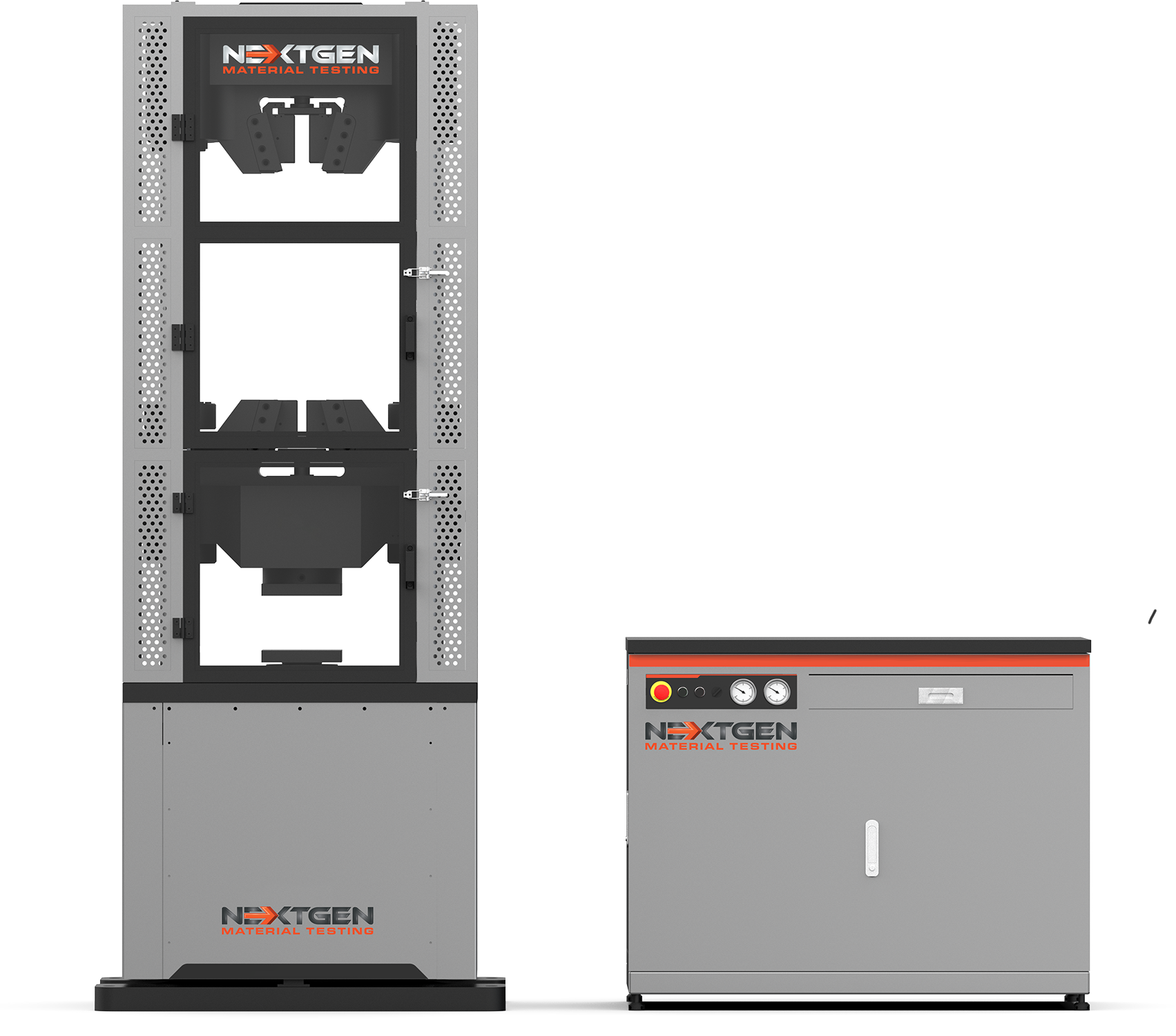

Metal Testing Equipment

Standards

ASTM E92, ASTM E8, ASTM A370, ISO 7500-1, ASTM E4, ISO 527, ISO 6892-1, ASTM E21, ISO 6892-2, ISO 9513, ASTM D3039, ASTM F606, EN ISO 15630-1, EN 10002-1

