Metal Testing Equipment

NextGen Material Testing offers a full range of consumables for all metallography and hardness testing applications. Our metallographic consumables can be used for our own NextGen line up of testing equipment along with various other brands on the market. From abrasive sectioning, precision saw blades, vices, mounting, grinding, polishing and hardness testing, NextGen has what you need for all applications. Contact our experienced quality control consultant today to discuss how we can provide a solution for you.

Download Your Catalogue

FULL CONSUMABLES CATALOGUE

Full Scope of Metallography Consumables and Their Applications

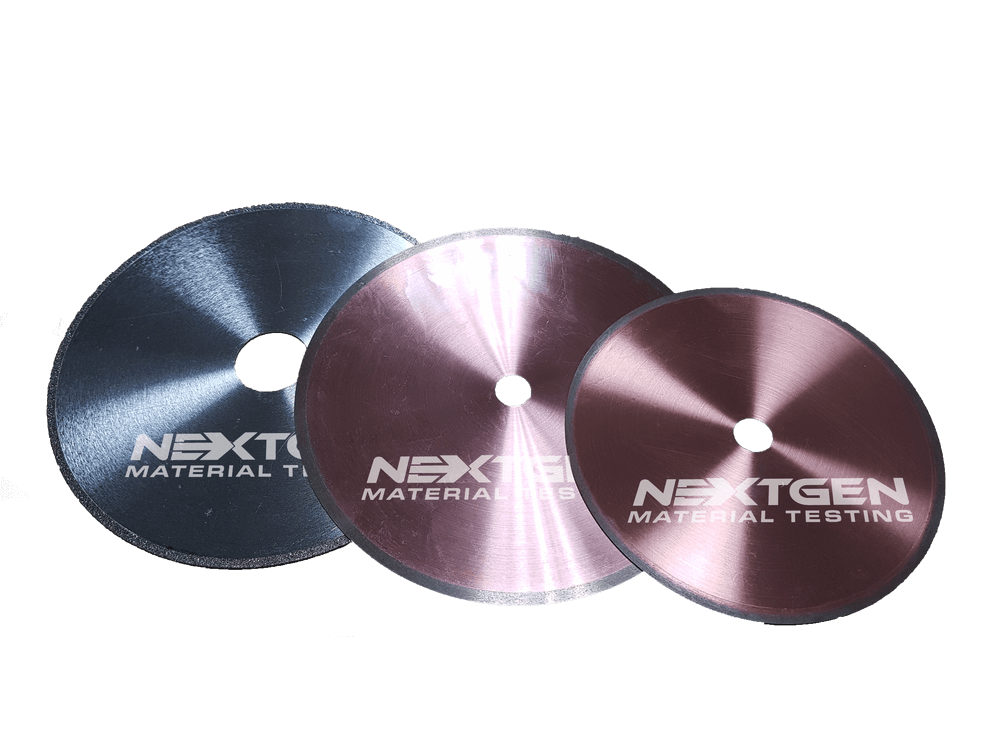

Sectioning

From abrasive sectioning to precision cutting, we have it all! Check out our full catalogue including metallographic abrasive blades (both resin bonded and resin-rubber bonded), precision diamond wafering blades (and cubic boron nitride blades), and cutting fluid in various sizes and quantities.

Hot and Cold Mounting

A complete list of mounting consumables to suit all materials including compression mounting and castable mounting. Compression mounting resins are available in various colors and with a wide range of fillers to improve hardness or conductivity. Epoxy, acrylic Resins and polyesters are available for all castable mounting procedures in various sizes of powders and hardeners.

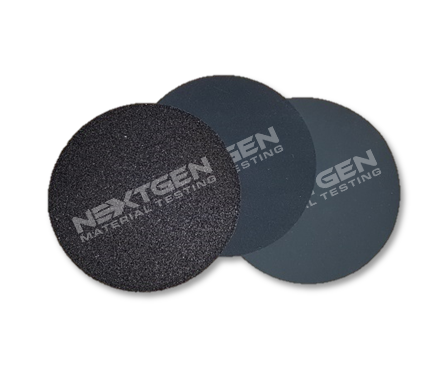

Grinding and Polishing

An extensive list of grinding papers, diamond disks, composite disks, lapping films, polishing pads and polishing abrasives to ensure the best finish for further metallographic analysis. Including a wide variety of diamond suspensions, pastes and lubricants to achieve your desired finish. Contact a specialist today and check out our catalogue for the detailed list of available items.

Metallographic Cleaning and Etching

Etching aids in the process of revealing the structure of your material for further microscopic analysis. Etchants are available for both chemical and electrochemical etching. Cleaning solutions are also available to remove polishing residue and any particulates on the surface which could potentially lead to misleading results. Check out our catalogue for all of our cleaning and etching consumables!

