Metal Testing Equipment

Standards

ISO 2507, ISO 75, ISO 306, ASTM D648, ASTM D1525, GB/T 8802, GB/T 1633, GB/T 1634

Description

The HDT/VICAT testing machine offers high precision, reliability, and efficiency for the thermal analysis of thermoplastics and polymers. Engineered with advanced sensors and high-temperature-resistant components, it ensures minimal deformation, fast response, and precise data transmission, delivering consistent and accurate test results. When integrated with a chiller system, testing capacity doubles, significantly enhancing productivity.

The test station, made from a low-expansion coefficient alloy, maintains measurement accuracy up to 200°C without recalibration, complying with international standards. Widely used for HDT and Vicat softening temperature testing, this HDT/VICAT machine is essential for plastic and pipe manufacturers, quality control laboratories, construction engineering, and research institutions. Designed for product development, material testing, and regulatory compliance, it is a crucial tool for manufacturers, quality assurance teams, and research professionals seeking precise and efficient thermal analysis solutions.

HDT/Vicat Testing Machine Features

-

Simultaneous HDT and VICAT Testing – Conduct both tests at the same time, improving efficiency and throughput.

-

High-Stability Test Station – Minimal deformation under heat, with deflection temperature accuracy up to 200°C without recalibration.

-

Automatic Loading & Lifting – Eliminates manual weight handling for easier and more efficient operation.

-

Compact & Cost-Effective Design – Tank volume is reduced by over 50%, significantly lowering operational costs compared to traditional designs.

-

Precision Displacement Measurement – Swiss-made high-precision micrometer ensures exceptional accuracy and stability.

-

Multi-Station Capability – Supports up to six test stations, with up to six deformation transducers and one temperature transducer for precise monitoring.

-

Motor-Driven Test Stations – Easily raise stations from the bath at the touch of a button, simplifying specimen placement.

-

Fully Automated Testing Process – Once the software is started, the test runs automatically according to user-defined parameters.

-

Automatic Bath Cooling – After test completion, the system cools the bath to 280°C, improving equipment utilization for continuous testing.

-

User-Friendly Software – Professional testing software with an intuitive interface for easy operation and data management.

Optimized Cooling System for Maximum Efficiency

Equipping the HDT/VICAT testing machine with a chiller system significantly enhances cooling performance, reducing downtime and increasing operational efficiency. Compared to traditional cooling methods, this advanced system offers several key advantages:

-

High Initial Cooling Temperature – The system supports an initial cooling temperature of up to 280°C, ensuring rapid heat dissipation.

-

Fast Cooling Speed – When used with a chiller, cooling time is reduced to just 45 minutes, dramatically improving equipment utilization and workflow efficiency.

-

Optimized Temperature Control – The chiller lowers the oil temperature to below 25°C, minimizing test errors and ensuring compliance with ISO and ASTM standards for initial heating temperatures.

-

Water-Saving Design – The water chiller recycles water, significantly reducing water consumption while maintaining effective cooling.

Test Station

-

Flexible Test Configurations – Available with 3, 4, or 6 test stations to accommodate different testing needs.

-

Precision Loading System – Includes 10N and 50N dead weights for accurate load application.

-

Ultra-Accurate Deformation Measurement – Swiss-made high-precision micrometer with 0.001mm resolution and ±0.005mm accuracy ensures precise specimen deformation analysis.

-

High-Accuracy Temperature Control – Japan-made RKC temperature controller with ±0.5°C accuracy guarantees consistent thermal conditions.

-

Invar Steel Test Station Assembly – Constructed from low-expansion Invar Steel, minimizing deformation at high temperatures for exceptional test stability and accuracy.

Technical Specifications

| Model | NG-HDT300 | NG-HDT400 | NG-HDT600 |

| Type | A | B | C |

| Test station | 3 | 4 | 6 |

| Immersion bath | 1 | 1 | 1 |

| Heat transfer medium |

Methyl Silicon oil,22 liter Viscosity: 300 cSt, or 300 mm2/s Silicon oil brand: DON CORNING PMX-200 350 cSt, KF96-300 Or transformer oil, 10#, 22 liter |

||

| Temperature sensor | 3 | 4 | 6 |

| Temperature range |

Ambient (20℃)-300℃ |

||

| Temperature accuracy |

±0.5℃ |

||

| Heating Speed | Speed A:

