Plastic Testing Equipment

Standards

ASTM D1424, DIN 53862, ISO 9290, EN ISO 13937-1, ISO 4674-2, M&S P29, NEXT 17, GB/T 3917.1

Description

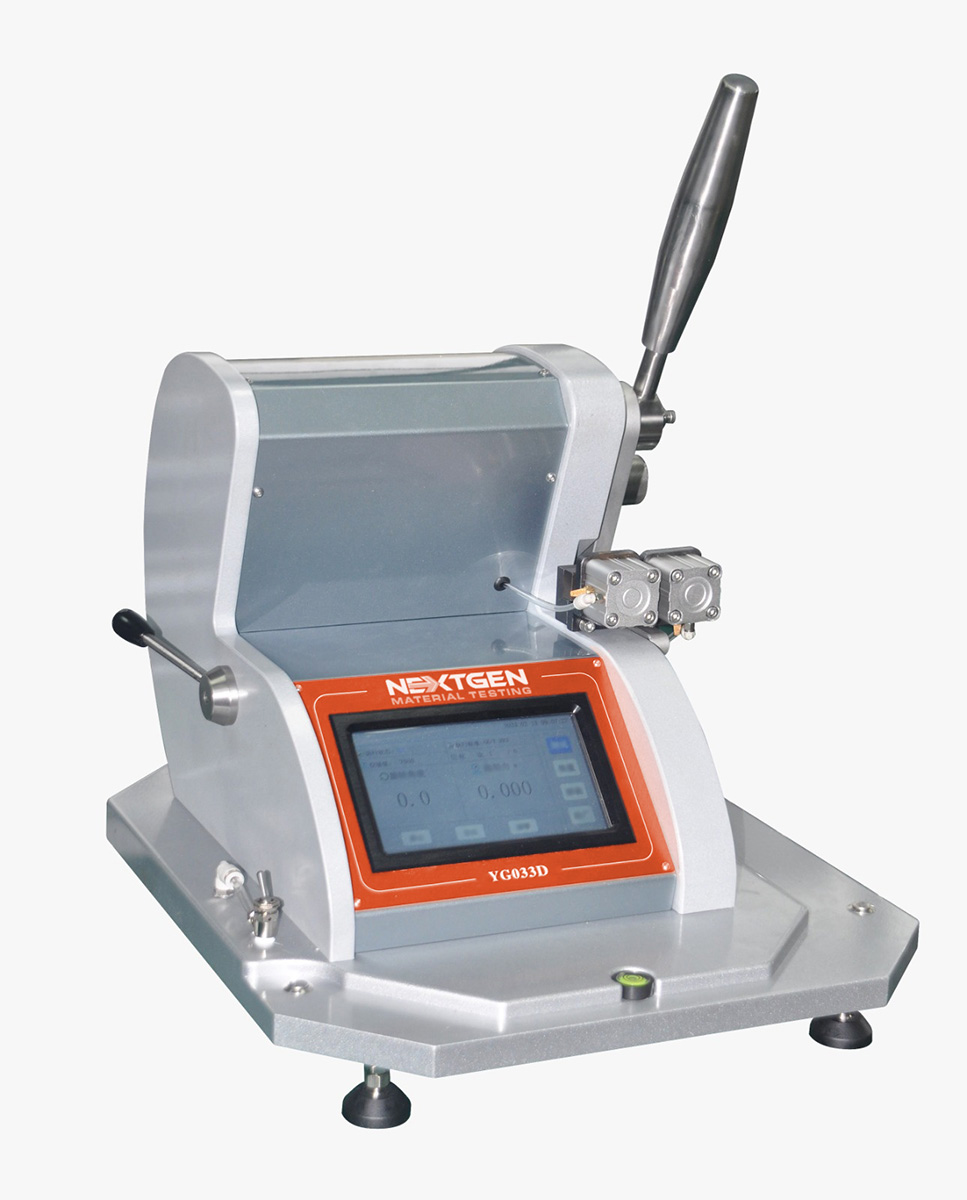

The NG-HE Elemendorf is used to measure the tearing strength of paper, plastic, cloth, film, electrical tape, metal foil and a variety of other materials.