You may learn more about metallography basics, including primary metallography stages, and how to reduce the wear and tear on your metallography consumables by visiting our All You Need to Know About Metallography Basics blogs.

Additional Consumables for Quality Control Laboratory

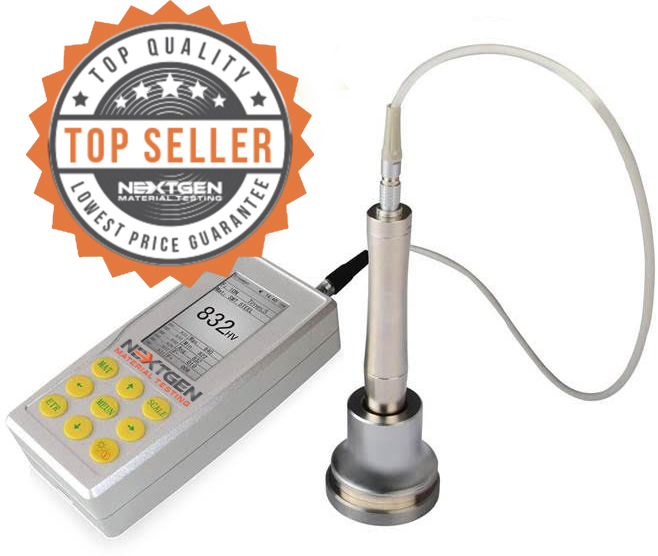

Hardness Testing

From Rockwell, Brinell, Vickers, Knoop, Telebrineller and various other portable hardness testing solutions, we are your provider for all hardness consumables. Learn more about our hardness testing consumables by contacting our specialist today to discuss your requirement for indenters, hardness test blocks, anvils, and much more!

FAQs

Diamond suspensions are used in the sample preparation stage to quickly remove raw materials and produce perfectly polished surfaces for analysis. The type of diamond suspension to use depends on the material being polished and the desired surface finish. Monocrystalline diamond suspensions are generally good performers, but in some cases, Polycrystalline diamond suspensions will be required. Polycrystalline diamond is particularly effective at removing stock and polish from hard or sintered materials.

Glycol Based Suspensions: A water-soluble and environmentally friendly diamond suspension mixed with glycol lubricant. Ideal for manual application or automatic –drip" dispensing systems. Colour-coded for easy identification of micron size.

Water Based Suspensions: Water soluble and environmentally friendly, this 99% water-based formula is recommended for manual application or automatic –"spray"/"drip" dispensing systems, where the lubricant is also applied.

DiaLube Diamond Suspensions: Water soluble and environmentally friendly diamond suspension pre-mixed with a propylene glycol-based polishing lubricant. Excellent for quick application of both abrasive and lubricant without the need for precise dripping ratios.

Alcohol-Based Slurries: An alcohol-based slurry made with 100% polycrystalline diamond, recommended for water-sensitive materials such as zinc, magnesium, and steel with non-metallic inclusions. Use with alcohol-based lubricants only. Recommended for manual application or automatic –spray"/–drip" dispensing systems, where the lubricant is also applied.

If you would like to obtain a personal quote on Diamond Abrasive Suspension and other Metallography Consumables, please click here.

Preparation of material for microscopic examination is the most common method used for mechanical specimens. The surface preparation necessary for a specific analysis or examination is determined by the type of analysis or examination being performed. The process of preparing mechanical specimens involves removing the material on their surface until the desired result is achieved. This can be done with progressively finer particles until the desired surface finish is reached.

Proper grinding removes damaged or deformed surface material while limiting additional surface deformation. The goal is to produce a polished surface with minimal damage that can be easily removed during polishing. Grinding removes material using a fixed abrasive particle that produces small chips of the specimen material. The process of making small chips with a sharp abrasive grain produces the lowest amount of deformation in the specimen while providing the highest removal rate.

Click here to obtain a personal quote on Metallography Consumables from NextGen.

Unfortunately, not all Diamond Blades last forever. If you know when your Diamond Blade is starting to wear down, it will slowly start to lose its effectiveness. The results of using a worn diamond blade are hard to see, but if you compare a brand new blade to a week-old blade that has been used, you will definitely notice the difference. If you learn to notice when it wears out, then you will save time, and your work will become more efficient.

Nevertheless, a diamond blade is not blunt or have dull edges like a Jigsaw Blade or Sabre saw blade. This means you can't just replace it when you notice it's dull. You have to pay attention to the type of blade cut and if it is different from the first time you use it. Your diamond blade will likely need to be replaced even if it still cuts. A fast, clean cut is always better than a slow, dull one.

Chemical etching is a technique used to remove the material with a high-pressure, high-temperature chemical spray, creating a permanently etched image in metal. A resist is applied to the material's surface and is selectively removed, revealing the underlying metal. This process is then repeated to create the desired image. An etching machine uses a corrosive reaction between a chemical and a material to create an image. The machine is then heated and sprayed at high pressure to amplify the effect.

