Metal Testing Equipment

Standards

GB/T230, EN ISO 6508, ASTM E18

Description

This Automatic Digital Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell scale. There are variations of the RockGen DGEN - Digital Rockwell Hardness Tester system for Rockwell Regular and Superficial Testing Scales. With an easy to navigate operational menu, the RockGen DGEN-AUTO - Digital Rockwell Hardness Tester provides the solution for any Rockwell testing requirements. With a resolution of 0.001, the system will provide you with the absolute highest accuracy on the market combined with a fully automatic work table and user-friendly digital display for the optimal accuracy and efficiency

Main Function and Features of RockGen DGEN

- Rockwell Regular and Superficial Scale Tester

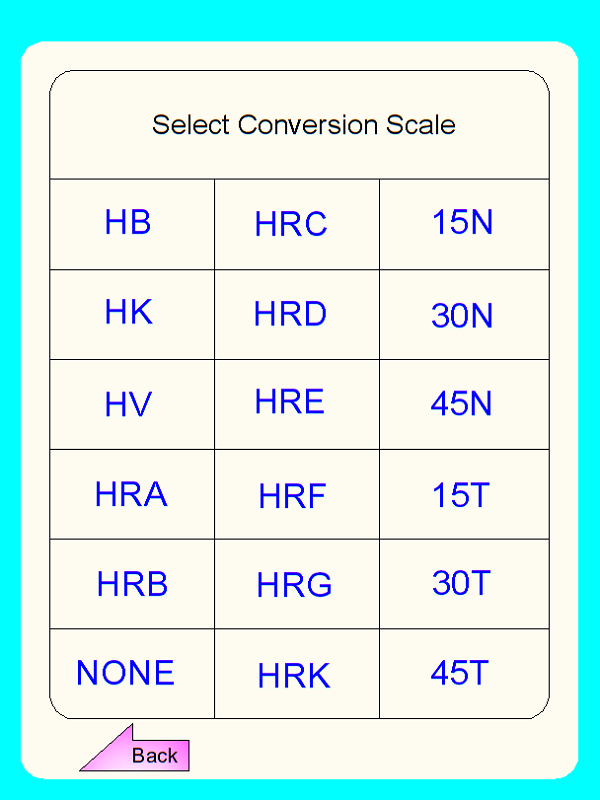

- Supports various relative conversion scales

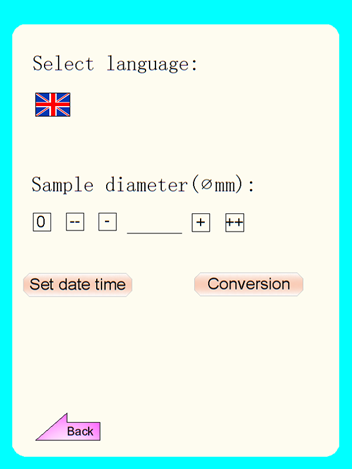

- Equipped with Arc correction function

- Touch Screen Display Dynamically Displays the Working Table Functionality

- Fast Indentation Cycle

- Once touch operation for a full specimen cycle including loading, dwell and loading as well as hardness value display and automatic homing.

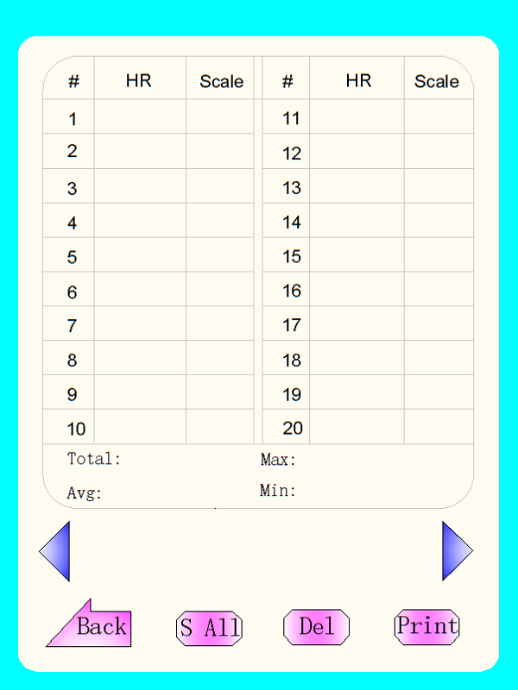

- Data storage function with automatic calculation of the maximum, minimum, average of the hardness value, the test results can be printed for output, and with a RS232 interface the operator can connect it to the computer for data transfer

Main Application

Chilled steel, hardened and tempered steel, annealed steel, casting, malleable cast, hard alloy, hardened steel plate, aluminum alloy, bearings steel.