Description

The NG-SHM Series A is engineered for laboratories that require controlled application of large static forces for material strength characterization. With capacity options from 300 kN up to 3000 kN, the system accommodates oversized metallic specimens where electromechanical frames are insufficient. A high-stiffness multi-column design minimizes frame deflection under load, improving the accuracy of yield and elongation measurements during tensile and compressive failure.

The dual-zone configuration allows tensile testing to be performed on the upper crosshead section while compression fixtures remain mounted on the lower platen, reducing reconfiguration steps during daily operation. This design is particularly beneficial for environments performing repetitive tensile/compression cycles or running certification tests under ISO/ASTM frameworks.

The system is appropriate for yield strength determination, proof testing, elongation analysis, fracture behaviour observation, tensile/compressive modulus evaluation, QC acceptance testing, and research-grade deformation studies. Compatibility with extensometers and hydraulic wedge grips enables secure clamping of smooth, ribbed, round, or flat metallic samples at varying dimensions.

Force Capacity: 300 kN, 600 kN, 1000 kN, 2000 kN, and 3000 kN

Load Frame Configuration: 4- or 6-column hydraulic structure with servo-controlled actuation for test space adjustment

Test Space Layout: Dual-zone configuration — tension on upper crosshead, compression on lower platen

Typical Specimens: Fasteners, reinforcing steel (rebar), metal bar/wire, chain links, welded joints, cast components, and general metallic samples

Typical Test Specimens

Below is a representative list of materials and component types compatible with the NG-SHM Series A high-force servo-hydraulic testing system. The machine supports medium- to large-scale metallic samples, structural components, and assemblies requiring high load capacity during tensile and compression evaluation:

- Reinforcing steel rebar, threaded bar, smooth bar, structural rod

- Metal plates, billets, heavy gauge sheet, and machined test coupons

- Steel wires, cables, chains, anchoring hardware, and lifting connectors

- Welded joints, heat-affected zones (HAZ), and welded plate specimens

- Cast and forged components, brackets, automotive/industrial metal housings

- Bolts, nuts, fasteners, studs, anchor bolts, and mechanical couplings

- Pipe segments, round bar, tubes, hollow cylinders, and cross-section samples

- Large compression blocks, load-bearing plates, die-forged elements

- High-strength alloys, carbon steel, stainless steel, tool steels, iron-base materials

- Industrial structural components, fittings, joint parts, rail sections, support elements

- Tensile/compressive samples prepared per ISO 6892-1 / ASTM E8 (E8M)

- Compression test specimens per ASTM E9 and related procedures

- Rebar and construction steel materials per EN ISO 15630-1 and comparable standards

- General metallic components across R&D, QA, and batch-release workflows

Key Features of the NG-SHM Series A UTM

This machine offers numerous engineering advantages. Below are the key features that define its performance and reliability:- High-stiffness multi-column load frame: Designed to maintain alignment and minimize deflection under high force.

- Servo-hydraulic actuation: Stable loading during tensile and compression testing of metallic specimens.

- Dual test-zone layout: Upper section for tension, lower section for compression without fixture removal.

- Hydraulic wedge grips: Secure clamping of round and flat samples during high-load testing.

- High-resolution force measurement: Strain-gauge load cell with 1/500,000 resolution for tension and compression.

- Intelligent hydraulic power unit: Pressure-regulated system with low-noise screw pump and 5 μm filtration.

- Active cooling system: Automatic air-cooled HPU cabinet for continuous operation.

- Safety and protection logic: Overload, travel limit, temperature monitoring, and emergency stop.