The chemical spray dissolves the unprotected metal areas, etching the material atom by atom for a smooth, burr-free finish. Almost any metal and metal alloy can be chemically etched. This includes steel and stainless steel, nickel, copper and aluminum. Most metals are etched using a ferric chloride etchant which is safe to use and can be recycled. Ferric chloride can be recycled and reused. Other types of proprietary etchants, such as nitric acid, are used for specific types of metals and alloys.

Click here to obtain a personal quote on Metallography Consumables or if you have any other questions.

Electroetching is a metal etching process that uses a solution of an electrolyte, an anode, and a cathode. The metal piece you want to etch is connected to the positive terminal of a source of direct electric current. To reduce unwanted electrochemical reactions, the anode and cathode should be of the same metal. The cation in the electrolyte should also be of the same metal as the metal in the battery.

When the current source is turned on, the anode metal dissolves and turns into the same cation as in the electrolyte, and at the same time, an equal amount of the cation in the solution turns into metal and is deposited on the cathode. Depending on the voltage used and the electrolyte concentration at the anode and cathode, other, more complex electrochemical effects may occur, but the main ones are dissolution at the anode and deposition at the cathode where.

To get a personal quote on Metallography Consumables, you can click here.

It is common to polish for extended periods of time (hours) on the vibratory polisher. This is most common for very hard materials like engineered ceramics. The effect of over polishing on metals it that you can begin to introduce relief or edge rounding where the specimen meets the mounting compound. This can also happen if the specimen is comprised of various phases/materials of varying hardness. A good example is a PCB where you might have soft materials like tin or copper alongside harder materials like ceramic.

The best practice is to play with times relative to your specimen and analysis. Checking the specimen on an optical microscope every 30 minutes is helpful when developing procedures for vibratory polishing. Also, keep in mind the colloidal silica will crystalize if allowed to dry out or dehydrate. I hope this is helpful.

A naturally occurring material, Alumina comes in either the alpha (hard at 2000 HV, mohs 9) or the gamma (soft at mohs 9) phase. The Alumna abrasive is mainly used for final polishing due to its durability and hardness. Unlike SIC abrasive, alumna is easier to break down into colloidal or submicron particles.

It is worth noting that bigger coated or bonded grit alumina sizes are available commercially. But, they are not recommended for metallurgic uses because they turn dull. This results to a lower cut rate and a higher subsurface and surface damage.

SIC abrasive is manufactured using the high temperature produced in the reaction between carbon and silica. Its structure has a hexagonal-rhombohedral crystal shape. Its hardness is around 2500 HV. The abrasive is ideal for grinding and cutting because of its sharp edges and hardness. It likewise has enough brittleness. It easily cleaves to create new sharp edges (self-sharpens).

SIC is superior in maximizing the cutting rates, while helping minimize subsurface and surface damage. In metallographic applications, it is used in abrasive blades as well as for coated abrasive grinding paper that range from the extremely coarse 60 grit to the extremely fine 1200 grit size.

Coated or bonded SIC abrasive papers are specifically designed to give the abrasive a big number of cutting points. This is possible by proper alignment of the abrasive particles that are about normal to the backing. It must be noted that coated abrasives aren?t quite coplanar. SIC papers thus produce maximum efficiency (stock removal, cut rate, and minimal damage) since new abrasive gets exposed and the old abrasive is broken down.

- Phenolics - Generally, phenolics are utilized because of their comparatively low cost. Phenolics are likewise available in various colors.

- Acrylics - The primary use of compression mounting acrylics is due to its excellent clarity. It is particularly important in locating specific features in the specimen mount.

- Epoxies/Diallyl Phthalates - Glass-filled epoxy and diallyl phthalate are types of compression mounting resins utilized for providing a tougher mounting support edge around the specimen. The resins are typically used as support for the coatings' edges, heat treated samples, as well as other specimens that require better flatness.

There's no apparent gap between the mounting material and the specimen. The glass-filled epoxies offer excellent support to the edge of the specimen even in extremely hard samples.

- Specialized Compression Mounting Resins - The addition of fillers like copper or graphite enables the compression mounting compounds to be more conductive.

A conductive mount is used for scanning electron microscopes (SEM) to keep the specimen from accumulating a charge. A conductive mount is also used for samples that require electrolytic etching or polishing.

The different types of compression mounting resins include:

- Acrylic Resins (clear)

- Phenolic Resins (available in standard colors of red, green, and black)

- Epoxy Resins (glass-filled)

- Diallyl Phthalate Resins (black and blue)

- Conductive Resins (phenolics w/ graphite or copper filler)

A diamond wafering blade is often used for sectioning delicate materials that require a precise cut. When sectioning with a wafering blade, it is important to consider the load, speed, and diamond size and concentration. The applied load and cutting speed are functions of the material to be cut.