Technical Specifications

| Model | RockGen TWIN DGEN |

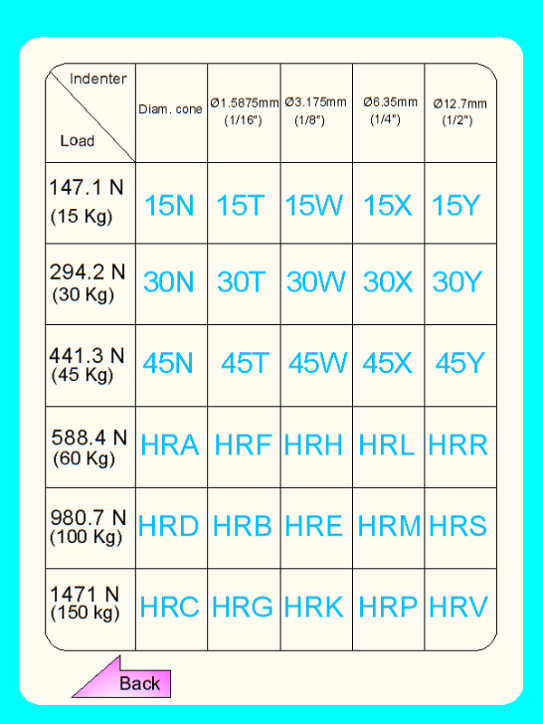

| Rockwell Initial test force | 3kgf, 10kgf 29.4N, 98N |

| Rockwell Total test force | 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N), 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N) |

| Indenter | Diamond Rockwell Indenter, ф1.588mm Ball Indenter |

| Loading Method | Automatic (Loading/Dwell/Unloading) |

| Automatic Test Table | Automatic Rising and Homing, One Key to Complete |

| Hardness Reading | Touch Screen |

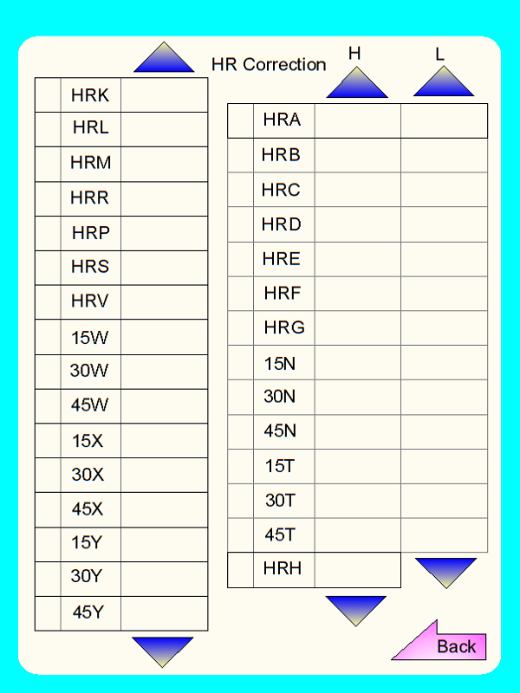

| Test Scale | HRA, HRD, HRC, HRF, HRB, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y |

| Conversion Scale | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HBW |

| Data Output | Built-in Printer, RS232 Interface |

| Resolution | 0.1HR |

| Dwell Time | 0-99s |

| Test space | 320mm/12.6'' x 150mm/5.9 (Height x depth) |

| Power Supply | AC110V / AC220V, 50Hz |

| Execute Standard | ISO 6508, ASTM E-18, JIS Z2245, GB/T 230.2 |

| Dimension | 21.1x13x35" 535x330x890mm, Packing Dimension: 32.3x18.1x46" 820x460x1170mm |