- DTC-500 digital controller: 24-bit acquisition, 1200 Hz control rate, closed-loop force/displacement/extension control.

- Connectivity and data handling: Ethernet/USB interface with TEDS support and noise-resistant signal architecture.

- GenTest™ software integration: Method templates, real-time graphing, automatic results, and export tools.

Frame & Mechanical Structure

The NG-SHM Series A uses a rigid multi-column frame designed to maintain alignment and minimize deflection under high load. The crosshead is adjusted by a lead-screw mechanism, allowing accurate positioning of the test area for tensile and compression work.

Key elements:

- Lead-screw crosshead drive for precise positioning

- High-stiffness 4/6-column frame for alignment stability

- Reinforced beams to reduce deflection and improve measurement accuracy

Load Cell & Force Measurement

Mounted at the lower grip, the strain-gauge load cell records force directly through the specimen. The system reads tensile and compression loads with a measurement resolution of 1/500,000 across the full scale without range switching.

Key points:

- Strain-gauge load cell for direct force acquisition at the specimen

- 1/500,000 resolution for high-fidelity load measurement

- Full-scale operation with no range change or step divisions

Hydraulic Power Unit

The NG-SHM Series A hydraulic unit regulates working pressure based on real cylinder demand, keeping an adjustable differential during load increase and lowering pump output when force requirements decrease. This pressure-following logic minimizes unnecessary energy circulation through the hydraulic loop, reducing heat buildup and improving stability during long test sequences. Lower energy loss results in smaller temperature rise, allowing the oil system to remain within operating limits for extended periods without drop in control accuracy. The cartridge valve architecture supports stable pressure transition and maintains consistent hydraulic delivery in high-load and low-load conditions.

Servo Control & Response Stability

A high-performance servo valve with low hysteresis is used as the main control element, enabling fast pressure response when force changes occur during tensile and compression stages. The rotor-driven screw pump provides smooth, pulse-free flow up to 27.5 MPa, improving control resolution and eliminating flow fluctuations that affect precision. The servo circuit incorporates standardized spool-position feedback for diagnostics, allowing real-time monitoring of status and enabling predictive maintenance. This configuration supports accurate regulation at small load increments while maintaining control smoothness when approaching yield or fracture.

Maintenance, Cooling & Filtration Architecture

The hydraulic power unit features a semi-open enclosure allowing direct access to internal components for inspection and service. The backplate can be removed without cabinet disassembly, streamlining checks on valves, filters and pump components. To control thermal load, the system uses automatic air cooling triggered when oil temperature reaches a preset threshold. Filtration is performed through multi-stage high-pressure elements with an absolute rating of 5 μm, protecting servo valves and pump internals from contamination and increasing service life. Overpressure protection is managed through a relief valve that opens once the system exceeds rated pressure. High-pressure lines and cone-seal bite-type fittings maintain sealing integrity under repeated assembly cycles and support leak-free operation during continuous duty.

Technical summary:

- Pressure-following logic adjusts output dynamically to reduce thermal and energy load

- Pulse-free hydraulic delivery up to 27.5 MPa for stable control response

- Servo-valve regulation with diagnostic feedback and low hysteresis

- Automatic fan-based cooling activates at oil-temperature threshold

- 5 μm absolute filtration for valve and pump protection

- Relief-valve overpressure protection and high-pressure sealing fittings

Control System – DTC-500

The NG-SHM Series A is powered by the DTC-500 digital controller, designed for accurate closed-loop management of force, displacement, and extension during static tensile and compression tasks. The platform uses 6-channel 24-bit A/D measurement with sampling and control rates up to 1200 Hz, enabling consistent and accurate signal capture even during high-force tests. Three high-speed digital input channels support encoder or grating ruler feedback up to 4 MHz, while a 20-bit digital input resolution maintains precision throughout the test range.