Elemendorf Features & Benefits

- Advanced calculation method (potential energy calculation) to ensure accurate testing and repeatability.

- Micro control system, Automatic testing, Result calculations, Analysis of results, Printing of test reports and Uploading test data to your computer

- User friendly touch screen control panel allowing operators to conveniently and quickly operate the tester

- All data and statistical results can be checked in the machine itself or reviewed in the test report after transferring data

- The test unit can be selected as N, gf, cN and cP and can automatically convert between units to meet different industry standards and requirements

- Pneumatic sample clamping and pendulum release ensures consistent clamping forced and provides an easier testing process for the operator

- NG-HE-Elemendorf can automatically cut the samples to ensure that the shape of the cut is consistent

- Included transfer software for analysis of the results on the computer

Elemendorf Technical Specification

|

Parameter |

Technical Data |

|

Range |

0-16N, 32N, 64N, 128N |

|

Measurement Accuracy |

≤±0.2%FS |

|

Unit of Measurement |

N, cN, gf, lbf |

|

Clamping Method |

pneumatic |

|

Length of the Cut |

20mm ± 0.1mm |

|

Clamp Mouth Distance |

2.8mm ± 0.3mm |

|

Dimensions |

20” x 16” x 24.4” / 500×400×620mm

|

|

Weight |

89 lbs. / 40kg

|

|

Power Requirements |

AC220V 50Hz 100W |

FAQs

The compact size and manageable weight of the High Energy Elemendorf machine make it a popular choice for laboratories, quality control departments, and manufacturing facilities of various sizes. Its small footprint means that it can be easily accommodated in even the most space-constrained environments, while its manageable weight ensures that it can be easily moved and transported as needed.

Despite its compact size, the NG-HE Elmendorf machine boasts a powerful pneumatic clamping method that ensures accurate and reliable test results, even when testing tough materials like metal foil or heavy plastics. This clamping method, combined with the machine's precise cutting and measurement capabilities, makes it a valuable tool for any materials testing or quality control program.

The machine's versatility makes it an excellent investment for businesses that work with a variety of materials and need a testing solution that can handle multiple types of tear testing.

With the ability to measure tearing strength in N, cN, gf, and lbf, the High Energy Elemendorf machine can provide accurate and reliable results for a wide range of materials and applications.

NG-HE Elmendorf Dimensions & Weight:

|

Dimensions |

20” x 16” x 24.4” / 500×400×620mm |

|

Weight |

89 lbs. / 40kg |

Click here to learn more about the product or here to receive a personalized quote.

ASTM D1424 is a standard for measuring the tearing strength of textiles. It provides a set of procedures that ensure consistent and accurate testing of materials, and is used by manufacturers, testing laboratories, and research institutions around the world.

The standard specifies the equipment and procedures required to measure the tearing strength of textiles. It outlines the necessary conditions for preparing test specimens, including their size and shape, as well as the testing conditions, such as the testing speed and temperature. It also specifies the calibration and verification procedures for the testing equipment, ensuring that results are accurate and repeatable.

ASTM D1424 provides guidelines for reporting the results of tearing strength tests. The standard specifies the units of measurement, the calculations to be performed, and the format for presenting the data. This ensures that results are consistent and easily comparable across different laboratories and testing facilities.

NextGen’s NG-HE Elmendorf complies with ASTM D1424 standard.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HE Elmendorf machine's use of the pneumatic clamping method is a significant advantage for those who need to test materials that require high tearing strength measurements, such as plastics and metal foils. The clamping method uses compressed air to apply a consistent and precise amount of pressure to the clamps, ensuring that the test sample remains firmly in place throughout the entire testing process.

This method offers an efficient testing process, allowing for greater productivity and throughput. It is a user-friendly method that reduces operator fatigue as it requires less physical effort than other manual clamping methods. For those who require frequent testing or have limited preparation time, the pneumatic clamping method is an ideal solution due to its ease of use and quick set-up time.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HE Elmendorf machine is a versatile device that can measure the tearing strength of a broad spectrum of materials, ranging from paper, plastic, cloth, film, to metal foils commonly used in the packaging and electrical industries. It finds applications in material development, quality control, and manufacturing processes.