| Weight | Net Weight: 176 lbs / 80kg, Gross Weight: 220 lbs / 100kg |

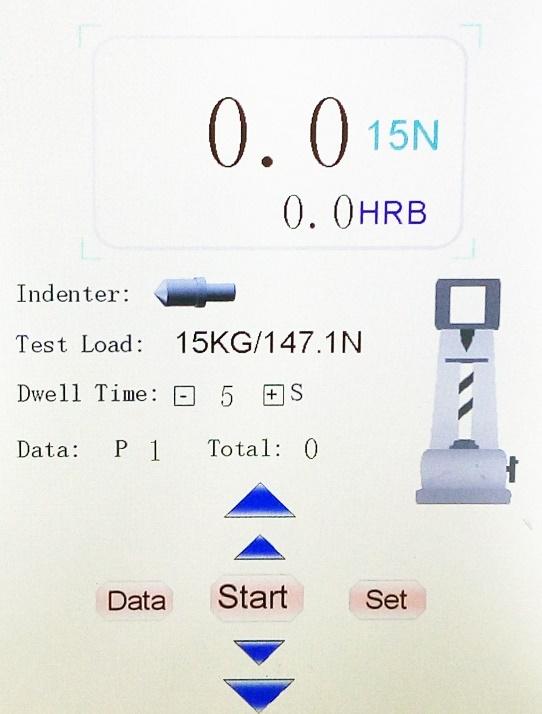

Operations Interface

FAQs

The GenRock NG-150 Series - Advanced Rockwell Hardness Tester measures metal hardness by determining the depth of penetration of an indenter under a specific load, according to the Rockwell scale. This precise testing method provides valuable insights into the strength and durability of a broad range of materials.

The system is built for both Rockwell Regular and Superficial Scales, allowing it to be used for testing different materials, including chilled steel, hardened/tempered steel, castings, aluminum alloys, and bearings. It automates the testing process, including loading, dwell, unloading, and displaying results, assuring accuracy and efficiency.

By providing support for multiple hardness scales and advanced features such as data storage, automatic calculations, and a user-friendly touchscreen interface, the GenRock NG-150 Series serves as an indispensable tool for industries requiring reliable and repeatable hardness measurements.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester can perform numerous hardness measurements using both Rockwell Regular and Superficial Scales. These include common Rockwell hardness scales such as HRA, HRB, HRC, HRD, HRF, HRG, HR15N, HR30N, HR45N, and many others, guaranteeing compatibility with diverse material testing requirements.

In addition to Rockwell scales, the tester supports conversion to other hardness scales, including HV (Vickers), HBW (Brinell), HK, and additional Rockwell scales. This flexibility allows users to interpret results based on multiple standards and testing methods.

The system’s precision and range make it ideal for materials like chilled steel, hardened and annealed steel, aluminum alloys, castings, and more. With its touchscreen interface and automatic data calculations, the GenRock NG-150 provides accurate and reliable hardness measurements suited to a range of industrial and research applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRock NG-150 Series – Advanced Rockwell Hardness Tester fully complies with ASTM E18, the standard specification for Rockwell hardness testing of metallic materials. This standard defines the methods and requirements for testing metal hardness, ensuring consistent and reliable results.

In compliance with ASTM E18, the tester guarantees precision and repeatability in measurements, allowing it to be used for industrial and laboratory applications. Compliance with this internationally recognized standard ensures that the results are accurate and meet quality assurance requirements. This makes the GenRock NG-150 Series an excellent choice for engineers, manufacturers, and researchers who require robust testing solutions for metals.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRock NG-150 Series – Advanced Rockwell Hardness Tester complies with EN ISO 6508, the international standard for Rockwell hardness testing of metallic materials. This standard outlines the methodology, requirements, and precision guidelines for Rockwell Regular and Superficial Scales.

Compliance with EN ISO 6508 guarantees that the tester provides accurate and consistent hardness measurements in line with globally recognized standards. Compliance with these standards is necessary for industries and laboratories that need to meet stringent quality control and testing protocols. By meeting this standard, the GenRock NG-150 Series delivers reliable and repeatable results, allowing it to serve as an excellent tool for evaluating the hardness of metals such as steel, castings, and alloys in numerous industrial applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRock NG-150 Series – Advanced Rockwell Hardness Tester complies with GB/T230, the standard for Rockwell hardness testing of metallic materials. This standard specifies the procedures, equipment, and accuracy requirements for Rockwell hardness tests.