The control architecture is fully digital with three closed loops, allowing smooth transitions between force, displacement, and extension control modes during operation. This enables reliable handling of ramp, hold, and cycling procedures without instability at switching points. Connectivity includes USB and high-speed Ethernet ports supported by a dedicated TCP/IP processing chip. Optional dual analog output channels can be used for external force, displacement, or extensometer signal integration.

For simplified setup, the system supports TEDS transducer recognition, allowing automated load cell and accessory identification. Safety layers include limit protection, overload protection, and an emergency stop function. Internally, a 4-layer PCB layout enhances noise immunity and electronic stability, while locking connectors maintain secure signal routing and enable quick plug-in replacement during maintenance.

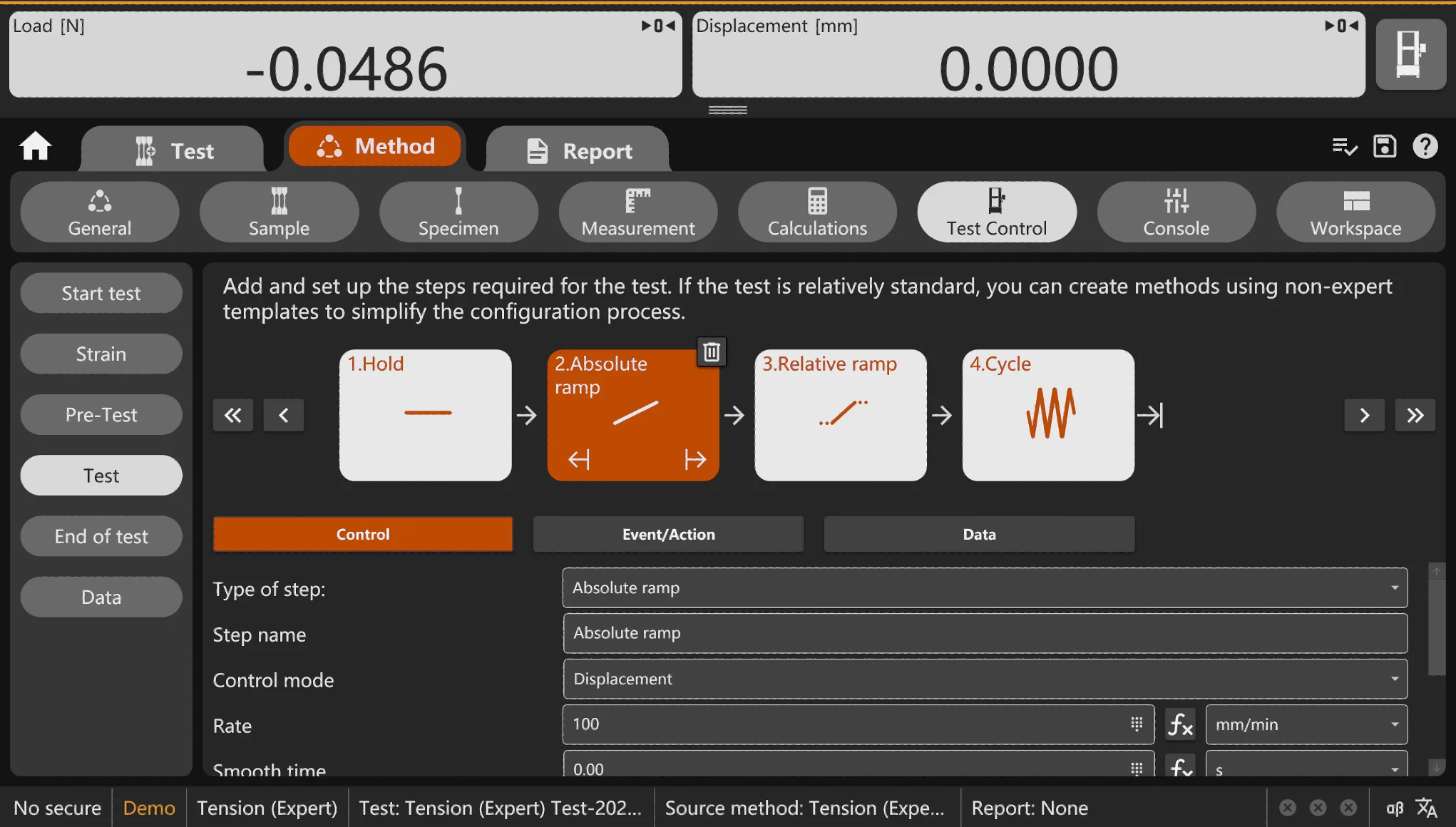

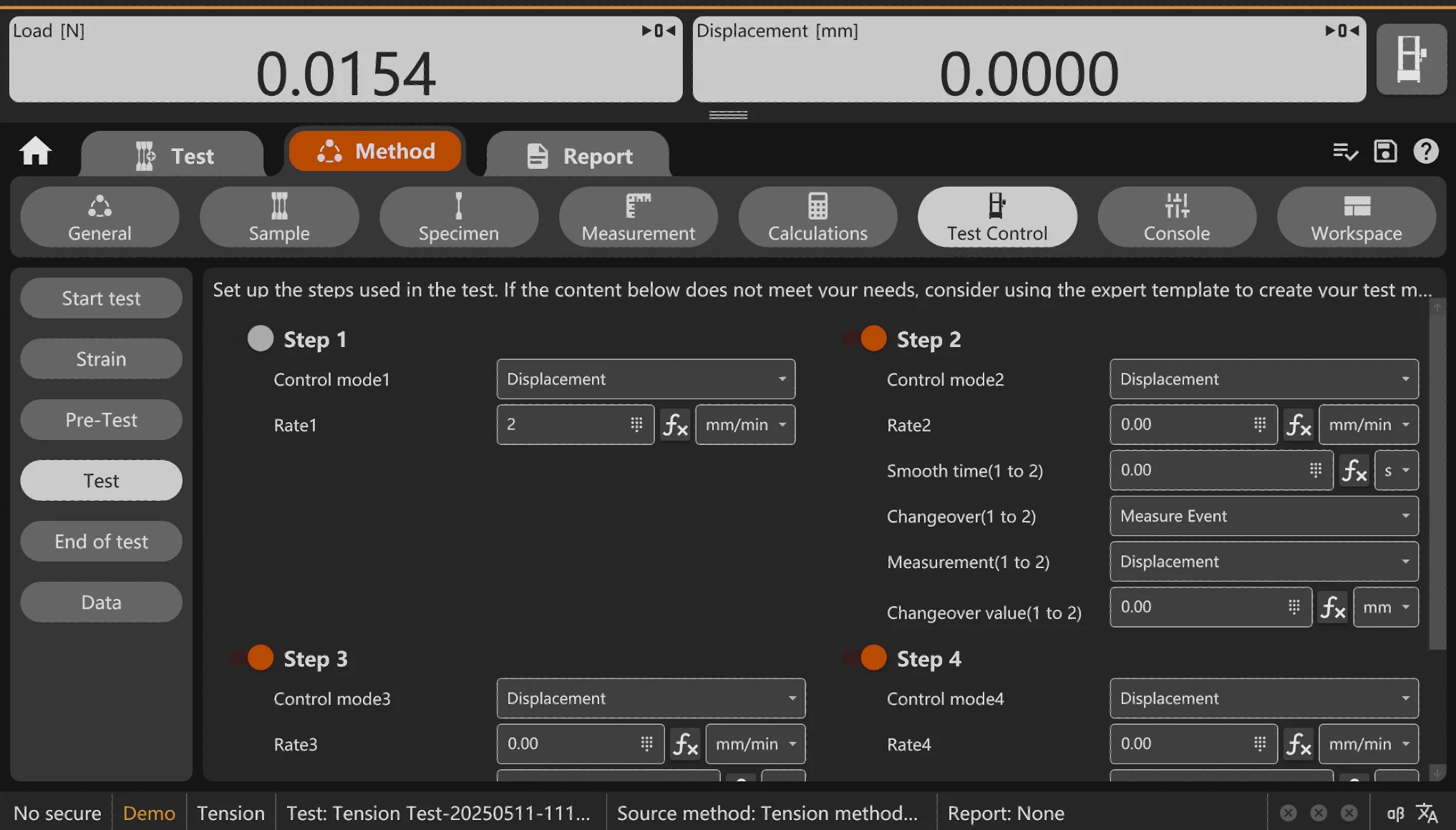

GenTest™ Professional Test Software & Control Platform

The NG-SHM Series A is supplied with GenTest™ software designed for standards-based mechanical testing and data acquisition. The system includes an expanding library of ready test methods and