5±0.5℃/6min Speed B: 12±1℃/6min |

||

| Micrometer | 3 | 4 | 6 |

| Deformation measurement range | 0-10mm | ||

| Deformation resolution | 0.001mm | ||

| Deformation measurement accuracy | 0.003mm | ||

| Vicat loading capacity |

GA=10N±0.2N, GB=50N±1N |

||

| Deformation measurement range | 0-10mm | ||

| HDT Test |

Method A: USE FIBRE STRESS 1.80Mpa Method B: USE FIBRE STRESS 0.45Mpa Method C: USE FIBRE STRESS 8.00Mpa |

||

| HDT Test Span |

Outer span: 100mm, ASTM D648 Inner span: 64mm, ISO 75 |

||

| Maximum heating power | 5000W | ||

| Power requirements |

220V 50/60Hz 3 Phase |

||

| Dimensions | 32" x 24.5" x 28.5" | ||

| Weight | 253 lbs | 253 lbs | 617 lbs |

| Cooling |

Nature cooling or water cooling (less than 150℃) |

||

Standard Accessories

| Model | NG-HDT300 | NG-HDT400 | NG-HDT600 |

| Type | A | B | C |

| Main Frame | 1 set | 1 set | 1 set |

| Test Stations | 3 | 4 | 6 |

| Swiss-made Micrometers | 3 sets | 4 sets | 6 sets |

| Platinum resistance temperature sensors | 3 sets | 4 sets | 6 sets |

| Temperature controllers | 3 sets | 4 sets | 6 sets |

| Loading nose for HDT | 3 sets | 4 sets | 6 sets |

| Needle for VICAT | 3 sets | 4 sets | 6 sets |

| Weight set (10N, 50N) | 3 sets | 4 sets | 6 sets |

| Test software | 1 set | 1 set | 1 set |

Related Products

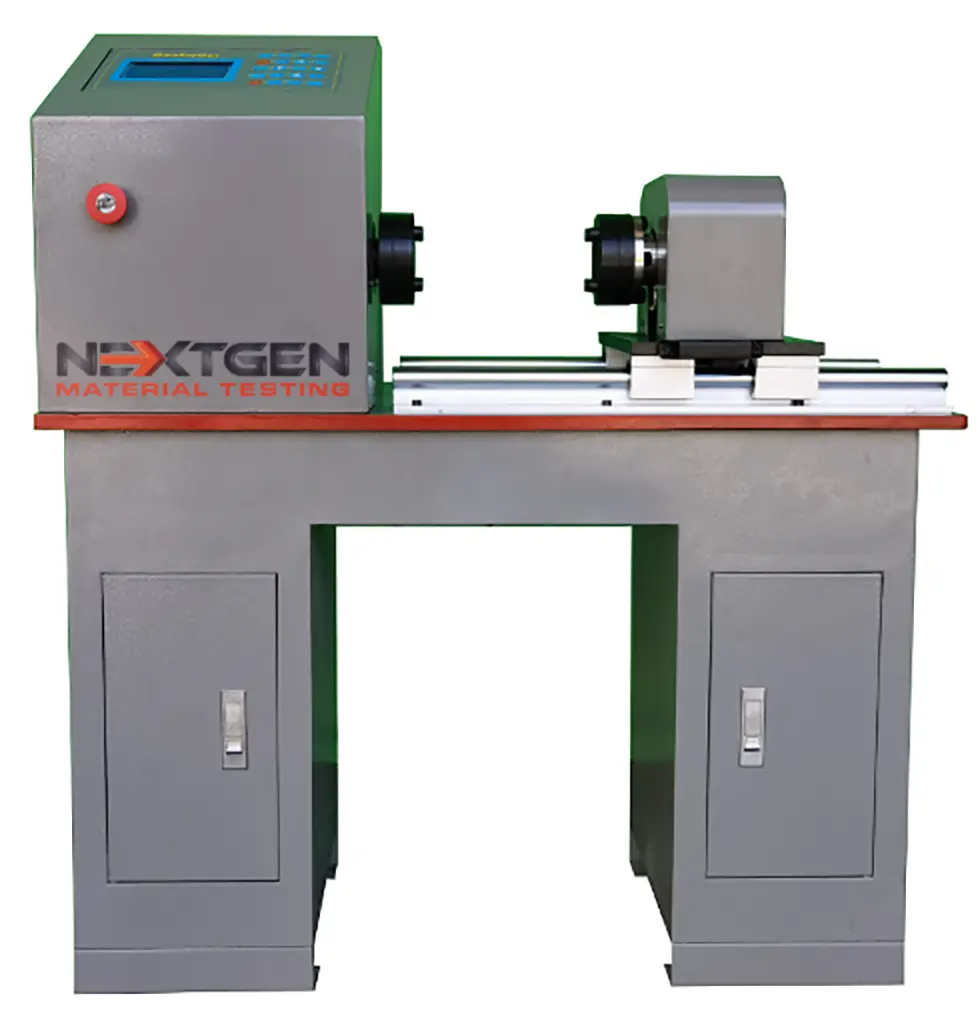

NextGen GenTor Horizontal Torsion Tester

NextGen GenTor Torsion Tester boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.