Through compliance with GB/T230, the tester guarantees compatibility with popular testing protocols. Compliance guarantees that measurements are accurate, reliable, and meet quality control expectations in industries such as manufacturing, construction, and material research. Due to this, the GenRock NG-150 Series is an ideal solution for laboratories and facilities that operate on international markets requiring adherence to diverse testing standards.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester supports both Rockwell Regular and Superficial Testing Scales, providing flexibility for a broad range of hardness testing applications.

The Rockwell Regular scales are ideal for testing harder materials such as steel, castings, and hard alloys, while the Superficial scales are better suited to softer or thinner materials like aluminum alloys and lightly hardened metals. This flexibility allows users to perform precise hardness evaluations across different material types and industrial requirements.

The system’s ability to switch between these testing scales guarantees that it meets the needs of diverse testing conditions, providing a valuable tool for laboratories and industries requiring comprehensive hardness assessments.

Click here to learn more about the product or here to receive a personalized quote.

How does the GenRock NG-150 Series – Advanced Rockwell Hardness Tester simplify operation for users?

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester features an easy-to-navigate operational menu, which makes the device user-friendly for operators of all experience levels. This intuitive interface simplifies the testing process, allowing users to quickly access and adjust settings for any Rockwell hardness testing requirement.

The straightforward menu structure minimizes the learning curve and reduces the risk of operator error, resulting in tests being performed efficiently and accurately. Whether switching between testing scales, managing data, or customizing parameters, the user-friendly menu provides complete control over all functions. This increased usability makes the GenRock NG-150 Series an ideal choice for laboratories and industries seeking precision and efficiency in Rockwell hardness testing procedures.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester offers exceptional precision with a resolution of 0.001, which makes it one of the most accurate systems available on the market. This high resolution allows for precise and reliable hardness measurements, even for materials with minimal hardness variations.

The system is further enhanced by a fully automatic work table, which simplifies the testing process by automating operations such as loading, dwell, unloading, and homing. Automation reduces human error and helps maintain consistency across tests. Additionally, the user-friendly digital display provides clear and accessible readings, enabling operators to monitor and manage tests with ease.

GenRock NG-150 Series hardness testers are characterized by advanced accuracy, automation, and intuitive design, providing a valuable tool for laboratories and industries that require precise hardness measurements.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester is equipped with an Arc Correction function, which improves hardness measurement accuracy by compensating for irregularities in the test specimen’s surface.

This feature is particularly useful when testing curved or uneven surfaces, where traditional methods may yield less accurate results. By automatically adjusting for the material arc, the tester achieves consistent and reliable measurements across all test samples. In addition, this feature expands the range of materials that can be tested, making the GenRock NG-150 Series an indispensable tool for industries that deal with complex material geometries.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester features a dynamic touchscreen display that enhances usability by providing real-time visualization of the working table functionality. This intuitive interface allows operators to monitor and control the test table position and operation directly from the display.

By dynamically displaying the status and movement of the work table, the touchscreen simplifies hardness test setup and execution. Operators can easily navigate through settings, adjust parameters, and view results with minimal effort. This user-friendly design reduces errors and provides efficient operation, making the GenRock NG-150 Series an ideal choice for laboratories and industries that require precise and streamlined Rockwell hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The Fast Indentation Cycle in the GenRock NG-150 Series – Advanced Rockwell Hardness Tester significantly improves testing efficiency. This feature allows for rapid execution of the complete testing cycle, including loading, dwell, unloading, and displaying the hardness value.

The quick cycle time reduces the overall testing duration, enabling laboratories and industries to perform multiple tests in a shorter timeframe without compromising accuracy. This is particularly beneficial in high-throughput environments where speed and precision are critical. By simplifying the testing process, the Fast Indentation Cycle increases productivity and guarantees consistent results, resulting in GenRock NG-150 Series a reliable and efficient solution for Rockwell hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The one-touch operation feature of the GenRock NG-150 Series – Advanced Rockwell Hardness Tester simplifies the entire testing process by automating the full specimen cycle. With a single touch, the system performs key operations, including loading, dwell, unloading, hardness value display, and automatic homing.