Commonly, diamond wafering is performed at a speed of anywhere between 50 and 5000 rpm with varying loads from 10 to 1000 grams. In general, a harder specimen is cut at a higher speed and load (for instance, minerals and ceramics) as well as more brittle samples are cut at lower speeds and loads (such as electronic silicon substrates).

A number of factors must be considered when choosing the right watering blade, including the diamond concentration (high and low), diamond size (medium or fine), diamond bond (metal plate), blade thickness, and diameter.

Diamond concentration is crucial since it affects the applied load directly during cutting. For instance, brittle materials like ceramics need a higher effective load to section, unlike ductile materials like metals that need more cutting points. Thus, low concentration blades are better when sectioning hard brittle materials like ceramics. On the other hand, high concentration blades are preferred for ductile materials that contain a large portion of plastic or metal.

The diamond bonding material likewise considerably affects the cutting performance of the blade. A metal plated wafering blade requires periodic dressing to keep it in top performance. Contrary to what many people think, the cutting performance doesn’t diminish when the diamond is taken out of the blade. The metal bond, in reality, mainly smears over the diamond, and blinds the diamond abrasive.

The smeared material is taken away and the cutting rate is restored with periodic dressing.

Precision wafer cut is most often applied with a diamond wafering blade. For some materials, however, cubic boron nitride (or CBN) is the more appropriate and efficient watering blade to use. Optimal wafer cutting is also done by optimizing the abrasive size and concentration, and choosing the most suitable cutting load and speed.

Precision wafer cutting is applied to section extremely delicate samples and to section samples to a quite precise location. Typically, precision wafering saws are equipped with micrometers to accurately align and position the samples. They also have variable cutting land loading speed control.

The typical precision wafering saw ranges in speed from 50 to 1500 rpm or 300 to 3000 rpm. Faster saws are needed to section extremely hard materials like treated steals, minerals, and ceramics.

The selection of the right abrasive blade to use depends on the cut-off machine's design, and to a large degree, the preference of the user. In general, abrasive blades are characterized by the type of abrasive, hardness, and bond type.

Determining the right blade depends on the material or hardness of the metal, and whether the metal is ferrous or non-ferrous. In common practice, it usually comes down to blade life and odor. Resin/rubber blades tend to smell more since the rubber will slightly burn during the cutting process. But, this type of blade wears more slowly, and thus lasts longer.

Resin blades, on the other hand, don't produce the smell of burnt rubber and are more versatile. However, the break down more easily. Resin blades likewise offer a slightly better cut. This is because the abrasive is continuously renewed, producing a cleaner cut in the process.

It is also worth noting that the traditional, old-fashioned technology used to produce abrasive blades resulted to highly specialized resin/rubber blades. Thus, finding the right resin/rubber hardness, blade thickness, and abrasive size that matches the properties of the sample as well as the cutting machine parameters required lots of experimentation and testing.

In the past, the resin/rubber blade was more common in the US. However, with the improvement of resins in recent years, the trend has seen a gradual shift towards resin bonded types of abrasives. In contrast, resin bonded blades have been more popular in the Asian and European markets for many years now.

- Resin bonded blades - more versatile, higher wear, less sample burning, and less smell

- Resin-rubber bonded blades - tends to burn the sample, burnt rubber smell, longer life, and harder to find the appropriate blade

The best use of monocrystalline diamond is during the initial application of several diamond beads/extenders for the initial pad wetting. Notice that the pad saturation is neither recommended nor necessary. Additional dispensing is typically dripped on the surface at 1 to 2 drops for every 10 to 15 seconds, depending on the sample?s surface area and polishing speed.

For ceramic and mineral specimen preparation, it is best that colloidal silica and diamond be dispensed alternately. This results to a chemo-mechanical polishing action that considerably improves removal rates, lessens subsurface damage, and enhances surface finish.

The technique is ideal for use with 6 micron diamonds and other smaller polycrystalline diamonds. For best results for the application, it is recommended to clean the samples and the cloth during the cycle?s final 15 seconds. Allow running water to flow on the surface of the polishing pad.

Polycrystalline diamond is most efficient when used for the initial application of several diamond beads/extenders for pad wetting. Notice that the pad saturation is not necessary. Neither is it recommended. Additional dispensing is typically dripped on the surface at 1 to 2 drops per 10 to 15 seconds, depending on the speed of polishing and the sample?s surface area.

For the preparation of mineral and ceramic specimens, the recommendation is the alternate dispensing of diamond and colloidal silica (or SIAMAT colloidal silica). This results to a chemo-mechanical polishing (or CMP) action that considerably improves removal rates, lowers subsurface damage, and makes the surface finish better.

The technique is ideal for use with 6 micron diamonds and other smaller polycrystalline diamonds. For best results for the application, it is recommended to clean the samples and the cloth during the cycle?s final 15 seconds. Allow running water to flow on the surface of the polishing pad.