supports ASTM, ISO, DIN, EN, BS and other international procedures. Operators can run tensile, compression, flexural and custom test protocols with clear setup navigation, real-time monitoring, and automatic result processing.

Key software functionality:

- Integrated library of standards-compliant methods for routine and research-grade testing

- Modular architecture supporting expansion with additional material or standard packages

- Pre-configured report templates with export capability to Excel or Word

- Real-time graphical display: displacement-load, stress-strain, displacement-time, load-time and related curves

- Statistical analysis tools for automatic calculation of values such as Fm, ReL, ReH, Rp and others

- Flexible unit selection: N, kN, kgf, lbf, MPa and user-defined units via custom formulas

Technical Specifications — NG-SHM Series A

Below you can find a complete technical overview of the main specifications for the NG-SHM Series A hydraulic universal testing systems.| Specification | SHM305 | SHM605 | SHM106 | SHM206 | SHM306 |

|---|---|---|---|---|---|

| Frame Type | Type A | ||||

| Capacity (kN) | 300 | 600 | 1000 | 2000 | 3000 |

| Calibration Accuracy | Class 0.5 | ||||

| Force Accuracy | ±0.5% | ||||

| Force Range | 1% to 100% FS | ||||

| Force Resolution | 1/500000 FS | ||||

| Extension Accuracy | ±0.5% | ||||

| Extension Resolution | 1/500000 of max extension | ||||

| Position Resolution | 0.004 mm | ||||

| Position Accuracy | ±0.5% of reading | ||||

| Actuator Stroke | 5.91 in (150 mm) | 9.84 in (250 mm) | 9.84 in (250 mm) | 9.84 in (250 mm) | 11.81 in (300 mm) |

| Actuator Speed | 0–180 mm/min | 0–140 mm/min | 0–90 mm/min | 0–70 mm/min | 0–100 mm/min |

| Crosshead Speed (adjustment) | 13.78 in/min (350 mm/min) | 10.63 in/min (270 mm/min) | 12.20 in/min (310 mm/min) | 14.17 in/min (360 mm/min) | 9.45 in/min (240 mm/min) |

| Force Loading Speed | 0.05%–2% FS/s | ||||

| Column Number | 4 | 6 | 6 | 6 | 6 |

| Column Spacing (test width) | 16.14 in (410 mm) | 17.13 in (435 mm) | 17.72 in (450 mm) | 28.74 in (730 mm) | 20.87 in (530 mm) |

| Max Tension Space | 20.47 in (520 mm) | 27.95 in (710 mm) | 29.53 in (750 mm) | 35.43 in (900 mm) | 47.24 in (1200 mm) |

| Max Compression Space | 20.47 in (520 mm) | 27.56 in (700 mm) | 29.53 in (750 mm) | 29.53 in (750 mm) | 39.37 in (1000 mm) |

| Round Specimen Ø Range | Ø10–Ø20 mm / Ø20–Ø32 mm | Ø10–Ø21 mm / Ø21–Ø31 mm | Ø12–Ø23 mm / Ø23–Ø35 mm | Ø15–Ø30 mm / Ø30–Ø55 mm | Ø30–Ø70 mm / Ø70–Ø110 mm |