This simplified process minimizes manual intervention, reducing operator error and assuring consistent and reliable results. One-touch functionality is particularly valuable in high-throughput environments, as it speeds up testing without sacrificing precision. By automating these critical steps, the GenRock NG-150 Series enhances usability, efficiency, and accuracy, resulting in an indispensable tool for modern hardness testing applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester includes a comprehensive data storage function that automatically calculates and records the maximum, minimum, and average hardness values for each test. This feature simplifies data analysis and makes sure that key metrics are readily available.

The system also supports data output through a built-in printer for on-the-spot results printing. Additionally, the RS232 interface enables easy connection to a computer for data transfer, allowing operators to export test results for further analysis, documentation, or integration into laboratory management systems.

These features enhance tester functionality by improving data management, traceability, and reducing manual calculations. The combination of automated storage and flexible output options contribute to making the GenRock NG-150 Series a reliable and efficient tool for hardness testing in different industrial and research environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester is suitable for testing many types of metals and alloys. Its primary applications include:

- Chilled Steel: Used on wear-resistant surfaces.

- Hardened and Tempered Steel: Essential for tools and machine parts requiring high durability.

- Annealed Steel: Commonly used in construction and manufacturing.

- Casting and Malleable Cast Iron: Evaluate cast components' hardness for structural integrity.

- Hard Alloys: Assures consistent hardness in precision parts.

- Hardened Steel Plates: Verifies structural steel hardness.

- Aluminum Alloys: Tests lightweight and versatile materials for the aerospace and automotive industries.

- Bearing Steel: Critical for testing components used in high-load, high-speed applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester offers an initial test force range of 3 kgf (29.4 N) and 10 kgf (98 N). These force levels are crucial for setting the preliminary indentation before the full testing load is applied.

This initial test force guarantees the proper seating of the indenter and prepares the material for accurate hardness measurement. The precise control of the initial force contributes to the results' reliability and repeatability, which makes the GenRock NG-150 Series an ideal choice for diverse testing needs in a wide range of industries and materials.

Click here to learn more about the product or here to receive a personalized quote.

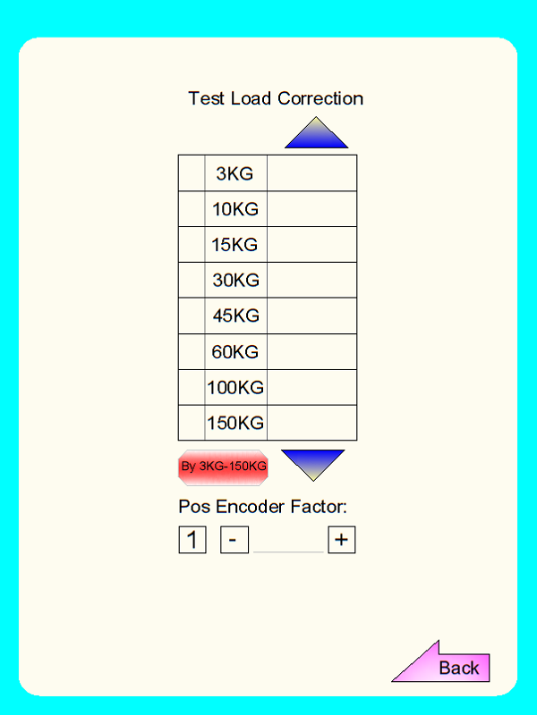

What is the total test force range of the GenRock NG-150 Series – Advanced Rockwell Hardness Tester?

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester offers a comprehensive range of total test forces, providing compatibility with various materials and testing requirements. The total test forces include:

- 15 kgf (147.1 N)

- 30 kgf (294.2 N)

- 45 kgf (441.3 N)

- 60 kgf (588.4 N)

- 100 kgf (980.7 N)

- 150 kgf (1471 N)

With such a broad range of test forces, the tester can accommodate both Rockwell Regular and Superficial Scales. By providing precise force control, the GenRock NG-150 delivers accurate and reliable hardness measurements for materials ranging from soft aluminum alloys to hardened steel and other robust metals. This flexibility makes the tester a vital tool for industries requiring precise hardness evaluations.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester is equipped with two types of indenters to accommodate a variety of hardness testing applications:

- Diamond Rockwell Indenter: Used for testing hard materials such as steel, hardened alloys, and ceramics. Due to its precision and durability, it is suitable for Rockwell C scales as well as other high-force tests.