What are the benefits of metallographic polycrystalline diamond polisher use in the polishing cycle?

- Very uniform surface finish

- High cutting rates

- More uniform distribution of particle size

- The self-sharpening abrasives offer high removal rates

- Tougher/harder particles

- Blocky shape

- Hexagonal microcrystallites that are similarly hard in any direction

- Very rough surface because of more cutting points

- A surface area 300 times more than monocrystalline diamonds

- Absence of abrasion-resistant directionality as the abrasion is independent of the orientation of the particle

- CERMESH Metal Mesh Cloth - The wire mesh material is coarse as well as intermediate lapping/polishing. The wire's texture allows the abrasive be semi-fixed. It therefore offers the edge of minimizing damage while increasing stock removal.

- POLYPAD Polishing Pad - The synthetic polyester polishing pad works similar to a nylon pad, except that the Polypad is a lot more durable. It is ideal for use in intermediate polishing tasks.

- TEXPAN Polishing Pad - The pad is the most frequently used cloth for intermediate polishing jobs. The polishing pad is non-woven.

- CHEM 2 Polishing Pad (Black) - The porometric polymer pad has the same consistency of a rubber type of pad. The CHEM 2 Black pad possesses a low nap, but acts as a polishing pad for intermediate applications. Its performance is somewhere between that of a low nap pad and a high nap pad.

- DACRON II Polishing Cloth - The low nap type of polishing pad is primarily used for polishing with a 1 - 15 micron diamond abrasive. It is the most frequently used intermediate polishing pad for metals in Europe. It has a high nap that allows the pad to provide a very gentle and soft polishing action.

- GOLDPAD Polishing Pad - A low-napped pad for intermediate polishing applications, it is mainly used with a 1 - 9 micron diamond.

- ATLANTIS Polishing Pad - A low napped woven pad for final applications, it has a foam backing that allows for better matting to the sample. It is a superior polishing pad used with 1 - 6 micron diamonds.

- NYPAD Polishing Pad - The low napped polishing pad made from silk is ideal for intermediate polishing applications. It is used mainly with diamond intermediate abrasives.

- MICROPAD Polishing Cloth - The most prevalent high nap pad used for final polishing of most polymers and metals, the nap offers a very gentle and soft polishing action.

- TRICOTE Polishing Pad - The tight high napped pad is ideal for final polishing of most metal materials. It is equipped with a tighter nap compared to the MICROPAD Polishing Pad.

- MOLTEC 2 Polishing Pad - The wool polishing cloth is ideal for final polishing use, and comes with an extremely high nap. It is typically used for the final polishing of metals where edge retention is not a big factor.

- NAPPAD Polishing Pad - Another high napped variety for final polishing, the pad is mostly used form most polymers and metals. Compared to the MICROPAD, the NAPPAD has a higher nap that provides an extremely gentle polishing action. It is quite useful for polishing softer materials like aluminum, copper, and austentite steels.

- FELTPAD Polishing Pad - The thick felt pad is mainly used for the final polishing of glass and other area parts with large surfaces.

Zirconium silicate or Zircon is a not-so-commonly used coarse grinding abrasive. Because of its extreme toughness, it lasts longer. But, it isn’t, in general, as hard or sharp as the more popular abrasives. It thus needs a higher pressure to be effective. Usually, the 120 or 60 grit sizes are considered the most useful for metallographic grinding applications with Zircon.

The particle size for metallographic abrasives is classified typically by their grit size or the average particle size measured in microns. Grit size refers to the particle size if sized or classified with mesh screens. Grit size, in general, represents the number of wire mesh or wires per given area. Larger grit numbers thus represent more or smaller mesh screen openings, and mean smaller particle sizes.

For instance, a 120 grit particle is around 105 microns in size, while a 1200 grit particle is 2.5 microns in size. The variance between the P-grading system used in Europe and the more prevalent CAMI or ANSI standard is mainly due to the European number being based on how many openings there are if the wire mesh width is not considered in the calculation.

For larger particles, therefore, Europe’s P-grading is about the same as the CAMI or ANSI number. For example, 120 grit is equivalent to P120 grit. For finer particles, on the other hand, you will see a much bigger value such as P4000 grit compared to 12000 grit.

At 8000 HV, mohs 10, diamond is acknowledged as the hardest material around. Its structure is of cubic crystal. It is available either as an artificial or natural product. While diamond is perfect for coarse grinding, its cost renders it an ineffective grinding material for everything except hard ceramics. For metallographic purposes, specifically as a rough polishing abrasive, polycrystalline diamond is ideal.

After the 3 months expiry date, the etchants may still produce the expected results, with no apparent effect on quality. This is especially true if the etchants are stored in a cool, dark and dry environment. The issue is that not all of them will last longer than 3 months. Some of them will degrade to the point of being unusable around 90 days or so. Because of this, all etchants have a 3-month shelf life.