| Flat Specimen Thickness | 2–13 mm / 13–25 mm | 2–16 mm / 16–30 mm | 2–20 mm / 20–40 mm | 10–40 mm / 40–70 mm | 10–60 mm / 60–100 mm |

| Compression Platens Ø | Ø120 mm | Ø150 mm | Ø200 mm | Ø240 mm | Ø280 mm |

| Frame Dimensions (L×W×H) | 32.28 × 22.44 × 76.97 in (820 × 570 × 1955 mm) | 37.01 × 25.59 × 94.49 in (940 × 650 × 2400 mm) | 40.16 × 26.38 × 102.36 in (1020 × 670 × 2600 mm) | 53.94 × 32.28 × 124.02 in (1370 × 820 × 3150 mm) | 52.01 × 37.40 × 155.51 in (1320 × 950 × 3958 mm) |

| HPU Dimensions (L×W×H) | 45.28 × 23.62 × 35.43 in (1150 × 600 × 900 mm) | 45.28 × 24.80 × 39.37 in (1150 × 630 × 1000 mm) | |||

| Hydraulic Power Unit Weight | 661 lb (300 kg) | (882 lb) 400 kg | |||

| HPU Flow Rate (L/min) | 5 | 5 | 5 | 7.2 | 12 |

| Power Consumption (kW) | 2.5 | 3.5 | 4 | 6 | 6 |

| Power Supply | 220 V AC, 50/60Hz | ||||

| Frame Weight | 3307 lb (1500 kg) | 5512 lb (2500 kg) | 7716 lb (3500 kg) | 14991 lb (6800 kg) | 22513 lb (10220 kg) |