- ф1.588 mm Ball Indenter: Designed for soft materials, including aluminum alloys and soft steels. This indenter is ideal for Rockwell B scales and similar low-force tests.

These versatile indenter options enable the tester to handle a wide range of materials with precision, resulting in reliable and accurate results for diverse industrial and laboratory testing needs.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester uses a fully automatic loading method, including loading, dwell, and unloading phases. This automation allows for the precise application of force throughout the testing cycle, minimizing operator error and improving repeatability.

By automating these critical steps, the system simplifies the hardness testing process, enhancing efficiency and accuracy. This feature is particularly valuable in high-throughput environments where consistent and reliable results are a necessity. The automated loading method offers the advantage of making the GenRock NG-150 Series user-friendly and reliable for industries requiring precise hardness evaluations of various materials.

Click here to learn more about the product or here to receive a personalized quote.

The automatic test table in the GenRock NG-150 Series – Advanced Rockwell Hardness Tester is intended to simplify and speed up the testing process. Key features include:

- Automatic Rising and Homing: The test table adjusts its position automatically to achieve precise alignment of the sample with the indenter, enhancing accuracy and repeatability. After completing the test, the table returns to its default position, ready for the next specimen.

- One-Key Operation: The entire process, including table adjustment, test execution, and homing, can be initiated with a single key press. This user-friendly functionality reduces operator effort and allows for efficient operation.

In laboratories and industrial environments where speed, accuracy, and ease of use are crucial for hardness testing, the GenRock NG-150 Series is highly efficient and convenient.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester features a touchscreen interface for displaying hardness readings, offering several significant advantages for operators:

- Clear and Real-Time Display: The touchscreen provides immediate and easy-to-read hardness results, allowing operators to monitor and verify test outcomes without delay. Real-time feedback improves operational efficiency and ensures accuracy during testing.

- User-Friendly Navigation: The intuitive touchscreen interface simplifies settings, scales, and test parameters. This reduces the learning curve and minimizes operator errors, even for users with minimal training.

- Dynamic Functionality: Beyond displaying readings, the touchscreen integrates multiple functions, such as data storage, automatic calculations (maximum, minimum, and average values), and test cycle management. Operators can perform all necessary operations directly on the screen without additional devices.

- Enhanced Accessibility: The touchscreen eliminates traditional buttons or knobs, providing a modern and ergonomic design. It allows users to access information and adjust quickly, saving valuable time in high-throughput environments.

GenRock's NG-150 Series is a reliable and efficient option for hardness testing across various applications due to the advanced touchscreen system.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester supports a comprehensive range of Rockwell test scales, allowing for testing an array of types of materials with different hardness levels. The supported scales include:

- Regular Rockwell Scales: HRA, HRB, HRC, HRD, HRF, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV.

- Superficial Rockwell Scales: HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y.

As a result of this extensive range, the tester is capable of measuring the hardness of a variety of materials, ranging from soft aluminum alloys to hardened steels and high-strength alloys. The tester accommodates both Regular and Superficial scales, providing flexibility for a broad spectrum of applications, including industrial quality control and laboratory research.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester offers a variety of data output options to maximize reporting and record-keeping efficiency. These include:

- Built-in Printer: The integrated printer allows operators to generate hard copies of test results directly from the machine. This feature is particularly useful for on-the-spot documentation and quality control processes.

- RS232 Interface: This interface enables smooth data transfer to external devices such as computers or laboratory information systems. By connecting the tester to a PC, operators can store, analyze, and integrate test results into comprehensive reports or databases.

These output options provide flexibility for laboratories and industries that require efficient data management so that test results are easily accessible, shareable, and well-documented for future reference. The combination of built-in and external output capabilities makes the GenRock NG-150 Series a reliable and convenient choice for hardness testing applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester features a resolution of 0.1HR, resulting in highly precise and accurate hardness measurements. This fine resolution allows the tester to detect even small variations in material hardness, which makes it ideal for applications where precision is critical.