Occasionally we advise customers to continue using their etchant until they no longer get the results they need. In other cases where safety is tightly regulated, they may not have this option. Learn more by contacting our Quality Consultants today.

The best way is to send NextGen your samples and have our metallographic experts work with your samples to working out the best consumables to achieve your desired finish. Contact a sales representative today to have your samples evaluated!

- Phenolic Resins (standard colors are black, red and green) - low cost and a variety of colours

- Acrylic Resins (clear) - excellent clarity

- Diallyl Phthalate Resins (blue and black) - provides a harder mounting support edge next to the specimen often used for coatings or heat treating sample analysis

- Epoxy Resins (glass-filled) - provides a harder mounting support edge next to the specimen often used for coatings or heat treating sample analysis

- Conductive Resins (phenolics with copper or graphite filler) - special resins can be made conductive for scanning electron microscopes SEM to prevent the specimen from building up a charge

Diamond wafering blades are the most common for precision sectioning, however, cubic boron nitride CBN blades are sometimes more efficient. Wafer cutting is often used for sectioning delicate samples or within a precise location.

Resin bonded blades and Resin-rubber bonded blades. Resin bonded have less smell, quicker wear, less sample burning and more versatile. Resin-rubber bonded blades certainly have a longer lifespan but will have a burnt rubber smell during the cutting process. They often burn a sample and are usually much more difficult in finding the best blade for the application.

Abrasive blades are characterized by their abrasive type, bond type and hardness. The main factor when deciding which blade is right for you will be heavily dependant on your material hardness and whether it is a ferrous or a non ferrous metal.

Historically, there are two methods of polishing and grinding process for composite materials:

Traditional Method:

Grinding process - 320, 600, 800, and 1200 grits

Polishing process - 6 um (polishing cloth), 3um (polishing cloth), 1um (polishing cloth) along with aluminum oxide powder or diamond suspension fluid

Contemporary Method:

Grinding process - 240 SIC paper

Polishing process - 9um (diamond platen - Golden), 6um (polishing cloth), 1um (polishing cloth) with diamond suspension fluid

Standard Engineering Recommendations:

The below process offers a standard recommendation for polishing and grinding needs. This can be adjusted as needed, depending on your materials and surface finish requirements. Contact our qualified consultants to learn more.

Here is a cost effective

GRINDING:

The most cost-effective consumables option for grinding would include a combination of our 12-inch MAGNEPAD Stainless Steel Magnetic Base Plate - Part #: SSMAG-P12 combined with the following adhesive backed grinding pads. Our recommendation based on your material and relatively smooth starting surface would be to start with:

240 Grit paper - Part #: SIC-240P12-100

600 Grit paper - Part #: SIC-600P12-100

1200 Grit paper - Part #: SIC-1200P12-100

You can always add more grinding paper grits as needed.

NOTE: For optimal convenience, you would require one Steel Magnetic Base Plate per grinding paper.

This combination will allow you to easily switch out your stainless steel magnetic base plates with grinding paper as needed; while benefiting from using the adhesive backed grinding paper, which is much more cost effective than magnetic grinding paper.

POLISHING:

After your grinding procedure, we would recommend using our 12-inch ATLANTIS Polishing Pad with Magnetic Rubber (Part #: ATL-3012-MAG) along with 1 micron DIAMAT Polycrystalline High Viscosity Diamond Abrasive (Part #: PC-1001-500).

The pads can go directly onto the magnetic base plates of the main unit. They are extremely easy to switch out and have a high life-span.

NOTE:

Should better polishing be required, we would suggest moving into the alumina diamond suspensions.

Should need additional guidance, contact us today to learn more.

Related Products

NG - LeebGen 3000 - Leeb Rebound Portable Hardness Tester

LeebGen3000 is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

Ultrasonic Contact Impedance Hardness Tester - UH200

Welcome to our most advanced and cost-effective Ultrasonic Hardness Testing System. This portable machine is all you need and more!