This machine is capable of testing various types of paper, including tissue paper, newsprint, and cardboard, as well as different plastic materials, such as polyethylene and polypropylene films. It can also evaluate the strength of different textile materials, such as cloth and wool fabrics.

Also, it can test the tearing strength of laminated materials, which have become increasingly popular in industrial applications. These materials combine multiple layers of paper, plastic, or foil to create composite materials with improved properties.

Click here to learn more about the product or here to receive a personalized quote.

The High Energy Elemendorf technical specifications indicate that it has a measurement accuracy of ≤±0.2%FS. This level of accuracy ensures that the test results are reliable and reproducible, providing manufacturers and quality control personnel with precise data for their materials.

The machine's range of 0-16N, 32N, 64N, and 128N is suitable for testing many different materials, from thin films to thick textiles and paper. Measurement unit can be set to N, cN, gf, or lbf, depending on the preference of the user.

Furthermore, the NG-HE Elmendorf machine uses a pneumatic clamping method that ensures a consistent and reliable grip on the material being tested, reducing the risk of measurement errors. The length of the cut is precise, at 20mm ± 0.1mm, ensuring that the samples are standardized and consistent for accurate results.

Click here to learn more about the product or here to receive a personalized quote.

|

Parameter |

Technical Data |

|

Range |

0-16N, 32N, 64N, 128N |

|

Measurement Accuracy |

≤±0.2%FS |

|

Unit of Measurement |

N, cN, gf, lbf |

|

Clamping Method |

pneumatic |

|

Length of the Cut |

20mm ± 0.1mm |

|

Clamp Mouth Distance |

2.8mm ± 0.3mm |

|

Dimensions |

20” x 16” x 24.4” / 500×400×620mm |

|

Weight |

89 lbs. / 40kg |

|

Power Requirements |

AC220V 50Hz 100W |

Click here to learn more about the product or here to receive a personalized quote.

The NG-HE Elmendorf machine comes equipped with various features to ensure accurate testing and repeatability. It utilizes an advanced calculation method, known as potential energy calculation, to provide precise measurements. The micro control system enables automatic testing, result calculations, and analysis of results, with the ability to print test reports and upload data to a computer.

The touchscreen control panel is user-friendly, allowing operators to easily and quickly operate the tester. All data and statistical results can be viewed on the machine itself or in the test report after transferring data. The machine offers the flexibility to select the test unit as N, gf, cN, or cP, and it can automatically convert between units to meet various industry standards and requirements.

The pneumatic sample clamping and pendulum release system ensures consistent clamping force and provides an easier testing process for the operator. The NG-HE Elmendorf machine can automatically cut the samples to ensure consistent cutting shape.

Click here to learn more about the product or here to receive a personalized quote.

DIN 53862 is a standard used for determining the tear resistance of a wide range of materials. In order to initiate the tear, a sample of the material is cut in a specific shape and a force is applied perpendicular to the cut direction.

Test conditions specified by DIN 53862 include sample size, cut shape, and rate of application of tearing force.

This standard is used in the textile, paper, and plastic industries to evaluate the quality of their products. In determining the durability and suitability of a material for various applications, its tear strength is one of the most important factors.

NextGen’s NG-HE Elemendorf complies with DIN 53862 standard.

Click here to learn more about the product or here to receive a personalized quote.

The Clamp Mouth Distance in the NG-HE Elmendorf machine is an important technical specification that refers to the distance between the clamps that hold the material being tested during the tear test. Specifically, it is the distance between the two clamping jaws that hold the sample in place before the pendulum is released to initiate the tear.

In the NG-HE Elmendorf machine, the Clamp Mouth Distance is specified as 2.8mm ± 0.3mm, meaning that the distance between the clamping jaws should be between 2.5mm to 3.1mm. This ensures that the sample is held firmly and consistently during the tear test, which is essential for obtaining accurate and reliable results.

The Clamp Mouth Distance is an important parameter to consider when selecting a tear testing machine, as it can affect the tearing force measurement. A wider or narrower distance between the clamping jaws may result in a lower or higher tearing force measurement, respectively, due to changes in the clamping force applied to the sample.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HE Elmendorf machine requires an AC220V power supply with a frequency of 50Hz and power consumption of 100W. This power requirement is typical for industrial testing equipment and is readily available in most manufacturing environments. It is important to ensure that the power supply is stable and reliable, as fluctuations or interruptions in the power source could potentially affect the accuracy and reliability of the test results.

