, the operator sends the values into the system with a single click using the built-in encoder. The hardness value is then calculated automatically and shown on the LCD screen.

The NG-1000DGEN is a digital configuration designed for users who prefer direct measurement through the eyepiece. After measuring the diagonals with the micrometers, the operator sends the values into the system with a single click using the built-in encoder. The hardness value is then calculated automatically and shown on the LCD screen.

This approach speeds up the workflow compared to manual data entry and reduces the chance of operator error. The NG-1000DGEN is often chosen by laboratories that want a reliable digital system without camera integration, while still maintaining compliance with ASTM E384, ASTM E92, and ISO 6507 standards.

NG-1000AGEN – Standard Digital Model

The NG-1000AGEN is the entry-level digital version of the series. Measurements are taken through the eyepiece, and the operator records the diagonals with the micrometers. The values are then entered manually into the keypad, and the hardness result is displayed on the LCD.

The NG-1000AGEN is the entry-level digital version of the series. Measurements are taken through the eyepiece, and the operator records the diagonals with the micrometers. The values are then entered manually into the keypad, and the hardness result is displayed on the LCD.

This configuration offers a straightforward process without advanced automation. It is well-suited for smaller laboratories or facilities that want a dependable tester while keeping the workflow simple. Like other models in the series, it fully complies with ASTM E384, ASTM E92, and ISO 6507 standards.

NG-1000CCD SEMI – Digital With Semi-Automation

The NG-1000CCD SEMI builds on the CCD model by adding a motorized XY stage. The operator brings the sample into focus using the manual Z-axis, while the stage handles movement between test points.

With this setup, the software can run boundary scans, perform automatic indentation plotting, and generate full reports with minimal operator input. This configuration is ideal for users who need higher throughput and consistency than the standard CCD, while still keeping manual control over focusing.

NG-1000CCD FA – Fully Automatic Configuration

The NG-1000CCD FA is the top-level model in the series. It includes everything from the CCD SEMI configuration and adds automated Z-axis control. This allows the system to focus automatically, creating a fully automated process from indentation to measurement and reporting.

The NG-1000CCD FA is the top-level model in the series. It includes everything from the CCD SEMI configuration and adds automated Z-axis control. This allows the system to focus automatically, creating a fully automated process from indentation to measurement and reporting.

With complete control over XY movement and Z focusing, the NG-1000CCD FA delivers the highest level of efficiency and repeatability. It is the best choice for laboratories and production environments that require continuous testing, minimal operator involvement, and maximum accuracy.

Standards for Micro Vickers and Knoop Hardness Testing

As mentioned earlier, the NG-1000 Series complies with the most recognized international standards. To give a clearer picture, here is a detailed list of the key standards for Micro Vickers and Knoop hardness testing. These cover American, European, and other widely adopted regulations.

As mentioned earlier, the NG-1000 Series complies with the most recognized international standards. To give a clearer picture, here is a detailed list of the key standards for Micro Vickers and Knoop hardness testing. These cover American, European, and other widely adopted regulations.

- ASTM E384 – Standard Test Method for Microindentation Hardness of Materials: Defines the procedures for Vickers and Knoop testing at micro-loads, covering equipment, test method, and data reporting.

- ASTM E92 – Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials: Provides test methods for both micro and macro ranges, ensuring accuracy across different loads.

- ASTM E140 – Standard Hardness Conversion Tables for Metals: Offers official conversion charts between Vickers, Knoop, Rockwell, and Brinell scales.

- ASTM E18 – Standard Test Methods for Rockwell Hardness of Metallic Materials: While not Vickers/Knoop directly, it is commonly referenced for conversion and correlation of results.

- ISO 6507 – Metallic Materials – Vickers Hardness Test: International reference for Vickers hardness testing, including equipment, procedures, and load ranges.

- ISO 4545-2 – Metallic Materials – Knoop Hardness Test – Part 2: Covers the testing method for Knoop hardness, including test procedures and verification requirements.

- ISO 6506 – Metallic Materials – Brinell Hardness Test: Often paired with Vickers/Knoop results for conversion and comparative reporting.

- JIS Z 2244 – Vickers Hardness Test: Japanese Industrial Standard equivalent to ISO 6507, widely used in Asian markets.

- JIS Z 2251 – Knoop Hardness Test: Japanese Industrial Standard equivalent to ISO 4545, ensuring consistency with global practices.

Applications and Benefits

The NG-1000 Series Micro Vickers and Knoop Hardness Testers are designed to cover a wide scope of applications in material testing. Their flexibility makes them valuable tools for both research and production environments.

Materials and Samples

The system is capable of testing:

- Metallic and non-metallic coatings

- Ferrous and non-ferrous metals

- High-strength alloys and composites

- Ceramics and glass

- Thin films, surface treatments, and hardened layers

Typical Applications

These testers are used for:

- Measuring hardness of case-hardened surfaces

- Evaluating coating adhesion and uniformity

- Checking weld zones and heat-affected areas

- Studying microstructures and thin sections

- Researching brittle materials where shallow indents are required

Industries

The NG-1000 Series is applied in:

- Aerospace and automotive

- Metallurgy and steel production

- Electronics and semiconductor

- Research laboratories and universities

- Quality control departments across manufacturing sectors

Why NG-1000 is the Right Choice

This model combines precision with a range of configurations to fit different testing needs. Users benefit from reliable measurements, automated features that save time, and compliance with international standards. Engineers, researchers, and QA managers can depend on the NG-1000 for consistent results, clear reporting, and a long service life that supports everyday testing tasks.

Final Thoughts on the NG-1000 Series

If you are considering equipment for micro-scale hardness testing, the NG-1000 Series is worth a closer look. With multiple configurations, compliance with international standards, and flexibility for different materials and applications, it offers a solid platform for both research and industrial environments.

Should you have any questions or need more details about this model or any of our other testing solutions, please contact us directly or request an online quote. Our team will be glad to provide clear answers and help you choose the right equipment for your requirements.