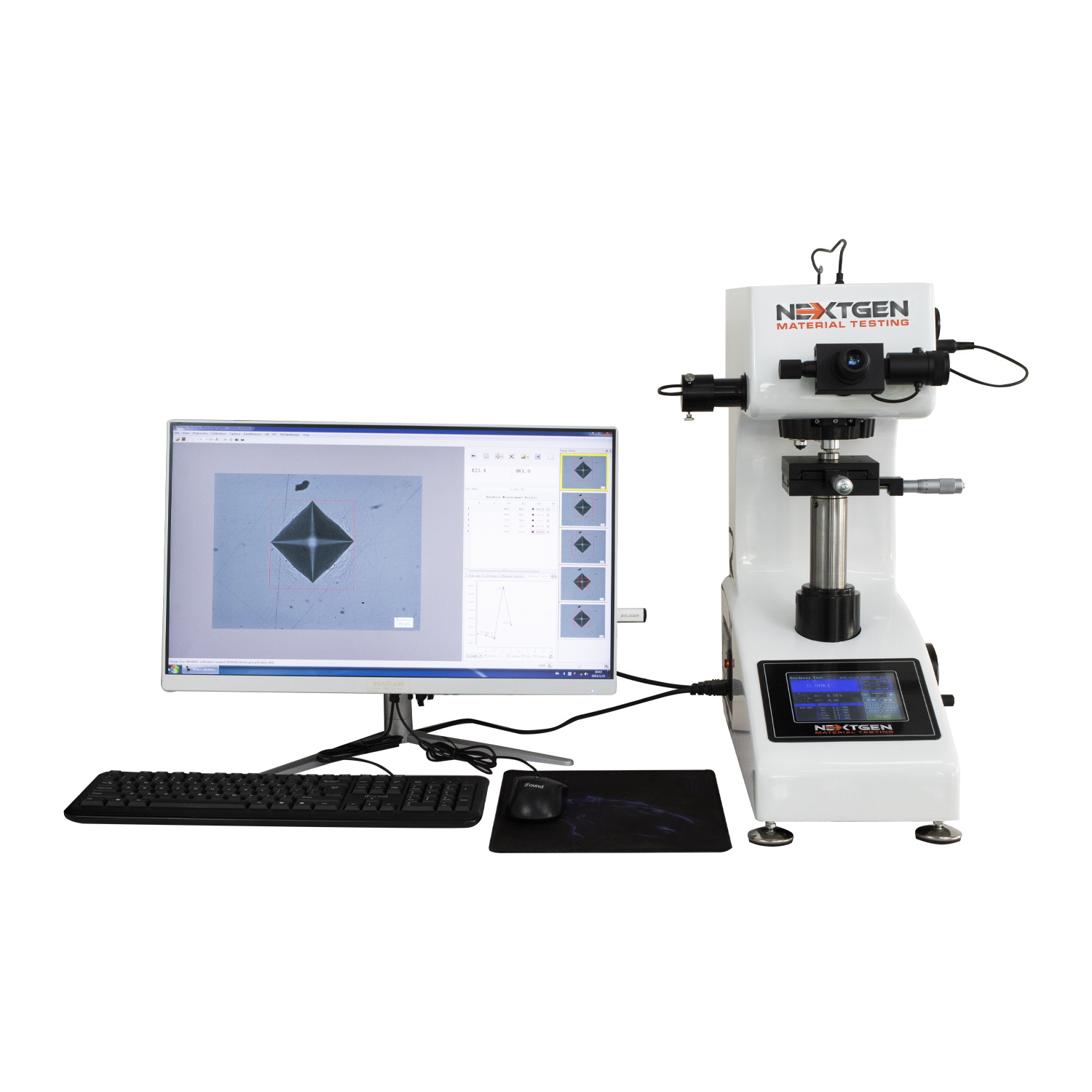

Micro Vickers and Knoop Hardness Tester - Digital and Digital with CCD Optical Analysis Software

NG-1000 Series

NextGen Micro Hardness testers provide solutions for Vickers and Knoop hardness testing with micro loads ranging from 10gf to 1kgf. The NG1000 series is available in Standard Digital, Digital and CCD configurations for Micro Vickers/Knoop testing.

Macro Vickers Hardness Tester - Standard Digital, Digital and Digital with CCD Optical Analysis Software

NG-5000 Series

NextGen Macro Vickers Hardness testers are available with different load capacities and are available in Standard Digital, Digital or CCD configurations. With 5kgf, 10kgf, 30kgf and 50kgf maximum loads available, the NextGen Macro hardness testers can fit all of your Macro testing requirements.

BrinGen - 3000 Series - Digital Brinell and Automatic Brinell Hardness Tester - Closed Loop System

BringGen 3000 is a digital and automatic Brinell testing system equipped with closed loop technology. The forces range from 62.5kgf to 3000kgf and are electronically controlled according to ASTM E10 for precise and repeatable measurements.

BrinGen Scope - Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System

BrinGen Scope - is a Optically Advanced CCD Brinell Measuring Scope for Manual or Digital designed as Brinell Hardness Testing automatic scanning system. It is engineered to work with a computer or a laptop to make your testing program faster and more accurate. The Optical Brinell Scope is equipped with real-time result support.

NG-RockGen - Analogue Series Rockwell Hardness Tester - Manual and Electronic Models

The NG-RockGen Analogue Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell regular scales.

NG-RockGen DGEN Series - Digital Rockwell Hardness Tester - Rockwell Regular, Rockwell Superficial and Rockwell TWIN Digital Models

The NG RockGen Digital Series provides an automatic, digital, high accuracy solution to your Rockwell testing requirements. The Digital series is completely automated and is available in Rockwell Regular or Rockwell Superficial scale configurations.