The 0.1HR resolution allows for consistent and repeatable results, which is necessary for quality control, material research, and industrial testing. By providing detailed and reliable data, the tester supports informed decision-making in industries such as manufacturing, aerospace, and construction. This high level of accuracy, combined with advanced features like automatic test cycles and data output options, makes the GenRock NG-150 Series an indispensable tool for rigorous hardness testing requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester offers an adjustable dwell time range of 0 to 99 seconds, allowing operators to customize the duration for which the load is applied during testing. This flexibility allows for accurate and consistent hardness measurements specific to different materials and testing standards.

By enabling precise control over dwell time, the tester accommodates many types of applications, from softer materials like aluminum alloys to harder metals such as steel and castings. The ability to adjust dwell time enhances results reliability by making sure that the material has sufficient time to stabilize under the applied load before measurement. This feature makes the GenRock NG-150 Series an effective and precise tool for diverse hardness testing applications in laboratories and industrial environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester provides a test space of 12.6 inches (320 mm) in height and 5.9 inches (150 mm) in depth. Its spacious construction allows for the testing of a wide spectrum of materials and components due to its ability to accommodate a diverse range of sample sizes and shapes.

The generous test space allows for easy positioning and alignment of test specimens, thus allowing for accurate and efficient hardness measurements. This feature is particularly beneficial for industries dealing with large or irregularly shaped samples, as it provides flexibility without compromising precision. The ample test space, combined with automatic table adjustments, increases usability and efficiency, thus making GenRock NG-150 Series a versatile solution for Rockwell hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester operates on a dual voltage system, compatible with both AC110V and AC220V and has a 50Hz frequency. This flexible power requirement makes it possible for the tester can be used in laboratories and facilities worldwide without the need for additional voltage conversion equipment.

This degree of adaptability allows the tester to integrate easily into various testing environments, enabling it to be a reliable choice for global operations. Dual voltage capability also provides convenience for facilities with varying power supply standards, assuring consistent performance regardless of location. The tester's adaptability and suitability for a variety of industrial and research applications has been enhanced by this feature.

Click here to learn more about the product or here to receive a personalized quote.

There are a number of internationally recognized standards that the GenRock NG-150 Series - Advanced Rockwell Hardness Tester complies with:

- ISO 6508: International standard for Rockwell hardness testing of metallic materials.

- ASTM E-18: American standard outlining Rockwell hardness testing procedures and requirements.

- JIS Z2245: Japanese standard for Rockwell hardness tests on metals.

- GB/T 230.2: Chinese national standard for Rockwell hardness testing of metallic materials.

GenRock NG-150 is compliant with these standards so that it delivers accurate, consistent, and reliable results, meeting the requirements of a wide range of global industries.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester has compact and manageable dimensions to fit easily into laboratory or industrial environments. The machine's dimensions are 21.1 x 13 x 35 inches (width x depth x height), or 535 x 330 x 890 mm. For shipping and storage, the packing dimensions are 32.3 x 18.1 x 46 inches, or 820 x 460 x 1170 mm.

These dimensions make the tester versatile and space-efficient while guaranteeing its robustness to handle rigorous testing operations. The thoughtful design supports both functionality and ease of placement, catering to an array of facilities with limited or specialized workspace requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenRock NG-150 Series – Advanced Rockwell Hardness Tester has a net weight of 176 lbs (80 kg), making it sturdy and stable for precise hardness testing. The gross weight, including packaging, is 220 lbs (100 kg), enabling safe transportation and delivery.

The tester's weight reflects its robust construction, which is crucial for maintaining accuracy and durability in industrial and laboratory environments. Despite its solid build, the tester remains manageable for installation and relocation within facilities. This balance of sturdiness and practicality makes the GenRock NG-150 Series a reliable choice for rigorous and repeatable Rockwell hardness testing.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-RockGen - Analogue Series Rockwell Hardness Tester - Manual and Electronic Models

The NG-RockGen Analogue Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell regular scales.

NG-RockGen DGEN Series - Digital Rockwell Hardness Tester - Rockwell Regular, Rockwell Superficial and Rockwell TWIN Digital Models

The NG RockGen Digital Series provides an automatic, digital, high accuracy solution to your Rockwell testing requirements. The Digital series is completely automated and is available in Rockwell Regular or Rockwell Superficial scale configurations.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.