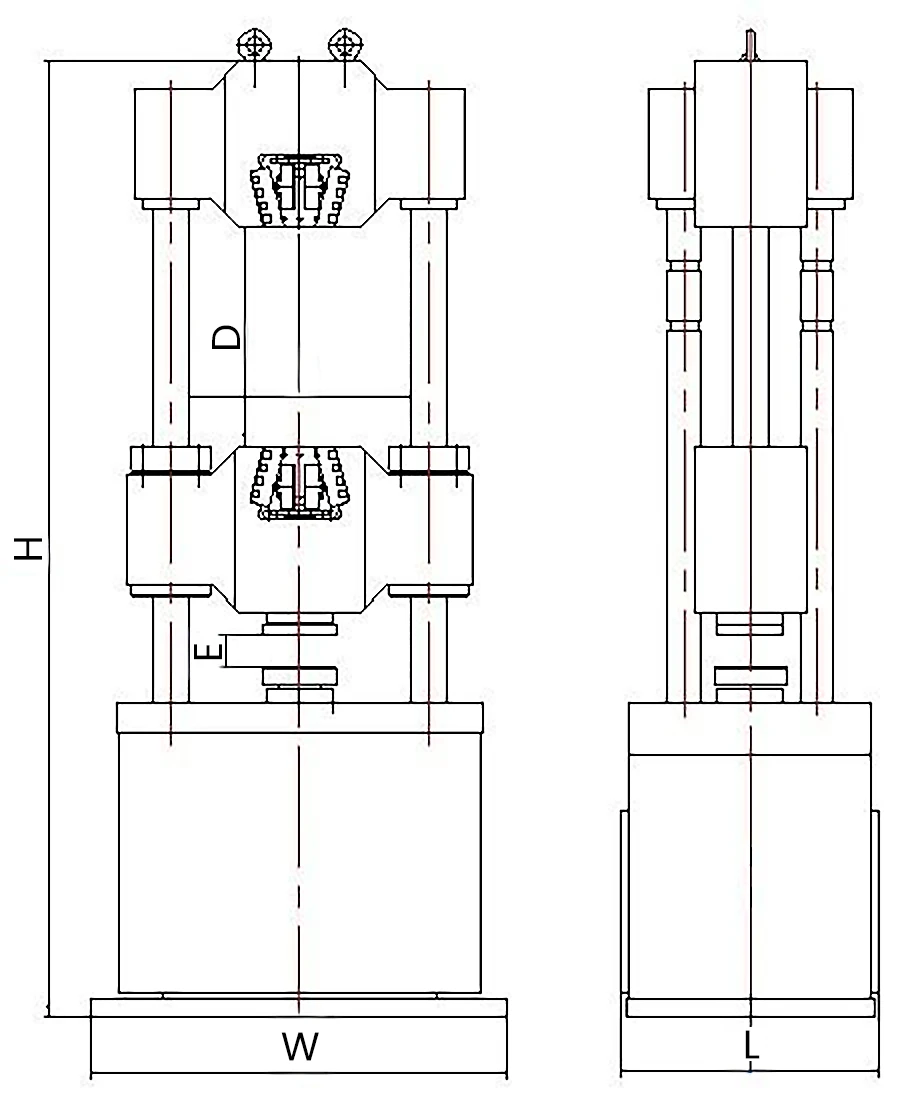

Frame Dimensions — NG-SHM Series A

The following table provides the frame dimensions for all listed models:| Model | Outside Dimensions (L × W × H) | Tensile Space (D) | Compression Space (E) | Test Width (F) | Piston Travel |

|---|---|---|---|---|---|

| SHM305 | 32.28 × 22.44 × 76.97 in (820 × 570 × 1955 mm) | 20.47 in (520 mm) | 20.47 in (520 mm) | 16.14 in (410 mm) | 5.91 in (150 mm) |

| SHM605 | 37.01 × 25.59 × 94.49 in (940 × 650 × 2400 mm) | 27.95 in (710 mm) | 27.56 in (700 mm) | 17.13 in (435 mm) | 9.84 in (250 mm) |

| SHM106 | 40.16 × 26.38 × 102.36 in (1020 × 670 × 2600 mm) | 29.53 in (750 mm) | 25.98 in (660 mm) | 17.72 in (450 mm) | 9.84 in (250 mm) |

| SHM206 | 53.94 × 32.28 × 124.02 in (1370 × 820 × 3150 mm) | 35.43 in (900 mm) | 29.53 in (750 mm) | 28.74 in (730 mm) | 9.84 in (250 mm) |

| SHM306 | 52.01 × 37.40 × 155.51 in (1320 × 950 × 3958 mm) | 47.24 in (1200 mm) | 39.37 in (1000 mm) | 20.87 in (530 mm) | 11.81 in (300 mm) |

FAQs

The hydraulic wedge-action gripping system in the NG-SHM Class A – Servo Hydraulic Testing Machine is designed to reduce variables that could affect material deformation and fracture behavior, allowing test results to accurately reflect the material’s true mechanical properties.

One of the key concerns in tensile and compression testing is specimen slippage or improper clamping, which can lead to uneven force distribution and inaccurate strain measurements. The wedge-action mechanism addresses this by automatically increasing clamping force as load is applied, securing the specimen with a uniform grip. This prevents premature deformation or micro-movements that could alter stress distribution and strain analysis.

Additionally, hydraulic operation provides precise and repeatable clamping pressure, reducing inconsistencies caused by manual adjustments. By maintaining stable specimen positioning, the system allows for accurate force application, making sure that load values, elongation, and failure characteristics align with the material’s actual mechanical performance.

This level of control is particularly important for high-precision applications in aerospace, automotive, and metallurgical research, where understanding true material behavior is key for material qualification, safety assessments, and failure analysis.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

GenTest v3.0: Advanced Testing Software for Servo-Hydraulic Universal Testing Machines

Gentest is designed to enhance your ability to perform accurate and repeatable mechanical testing of materials, components and finished goods across a full spectrum of applications.