GenRock NG-150 Series - Advanced Rockwell Hardness Tester - Manual and Automatic Rockwell Hardness Testing System

The NG150 GenRock system can be equipped with a variety of accessories to meet all of your hardness testing requirements. A fully motorized stage, Jominy accessories and a wide variety of specimen fixtures are available to configure the NG150 RockGen system to meet your application.

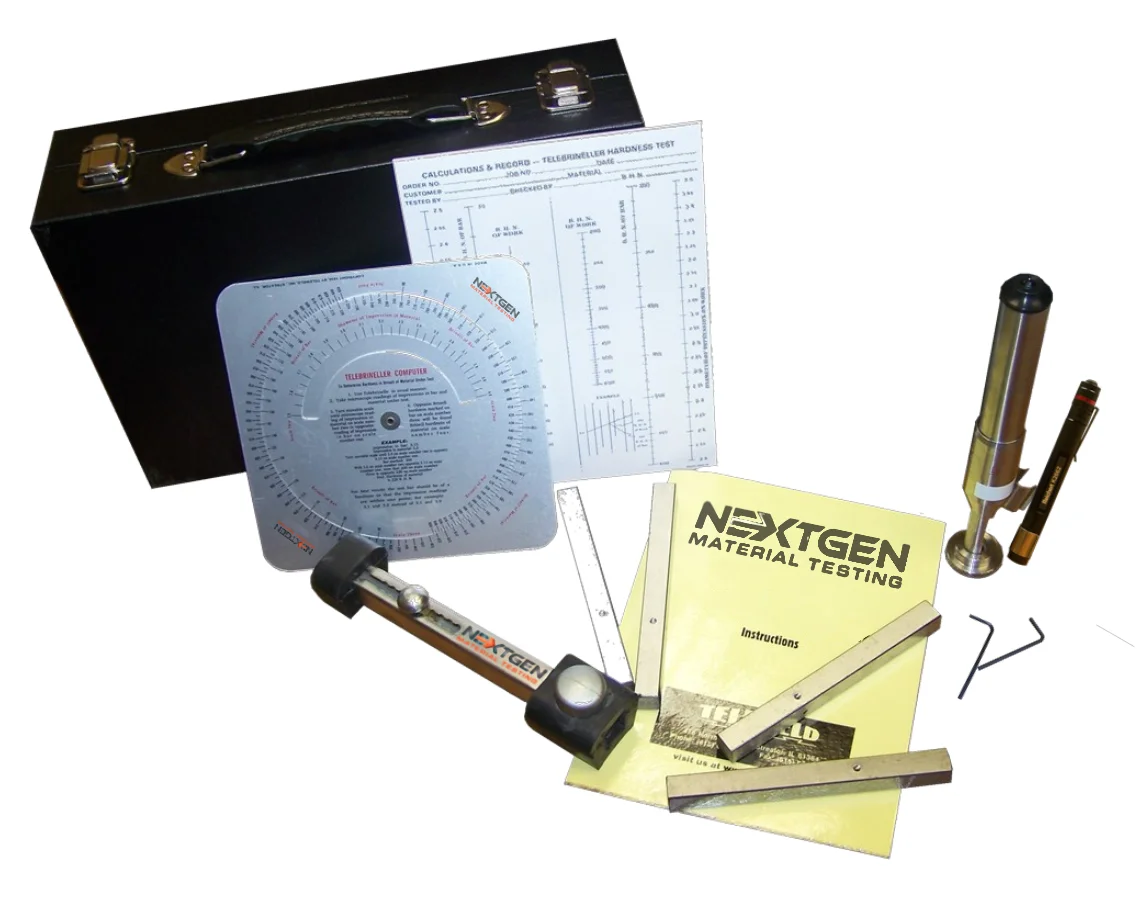

NextGen Telebrineller Brinell Hardness Testing System

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch quality. Developed specifically for welding crews, Telebrineller draws on over fifty years of field experience and solid metallurgical knowledge. Portable and practical, the entire Telebrineller system, housed in a case, weighs less than ten pounds. It's an ideal choice for Brinell hardness testing in any situation.

Surface Roughness Testers

High accuracy surface roughness testing systems for material surface analysis and statistical processing of data. Multiple model variations to help fit your technical and budgetary expectations.

UniGen Universal Hardness Tester – Rockwell, Vickers & Brinell Hardness Testing System

NextGen's Universal Hardness Tester is a closed loop load cell machine with an 8-inch touch screen interface is the ultimate user-friendly solution for your Vickers, Knoop, Rockwell and Brinell Hardness Testing requirements. The measurements are made through optical objective lens and CCD camera to collect indentation images and to generate your hardness reading on the touchscreen LCD.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.