To prevent any damage or malfunction of the machine, it is important to use the correct power supply and to ensure that the voltage and frequency of the power source match the specifications of the machine. Using a surge protector or voltage stabilizer is highly recommended to protect the machine from any possible power surges or fluctuations.

Click here to learn more about the product or here to receive a personalized quote.

The NG-HE Elmendorf machine, although designed for single-sample testing, is highly efficient and capable of conducting multiple tests in a short time frame. Its advanced features such as automatic testing, result calculations, and analysis of results, as well as printing of test reports and uploading of test data to a computer, enable operators to operate the tester effortlessly and obtain reliable and precise test results.

The machine is extensively used in the textile, paper, and plastic industries for evaluating the tensile strength and tear resistance of various materials. Its precise and efficient testing abilities have made it an essential tool for quality control and research and development purposes.

Click here to learn more about the product or here to receive a personalized quote.

The High Energy Elmendorf machine boasts transfer software that enables operators to conveniently upload test data to a computer for further analysis. This software is equipped with several capabilities, including data management, analysis, and reporting functions.

Users can analyze test results in a range of formats, including graphical representations, histograms, and statistical summaries. Advanced analysis functions such as regression analysis, outlier detection, and data filtering can be performed to uncover trends and patterns in the test data.

The software has the capability to create comprehensive test reports that comprise all pertinent test parameters, results, and statistical analysis, which can be customized to suit various industries and regulatory requirements.

Click here to learn more about the product or here to receive a personalized quote.

ISO 9290 is a standardized test method used to determine the tearing strength of paper and board. The method involves cutting a sample into a specified shape, making a slit in the sample, and then using a pendulum-type tearing tester to tear the sample along the slit. The force required to tear the sample is measured, and this value is used to calculate the tearing strength of the material.

The test method specifies the conditions for testing, including the size and shape of the sample, the orientation of the sample, and the speed of the pendulum. It also provides guidelines for the calculation and expression of results.

ISO 9290 is widely used in the paper and board industry to ensure product quality and consistency. It is an internationally recognized standard that helps to ensure that tearing strength measurements are accurate and comparable across different laboratories and testing facilities.

NextGen’s NG-HE Elmendorf complies with ISO 9290 standard.

Click here to learn more about the product or here to receive a personalized quote.

ISO 13937-1 is a standard used for measuring the tear strength of textiles using the tongue tear method. This test involves cutting a rectangular sample with a tongue-shaped slit and then applying force to the sample in the direction perpendicular to the slit until it tears. The peak force required to tear the sample is recorded as the tear strength.

The standard specifies the testing procedure, including sample preparation, equipment calibration, and test conditions. It also provides guidelines for reporting the test results, including the tear force and the direction of tear propagation.

This standard is widely used in the textile industry to evaluate the tear resistance of fabrics and garments. It is important for manufacturers to comply with this standard to ensure consistent and reliable measurement of tear strength, which is a crucial factor in determining the durability and quality of textile products.

NextGen’s NG-HE Elmendorf complies with EN ISO 13937-1 standard.

Click here to learn more about the product or here to receive a personalized quote.

The NEXT 17 standard is a widely recognized measure of fabric quality, specifically in terms of its resistance to pilling. This standard outlines the test method for determining the propensity of a fabric to pill, or form small balls of tangled fibers on its surface, through the use of a standard testing machine and controlled abrasion.

The test involves rubbing the fabric sample against a standard abrasive material for a set amount of time, after which the sample is visually evaluated for the degree of pilling using a rating scale. The results are then recorded and compared against the standard classification system to determine the fabric's pilling resistance.

This standard is important in the textile industry as it helps manufacturers ensure that their products meet the quality standards expected by consumers. It also enables buyers to compare the pilling resistance of different fabrics and make informed purchasing decisions based on their needs.

NextGen’s NG-HE Elmendorf complies with NEXT 17 standard.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.